316L stainless steel ranks as the second most popular austenitic stainless steel after 304/A2, and people commonly know it as marine grade or A4 stainless steel. The steel’s exceptional resistance to corrosion makes it valuable, especially in harsh environments with chlorides that damage other metals. This high-performance alloy protects better against pitting and general corrosion when exposed to reducing acids, thanks to its unique makeup.

The steel consists of iron mixed with chromium (16–18%), nickel (10–12%), and molybdenum (2–3%). 316L’s carbon content maxes out at 0.03% compared to 316’s 0.08%, which makes it easier to form during manufacturing. These properties make 316L the better choice when you need corrosion resistance or work with high temperatures.

316L proves its worth among the 150+ grades of stainless steel available today. The steel stays non-magnetic, keeps its high density (60% and above), and maintains its shine longer. You’ll find 316L in watches, marine equipment, medical devices that go inside the body, and jewelry. Its high tensile strength and oxidation resistance make it last exceptionally long.

This piece covers everything about 316L stainless steel. You’ll learn about its chemical makeup, mechanical properties, and how industries use it. We also explore specialized manufacturing methods like metal injection molding.

Chemical Composition and Alloying Elements in 316L

Type 316L stainless steel has a unique chemical makeup that delivers outstanding corrosion resistance and mechanical properties. The right mix of alloying elements makes it popular in industries of all types.

Chromium (16–18%) and Nickel (10–14%) Content

Chromium serves as the cornerstone of 316L’s corrosion resistance. When present at 16–18% concentration, it creates a passive oxide layer on the surface to protect the metal underneath. This composition puts 316L in the “18/10” stainless steel family, which refers to its chromium and nickel percentages.

Nickel, at 10–14%, works with chromium to keep the austenitic microstructure stable at room and low temperatures. It also makes the material more ductile, which helps in manufacturing and shaping. While 8-9% nickel would be enough for an austenitic structure, 316L needs higher levels because of its molybdenum content.

Molybdenum (2–3%) for Chloride Resistance

316L stands out from other austenitic stainless steels because it contains 2–3% molybdenum. This element is a big deal as it means that the steel resists pitting and crevice corrosion, especially when exposed to chlorides. The steel also performs better against reducing acids like sulfuric and phosphoric acid.

Marine applications benefit from molybdenum’s ability to handle waters with up to 2000 ppm chloride. The protective layer becomes more stable with molybdenum, which leads to more durable components.

Low Carbon Content: 0.03% Max in 316L

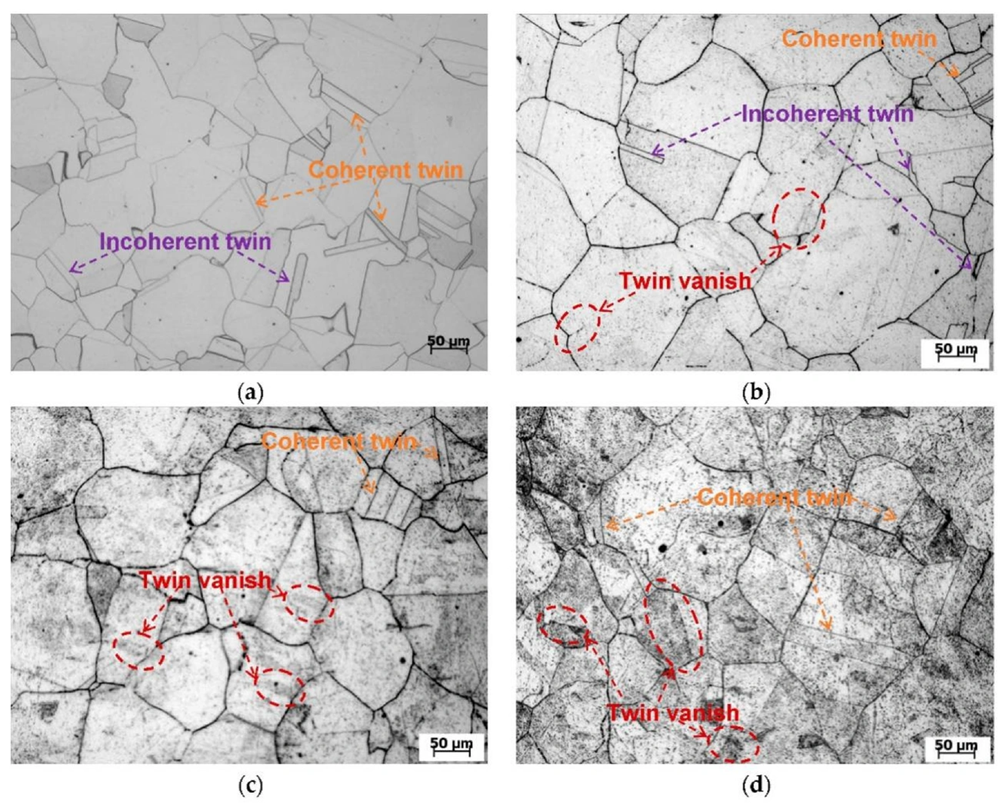

316L gets its “L” designation from “low carbon,” with carbon maxing out at 0.03%. Regular 316 stainless steel can have up to 0.08% carbon. Less carbon prevents sensitization—corrosion at grain boundaries—and stops chromium carbide from forming during welding.

This makes 316L perfect for welded applications, as it keeps its corrosion resistance after welding, particularly in components thicker than 6mm.

Trace Elements: Manganese, Silicon, Phosphorus, Sulfur

316L’s properties are influenced by several trace elements:

- Manganese: Maximum 2.00%

- Silicon: Maximum 1.00%

- Phosphorus: Maximum 0.045%

- Sulfur: Maximum 0.03%

Each element plays a specific role. Silicon and manganese help remove oxygen during melting. Sulfur levels need careful control since too much can hurt corrosion resistance unless you’re using TIG welding.

Some manufacturers add trace elements like titanium to remove oxygen, which can boost corrosion resistance.

Mechanical and Corrosion Properties of 316L

316L stainless steel’s mechanical and corrosion properties come directly from its unique chemical makeup. This makes the alloy perfect for applications that standard steels can’t handle.

Tensile Strength and Yield Behavior in Cold-Worked 316L

Cold-working substantially boosts 316L’s mechanical properties. The annealed condition gives 316L a minimum tensile strength of 485 MPa and yield strength of 170 MPa with 40% elongation. These values rise dramatically with cold-working. Fully cold-finished 316L reaches 700 MPa ultimate tensile strength and 430 MPa yield strength. Manufacturers can adjust their strength through controlled deformation. A 50% cold reduction can raise tensile strength above 1110 MPa.

Intergranular Corrosion Resistance in Welded Joints

316L’s low carbon content (≤0.03%) gives it excellent resistance to intergranular corrosion after welding. Standard stainless steels form chromium carbides at grain boundaries during welding. However, 316L keeps its protective chromium content throughout the microstructure. This prevents sensitization and weld decay, which ensures welded components stay strong without post-weld heat treatment.

Non-Magnetic Behavior in Austenitic Structure

Annealed 316L shows non-magnetic properties with relative magnetic permeability values around 1.003 to 1.005. The austenitic crystal structure creates this paramagnetic behavior. Cold-working might cause slight magnetism through martensite formation. Yet 316L stays more resistant to this change than other austenitic grades, making it perfect for non-magnetic applications.

Heat Resistance up to 2000°F

316L shows excellent oxidation resistance in intermittent service up to 870°C (1600°F) and continuous service to 925°C (1700°F). The material keeps its mechanical stability at high temperatures. Pressure vessel applications can use it at temperatures reaching 700°C in special cases.

Comparison: 316L vs 316 in Stress Corrosion Cracking

Both grades are a great way to get corrosion resistance. 316 has slightly better stress corrosion cracking resistance. 316L works better in welded applications. Both grades can develop stress corrosion cracking above roughly 60°C in chloride-rich environments. Notwithstanding that, their corrosion performance is nowhere near other stainless steel types.

Industrial Applications of 316L Stainless Steel

316L stainless steel’s unmatched corrosion resistance makes it the best choice in industries of all types where regular metals deteriorate faster. Engineers and designers should learn about what 316L stainless steel can do because it works well in challenging environments.

Marine Equipment and Desalination Plants

316L stainless steel stands out as the best choice for marine environments that need protection from saltwater corrosion. We used it in shipbuilding for hull cladding, ladders, railings, and fasteners that face constant seawater exposure. This grade helps extend maintenance cycles and reduces replacement costs. Offshore platforms depend on 316L for structural supports and components because it handles constant environmental exposure. Desalination facilities also benefit from 316L’s superior chloride resistance and can process waters with up to 2000 ppm chloride content.

Pharmaceutical and Food Processing Equipment

The pharmaceutical industry just needs materials that won’t react with active ingredients or excipients. 316L has become the standard grade for equipment that touches pharmaceutical products directly. It has a non-porous surface that fights off grime, mildew, and bacteria naturally. The material also resists cleaning and disinfection processes exceptionally well. 316L stainless steel works great in process industries with excess sulfur, like paper and pulp factories. Its 2% molybdenum content gives vital protection against corrosive chemicals used in pharmaceutical manufacturing.

Medical Devices and Surgical Implants

316L ranks among the most popular biomaterials for implants and medical devices. The material’s biocompatibility, corrosion resistance, and mechanical properties make it perfect for orthopedic surgery, circulatory system, and dental work. These implants cost only one-tenth to one-fifth of titanium and cobalt-based alloys. 316L shows up often in surgical instruments, dental devices, and various implants that must resist physiological fluids.

Architectural Use in Coastal Environments

Near seashores, 316L provides the minimum standard for corrosion resistance. Mirror-polished grade 316 has proven best for long life and looks great in coastal environments, even after years of use. The original cost runs 20-30% higher than 304, but its longer service life makes up for this through less maintenance, reduced downtime, and better sustainability. Buildings on the coast see more corrosion with less rainfall because chlorides build up more easily.

Potable Water and Wastewater Treatment Systems

304L and 316L welded stainless steel pipes work well in over 100 potable water treatment plants across North America. More than 1600 municipal wastewater treatment plants have used stainless steel components since the 1960s. 316L works best in clean, flowing water at rates above 1.5 to 2 ft/s. The material handles chlorine well, and crevice corrosion rarely occurs below 1000 mg/l of chlorides. Strong corrosion resistance and minimal maintenance needs make 316L the most cost-effective choice for long-term water infrastructure projects, even with higher upfront costs.

Powder Metallurgy and MIM Use of 316L

·

·

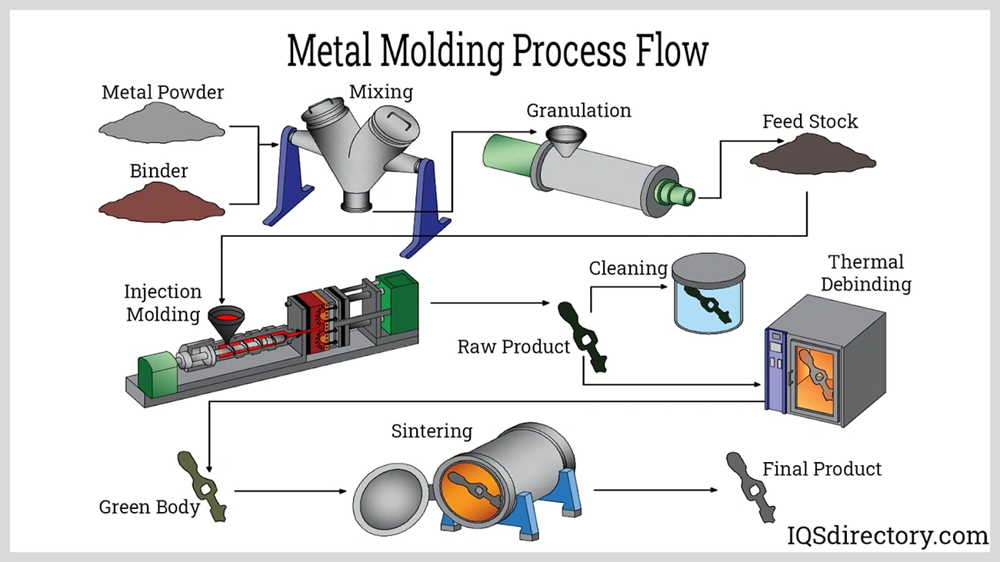

Metal Injection Molding (MIM) is a sophisticated manufacturing process. It combines 316L stainless steel powder with binder material. The mixture gets injection molded and sintered into high-density components.

316L Powder Characteristics for Metal Injection Molding

Gas-atomized 316L powders used in MIM have a spherical shape that creates high packing density and excellent flow characteristics. These features help manufacturers create feedstocks with high powder loading. This reduces binder costs and minimizes part shrinkage during processing. The particle size distribution plays a crucial role in packing density and how well the material flows. The best MIM results come from 316L powders ranging from 5-50 μm. The oxygen content of these powders affects carbon control and how consistently they sinter. Gas-atomized powders contain 100-500 ppm oxygen, while water-atomized powders have 2000-5000 ppm.

Sintering Behavior and Shrinkage Control

MIM 316L components shrink by 15-20% during sintering. This happens as the binder disappears and metal particles fuse. The sweet spot for sintering 316L is around 1350°C, which achieves 97.6% of theoretical density (7.81 g/cm³ compared to 8.0 g/cm³). Vacuum sintering environments work better than nitrogen atmospheres because they remove internal gas pressure in pores. The heating rate (usually 5-10°C/minute) and precise temperature control (±10°C) are crucial factors that determine the final density.

Surface Finish and Density in MIM Parts

MIM creates impressive surface finishes with 0.8μm Ra typically, and can even achieve 0.3–0.5μm Ra. The powder’s properties, sintering conditions, and finishing operations like bead blasting or tumbling all affect this surface quality. Tooling finish can leave its mark on the final components, especially with EDM pits. MIM 316L’s relative density reaches 94-98% of theoretical density, and some research shows it can go up to 99.2%.

Corrosion Resistance of MIM 316L vs Wrought 316L

Research shows MIM materials don’t resist corrosion as well as wrought 316L stainless steels. Yet properly processed MIM 316L can come close to wrought material’s performance. The level of porosity plays a big role in corrosion resistance – denser parts perform better. MIM 316L handles chloride environments better than regular powder metallurgy parts but still can’t match wrought 316L. Nickel release from MIM stainless steel watch parts can reach 2-24 mg/cm²/week, which is a big deal as it means that it exceeds the European Directive limit of 0.5 μg/cm²/week.

Applications: Watch Components, Dental Tools, Micro Parts

Watch manufacturers use MIM 316L to make cases and bracelet links that were traditionally machined. The material’s biocompatibility makes it perfect for dental tools and medical instruments. Manufacturers can create small, complex surgical devices affordably. MIM 316L works especially well with micro-sized components that need tight tolerances, offering 539 MPa tensile strength with 92% elongation. The combination of corrosion resistance, strength, and superb surface finish makes MIM 316L perfect for consumer products that need both performance and good looks.

Conclusion

316L stainless steel is a remarkable engineering material that shows unique versatility in industries of all types. The precise chemical composition gives 316L superior corrosion resistance compared to standard stainless steels. Adding molybdenum and reducing carbon content helps this alloy withstand harsh environments with chlorides that damage other metals. These properties make it a great choice for marine applications, pharmaceutical equipment, and medical implants.

The mechanical properties showcase 316L’s versatility even further. Cold-working boosts its strength substantially, while the austenitic structure keeps non-magnetic characteristics needed for specialized applications. The alloy’s heat resistance up to 2000°F lets it work in high-temperature environments without losing structural integrity.

316L finds its way into everything from marine equipment and desalination plants to pharmaceutical processing systems and surgical implants. The alloy costs 20-30% more than grade 304 stainless steel initially. However, its extended service life offers better economic value through lower maintenance needs and longer-lasting components.

Metal Injection Molding (MIM) has become the quickest way to manufacture complex 316L components. This process creates parts with high density, excellent surface finish, and impressive mechanical properties. Properly processed MIM 316L performs similarly to wrought 316L in many applications, though some limitations exist. The process works especially well for watches, dental tools, and micro-sized components.

Companies like JH MIM showcase how specialized manufacturing expertise has grown vital for this valuable alloy over the last several years. Their extensive facilities and skilled workforce represent the progress of 316L processing technologies that meet global demand for precision-engineered products.

316L stainless steel will remain a vital part of industries that need materials combining corrosion resistance, strength, and biocompatibility. As manufacturing technologies advance, this versatile alloy continues to be the foundation for engineers who need reliable performance in demanding environments.

Key Takeaways

Understanding 316L stainless steel’s unique properties and applications helps engineers select the right material for demanding environments where standard metals would fail.

• 316L contains 2-3% molybdenum and a maximum 0.03% carbon, providing superior chloride resistance and weldability compared to standard stainless steels.

• The alloy excels in marine environments, pharmaceutical equipment, and medical implants due to exceptional corrosion resistance and biocompatibility.

• Cold-working dramatically increases 316L’s strength from 485 MPa to over 700 MPa while maintaining non-magnetic austenitic properties.

• Metal Injection Molding (MIM) enables cost-effective production of complex 316L components with 94-98% density and 0.8μm surface finish.

• Despite 20-30% higher initial costs than 304 stainless steel, 316L delivers superior long-term value through reduced maintenance and extended service life.

While 316L costs more upfront, its exceptional performance in harsh environments and specialized manufacturing capabilities like MIM make it the preferred choice for critical applications across marine, medical, and industrial sectors.

FAQs

Q1. What are the main applications of 316L stainless steel? 316L stainless steel is widely used in marine equipment, pharmaceutical processing, medical devices, the food industry, and architectural applications in coastal environments. Its exceptional corrosion resistance makes it ideal for harsh environments containing chlorides.

Q2. What does the “L” in 316L stainless steel stand for? The “L” in 316L stands for “low carbon.” This grade contains a maximum of 0.03% carbon, compared to 0.08% in standard 316 stainless steel. The lower carbon content improves weldability and reduces the risk of carbide precipitation during welding.

Q3. How does 316L stainless steel compare to other grades in terms of corrosion resistance? 316L offers superior corrosion resistance compared to most other stainless steel grades, particularly in chloride-rich environments. Its molybdenum content (2-3%) significantly enhances its resistance to pitting and crevice corrosion, making it suitable for marine and chemical processing applications.

Q4. What are the mechanical properties of 316L stainless steel? In its annealed condition, 316L has a minimum tensile strength of 485 MPa and yield strength of 170 MPa with 40% elongation. When cold-worked, these values can increase significantly, with tensile strength potentially exceeding 700 MPa. It also maintains good mechanical properties at elevated temperatures.

Q5. How is 316L stainless steel used in Metal Injection Molding (MIM)? In MIM, 316L stainless steel powder is mixed with a binder, injection molded, and sintered to produce complex, high-density components. This process can achieve relative densities of 94-98% and surface finishes as smooth as 0.8μm Ra, making it ideal for producing intricate parts like watch components, dental tools, and micro-sized medical devices.