Type 304l stainless steel and Type 304 stand out as crucial grades in the stainless steel family. Type 304 leads as the most accessible austenitic stainless steel. People know it as “18/8” because it contains 18% chromium and 8% nickel. Both grades share several traits, but their carbon content makes each suitable for different uses.

Carbon limits create the main distinction between 304 and 304L stainless steel. Type 304 has a maximum carbon content of 0.08%, while 304L tops out at 0.03%. This difference substantially impacts their performance, particularly in welding. Type 304 stainless steel resists atmospheric environments and many corrosive substances effectively. However, its higher carbon content makes it nowhere near as suitable for welded corrosive applications. The ultimate tensile strength differs between these grades, too. Type 304 delivers 90 ksi (620 MPa), while 304L provides 85 ksi (586 MPa).

This piece will get into both grades’ chemical makeup, mechanical properties, weldability, and best uses. The information will help you pick the right stainless steel that matches your project’s needs.

Chemical Composition: Carbon Content as the Key Differentiator

The chemical makeup of stainless steel shapes how it performs. A comparison of 304 and 304L grades shows why they work differently in many applications.

304 vs 304L Carbon Limits: 0.08% vs 0.03%

The main difference between these similar alloys lies in their carbon content. Type 304 stainless steel has a maximum carbon content of 0.08%, while 304L has a much lower maximum of 0.03%. This small 0.05% difference creates distinct performance variations between the grades. The “L” in 304L stands for “low carbon”, which shows its key characteristic.

The carbon content difference matters most during manufacturing, especially with high-temperature processes. 304L’s lower carbon level makes it valuable for welding applications because its makeup reduces risks that could compromise the material’s strength.

Nickel and Chromium Ranges in Both Grades

Both 304 and 304L have similar levels of other key alloying elements despite their carbon differences. The chromium content ranges from 18% to 20% in both grades. This element creates a passive oxide layer on the surface to protect the metal underneath.

Nickel levels stay consistent, too, ranging from 8% to 10.5% in standard 304 and 8% to 12% in 304L. Nickel boosts the steel’s toughness and ductility while maintaining the austenitic structure. Other elements like manganese (≤2.00%), silicon (≤0.75%), phosphorus (≤0.045%), and sulfur (≤0.030%) appear in similar amounts in both grades.

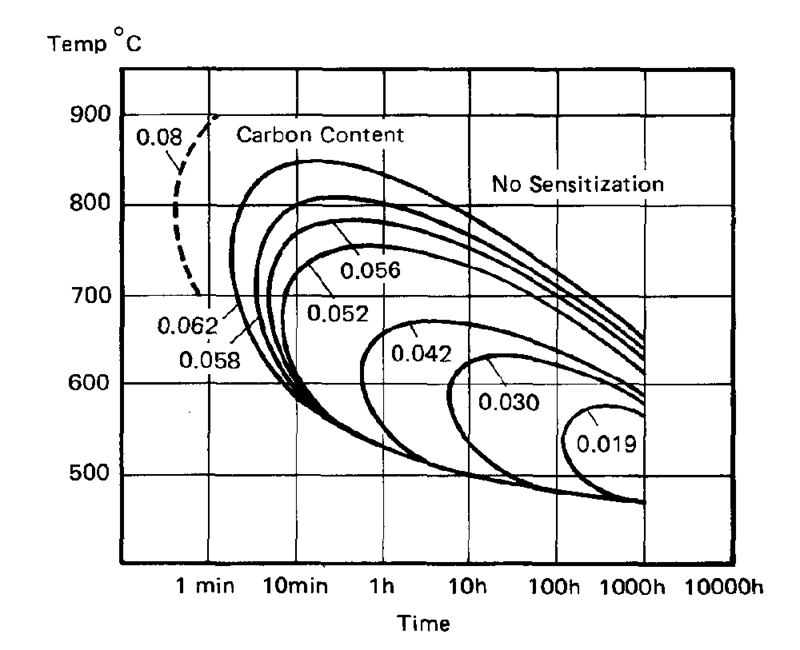

Impact of Low Carbon on Carbide Precipitation

304L’s lower carbon content serves a vital metallurgical purpose. Carbon in stainless steel can combine with chromium to form chromium carbides when exposed to temperatures between 480°C and 820°C (900-1,500°F). This process, called “sensitization,” happens mostly along grain boundaries.

The carbide formation then depletes chromium from the surrounding areas. This reduces the steel’s ability to form its protective oxide layer. The steel becomes vulnerable to intergranular corrosion without enough chromium – a dangerous form of degradation that attacks grain boundaries.

304L prevents this problem by having too little carbon for substantial carbide formation. This makes 304L ideal for welded components in corrosive environments because it can be used “as-welded” without extra heat treatment.

Mechanical Properties: Strength and Ductility Comparison

304 and 304L stainless steel grades show clear differences in their mechanical performance beyond their chemical makeup. These differences affect how suitable they are in different applications.

Ultimate Tensile Strength: 90 ksi vs 85 ksi

Ultimate tensile strength (UTS) shows how much stress a material can withstand before it breaks. Standard 304 stainless steel has a UTS of 90 ksi (620 MPa), which beats 304L’s 85 ksi (586 MPa) by about 6%. This means standard 304 resists breaking under tension better. Processing conditions can change these ranges slightly. Standard 304’s range sits between 80-95 ksi (550-655 MPa), and 304L falls between 70-90 ksi (480-620 MPa).

Yield Strength: 42 ksi vs 35 ksi

Yield strength tells us when a material starts to permanently deform. The numbers show a bigger gap here. Standard 304 stainless steel’s 0.2% yield strength reaches 42 ksi (289 MPa), which is 20% higher than 304L’s 35 ksi (241 MPa). This makes standard 304 much better at resisting permanent deformation under stress. Two wire baskets made the same way from these materials would prove this point – the 304 basket would stay rigid and resist bending better.

Elastic Modulus and Density Similarities

Both grades share the same physical traits despite their strength differences. The shared characteristics include:

- Density: 8.0 g/cm³

- Modulus of Elasticity: 193 GPa

- Melting Point: 1400-1450°C

- Thermal Conductivity: 16.2 W/m·K at 100°C

Components made from either grade will weigh the same and show similar elastic behavior because of these shared properties. Metal injection molding applications need special consideration of the strength difference. Engineers must weigh 304L’s better weldability against its lower strength when designing complex molded parts that need welding.

Standard 304 performs better in high-stress applications where structural integrity matters most. 304L makes more sense for welded components in corrosive environments. Its slight drop in strength is worth the trade-off for better corrosion resistance, making it the best choice for welded tanks, pipes, and chemical processing equipment.

Weldability and Corrosion Resistance in Harsh Environments

Welding capabilities play a key role in material selection for critical applications. The way 304 and 304L grades respond to welding determines where you can use them.

Intergranular Corrosion in Welded 304

Standard 304 stainless steel becomes vulnerable to sensitization during welding. This damaging process occurs at temperatures between 450-900°C. The process causes chromium carbide (Cr23C6) to form at grain boundaries. This creates zones near these boundaries that lack chromium. These areas don’t have enough chromium to resist corrosion, which leads to intergranular corrosion. The grain boundaries act like anodes compared to the grain interior. This creates electrochemical cells that speed up corrosion. We call this “weld decay” – it mostly affects the heat-affected zone (HAZ) where the metal cools more slowly through sensitization temperatures.

304L in As-Welded State Without Annealing

304L stainless steel works great in the “as-welded” state without needing annealing, even in harsh corrosive environments. Its lower carbon content (0.03% maximum) stops carbide formation during welding. 304L proves especially valuable when welding sections thicker than 5mm. This grade helps reduce manufacturing steps in metal injection molded parts that need welding, as it doesn’t need post-weld heat treatments. You still need to watch out for weld “hot cracking”, but the risk of sensitization is much lower.

Use of 304L in Chloride-Rich or Acidic Conditions

Both grades resist many environments well, but they have their limits. Neither grade holds up in seawater because of chloride-induced pitting and crevice corrosion. Type 304 works fine in water with chloride levels under 200 ppm. 304L shows better resistance to intergranular corrosion in acidic environments. Research shows that 316 stainless steel with molybdenum performs better than 304L in acidic chloride solutions. 304L’s corrosion resistance drops as chloride levels go up. For applications exposed to chlorides, especially those with welded parts, 304L offers much better protection against stress corrosion cracking.

Application Suitability and Metal Injection Molding Use Cases

Picking the right stainless steel grade means you just need to understand what your application requires. Each grade brings its own advantages to different manufacturing situations.

304 in Wire Baskets and High-Strength Components

Standard 304 stainless steel shines in applications that just need excellent mechanical strength. Its higher tensile strength (90 ksi) and yield strength (42 ksi) compared to 304L make it perfect for rigid structural components. Many manufacturers use grade 304 for wire baskets because it combines strength, corrosion resistance, and formability to create lasting products. You’ll find 304 in automotive parts, medical implants, and food processing equipment, where minimal welding takes place. The material’s excellent drawability lets you create stamped and deep-drawn components without annealing.

304L in Welded Tanks and Piping Systems

304L really stands out when you have lots of welding to do. The lower carbon content lets you use it in the “as-welded” state without post-weld annealing, even in corrosive environments. This makes 304L the go-to choice for welded tanks, piping systems, and storage containers where weld integrity is vital. The proof is in the numbers – all but one of these installations have worked perfectly in over 100 potable water treatment plants across North America.

304L in Metal Injection Molding for Complex Welded Parts

Metal Injection Molding (MIM) combines metal powder with polymer materials to create precision structural parts through forming and sintering. 304L gives you distinct advantages in MIM applications with welded components. The lower carbon content helps minimize sensitization during welding, so MIM 304L parts stay strong even after welding. This becomes especially valuable when you’re working with complex geometries that need welded connections.

Choosing Between 304 and 304L Based on Fabrication Needs

Your specific application requirements will determine which grade works best. 304 typically performs better in non-welded, high-strength applications. 304L becomes the smart choice when welding is a big part of fabrication—especially if post-weld heat treatment isn’t practical. The material’s resistance to intergranular corrosion makes it a better option for components in corrosive environments after welding, even though it’s not quite as strong.

Conclusion

The choice between 304 and 304L stainless steel depends on your project’s specific needs. These steel grades have a small but important difference in carbon content – 0.08% maximum for 304 and 0.03% maximum for 304L. This difference affects their performance in applications of all types.

Standard 304 stainless steel has better mechanical properties. It shows about 6% higher ultimate tensile strength (90 ksi vs. 85 ksi) and 20% greater yield strength (42 ksi vs. 35 ksi) than 304L. These strength advantages make 304 a great choice for high-stress structural components, wire baskets, and parts that don’t need much welding.

304L might have slightly lower strength, but it resists intergranular corrosion really well during welding. You won’t need post-weld heat treatments with this low-carbon variant. It works fine in the “as-welded” state, even in corrosive environments. That’s why it’s a great option for welded tanks, piping systems, and chemical processing equipment.

Metal injection molding experts should carefully evaluate these characteristics. Projects with complex welded shapes work better with 304L because of its excellent weldability and corrosion resistance at weld zones. Standard 304 might be the better choice for applications that just need maximum structural strength without welding.

Both grades share similar physical properties. Their density, modulus of elasticity, and thermal conductivity are the same. This means consistent weight and elastic behavior, whatever grade you pick. Neither grade works well in chloride-rich environments like seawater. However, 304L gives better protection against stress corrosion cracking when you can’t avoid chloride exposure.

Your fabrication needs and service conditions will determine the final choice. 304L works best for projects with lots of welding, especially when you can’t do post-weld annealing. Standard 304 shines in applications that need maximum strength without much welding. Learning about these differences helps engineers and designers pick the right grade for their stainless steel applications. This ensures the best performance and durability.

Key Takeaways

Understanding the differences between 304 and 304L stainless steel helps you select the right grade for optimal performance and cost-effectiveness in your specific application.

• Carbon content drives performance differences: 304 contains 0.08% max carbon vs 304L’s 0.03% max, making 304L superior for welding applications without post-weld heat treatment

• 304 offers higher strength: Standard 304 provides 90 ksi tensile strength and 42 ksi yield strength compared to 304L’s 85 ksi and 35 ksi, respectively

• 304L excels in welded applications: Low carbon content prevents intergranular corrosion in welded components, allowing use in the as-welded state even in corrosive environments

• Choose based on fabrication needs: Select 304 for high-strength non-welded components; choose 304L for welded tanks, piping, and complex MIM parts requiring weld integrity

• Both share identical physical properties: Same density (8.0 g/cm³), elastic modulus (193 GPa), and thermal characteristics ensure consistent behavior in design calculations

The key decision factor is whether your project involves significant welding. For welding-intensive applications, especially in corrosive environments, 304L’s resistance to sensitization outweighs its slightly lower strength. For structural components requiring maximum strength without welding, standard 304 typically provides better value.

FAQs

Q1. What are the main differences between 304 and 304L stainless steel? The key difference is carbon content: 304 has a maximum of 0.08% carbon, while 304L has a maximum of 0.03%. This affects their strength and weldability, with 304 offering higher strength and 304L providing better corrosion resistance in welded applications.

Q2. In which applications is 304L stainless steel preferred over 304? 304L is preferred in welding-intensive applications, especially for heavy-gauge components that require strong weld joints. It’s commonly used in welded tanks, piping systems, and chemical processing equipment where post-weld heat treatment is impractical.

Q3. Can 304L stainless steel corrode or rust? While 304L has excellent corrosion resistance, it can still corrode under certain conditions. It performs well in many environments but may be susceptible to corrosion in highly chlorinated or acidic conditions. However, it generally won’t rust under normal atmospheric conditions.

Q4. How does the strength of 304 compare to that of 304L stainless steel? 304 stainless steel offers higher strength properties compared to 304L. It has a higher ultimate tensile strength (90 ksi vs 85 ksi) and yield strength (42 ksi vs 35 ksi), making it more suitable for applications requiring greater structural integrity.

Q5. What is meant by 304/304L dual certification? 304/304L dual certification refers to stainless steel that meets the minimum property requirements of both 304 and 304L grades. This typically means it has the lower carbon content of 304L while maintaining the minimum strength properties of 304, offering versatility in various applications.