Metal Injection Molding Of Titanium

Titanium is an important structural metal developed in the 1950s. Titanium has the characteristics of high strength, good corrosion resistance, and high heat resistance. The density of titanium alloy is generally around 4.51g/cm3, which is only 60% of steel, and exceeds the strength of many alloy structural steels.

MIM Titanium is a metal injection molding technology (Metal Injection Molding MIM), which uses a powder metallurgy process to inject titanium alloy powder and binder mixture together. This technique can produce parts of complex shapes and is more cost-effective than traditional manufacturing methods. MIM Titanium is widely used in fields such as aerospace, medical equipment, and automobile manufacturing.

| Titanium Medical Uses | ||

| Medical grade titanium | Titanium in the body side | |

| TA1,TA2 | Ti | The manufacture of artificial bone joints, knee, elbow joints, and other implants, bone support columns, human body clamps, lock rings, and other suture equipment |

| ZTC4 | Ti-6A1-4V | Artificial bone joint, artificial knee joint, and can be combined into a holistic femur and tibia, artificial hemipelvis, used to treat primary malignant tumors of the pelvis |

| TC15 | Ti-5A1-2,5Fe | Tibial prosthesis |

| TC20 | Ti-6A1-7Nb | Various human surgical implants, such as various artificial joints, bone correction and fasteners, etc |

Medical titanium is mainly used in the production of surgical implants and orthopedic devices, such as dental implants, artificial joints, and vascular stents. According to the professional standards of orthopedic devices and surgical implants, medical titanium materials are classified as metal materials used in surgical implants.

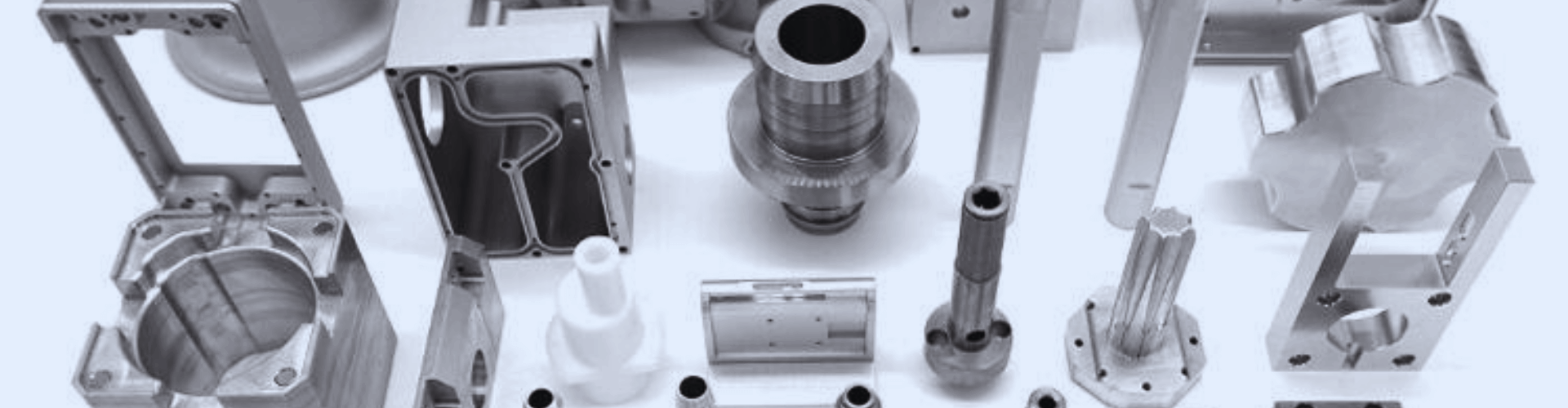

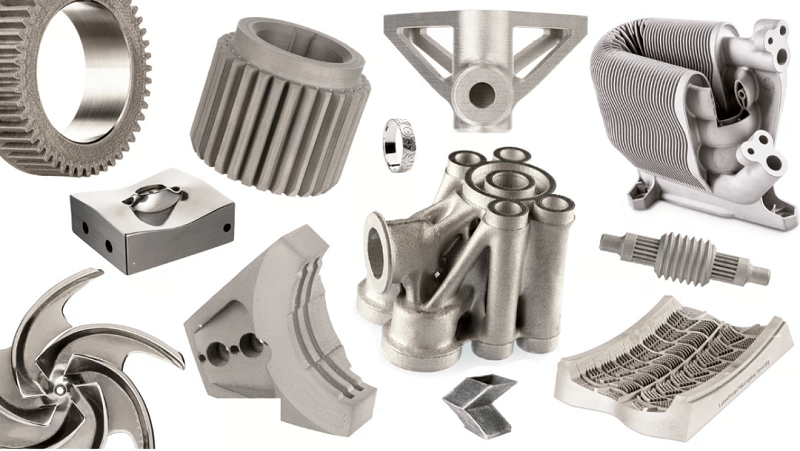

JH MIM, which started as metal injection molding, has established a sound product ecology by investing in advantageous enterprises in related industries. Now it can provide customers with one-stop services such as powder metallurgy, Die Casting, CNC, and 3D printing. It is equipped with integrated assembly capabilities and the quality of quality suppliers mentioned above. Please click the link below for more detailed information.