Sintering is a heat treatment process used to produce dense solid objects from powdered materials like metals, ceramics, or composites. Here are the key points about sintering:

What is Sintering?

- Sintering involves heating a compressed powder compact below its melting point, causing the particles to bond together and form a solid mass.

- It eliminates porosity and enhances strength by allowing diffusion between the particles, fusing them together without fully melting.

- The sintered part achieves near-theoretical density (close to 100%) and properties comparable to the bulk material.

Sintering Process

The main physical process of metal sintering:The porosity in the billet reaches 35~60%,Point contact or no contact between particles;

As the temperature rises, the particles become indirect Contact area increases → particles aggregate → particles The center is close;

Gradually forming grain boundary → pore deformation,Grain deformation → pore shrinkage, compact body Shrinkage, gas removal;

Connected pores → isolated closed pores,Until most of the gas is removed.

After sintered metal, the strength of sintered body increases, first of all, the bonding strength between particles increases, that is, the gravitational attraction between atoms on the bonding surface increases.

At high temperature, due to the increase of the amplitude of atomic vibration, diffusion occurs, and more atoms on the contact surface enter the range of atomic force to form a bonding surface.

The bonding surface expands and then forms the sintering neck, which makes the original grain interface form the grain interface and the grain boundary move to the inside of the grain, resulting in the grain growth.

Types of Sintering

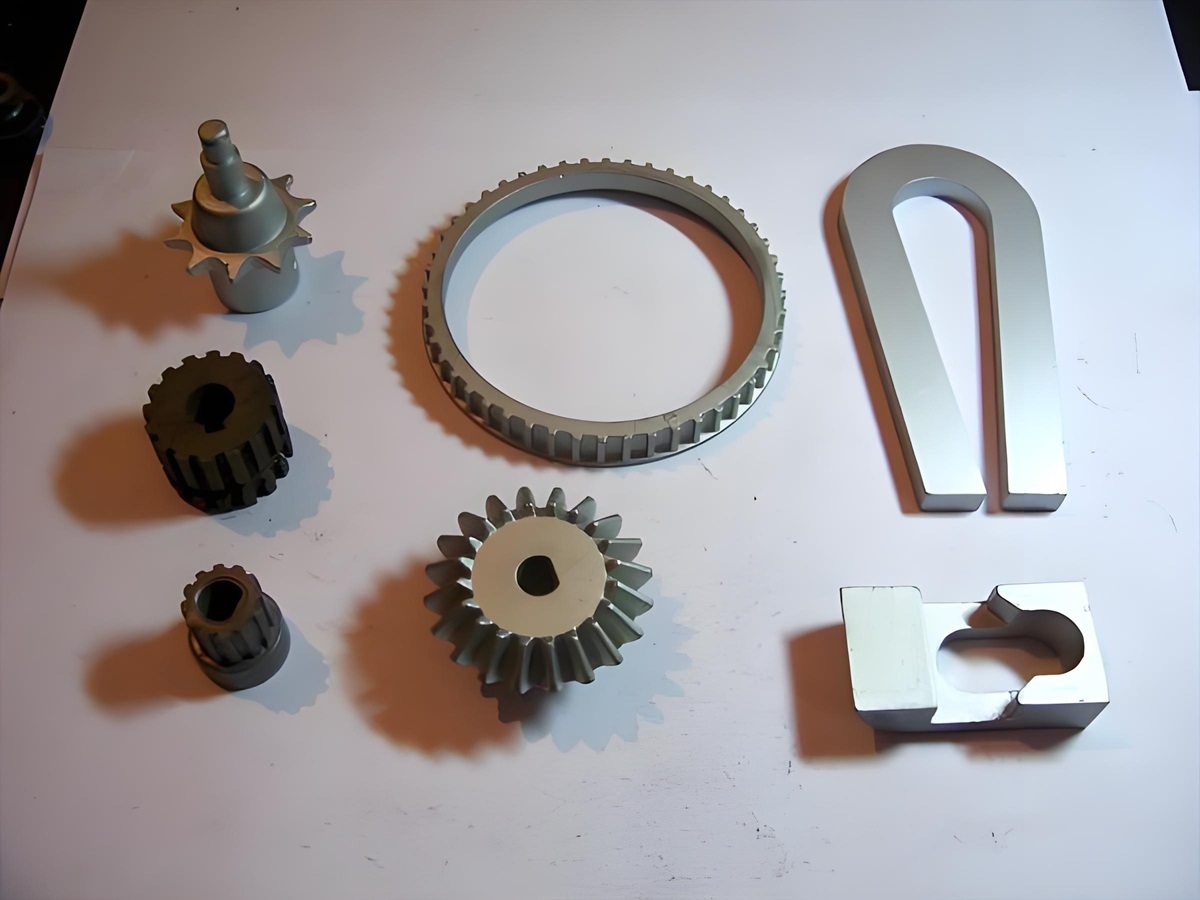

Powder Metallurgy Sintering Parts

Sintering Materials

Here is a table listing various materials that can be used in sintering processes, along with their applicable sintering methods and characteristics:

| Material Type | Example Materials | Applicable Sintering Processes | Characteristics and Applications |

|---|---|---|---|

| Metals | Iron, Copper, Titanium, Tungsten, Stainless Steel, Nickel-Based Alloys | Solid-State Sintering, Liquid Phase Sintering, Hot Pressing, Hot Isostatic Pressing, Spark Plasma Sintering (SPS) | Excellent mechanical properties and corrosion resistance, widely used in aerospace, automotive, and medical industries |

| Hard Metals | Tungsten Carbide (WC), Titanium Carbide (TiC) | Liquid Phase Sintering, Pressure-Assisted Sintering (Hot Pressing) | High hardness and wear resistance, used for cutting tools, wear-resistant parts, and molds |

| Ceramics | Alumina (Al₂O₃), Silicon Nitride (Si₃N₄), Zirconia (ZrO₂) | Solid-State Sintering, Liquid Phase Sintering, Hot Pressing, Microwave Sintering | High hardness and heat resistance, suitable for wear-resistant parts, high-temperature structural materials, and electronic ceramics |

| Cermets | TiC-Ni, TiCN-Ni, WC-Co | Liquid Phase Sintering, Pressure-Assisted Sintering, Spark Plasma Sintering (SPS) | Combines the toughness of metals with the hardness of ceramics, commonly used in cutting tools and wear-resistant parts |

| Composites | Metal Matrix Composites (MMC), Ceramic Matrix Composites (CMC) | Solid-State Sintering, Liquid Phase Sintering, Reactive Sintering, Hot Isostatic Pressing, Spark Plasma Sintering (SPS) | Multifunctional properties like high strength, lightweight, and heat resistance, used in aerospace and automotive sectors |

| Magnetic Materials | Neodymium Iron Boron (NdFeB), Samarium Cobalt (SmCo) | Solid-State Sintering, Liquid Phase Sintering | Used for high-performance magnets in electronics, automotive, and wind power generation |

| Polymer Matrix Composites | PTFE/Ceramic, PEEK/Carbon Fiber | Ultrasonic Sintering, Microwave Sintering | Excellent chemical stability and mechanical properties, used in aerospace, electronics, and medical devices |

| Glass and Glass Ceramics | Quartz Glass, Aluminosilicate Glass, Borosilicate Glass | Solid-State Sintering, Microwave Sintering, Hot Isostatic Pressing | Excellent thermal stability and low thermal expansion coefficient, suitable for optical components and high-temperature structural materials |

| Superhard Materials | Diamond, Cubic Boron Nitride (cBN) | Hot Pressing, Hot Isostatic Pressing | Extremely high hardness and wear resistance, used for superhard cutting tools and abrasives |

| Powder Metallurgy Polymers | Polyamide, Polyphenylene Sulfide (PPS) | Pressure-Assisted Sintering, Microwave Sintering | Excellent heat resistance and mechanical properties, suitable for high-performance industrial parts |

- Different materials are selected for specific sintering processes based on their characteristics to achieve optimal performance and application results.

- Metals and ceramics are the most commonly sintered materials, widely used across various industrial sectors.

- Sintering processes for composites and magnetic materials are continually evolving to meet specific application requirements.

Advantages of powder sintering technology

- powder metal sintering not limited by shape and structure, it can maximize the rational design and layout of the mold runner system, and the surface of the runner is smooth and smooth, so that the product quality of the injection molding is higher, the molding time is shorter, and the production waste is less.

- The mold housing and the runner system are formed in one, without seams, and are durable. Compared with traditional mold manufacturing technology, the use of SLS metal powder sintering molding technology to manufacture molds can be significantly reduced by more than 70%, in today’s era of time is money, for manufacturers or manufacturers, rapid manufacturing technology has brought them significant benefits.

- The variety of metal materials used for sintering molding, excellent performance, can meet the mold quality needs of different production fields, such as injection molds, die casting molds, tensile molds, no copper penetration process.

Sintered metal is made with JH-MIM.

JH MIM specializes in the process of metal sintering. In order to get the metal powder to solidify, this technique entails heating it slightly below the melting point. With more than 20 years of experience, JH MIM’s staff can sinter a variety of metals, including titanium, nickel, stainless steel, ceramic, and more. Additionally, we can use supplies that customers supply.

Sintering is a universal method that enables the production of parts in a variety of shapes and sizes. The method is excellent for mass manufacturing because it is also rather quick and effective. Sintering can also generate pieces with intricate internal features or complex geometries that are challenging to manufacture using other manufacturing processes.

If you want to know more about how metal sintering can make your parts work better. To explore your specific requirements and determine how we can assist you in advancing product development, contact our team now.