Selecting from the vast array of Stainless Steel Grades ensures optimal performance and longevity in industrial and consumer products. The top 10 grades include 304, 316, 430, 410, 420, 201, 409, 321, 904L, and 2205 Duplex.

| Stainless Steel Grade | Global Usage Share | Key Characteristics | Typical Applications |

|---|---|---|---|

| 304 | ~50% | Excellent corrosion resistance, weldable | Kitchen sinks, cookware, medical instruments |

| 316 | High | Superior chloride resistance, durable | Marine hardware, chemical processing |

| Others | – | – | – |

Choosing the correct grade reduces failure rates, prevents corrosion, and lowers maintenance costs. Grades differ in composition and properties, so matching the right one to the service environment remains essential for reliable results.

Key Takeaways

- Stainless steel grades differ in corrosion resistance, strength, and cost, so choosing the right grade ensures durability and lowers maintenance.

- Grade 304 is the most common, offering good corrosion resistance and versatility for kitchen, medical, and construction uses.

- Grade 316 excels in harsh environments like marine and chemical industries due to its superior resistance to salt and chemicals.

- Ferritic grades like 430 and 409 are cost-effective and good for appliances and automotive parts but have lower corrosion resistance.

- Martensitic grades such as 410 and 420 provide high hardness and strength, ideal for cutlery and surgical tools, but need proper heat treatment.

Stainless Steel Grades: 304

Key Properties

Grade 304 stands as the most widely used stainless steel in the world. This austenitic alloy contains 18% chromium and 8% nickel, which gives it excellent corrosion resistance in a wide range of environments. The material resists oxidation and maintains its strength at high temperatures. Fabricators value 304 for its outstanding weldability and formability. It does not harden by heat treatment, but cold working can increase its strength. The smooth surface finish makes it easy to clean, which supports hygiene in sensitive settings. Grade 304 also resists most acids, alkalis, and chlorides, though it may show some vulnerability to chlorides in highly aggressive environments.

Tip: Grade 304 offers a balance of strength, corrosion resistance, and affordability, making it a top choice for both industrial and household applications.

Main Applications

Manufacturers across many industries rely on grade 304 for its versatility and reliability. The food processing sector uses it for equipment such as wine and beer brewing tanks, milk processing machinery, and kitchen sinks. In the cooking and kitchenware field, pots, pans, and appliances often feature 304 stainless steel due to its non-reactive surface and ease of cleaning. The chemical industry selects this grade for containers that transport various substances safely.

Aerospace and automotive companies use 304 for structural components and braces. The construction industry incorporates it into building materials, paneling, and architectural details. Marine environments benefit from 304’s corrosion resistance, making it suitable for nuts, screws, and bolts exposed to moisture. Interior designers specify 304 for elevator panels, handrails, and decorative trim.

| Industry/Field | Specific Products/Applications |

|---|---|

| Food Processing | Brewing tanks, milk equipment, kitchen sinks |

| Cooking/Kitchen | Pots, pans, appliances |

| Chemical | Transport containers |

| Aerospace & Automotive | Structural components, braces |

| Construction | Building materials, paneling, trim |

| Marine | Nuts, screws, bolts |

| Interior Design | Elevator panels, handrails, trim |

Grade 304’s adaptability explains its dominance among Stainless Steel Grades. Its combination of durability, corrosion resistance, and ease of fabrication ensures continued demand across diverse sectors.

Stainless Steel Grades: 316

Key Properties

Grade 316 stainless steel stands out for its exceptional resistance to corrosion, especially in environments rich in chlorides and saltwater. The addition of molybdenum in its composition enhances its ability to withstand harsh chemicals and pitting, making it a preferred choice for demanding settings. Compared to grade 304, grade 316 offers superior performance in marine and chemical environments, though it comes at a higher cost and with slightly lower tensile strength. The following table highlights the key differences between grade 316 and grade 304:

| Property | Grade 316 Stainless Steel | Grade 304 Stainless Steel |

|---|---|---|

| Corrosion Resistance | Exceptional (marine, chloride-rich) | Excellent |

| Tensile Strength (MPa) | 480–621 | 540–750 |

| Hardness (Rockwell B) | 80 | 70 |

| Elongation at Break (%) | 60 | 70 |

| Machinability | Fair (more tool wear) | Fair, better than 316 |

| Malleability | Less malleable | More malleable |

| Typical Applications | Marine, food, medical sectors | General purpose |

| Cost | More expensive | Less expensive |

Grade 316 maintains its strength and stability at high temperatures, up to approximately 1700°F (925°C). Fabricators note its fair machinability and reduced malleability compared to grade 304. The alloy’s durability and resistance to chemical attack make it a top performer among Stainless Steel Grades.

Note: Grade 316’s molybdenum content provides a significant advantage in environments where exposure to salt, acids, or harsh chemicals is common.

Main Applications

Industries select grade 316 for projects that demand high corrosion resistance and durability. Its primary applications include:

- Boat building and marine construction

- Marine equipment and dock hardware

- Offshore oil and gas industries

- Marine exhaust systems and underwater components

- Seawater desalination equipment

- Tanks, pipes, and reactors in chemical and petrochemical industries

- Specialized industrial plants in food, paper, and cellulose production

These uses leverage grade 316’s ability to resist saltwater corrosion, chemical attack, and high temperatures. Engineers and designers rely on this alloy for critical components exposed to aggressive environments, ensuring long service life and reduced maintenance.

Stainless Steel Grades: 430

Key Properties

Grade 430 belongs to the ferritic family of stainless steels. This material contains 16–18% chromium and a low nickel content, which gives it moderate corrosion resistance and good formability. Manufacturers often select grade 430 for its cost-effectiveness and ease of fabrication. The alloy does not harden quickly during cold working, making it suitable for mild forming operations. However, it offers lower weldability compared to austenitic grades and may require post-weld heat treatment to maintain its properties.

The following tables summarize the chemical composition, mechanical, and physical properties of grade 430:

Chemical Composition (wt%)

| Element | Range / Max Value |

|---|---|

| Carbon | Up to 0.12 |

| Chromium | 16.0 – 18.0 |

| Nickel | Up to 0.75 |

| Manganese | Up to 1.00 |

| Silicon | Up to 1.00 |

| Phosphorus | Up to 0.040 |

| Sulfur | Up to 0.030 |

Mechanical Properties (Annealed Condition)

| Property | Value |

|---|---|

| Yield Strength | 30 ksi (minimum) |

| Tensile Strength | 65 ksi (minimum) |

| Elongation | 22% (minimum) |

| Hardness (Rockwell B) | 89 (maximum) |

Physical Properties

| Property | Value |

|---|---|

| Density | 0.276 lb/in³ |

| Modulus of Elasticity | 29.0 x 10^6 psi |

| Coefficient of Thermal Expansion (68-212°F) | 5.7 x 10^-6 /°F |

| Thermal Conductivity | 13.8 Btu/ft·hr·°F |

| Specific Heat | 0.11 Btu/lb·°F |

| Electrical Resistivity | 23.6 microohm-in |

Grade 430 provides corrosion resistance close to that of 304 in many indoor environments. Its moderate heat resistance and attractive finish make it a popular choice for visible or decorative applications.

Note: Grade 430 does not perform well in highly corrosive or marine environments but excels in less aggressive settings where appearance and cost matter.

Main Applications

Manufacturers and designers use grade 430 in a wide range of household and industrial products. Its combination of corrosion resistance, affordability, and moderate heat tolerance supports its popularity in the following areas:

- Kitchen appliances and cookware: sinks, range hoods, oven liners, pots, pans, and appliance panels

- Household appliances: cookers, washing machines, dishwashers, and stove element supports

- Automotive trim and accents: decorative trim, muffler systems, exhaust pipes, catalytic converter housings, and flue linings

- Architectural applications: door frames, window frames, handrails, and decorative trim

- Industrial equipment: storage tanks, hoppers, chemical processing equipment, heat exchangers, pumps, valves, fasteners, hinges, and brackets

Grade 430 stands out among Stainless Steel Grades for its versatility in both functional and decorative roles. Its widespread use in appliances, automotive parts, and architectural features demonstrates its value in cost-sensitive applications where moderate corrosion resistance is sufficient.

Stainless Steel Grades: 410

Key Properties

Grade 410 stands out as a martensitic stainless steel known for its impressive strength, hardness, and moderate corrosion resistance. Manufacturers often select this grade for its ability to be heat treated, which significantly enhances its mechanical properties. The alloy contains about 11.5–13.5% chromium, providing a balance between corrosion resistance and mechanical durability. When heat treated, grade 410 achieves high hardness levels, making it suitable for applications that demand wear resistance and structural integrity.

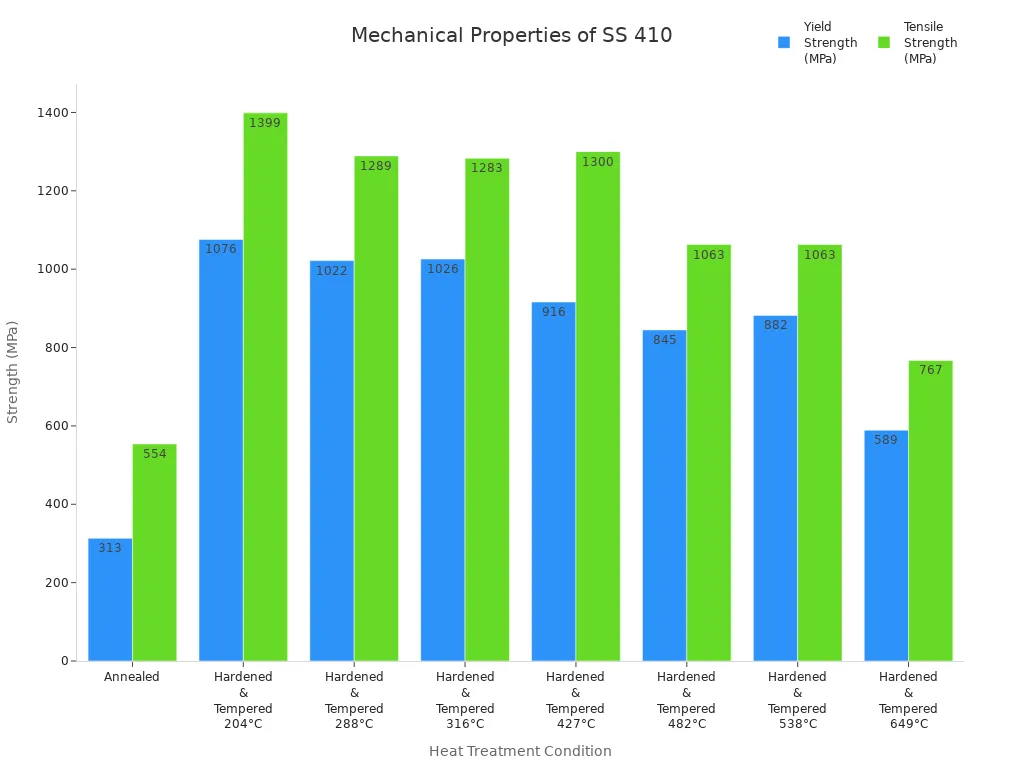

The following table summarizes the mechanical properties of grade 410 under various conditions:

| Condition | Hardness (Rockwell) | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) |

|---|---|---|---|---|

| Annealed | 81 HRB | 313 | 554 | 20 |

| Hardened & Tempered 204°C | 43 HRC | 1076 | 1399 | N/A |

| Hardened & Tempered 288°C | 40 HRC | 1022 | 1289 | N/A |

| Hardened & Tempered 316°C | 40 HRC | 1026 | 1283 | N/A |

| Hardened & Tempered 427°C | 41 HRC | 916 | 1300 | N/A |

| Hardened & Tempered 482°C | 41 HRC | 845 | 1063 | N/A |

| Hardened & Tempered 538°C | 35 HRC | 882 | 1063 | N/A |

| Hardened & Tempered 649°C | 98 HRB | 589 | 767 | N/A |

Grade 410 maintains its mechanical properties at moderately elevated temperatures, up to about 649°C (1200°F). As the tempering temperature increases, both hardness and strength decrease. The alloy’s hardening temperature ranges from approximately 815°C to 900°C (1500°F to 1650°F), while hot working occurs between 1093°C and 1204°C (2000°F to 2200°F).

Note: Grade 410 offers a unique combination of mechanical durability and moderate heat resistance, making it ideal for components exposed to both wear and elevated temperatures.

Main Applications

Engineers and manufacturers rely on grade 410 for a wide range of demanding applications. Its high strength, hardness, and moderate corrosion resistance make it a preferred choice in several industries:

- Cutlery industry: knives, scissors, and other cutting tools

- Oil and gas industry: valves, pumps, and shafts exposed to high temperatures and corrosive environments

- Aerospace industry: gas turbine blades, jet engine parts, and aircraft exhaust systems

- Medical industry: surgical instruments, dental and orthopedic implants

- Automotive industry: mufflers, exhaust systems, and suspension components

- Construction industry: structural components, handrails, and balustrades

- Food processing industry: equipment and machinery resistant to food acids and salts

Grade 410’s versatility supports its use in products that require both mechanical strength and resistance to moderate corrosion. Its ability to maintain performance at elevated temperatures further expands its application range.

Stainless Steel Grades: 420

Key Properties

Grade 420 is a martensitic stainless steel recognized for its high hardness and moderate corrosion resistance. Manufacturers can adjust its hardness through heat treatment, making it suitable for applications that require a sharp edge or wear resistance. The alloy contains approximately 0.15–0.4% carbon and around 12% chromium. This composition allows grade 420 to reach a Brinell hardness of up to 241, depending on the specific heat treatment process used.

The following table summarizes the key characteristics of grade 420:

| Property | Characteristic / Value |

|---|---|

| Hardness | Brinell hardness up to 241 max, adjustable by heat treatment (annealing and hardening) |

| Corrosion Resistance | Good in mild environments; not suitable for highly corrosive or extreme conditions |

| Composition | Carbon 0.15-0.4%, Chromium ~12% |

| Applications | Cutlery, surgical instruments, industrial components due to hardness and corrosion resistance |

| Limitations | Can stain/discolor easily; not recommended above 500-550°C; less resistant than 304 or 316 stainless steels |

Grade 420 performs well in mild environments but does not match the corrosion resistance of austenitic grades like 304 or 316. It can discolor or stain if exposed to harsh chemicals or high temperatures above 500–550°C. Users should consider these limitations when selecting materials for demanding environments.

Note: Grade 420 offers a balance between hardness and corrosion resistance, making it a popular choice for tools and components that require both durability and a sharp edge.

Main Applications

Engineers and product designers often select grade 420 for items that demand high hardness and moderate corrosion resistance. Its ability to be hardened makes it ideal for cutting tools and precision instruments.

Common products manufactured using grade 420 include:

- Bearings

- Cutlery

- Jewelry

- Knives and other cutting tools

- Pumps

- Saw blades

- Springs

- Surgical instruments

- Valves

The table below highlights additional tools and components made from grade 420:

| Tools/Products Manufactured Using Stainless Steel Grade 420 |

|---|

| Ball Bearings |

| Cams |

| Cutlery |

| Gauges |

| Plastic Extrusion Dies |

| Plastic Mold Cavities |

| Shafts |

| Surgical and Dental Instruments |

| Valves |

Grade 420’s versatility supports its use in both household and industrial settings. Manufacturers rely on its hardness for sharp blades and its moderate corrosion resistance for medical and food-related tools. However, users should avoid exposing grade 420 to highly corrosive environments or prolonged high temperatures.

Stainless Steel Grades: 201

Key Properties

Grade 201 stainless steel offers a cost-effective alternative to traditional austenitic alloys. This grade contains lower nickel content, replaced partly by manganese and nitrogen. As a result, manufacturers can reduce production costs while maintaining good mechanical properties. Grade 201 demonstrates high tensile strength and excellent toughness, even at low temperatures. The alloy resists corrosion in mild environments, although it does not match the performance of grades 304 or 316 in highly corrosive settings.

The material exhibits good formability and can undergo deep drawing and shaping processes. Fabricators often choose grade 201 for its ability to withstand moderate wear and tear. The surface finish remains attractive, making it suitable for visible components. However, grade 201 may experience surface discoloration if exposed to harsh chemicals or saltwater.

Tip: Grade 201 provides a balance between affordability and performance, making it a popular choice for applications where cost control is important.

Main Applications

Manufacturers use grade 201 in a wide range of consumer and industrial products. The alloy’s combination of strength, formability, and moderate corrosion resistance supports its popularity in the following areas:

- Kitchen utensils and cookware, such as pots, pans, and cutlery

- Food service equipment, including sinks, counters, and shelving

- Automotive trim, wheel covers, and decorative moldings

- Railway and subway car interiors

- Architectural features, such as doors, frames, and handrails

- Appliance components, including washing machine drums and panels

- Fasteners, clamps, and brackets for light-duty applications

Grade 201’s affordability allows manufacturers to produce high-volume items without sacrificing essential performance. Designers often specify this alloy for products that require a clean appearance and moderate durability. In environments with limited exposure to corrosive agents, grade 201 delivers reliable results.

Stainless Steel Grades: 409

Key Properties

Grade 409 stainless steel belongs to the ferritic family and serves as a practical choice for applications that require moderate corrosion resistance and good weldability. Engineers often select this alloy for its ability to withstand high temperatures, especially in automotive and industrial environments. The chromium content in grade 409 forms a passive layer that protects the surface from gas-related corrosion. This layer resists further damage, even if light surface rust appears. The alloy performs well under short-term exposure to temperatures up to 815°C and can handle continuous use at temperatures up to 675°C.

Weldability stands out as a key advantage of grade 409. Fabricators typically preheat the material to 150–260°C before welding. Using grade 309 electrodes or filler rods helps reduce grain growth during the process. For thin products, post-weld annealing is not necessary, which streamlines manufacturing. Automotive exhaust tubing often gets welded without filler rods, demonstrating the alloy’s adaptability.

| Feature | Details |

|---|---|

| Corrosion Resistance | Good resistance to exhaust gas and atmospheric corrosion; better than 410 but less than 430; mild surface corrosion limits decorative use. |

| Weldability | Preheating to 150–260°C recommended; grade 309 filler rods preferred; post-weld annealing optional for thin products. |

Note: Grade 409 offers a balance of cost, durability, and ease of fabrication, making it a popular choice for high-temperature service parts.

Main Applications

Manufacturers rely on grade 409 for components that must endure heat and corrosive gases. Its properties make it a staple in the automotive industry and beyond. Common uses include:

- Automotive exhaust systems

- Catalytic converters

- Mufflers

- Tailpipes

- Farm equipment

- Structural supports and hangers

- Transformer cases

- Furnace components

- Heat exchanger tubing

Grade 409’s performance in these roles highlights its value in demanding environments. The alloy’s combination of heat resistance, corrosion protection, and weldability ensures reliable service in both vehicles and industrial machinery.

Stainless Steel Grades: 321

Key Properties

Grade 321 stainless steel stands out for its titanium stabilization, which prevents chromium carbide precipitation during exposure to temperatures between 800 and 1500°F (427 to 816°C). This feature protects the alloy from intergranular corrosion, especially after welding or prolonged service in high-heat environments. Engineers value grade 321 for its ability to maintain mechanical integrity and resist oxidation at elevated temperatures. The alloy cannot be hardened by heat treatment, but cold working can increase its strength.

Grade 321 offers superior creep and stress rupture resistance compared to grades 304 and 304L. This advantage allows for higher allowable stresses in applications governed by the ASME Boiler and Pressure Vessel Code. The maximum recommended service temperature reaches 1500°F (816°C), making it suitable for continuous operation in demanding thermal conditions. Annealing at 1800 to 2000°F (928 to 1093°C) restores softness and ductility, while stress relief annealing within the 800 to 1500°F range does not cause intergranular corrosion.

Note: Grade 321 resists polythionic acid stress corrosion cracking and maintains stability during thermal cycling, which is critical for high-temperature industrial processes.

Main Applications

Aerospace manufacturers frequently select grade 321 for components exposed to high heat and stress. The alloy’s resistance to oxidation and corrosion, combined with good creep strength, makes it ideal for aircraft collector rings, exhaust stacks, and jet engine parts. Engineers also use grade 321 in carburetor air intensifier tubes, flexible couplings, and mufflers. Its titanium stabilization allows for welding without the risk of carbide precipitation, which is essential for parts that cannot be annealed after fabrication.

In the heat treatment industry, grade 321 serves in pressure vessels and heat exchangers that operate at elevated temperatures. The alloy’s ability to withstand prolonged heating without losing corrosion resistance ensures reliable performance in thermal processing equipment. Additional uses include furnace components, expansion joints, and chemical processing equipment where both heat and corrosion resistance are required.

| Application Area | Typical Products/Components |

|---|---|

| Aerospace | Collector rings, exhaust stacks, jet engine parts, flexible couplings, mufflers |

| Heat Treatment | Pressure vessels, heat exchangers, furnace parts |

| Chemical Processing | Expansion joints, piping, reactors |

Grade 321’s unique combination of high-temperature stability and weldability supports its widespread adoption in industries where safety and durability are paramount.

Stainless Steel Grades: 904L

Key Properties

Grade 904L stands out as a high-alloy austenitic stainless steel. Engineers value this material for its exceptional resistance to corrosion, especially in harsh environments containing acids and chlorides. The alloy’s unique composition includes high levels of nickel and molybdenum, along with copper and low carbon content. These elements work together to provide superior protection against pitting, crevice corrosion, and stress-corrosion cracking. The low carbon content helps prevent carbide precipitation, which preserves corrosion resistance after welding or thermal processing.

The following table summarizes the essential characteristics of grade 904L:

| Aspect | Details |

|---|---|

| Corrosion Resistance | Excellent resistance to pitting, stress-corrosion cracking, and crevice corrosion in acidic and chloride environments. Superior to type 316 stainless steel due to higher nickel content. Resistant to organic and inorganic acids including sulfuric, hydrochloric, acetic, and formic acids. |

| Key Alloying Elements | – Chromium (Cr): Provides corrosion resistance and forms a passive oxide layer. – Nickel (Ni) ~25%: Enhances resistance to chloride stress corrosion and overall toughness. – Molybdenum (Mo) ~4.5%: Improves resistance to pitting and crevice corrosion. – Copper (Cu) ~1.5%: Increases resistance to acids and prevents intergranular corrosion. – Low Carbon: Minimizes carbide formation, preserving corrosion resistance. |

| Microstructure | Low carbon austenitic structure reduces carbide precipitation, enhancing corrosion resistance. |

| Surface Finish | Smooth and clean surface finish recommended to prevent corrosion initiation sites. |

| Applications | Suitable for harsh environments such as petroleum refining and chemical processing due to superior corrosion resistance and mechanical properties. |

Note: Grade 904L’s smooth surface finish further reduces the risk of corrosion initiation, making it ideal for critical applications.

Main Applications

Many industries rely on grade 904L for equipment that must withstand aggressive chemicals or acids. Its robust corrosion resistance and mechanical strength make it a preferred choice in demanding environments. Typical applications include:

- Chemical processing equipment for the production of sulfuric, phosphoric, inorganic, and organic acids, as well as phosphate-based fertilizers

- Air pollution control systems, such as scrubbers in coal-fired power plants

- Metallurgical processing equipment, including pickling tanks that use sulfuric acid

- Offshore oil and gas process equipment exposed to seawater and harsh chemicals

- Pharmaceutical industry process vessels and piping

- Pulp and paper processing machinery

- Seawater and brackish water systems, including condensers, heat exchangers, and piping

These industries select grade 904L to ensure long service life and reliable performance in environments where standard stainless steels may fail. The alloy’s ability to resist a wide range of corrosive agents, including dilute sulfuric acid, sets it apart from other materials.

Stainless Steel Grades: 2205 Duplex

Key Properties

Grade 2205 Duplex stainless steel features a unique microstructure. It contains austenite pools surrounded by a continuous ferrite phase, with about 40–50% ferrite in the annealed state. This duplex structure combines the strengths of ferritic and austenitic alloys. The ferrite phase provides high strength and excellent resistance to stress corrosion cracking. The austenite phase offers good corrosion resistance and ease of fabrication.

Engineers value grade 2205 for its mechanical performance. The alloy delivers a minimum ultimate tensile strength of 95 ksi and a minimum 0.2% yield strength of 65 ksi. Its hardness does not exceed 31 on the Rockwell C scale. These properties make it suitable for demanding environments. The material resists chloride-induced pitting, crevice corrosion, and stress corrosion cracking. It also maintains good weldability and workability, which supports efficient manufacturing.

| Property | Value |

|---|---|

| Ultimate Tensile Strength | Minimum 95 ksi |

| 0.2% Yield Strength | Minimum 65 ksi |

| Hardness | Maximum 31 Rockwell C |

Note: Grade 2205 Duplex offers a balance of strength, corrosion resistance, and fabrication ease, making it a preferred choice for aggressive service conditions.

Main Applications

Grade 2205 Duplex finds widespread use in industries that demand both strength and corrosion resistance. Chemical processing plants use this alloy for pressure vessels, tanks, piping, and heat exchangers. Oil and gas companies select it for piping, tubing, and heat exchangers in exploration and processing facilities. Offshore platforms, riser systems, and pipelines benefit from its durability and resistance to chloride-induced corrosion.

- Pressure vessels and storage tanks in chemical processing

- Piping and tubing for oil and gas exploration

- Heat exchangers in both chemical and energy sectors

- Offshore platform structures and riser systems

- Pipelines exposed to aggressive chemicals and high pressures

The alloy’s ability to withstand high pressures and aggressive chemicals ensures long service life. Its resistance to stress corrosion cracking and pitting makes it essential for critical infrastructure in harsh environments.

Stainless Steel Grades Comparison Table

Selecting the right stainless steel grade depends on understanding how each type performs in real-world conditions. Engineers often compare grades based on corrosion resistance, mechanical strength, and cost. The following table summarizes these key differences among the most widely used Stainless Steel Grades:

| Stainless Steel Grade | Corrosion Resistance | Strength (Tensile/MPa) | Cost |

|---|---|---|---|

| 304 (Austenitic) | Excellent; suitable for most environments | ~621 | High |

| 316 (Austenitic) | Superior; resists chlorides and harsh chemicals | ~620 | Higher |

| 321 (Austenitic, stabilized) | Excellent; stable at high temperatures | ~620 | High |

| 430 (Ferritic) | Good; less than austenitic, not for marine use | ~450 | Low |

| 410 (Martensitic) | Moderate; best for mild environments | ~500 (hardened higher) | Low |

| 420 (Martensitic) | Moderate; can be hardened for tools | Up to 1,586 (hardened) | Low |

| 201 (Austenitic) | Good; less than 304, cost-effective | ~620 | Lower |

| 409 (Ferritic) | Fair; withstands heat, not decorative | ~380 | Low |

| 904L (Austenitic) | Outstanding; resists acids and chlorides | ~490 | Very High |

| 2205 Duplex | Excellent; superior pitting and stress corrosion resistance | ~800 | Moderate |

Engineers recommend reviewing both corrosion resistance and mechanical strength before making a selection. Cost also plays a significant role in large-scale projects.

The next table highlights mechanical characteristics and typical applications for each grade:

| Grade | Family Type | Mechanical Characteristics | Typical Applications | Notes on Performance |

|---|---|---|---|---|

| 304 | Austenitic | Good ductility, weldability | Medical, general purpose | Popular, reliable corrosion resistance |

| 316 | Austenitic | Higher strength, excellent corrosion | Chemical, marine, food processing | Superior in harsh environments |

| 430 | Ferritic | Magnetic, lower ductility | Appliances, automotive trim | Lower cost, less corrosion resistance |

| 410 | Martensitic | Hardenable, magnetic | Cutlery, surgical tools | High hardness after heat treatment |

| 420 | Martensitic | Very hard when treated | Blades, bearings, valves | Best for sharp edges, moderate corrosion |

| 201 | Austenitic | Good formability, moderate corrosion | Kitchenware, appliances | Cost-effective, less nickel |

| 409 | Ferritic | Heat resistant, weldable | Exhaust systems, furnace parts | Not for decorative use |

| 321 | Austenitic | Stable at high temperatures | Aerospace, heat exchangers | Titanium prevents carbide precipitation |

| 904L | Austenitic | Excellent acid/chloride resistance | Chemical, offshore, pharma | High cost, premium performance |

| 2205 | Duplex | High yield strength, excellent corrosion | Oil & gas, chemical, marine | Combines ferritic and austenitic traits |

These tables help professionals and students quickly compare Stainless Steel Grades for any application.

How to Choose the Right Stainless Steel Grade

Key Factors

Selecting the right stainless steel grade requires careful evaluation of several important factors. Engineers and designers should follow a systematic approach to ensure the material meets both performance and budget requirements.

- Assess the operating environment. Corrosion resistance is critical, especially when the application involves exposure to chemicals, high temperatures, or chloride ions. For example, grade 316 performs well in marine or chemical settings due to its superior resistance to chloride attack.

- Evaluate mechanical properties. Strength, ductility, and toughness determine how the material will respond to stress, impact, and deformation. Alloying elements such as chromium, nickel, and molybdenum influence these characteristics.

- Review processing requirements. Consider how the material will be formed, machined, welded, or cold worked. Some grades handle fabrication processes better than others.

- Address customer preferences. Surface finish and required certifications may dictate the choice of grade for specific industries or applications.

- Balance cost and availability. Weigh the initial material cost against long-term benefits, such as reduced maintenance and longer service life.

Tip: Matching the stainless steel grade to the specific environment and mechanical demands helps prevent premature failure and costly repairs.

Practical Tips

Mistakes in selecting stainless steel grades can lead to performance issues and increased costs. To avoid common pitfalls, professionals should keep these tips in mind:

- Choose the correct temper for the application. The wrong temper can cause machining problems or early fatigue.

- Inspect for burrs or poorly treated edges. These defects may disrupt production or create welding challenges.

- Verify tolerance specifications. Ignoring tolerances can result in poor fitting and calibration issues.

- Specify the right surface finish. The finish affects cleaning, contamination control, and corrosion resistance.

- Seek technical support when needed. Expert guidance ensures the best material choice and quick problem resolution.

A thoughtful selection process ensures that Stainless Steel Grades deliver optimal performance and value in every application.

The top 10 Stainless Steel Grades serve a wide range of industries, each offering unique benefits:

- 304 and 316: Food processing, marine, and medical equipment

- 430 and 409: Appliances, automotive exhausts

- 410 and 420: Cutlery, surgical tools

- 201: Kitchenware, appliances

- 321: Aerospace, heat exchangers

- 904L: Chemical, offshore, pharmaceutical

- 2205 Duplex: Oil and gas, chemical plants

| Grade Family | Typical Uses |

|---|---|

| Austenitic | Food, healthcare, outdoor enclosures |

| Ferritic | Cooking utensils, automotive exhausts |

| Martensitic | Blades, surgical instruments |

| Duplex | Heat exchangers, offshore, chemical processing |

Selecting the correct grade ensures optimal durability, reduces maintenance costs, and supports long-term performance.

FAQ

What is the main difference between austenitic and ferritic stainless steel grades?

Austenitic grades, such as 304 and 316, contain higher nickel and offer better corrosion resistance. Ferritic grades, like 430 and 409, have lower nickel and are magnetic. Austenitic steels suit harsh environments, while ferritic types work well for cost-sensitive applications.

Can stainless steel rust or corrode?

Stainless steel resists rust, but it can corrode under certain conditions. Chloride exposure, poor maintenance, or using the wrong grade may cause staining or pitting. Proper grade selection and regular cleaning help prevent corrosion.

Why do some stainless steel grades cost more than others?

Grades with higher nickel, molybdenum, or special alloying elements cost more. These elements improve corrosion resistance and mechanical strength. For example, 316 and 904L are more expensive than 304 or 430 due to their enhanced properties.

How does heat treatment affect stainless steel properties?

Heat treatment can increase hardness and strength in martensitic grades like 410 and 420. Austenitic and ferritic grades do not harden with heat treatment. Proper heat treatment ensures the desired mechanical performance for specific applications.

Which stainless steel grade is best for food contact?

Grade 304 is the most common choice for food contact. It offers excellent corrosion resistance, easy cleaning, and does not react with most foods. Grade 316 provides extra protection in environments with salt or acidic ingredients.