The emergence of the MIM process is accompanied by the development of the plastics industry.

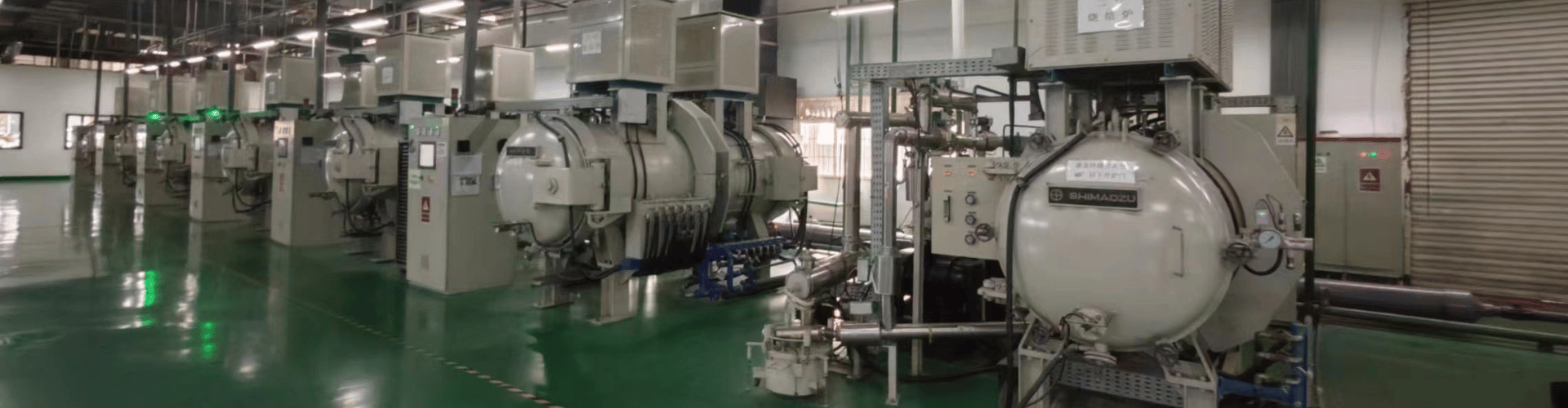

Metal Injection Molding process steps: 1.Feedback Compounding 2.Molding 3.Debinding 4.Sintering

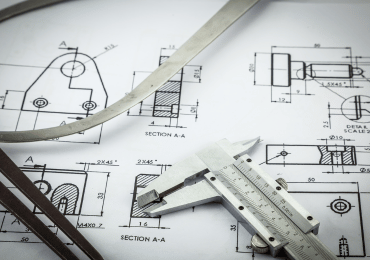

In MIM tooling,Jiehaung can design 1 to 16 mold cavities according to the demand of the purchase quantity Briefly

The MIM Design Guide is designed to evaluate the mold design of MIM products, design typing lines, gates, inject marks, etc.

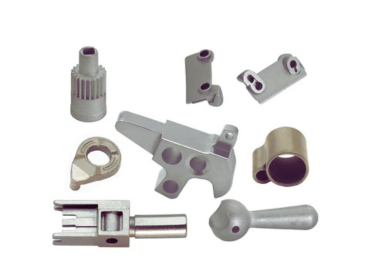

For Metal injection molding products, the surface finish is usually 32 µin Ra (through a sintering process).

MIM materials --- metal powders, usually include: iron alloys, stainless steel, titanium alloys, ceramics, etc.

The cost of MIM PARTS, consists of the following costs.

Tolerance is the allowable deviation of the measured value from the base measurement. Using tolerances helps ensure that the final product is easy to use

MIM vs. other Processing Methods,choice which?

MIM Technology

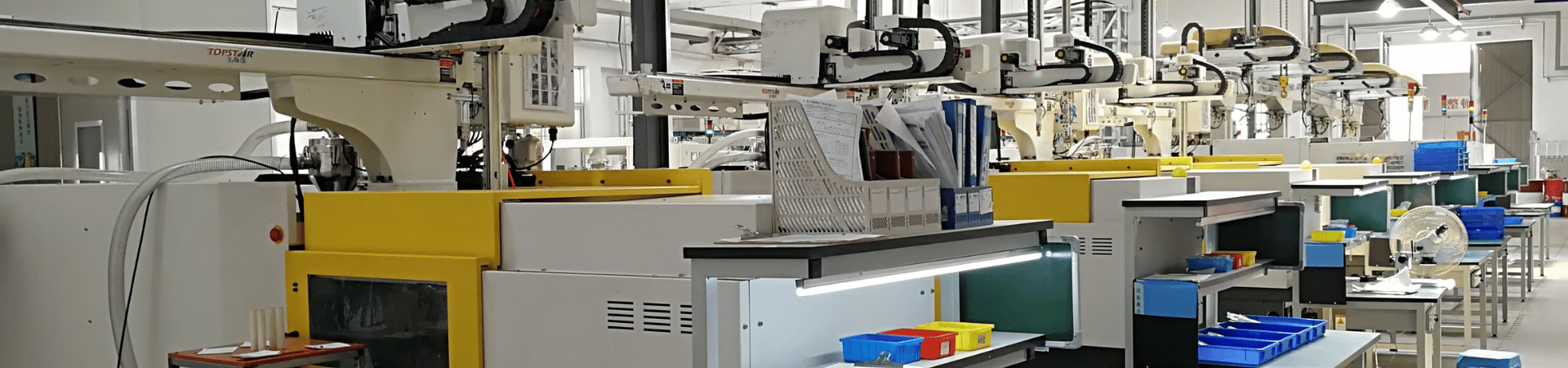

How to produce complex metal parts at a lower cost? This problem has been bothering the majority of metal parts manufacturers until it appeared-MIM Technology.

Metal injection molding can manufacture metal products of almost any geometric shape through mold design and injection molding process, and through sintering process, the hardness and strength of metal parts can be close to that of CNC products. In a large-scale production process, it can be produced at a lower cost.

If you have related product inquiries, or drawing design, please contact JH MIM’s engineer team, we will give you professional advice and reply.

Send Your Inquiry Today