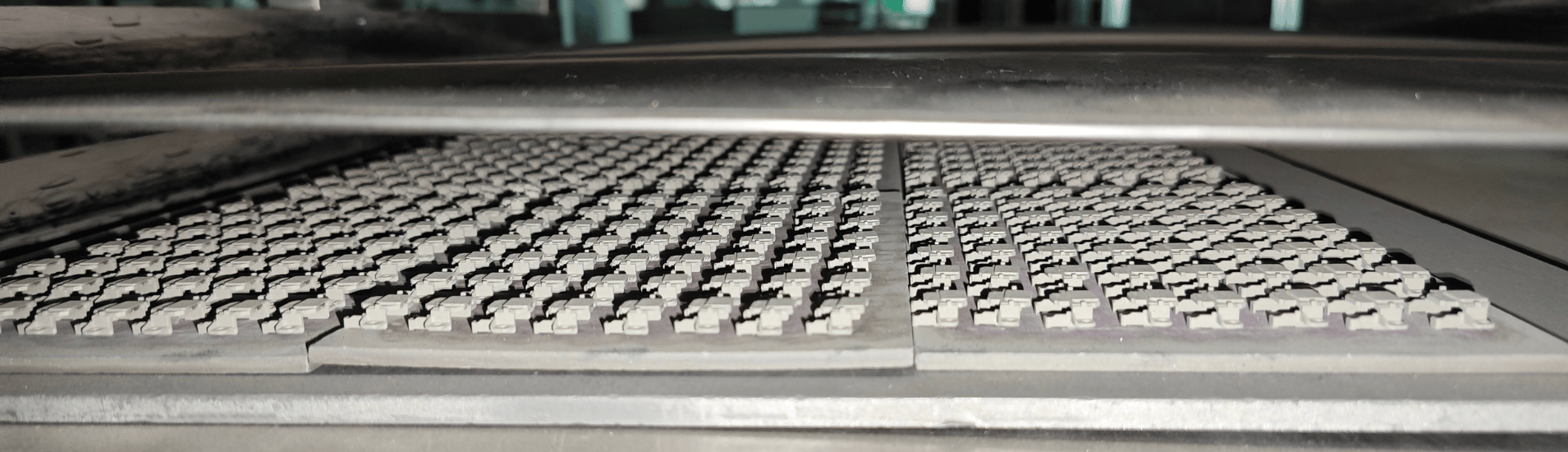

Advantages and Disadvantages of Metal Injection Molding (MIM)

Metal injection molding (MIM) is a manufacturing technique that combines the flexibility and cost-effectiveness of plastic injection molding with the strength and durability of traditional powder metallurgy processes. This article explores the advantages and disadvantages of metal injection molding and provides insights to determine if MIM is the right manufacturing process for your product.

1. Major Advantages of Metal Injection Molding (MIM)

- Complex Geometries

- High Density and Strength

- Stable Quality

- Material Selection

- High Material Utilization

- High Precision and Excellent Surface Quality

- Cost Efficiency

1. 1 Complex Geometries

MIM excels in producing components with complex internal structures, thin walls, and intricate shapes. This capability allows for the creation of parts that are both functional and aesthetically pleasing. Moreover, MIM provides high precision, maintaining tight tolerances essential for ensuring proper fit and function.

1.2 High Density and Strength

Products made through MIM have high density, achieving 95%-99%, resulting in superior mechanical properties such as high strength and hardness. This makes MIM suitable for parts that need to withstand high stress and wear.

1.3 Stable Quality

The MIM process ensures high consistency and quality due to several factors:

- Repeatability: Automation ensures uniform production, with each component meeting design specifications and tolerances, reducing defects.

- Material Consistency: The metal powders used in MIM maintain consistency in composition and particle size, ensuring the quality of the final product.

- Controlled Environment: A controlled production environment minimizes contamination risks and defects, resulting in parts free from porosity or inclusions.

1.4 Material Selection

MIM supports a wide range of metal materials, including iron-based, stainless steel, titanium alloys, hard metals, and various low-alloy steels. This versatility allows MIM to be widely used in electronics, automotive, medical, and other industries.

1.5 High Material Utilization

The MIM process significantly conserves raw materials, theoretically achieving 100% utilization. Compared to traditional metalworking methods, MIM reduces material waste, enhancing economic efficiency and reducing environmental impact.

1.6 High Precision and Excellent Surface Quality

The dimensional tolerances of MIM parts can reach ±0.5%, with some features achieving ±0.3%. Additionally, MIM parts have a high surface finish, achieving Ra0.8-Ra1.2, making them suitable for further surface treatments.

1.7 Cost Efficiency

MIM is a cost-effective method as it reduces labor requirements and minimizes waste. The inherent automation of MIM reduces reliance on manual labor, significantly saving costs, especially for high-volume production. Moreover, MIM generates minimal excess material, reducing waste and associated costs. The precision of MIM also reduces the need for secondary operations such as finishing and assembly, further saving costs.

2. Major Disadvantages of Metal Injection Molding (MIM)

- Complex Process

- High Mold Costs

- Material Limitations

- Size Limitations

- High Cost of Design Changes

- High Minimum Order Quantity (MOQ)

2.1 Complex Process

The MIM process involves multiple steps, including feedstock preparation, injection molding, debinding, and sintering. Each step requires strict control to ensure the final quality of the parts. This makes the process complex and time-consuming, with high technical demands on the operators.

2.2 High Mold Costs

Each MIM part design requires a dedicated mold, and the manufacturing cost of these molds is high. This results in a significant initial investment, especially for low-volume production or projects with frequent design changes.

2.3 Material Limitations

Although MIM supports a variety of metal materials, some metals that are prone to oxidation, highly reactive, or toxic are not suitable for the MIM process. For example, materials like lead, magnesium, and beryllium are difficult to handle in the MIM process due to their properties.

2.4 Size Limitations

The MIM process is most suitable for producing small to medium-sized parts. Molding large parts reduces the capacity of molds and furnaces, thereby increasing processing costs. Additionally, large parts are more prone to deformation and cracking during the sintering process.

2.5 High Cost of Design Changes

Since each design requires a specific mold, any design changes necessitate the redesign and manufacturing of new molds. This leads to additional costs and extended delivery times, making it costly for projects that require frequent design modifications.

2.6 High Minimum Order Quantity (MOQ)

While MIM is cost-effective for high-volume production, the unit cost is high for small orders. Therefore, many MIM manufacturers set high minimum order quantities. The typical MOQ ranges from 5,000 to 10,000 pieces, which can be a barrier for buyers with small-scale production or customized needs.

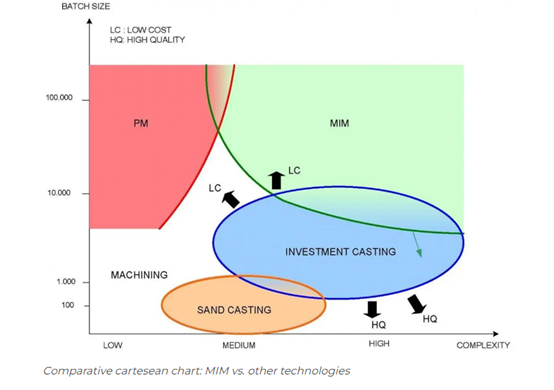

3. Comparison of Advantages and Disadvantages of MIM with Other Manufacturing Processes

3.1. Comparison between MIM and PM

3.2 Comparison between MIM and lost wax casting

3.2 Comparison between MIM and stamping

3.3 Comparison between MIM and CNC

3.1 Comparison of MIM with PM

| Characteristic | Metal Injection Molding (MIM) | Powder Metallurgy (PM) |

| Material Form | Mixture of metal powder and binder | Metal powder |

| Powder Particle Size | 2-15 microns | 50-100 microns |

| Forming Method | Injection molding | Press forming |

| Part Complexity | Suitable for complex geometries | Suitable for simple shapes |

| Dimensional Accuracy | High precision (±0.3%) | Generally lower |

| Surface Quality | High surface finish | Requires further processing |

| Production Volume | Suitable for high-volume production | Suitable for medium to low-volume production |

| Material Utilization | Very high | High |

| Density | 94-98% | <93% |

| Cost | Moderate | Low |

| Applications | Medical devices, electronics, automotive parts, aerospace | Automotive parts, tools, mechanical parts |

Advantages:

- MIM: Suitable for producing parts with complex geometries, high precision, and high density.

- PM: Lower cost, suitable for parts with simple shapes.

Disadvantages:

- MIM: Higher mold and material costs.

- PM: Lower part density and mechanical properties.

Summary

MIM is highly advantageous for producing parts with complex geometries, high precision, and superior surface quality, making it ideal for high-volume production in industries such as medical devices, electronics, automotive, and aerospace. It uses smaller powder particles (2-15 microns) and involves injection molding, resulting in parts with high density (94-98%) and minimal waste.

On the other hand, PM is better suited for simpler shapes and is cost-effective for medium to low-volume production. It uses larger powder particles (50-100 microns) and press forming, resulting in generally lower precision and surface quality, but it is widely used in automotive parts, tools, and mechanical components due to its lower cost.

3.2 Comparison of MIM and Investment Casting

| Characteristics | Metal Injection Molding (MIM) | Investment Casting |

| Material Form | Metal powder mixed with binder | Molten metal |

| Forming Method | Injection molding | Wax mold lost-wax casting |

| Part Complexity | Suitable for complex geometries | Suitable for complex geometries |

| Dimensional Accuracy | High precision (±0.3%) | High precision (±0.5%) |

| Surface Quality | High surface finish | High surface finish |

| Production Volume | Suitable for mass production | Suitable for small batch production |

| Material Utilization | Very high | High |

| Density | 94-98% | High |

| Cost | Medium | High |

| Applications | Medical devices, electronics, automotive parts, aerospace | Aerospace, artworks, medical devices |

Advantages:

- MIM: Suitable for mass production, high material utilization, high production efficiency.

- Investment Casting: Can produce large and complex parts, good surface quality, suitable for small batch production.

Disadvantages:

- MIM: High mold cost, high material cost, limited part size.

- Investment Casting: Long production cycle, high cost, suitable for small batch production.

3.3 Metal Injection Molding (MIM) vs. Stamping

| Characteristics | Metal Injection Molding (MIM) | Stamping |

| Material Form | Metal powder mixed with binder | Metal sheet |

| Forming Method | Injection molding | Stamping |

| Complexity of Parts | Suitable for complex geometries | Suitable for simple shapes |

| Dimensional Accuracy | High accuracy (±0.3%) | Generally lower |

| Surface Quality | High surface finish, often no further processing needed | Requires post-processing |

| Production Volume | Suitable for large-scale production | Suitable for large-scale production |

| Material Utilization | Very high | Generally high |

| Cost | Moderate | Low |

| Applications | Medical devices, electronic products, automotive parts, aerospace | Automotive parts, electronic products, household appliances |

Advantages:

• MIM is suitable for producing parts with complex geometries, offering high precision and density.

• Stamping has low production costs and is suitable for mass production of parts with simple shapes.

Disadvantages:

• MIM has high tooling costs.

• Stamping is not suitable for producing parts with complex shapes.

3.4 Comparison Between MIM and CNC

Machining

| Characteristics | Metal Injection Molding (MIM) | CNC Machining |

| Material Form | Mixture of metal powder and binder | Solid metal blocks |

| Forming Method | Injection molding | Subtractive machining (cutting) |

| Complexity of Parts | Suitable for complex geometries | Suitable for complex geometries |

| Dimensional Accuracy | High precision (±0.3%)) | High precision |

| Surface Quality | High surface finish | High surface finish |

| Production Batch | Suitable for large batch production | Suitable for small batch production |

| Material Utilization | High Varies | typically lower |

| Cost | Moderate | High |

| Applications | Medical devices, electronics, automotive parts, aerospace | Aerospace, medical equipment, mold manufacturing |

Advantages:

- MIM is suitable for large-scale production of complex geometric parts, with high material utilization.

- CNC machining is suitable for small-batch production, with high precision and flexibility.

Disadvantages:

- MIM has high mold costs.

- CNC machining has lower material utilization and higher costs.

POWDER METALLURGY |

INVESTMENT CASTING |

PRESSURE DIE CASTING | MACHINING | STAMPING | |

| DENSITY | 85% | 100% | 100% | 100% | 100% |

| STRENGHT | LOW | VERY HIGH | MEDIUM | VERY HIGH | HIGH |

| ROUGHNESS | MEDIUM | LOW | HIGH | VERY LOW | VERY LOW |

| WEIGHT | MEDIUM LOW | MEDIUM 1gr./30kg: | MEDIUM | MEDIUM | LOW |

| FINE DETAILS |

NO | YES | NO | YES | NO |

| COMPLEXITY | LOW | HIGH | MEDIUM | HIGH | LOW |

| LOTS | LARGE | SMALL TO LARGE | LARGE | MEDIUM | VERY LARGE |

| COST | LOW | MEDIUM | LOW | HIGH | LOW |

| DIE COST | VERY HIGH | MEDIUM | HIGH | — | — |

| TOLERANCES | VERY GOOD | GOOD | MEDIUM | VERY GOOD | MEDIUM |

4. Checklist: Is Metal Injection Molding Suitable for You?

Now that you have gained a better understanding of metal injection molding and its applications in various industries, we have prepared a checklist to assist you in determining if metal injection molding is suitable for your production needs.

| Metal Injection Molding Suitability Checklist | ||

| Check item | Question | Applicability judgment |

| Production volume | Do you need to produce a large number of parts? | If so, then MIM may be a good choice |

| Part size | Are your parts small and intricately designed? | If so, then MIM may be a good choice |

| Precision and consistency | Do these parts need to meet strict specifications and tolerances? | If so, then MIM may be a good choice |

| Productivity | Are you looking for an efficient production process? | If so, then MIM may be a good choice |

| Complex geometries | Do these parts have complex design or functional requirements? | If so, then MIM may be a good choice |

While MIM is an efficient and versatile production process, there are some situations where it may not be the best choice.

| Limitations of Metal Injection Molding | ||

| Limiting factors | Question | Cases where MIM is not suitable |

| Frequent design changes | Do you need to make frequent design changes? Due to the use of molds, once production begins, MIM has high costs for modifications, making it not suitable for prototyping. | If so, then MIM may not be the best choice.

|

| Delivery time | Is fast delivery an important factor? MIM requires the manufacture of specialized tools, including injection molds and binding fixtures. Tool manufacturing may take several weeks or even months, depending on the complexity of the parts. | If so, then MIM may not be the best choice.

|

By considering these factors, you can ensure that you choose a production process that is suitable for your specific needs.

The ultimate goal of choosing MIM work: maximize your production benefits.

After considering these factors, you can ensure that you choose a production process that fits your specific needs. The ultimate goal of choosing to work with MIM: maximize your production efficiency. As you can see, metal injection molding has many advantages over traditional metal forming methods, including complex geometries, cost-effectiveness, consistent quality, and a wide range of material choices. However, it also has its limitations, including lead times, part size limitations, material costs, and surface finishing. When considering MIM for your manufacturing needs, it is important to carefully weigh the pros and cons to determine if it is suitable for your end product.

Yes, this is a routine operation for most companies before inquiring.

We have metal 3D printing equipment and can provide sample 3D printing.

3D drawings allow engineers to better understand the structure of the product, and 2D documents can provide more information, including materials, tolerances, surface treatment, etc. More detailed information is conducive to more accurate quotation by engineers.

In the case of detailed inquiry drawings and information, it usually only takes 2-3 days for us to give you a detailed quotation, including product price and mold price.

After confirming the order, we usually take 5-7 days to prepare the DFM report of the product. After confirmation, we spend 25 days to complete the mold, and provide T1 samples to customers for testing in the following 10-15 days.

If there is a problem with the test, we will re-sample it for free based on the feedback and provide a suitable sample.

MIM products MOQ 2000 PCS,

CNC products MOQ 2000 PCS,

Alu die casting, MOQ 2000 PCS

PM product MOQ 5000 PCS

Typically, the lead time for processing and submitting samples is 30 days. However, according to the order quantity and special requirements of customers, we can extend or shorten the delivery cycle accordingly.

1-year product warranty

World-class testing equipment

30+QC Workers

Key sizes 100% checking before shipment

ISO9001+IATF16949

Usually T/T is used as the payment method

Mold: 50% deposit, 50% payment after confirming the sample.

Bulk production: 30% deposit, 30% see bill of lading Copy, pay 70% balance.

JH MIM, which started out as MIM, has established a sound product ecology by investing in advantageous enterprises in related industries. Now it can provide customers with one-stop services such as PM, Die Casting, CNC, and 3D printing. It is equipped with integrated assembly capabilities and the quality of quality suppliers mentioned above. Please click the link below for more detailed information.