MIM Equipment

Feedstock Elaboration

We have the competence to use a dedicated device for MIM raw materials mix production. We can accurately mix batch powder and binder under a controlled environment, and then maintain high quality and flexibility.

Injection Molding

We use the most advanced and sophisticated MIM machines in the market. We believe that we can realize higher performance and production quality by using machines debugged by technicians. We update injection equipment and achieve automation production.

Debinding and Sintering

Before sintering, we utilize a special debinding technology to remove the binder, which is an environment-friendly process and easy to monitor. The sintering process keeps running under a vacuum or high temperature. We can precisely control various alloys by using different gases. Our continual sintering furnaces can meet customer’s demands in the aspect of high productivity and efficiency.

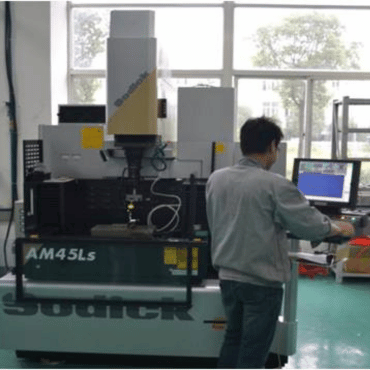

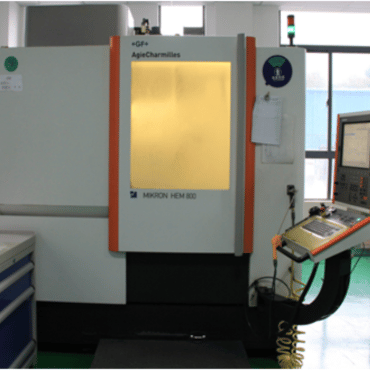

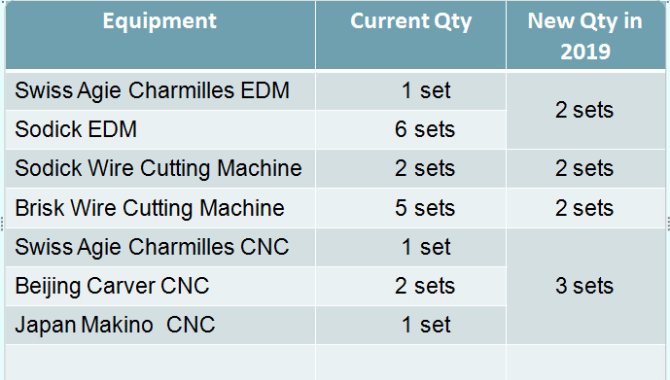

Facilities-Tooling

Facilities-Production

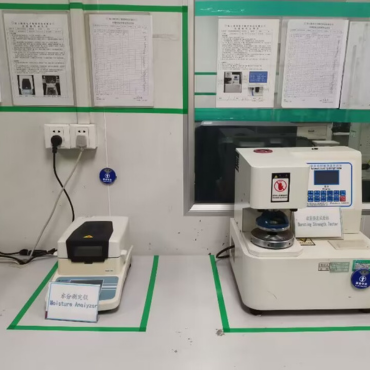

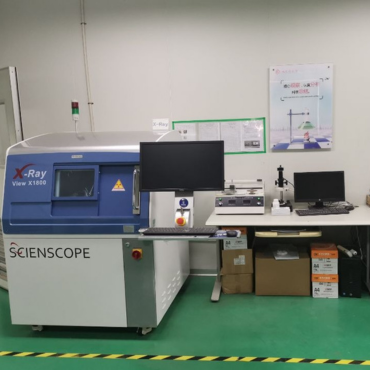

World Class Facilities-Test

Manual Testing

Tooling Machine List

JH MIM has complete MIM process capabilities, and our team can handle all processes from casting molds to MIM product production

The following is JH MIM’s mold service

- Mold design and mold flow analysis

- CNC milling machine imported from Japan*4

- EDM sinker type *6 and modern wire*3 imported from Germany

- Precision grinding*4

- Modular general tooling

- Hard milling

- CMM scanning head

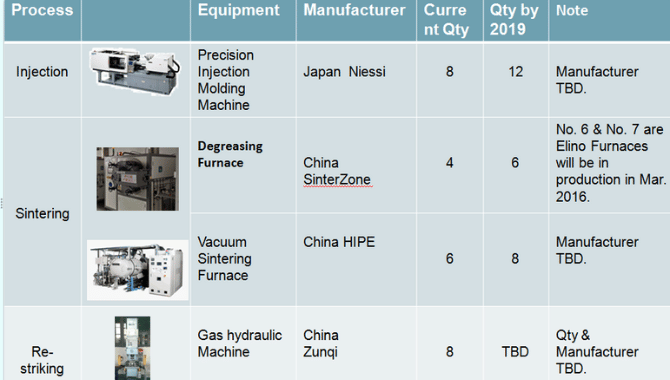

Facilities-Equipment List

JH MIM has been deeply involved in the MIM industry and has more than 10 years of experience. Through the industry’s senior engineers and world-class equipment, our products have stable quality

- Injection machine imported from Japan*8

- Degreasing furnace*4

- Vacuum sintering furnace*6

- Re-striking machine*8

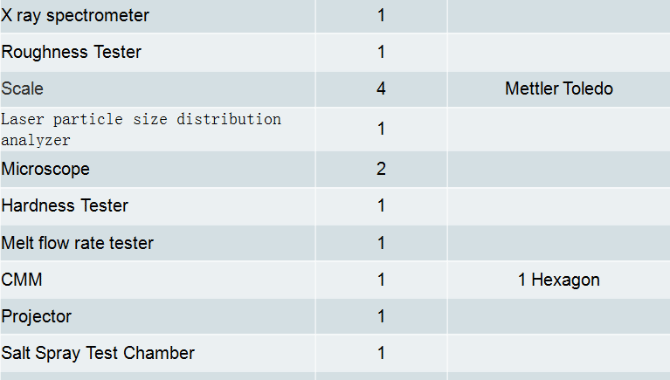

World Class Facilities-Test Equipment List

We pay great attention to product quality control, to provide customers with high-quality products through the following aspects to implement

1.6S control system, all materials, production processes have inspection records can be checked

2.Over 10 people QC management team

3,Perfect testing equipment, perfect testing of size, material, hardness, density, etc.

4.Customer feedback problems, within 48 hours to find the cause of the problem, to provide solutions

JH MIM Is The The Best Worthy One-stop PM and MIM Manufacturer