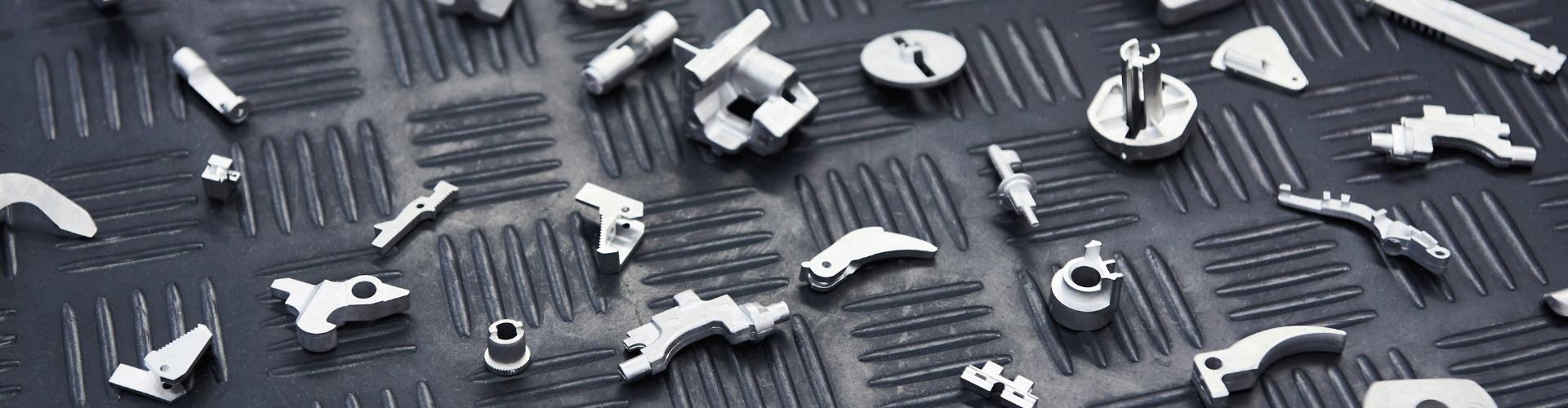

MIM parts JH MIM Produce

- Housing blocks

- Compressed air nozzles

- Rifle and revolver components, including handle bodies and yokes

- Lock bars, pins, and racks

- Orthodontic brackets

- Parts for surgical tools, including forceps, pins and suturing devices

- Handcuff parts

- Mobile phone hinges and sliders, sim tray

- Watch casings

- Gears and latches

- Earphone and Headsets parts

What Are MIM Parts

Metal injection molding MIM is a method for creating freestanding parts that can be used in a variety of industries. MIM allows for the production of complex geometries with little or no post-processing, putting them at an advantage over assembly, machining, and casting techniques.

MIM parts mean those metal parts made by metal injection molding process. MIM is just another metalworking method, like forging and casting. Compared to those well-established metalworking methods, MIM usually performs better when producing small size, complex shapes metal components in large quantities. MIM parts make use of wide ranges of materials such as varieties of stainless steel, low alloy steel, iron-based, titanium, etc. Recently MIM has acquired increasing significance in various fields of Industry, Automotive, Electronics, Medical, Tools, Firearms and others.

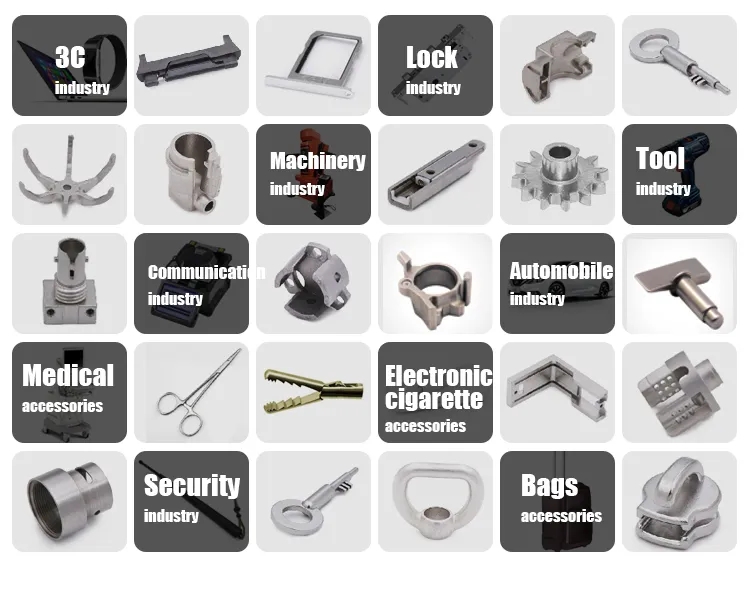

Metal Injection Molding Industrial applications

Metal Injection Molding (MIM) Widely used in consumer electronics industry , automotive industry , medical industry, and industrial

We can provide cost-effective Metal Injection Molding (MIM) medical device, orthopedic and orthodontic.

MIM parts for the automobile sector in a variety of applications including vehicle safety, fuel systems, powertrain, and more.

JH MIM have experience designing and manufacturing a variety of aircraft components, such as bushings, fasteners, compressor blades, rotors, brackets, and inlets.

MIM is employed in the production of micro gears, power tools, cutting tools, wear parts, toy robots, lock parts, hardware, business machines, and other components for textile machinery.

MIM Wear Parts including Camera bracket,Key assembly,Rotating shaft,Key hook,Bracket,Buckle assembly etc.

JH MIM offers specially designed MIM or Powder Metallurgy products for hardware, power equipment, and consumer electronics.

MIM Materials

Metal Injection Molding Materials:

Stainless Steel: 304L, 316L, 17-4 PH, 420, 430, 440

Titanium Alloy: Ti-6Al-4V

Superalloys: Inconel, Hastelloy, Co-based Low Alloy Steels, 2-8% Ni (4600, 4650)

Magnetic Alloys: 2-6% Si-Fe, 50% Ni-Fe, 50% Co-Fe

Controlled Expansion Alloys: Fe-36Ni (Invar), F-15 (Kovar)

Electrical Materials: Pure Copper, Beryllium-Copper, Brass

Tool Steels: AISI M2, M3/2, M4, T15, M42, D2

Heavy Alloys: Tungsten-Copper, W-Fe-Ni, Molybdenum-Copper, Custom compostions to suit customer specifications

WHY CHOOSE JIEHUANG INDUSTRY MIM COMPONENTS

JH MIM process and systems are documented and well controlled to deliver consistent results, time after time. We plan for success, perform to expectation, constantly monitor performance and continuously improve on everything we do.

JH MIM have developed over 6000+ MIM products for a variety of markets and applications. This vast experience has honed our engineering and manufacturing expertise for fast and efficient development of new products.

JH MIM provide highly flexible solutions and will adapt our process and capabilities to suit our customers’ needs. We are constantly in motion to meet the most demanding requirements for any product, application and market.

YOUR BEST CHOICE

- Reply Yor RFQ With In 24 Hours

- Offer Quotations In 3 Days

- Offer DFM Reports In 7 Days

- Lock bars, pins, and racks

- Finish Moulds In 25 Days

- Free Warrantly Service in 365 Days