Casting vs molding presents a critical manufacturing decision for engineers during part production design. Foundries report casting rejection rates around 5 to 7 percent due to defects like gas bubbles and inclusions. Both processes create parts through cavity filling with material. They differ fundamentally in applications and materials.

Material selection drives the primary difference between casting and molding manufacturing processes. Casting involves metals or cold setting materials like epoxy, concrete, plaster, and clay. Molding focuses on plastics. Die casting specifically requires heating metals into molten form before remolding under high-pressure conditions. Financial implications affect the molding vs casting decision. Cast molding provides lower tooling costs compared to injection molding. Injection molding requires hard tooling for prototyping with higher costs and longer lead times.

Engineers require an understanding of these fundamental differences between casting and molding for informed decisions. Each manufacturing path presents unique challenges and advantages. Defect sensitivity, material options, production speed, and cost-effectiveness vary significantly. Analysis of both processes determines which approach suits specific engineering requirements and project parameters.

Understanding the Basics of Molding and Casting

Molding and casting represent fundamental manufacturing processes. Understanding their distinct characteristics helps engineers select the right approach for specific applications.

Definition of Molding: Creating the Negative Cavity

Molding creates a mold with a negative cavity—a hollow space that forms the inverse shape of the desired object. This negative cavity captures the external features of the intended part in reverse. The process begins with a positive model. Mold material forms around this model to create the inverse impression. Molding predominantly shapes plastics and polymers. The process applies force—raw materials are heated until malleable. They are pressed into a closed mold cavity under significant pressure. The material cools and stabilizes. The completed part can be ejected.

Definition of Casting: Filling the Mold to Form the Part

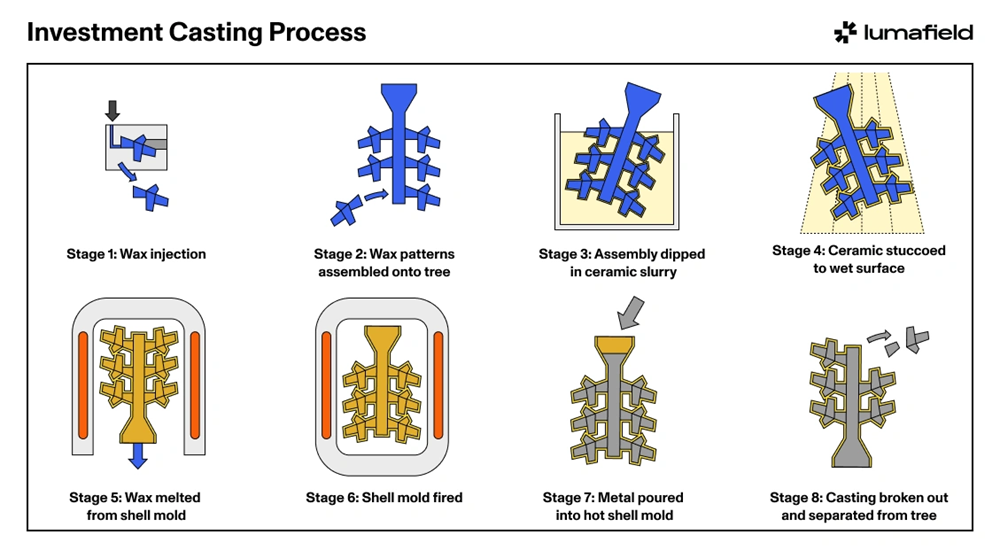

Casting involves pouring liquid material into a mold. The material solidifies. Dating back over 7,000 years, it stands among the oldest manufacturing methods. Materials—primarily metals but sometimes cold-setting substances like epoxy, concrete, or clay—are melted to liquid form. They are introduced into a mold cavity. The material cools and hardens. The solidified part, known as a casting, is ejected or broken out of the mold to complete the cycle. Gravity or pressure causes the material to flow and fill the mold rather than being forcefully injected.

Key Similarities and Differences in Concept

Both processes utilize a mold cavity to determine the shape of the final product. They differ significantly in several aspects:

- Material Selection: Casting primarily works with metals. Molding typically processes plastics and polymers.

- Material Introduction: Molding forces heated, softened material into a mold under pressure. Casting relies on flow as liquid material fills the cavity through gravity or applied pressure.

- Production Considerations: Molding excels at high-volume production with tight repeatability. Casting offers advantages for complex shapes and larger components.

- Application Focus: Parts requiring high tensile strength and thermal stability are suitable for casting. Components valued for light weight and electrical insulation properties favor molding.

Both techniques remain indispensable in modern manufacturing. Each offers unique benefits across industries from automotive to aerospace.

Process Mechanics and Material Behavior

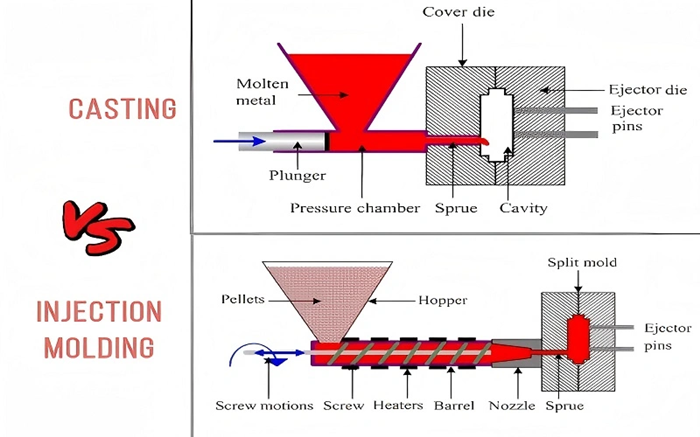

The mechanics distinguishing injection molding from die casting help engineers select optimal manufacturing processes for specific requirements.

Injection Molding vs Die Casting: Step-by-Step Breakdown

Injection molding and die casting follow similar operational sequences. Execution differs substantially. Injection molding begins with plastic pellets heated until molten in a barrel, typically at 200-300°C. High-pressure injection into the mold cavity follows. Die casting starts with metals heated to significantly higher temperatures, often 600-700°C+. Steel dies receive forced material under pressures between 15-100 MPa.

Both processes involve mold preparation through lubrication. Temperature regulation and part removal facilitation occur. Die casting requires this step more critically. A film forms between molten metal and mold.

Material Flow and Solidification: Thermoplastics vs Metals

Material behavior fundamentally impacts casting and molding processes. Thermoplastics contain long-chain polymer molecules held together by weak intermolecular forces that break when heated, allowing material flow. Metals solidify through crystallization as energy dissipates and temperature drops below melting point.

Plastic’s low thermal conductivity enables precise control over flow paths in mold cavities. Thin-walled, highly detailed parts become achievable in ways metals cannot match. Metals exhibit greater density after solidification. More pronounced shrinkage occurs, requiring compensation through careful riser design.

Cycle Time and Cooling: Seconds vs Hours

Cooling time dominates both manufacturing processes, comprising 60-80% of total cycle time. Plastic injection molding cycles typically complete in seconds to minutes. Metal casting may require minutes to hours, depending on part complexity and thickness.

Material properties create stark contrast in cycle times. Plastics must cool until rigid enough to maintain shape without deformation. Even thick sections solidify relatively quickly. Metal casting requires extended cooling periods due to higher processing temperatures and thermal mass.

Shrinkage and Warpage: How Each Process Handles It

Shrinkage occurs in both casting and molding manufacturing processes as materials transition from liquid to solid states. Semi-crystalline plastics like HDPE exhibit 1.5-4.0% shrinkage. Amorphous polymers like ABS show only 0.4-0.7%. Metal casting shrinkage manifests in three distinct phases: liquid shrinkage, liquid-solid shrinkage, and solid shrinkage.

Warpage in injection molding results from uneven cooling, excessive holding pressure, or material thickness variations. Casting deformation stems from uneven cooling rates, improper mold design, and hindered normal shrinkage. Both processes employ strategic techniques to minimize these effects. Directional solidification, balanced cooling channels, and precise pressure control provide solutions.

Tooling, Tolerances, and Surface Finish

Tooling investment represents a critical decision point in casting and molding manufacturing processes. Project economics and production quality depend significantly on tooling selection.

Tooling Cost: High-Precision Molds vs Sand Patterns

Financial investment varies dramatically across manufacturing methods. Sand casting molds provide the lowest entry point at USD 6,000-20,000. These molds are single-use. Permanent molds require USD 10,000-90,000. They produce approximately 60,000 parts before replacement. Die casting demands the highest investment—USD 60,000-500,000. These molds last through 100,000+ production cycles.

Tolerances: ±0.005 in Molding vs ±0.01 in Casting

Precision capabilities differ substantially between processes. Sand castings achieve CT9-CT11 tolerances (±0.010″ to ±0.030″). Die castings deliver CT6-CT7 tolerances (±0.002″ to ±0.005″). Metal injection molding (MIM) delivers tighter tolerances than die casting. MIM offers excellent repeatability for complex geometries.

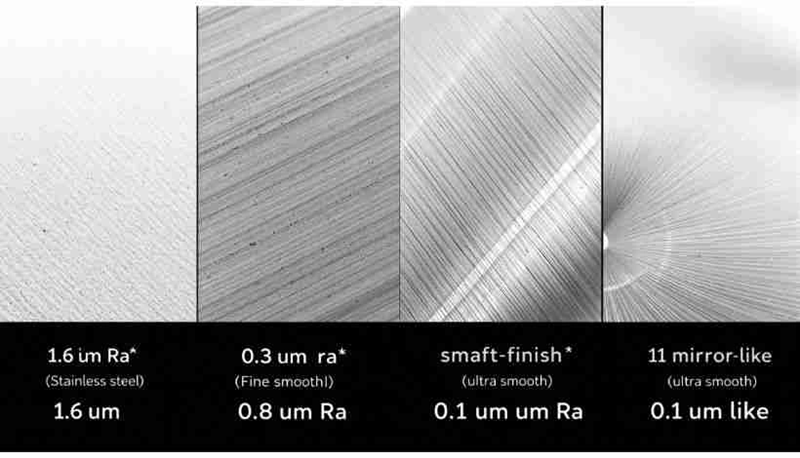

Surface Finish: Glossy Plastic vs Textured Metal

Surface quality varies across manufacturing methods. Die-cast components exhibit smoother surfaces directly from the mold. MIM may require additional post-processing. It excels in micro-detailing capabilities. Sand castings emerge with rougher surfaces. Additional finishing operations are required.

Common Defects: Sink Marks vs Porosity

Each process presents unique quality challenges. Injection molding produces sink marks—shallow depressions occurring in thicker sections. Plastic contracts unevenly during cooling. Casting struggles with porosity—gas bubbles trapped in solidified metal. These compromise structural integrity. Rounded air pockets result from metal turbulence or hydrogen gas reactions.

Post-Processing Needs: Trimming, Machining, Coating

Manufactured components require finishing operations. Injection-molded parts need gate trimming. This removes excess material at injection points. Cast components demand more extensive post-processing: fettling, grinding, and machining. These achieve final dimensional specifications. Modern CNC trimming has improved manufacturing efficiency through automation. Cycle times reduce while maintaining consistency.

Choosing the Right Process for Your Project

Manufacturing process selection requires evaluation of specific project requirements and constraints. The right choice depends on multiple key factors.

Volume Considerations: Prototyping vs Mass Production

Production volume determines manufacturing process economics. Low volumes (1-10,000 units) favor CNC machining. Injection molding becomes cost-effective at 500+ parts as tooling costs distribute across more units. Die casting shows optimal economics near 1,000 units. Cost advantages increase substantially at 10,000+ units. Prototyping or quantities under 100 benefit from 3D printing with fastest turnaround and lowest per-part price.

Material Selection: Plastics, Metals, and Hybrids

Material compatibility shapes process decisions. Die casting works with non-ferrous metals like aluminum, zinc, and magnesium. These materials deliver superior mechanical strength and heat resistance. Injection molding excels with thermoplastics. Components offer lighter weight with good electrical insulation properties. Material flowability affects manufacturing success. Thin-wall applications require high melt flow rates.

Design Complexity: Thin Walls vs Internal Cavities

Design features determine process selection. Die casting accommodates complex geometries including cast-in bosses, ribs, and threads within single parts. Injection molding handles wall thicknesses between 0.060-0.120 inches (1.5-3.0mm) optimally. Casting excels for parts with intricate internal geometry or large monolithic shapes.

Cost and Lead Time: Tooling Investment vs Flexibility

Upfront costs versus long-term economics require analysis. Die casting molds cost 2-3x more than injection molds but last significantly longer. Prototype tooling ranges from $6,000-$15,000 depending on complexity. Injection molding offers shorter production lead times compared to casting. Prototype molds deliver parts within 2-4 weeks versus 6-8 weeks for production molds.

Decision Matrix: When to Use Molding or Casting

Material requirements determine initial selection. Structural metals suit casting while plastics favor molding. Volume evaluation follows. Tens to hundreds of parts often favor sand casting, while thousands to millions benefit from injection molding. Geometry complexity, tolerance requirements, and budget constraints require assessment. Balancing these factors leads to optimal manufacturing decisions.

Comparison Table

| Characteristic | Casting | Molding |

|---|---|---|

| Primary Materials | Metals, epoxy, concrete, plaster, clay | Plastics and polymers |

| Material Introduction | Flow through gravity or applied pressure | Heated, softened material forced under pressure |

| Processing Temperature | 600-700°C+ (metals) | 200-300°C (plastics) |

| Cycle Time | Minutes to hours | Seconds to minutes |

| Typical Tolerances | ±0.010″ to ±0.030″ (sand casting) | ±0.002″ to ±0.005″ |

| Tooling Costs | $6,000-$500,000 (varies by type) | Higher initial tooling costs than cast molding |

| Tool Lifespan | Up to 100,000+ cycles (die casting) | Not specified |

| Common Defects | Porosity, gas bubbles | Sink marks, uneven cooling |

| Shrinkage | Three phases: liquid, liquid-solid, solid | 0.4-0.7% (amorphous polymers), 1.5-4.0% (semi-crystalline) |

| Optimal Production Volume | Cost-effective at 1,000+ units | Cost-effective at 500+ units |

| Surface Finish | Rougher, requires finishing | Smoother surface directly from mold |

| Best Applications | Complex shapes, larger components, high strength requirements | High-volume production, tight repeatability |

| Post-Processing Requirements | Extensive – fettling, grinding, machining | Minimal – gate trimming |

Conclusion

Casting and molding manufacturing processes serve as fundamental production methods in modern manufacturing. Each process offers distinct characteristics for specific engineering applications. Material selection, operational mechanics, and production capabilities differ between these manufacturing approaches.

Material requirements determine process selection. Metals and cold-setting materials require casting processes. Plastics and polymers demand molding approaches. Production volume affects cost-efficiency. Casting proves economical for lower quantities. Molding demonstrates superior economics at higher volumes, particularly beyond 500 units.

Design complexity influences manufacturing decisions. Casting handles complex internal geometries and larger monolithic shapes. Molding delivers tighter tolerances and smoother surface finishes directly from production. Cycle time differences affect production planning. Molding completes in seconds to minutes. Casting requires minutes to hours per cycle.

Tooling investment varies significantly across manufacturing methods. Sand casting molds start at $6,000. Complex die casting tools reach $500,000. Upfront costs require balancing against production volume, tool lifespan, and part complexity.

Engineers require systematic evaluation of material requirements, production volume, geometric complexity, tolerance needs, and budget constraints. This analysis determines the most economical manufacturing approach for specific project parameters.

Companies with extensive manufacturing experience provide guidance through these complex decisions. Their expertise demonstrates how proper process selection affects product quality and performance directly.

Engineers with knowledge of both casting and molding processes make informed manufacturing decisions. This understanding balances technical requirements against economic constraints. Products meet specifications while maintaining competitive pricing and delivery schedules in demanding market conditions.

Key Takeaways

Understanding the fundamental differences between casting and molding helps engineers make informed manufacturing decisions that balance technical requirements with economic constraints.

• Material drives process selection: Casting works with metals and cold-setting materials, while molding primarily handles plastics and polymers with different temperature and pressure requirements.

• Volume economics favor different approaches: Molding becomes cost-effective at 500+ units for high-volume production, while casting proves economical for lower quantities and complex geometries.

• Precision capabilities vary significantly: Molding achieves tighter tolerances (±0.002″ to ±0.005″) compared to casting (±0.010″ to ±0.030″), affecting quality requirements.

• Cycle times impact production planning: Molding completes in seconds to minutes versus casting’s minutes to hours, directly affecting manufacturing throughput and delivery schedules.

• Tooling investment ranges dramatically: Initial costs span from $6,000 for sand casting molds to $500,000 for complex die casting tools, requiring careful ROI analysis.

The decision matrix approach—evaluating material requirements, production volume, geometric complexity, tolerance needs, and budget constraints—provides engineers with a systematic framework for selecting the optimal manufacturing process for their specific project parameters.