Sintered metal powder tubes can filter particles from 1 micrometer to 250 micrometers and beyond. These tubes play a crucial role in modern industrial filtration systems. The manufacturing process involves stainless-steel metal mesh filters that are rolled with multiple perforated metal layers and sintered together to create one solid structure. The tubes’ exceptional mechanical strength helps them deliver peak filtration performance even under heavy pressure.

The adaptable nature of sintered powdered metal makes it perfect for a variety of industries. Manufacturers can produce these filter tubes in different sizes, with some as compact as 10 mm on the inside. The tubes can be made from various materials to match specific needs. Stainless steel versions handle natural heat and pressure without any damage. Prices change based on what you need, while the highest temperature these tubes can handle depends on the material choice. Companies like JH MIM bring years of expertise to create precision-engineered sintered powder metal ultrafine tubes for customers worldwide.

Industrial Use Cases Driving Sintered Tube Demand

People just need sintered metal powder tubes more than ever in industries of all sizes because they last longer and filter better. These special parts are crucial in high-stakes applications where precision, reliability, and performance in tough conditions matter most.

Filtration in Petrochemical Plants

Sintered filter tubes are vital in petroleum refineries and petrochemical facilities. They keep petroleum products pure by removing contaminants. Large refineries use FCC (Fluid Catalytic Cracking) slurry oil filtration systems that can handle 100 mt/day to over 350 mt/day. Chinese facilities have installed these systems in more than eight FCC slurry oil filtration operations since 1997, mostly with existing RFCC units.

A typical RFCC slurry oil unit runs in tough conditions – around 350°C and 20 kg/cm2. The catalyst solids concentration ranges from 2000 ppm to 12,000 ppm. These systems still deliver filtrate quality below 50 ppm, which shows amazing efficiency of 99.5% or better.

Refineries use inside-out dual or triple filter setups to remove FCC catalyst fines from slurry oil. These automated systems handle high flow rates nonstop. They achieve longer cycle times by running two filters at once but at different stages. The third filter stays ready when one filter needs backwashing. This setup improves oil product quality and protects downstream equipment from fouling. It also cuts down maintenance needs.

Gas Purification in Semiconductor Manufacturing

Filtration is crucial in semiconductor manufacturing processes that use gasses. The reason is simple: gasses that aren’t filtered properly bring contaminants that damage wafer surfaces. This lowers die-per-wafer yield and reduces wafer processing system output.

Good gas filtration is so important that multiple filters are installed on each gas line in a typical fab facility. You’ll find at least one filter at the bulk source, another at the gas distribution panel, one at the gas drop to the process tool, one at the process tool’s gas box, and one more at the process chamber. Some facilities add extra filters between their gas box and process chamber to boost protection.

Sintered metal elements have been the go-to choice for decades. The semi-standard for gas filtration calls for a 9-log reduction of particles down to 0.003 μm. New advances challenge these limits. One sintered metal element filter manufacturer has shown third-party verified efficiency of at least a 9-log reduction down to 0.0015 μm (1.5nm). Sintered metal fiber media has improved pressure drop performance compared to regular sintered metal powder elements. It costs less too.

Water Treatment in Power Generation

Hydroelectric power plants work better with sintered metal tubes that clean turbine water. These special filters help keep electric power production running smoothly. Sintered metal media works great in spent resin handling systems. It polishes wastewater from resin blowdown and reduces radwaste volume in nuclear power facilities.

Power plants need very low resin leakage—0.1 parts per billion or less—to stop corrosion in steam generators or reactors. Sintered metal media keeps resin leakage below one-tenth of a part per billion at full flow. This amazing performance and stability, even in tough conditions, make sintered powder metal tubes perfect for nuclear applications.

Yes, it is clear that sintered metal powder tubes are becoming more popular in these demanding industries. Companies like JH MIM, with almost 20 years of experience in powder metallurgy, make precision-engineered sintered powder metal ultrafine tubes that meet strict standards for these critical uses.

Performance Characteristics of Sintered Filter Tubes

Sintered metal powder tubes stand out because of their unique manufacturing process. Their material properties make them perfect for tough industrial environments. The manufacturing workflow lets engineers fine-tune these properties to match exact application needs.

Controllable Porosity and Flow Rate

Sintered filter tubes shine because you can customize their porosity. Manufacturers can deliver filtration ratings from 1 micrometer to 250 micrometers or more. The sintering process controls this precision. The mix of powder size, pressing pressure, and sintering conditions shapes the pore size distribution, strength, and how well fluids pass through the porous element.

These tubes create a network of connected pores that make fluid or gas flow predictable while catching contaminants. They work great when you need steady flow rates—anywhere from less than 1 sccm to over 40,000 sccm. The pressure drops can range from inches of water to thousands of psi.

Quality sintered powder metal tubes have uniform permeability. This comes from strict manufacturing controls that ensure reliable filtration across the tube’s surface. JH MIM brings nearly 20 years of powder metallurgy expertise to the table. They make ultrafine tubes with consistent pore structures that keep the flow steady and block unwanted particles.

Mechanical Strength Under High Pressure

The most vital feature of sintered metal tubes is their mechanical strength. These tubes can handle operating pressures up to 3000 psi without breaking. The metal particles bond permanently below their melting point during sintering, which adds to their strength.

The tensile strength of sintered porous metal composites ranges from 8.64 MPa to 25.1 MPa, based on sintering parameters. This strength means these filter tubes can:

- Filter well, even under high pressure

- Handle tough industrial conditions

- Keep their shape and structure throughout their life

Regular filtration materials often fail under pressure or stress, but sintered metal powder tubes stay strong.

Thermal and Corrosion Resistance

The heat tolerance of sintered filter tubes is remarkable. Standard 316L sintered tube filters work well at temperatures up to 900°C. Special compositions can even handle up to 950°C. This makes them ideal for hot industrial processes.

These tubes resist corrosion well, too, especially when made from the right alloys. Raw sintered materials corrode faster than wrought ones, but special coatings help fix this issue. Coating 316 stainless steel with Dursan, Silcolloy, or Silicon Nitride protects it from chloride corrosion.

The choice of material determines how well these tubes fight corrosion. Stainless steel works well for general use, but Hastelloy components last about 60 times longer than 316 stainless steel in harsh conditions. C-22 Hastelloy with Silcolloy or Silicon Nitride coatings offers the best protection. These coatings showed no corrosion after a week in hydrochloric acid.

JH MIM uses smart engineering and careful material selection to create sintered powder metal tubes that deliver exactly what each industrial application needs.

Design and Customization Options

Customization options are the cornerstone of sintered metal tube technology. Engineers can tailor filtration systems to meet specific industrial needs. These design choices affect everything from filtration efficiency to mechanical durability.

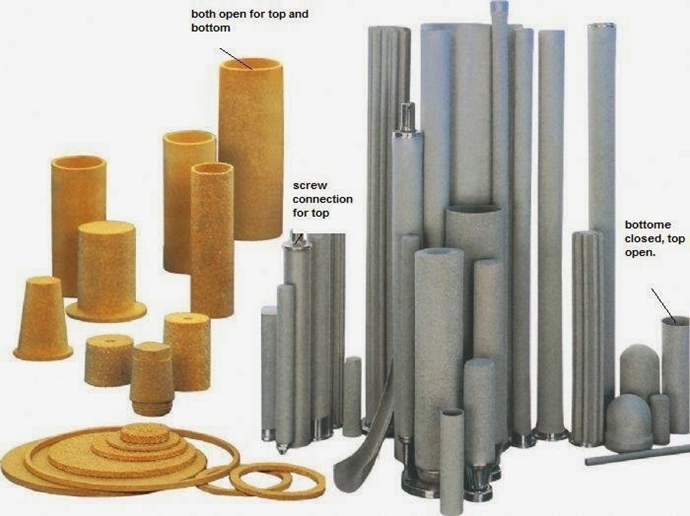

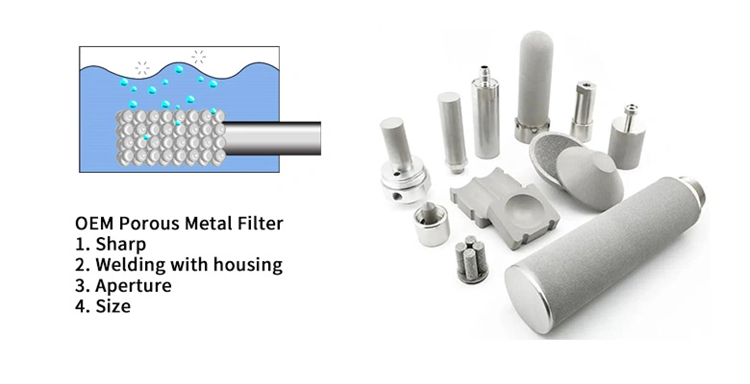

Pleated vs Porous Tube Configurations

The design choice between pleated and porous tube configurations affects filtration efficiency. Pleated sintered metal tubes have wrinkled surfaces that increase the available filtration area. Higher pleat counts lead to better filtration efficiency. Standard porous tubes feature a simple cylindrical structure with less surface area.

Pleated configurations shine when maximum filtration capacity is needed. Their wider surface area helps pleated sintered metal tubes perform better than standard porous designs. All the same, both configurations use similar manufacturing processes and materials. The choice depends on application requirements rather than production constraints.

The basic configuration offers several filter orientations:

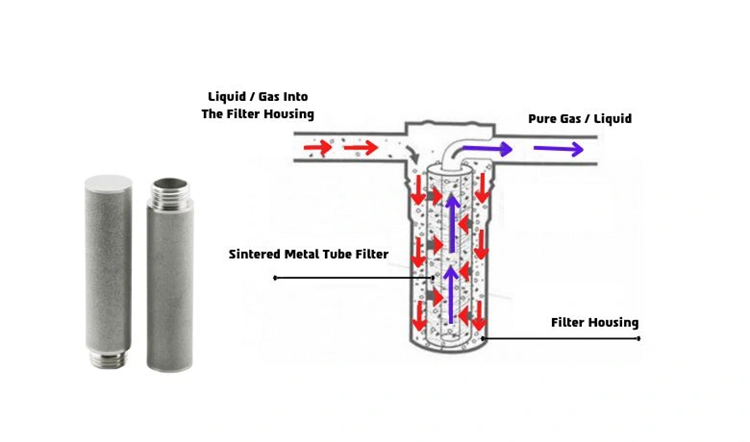

- Outside-in filtration: Contaminants collect on the outer perimeter

- Inside-out filtration: Particles gather on the inner surface

- Inside-out multimode: Offers both barrier and crossflow separation options

Tube Length, Diameter, and Wall Thickness Variants

Sintered powder metal tubes come with many dimensional customization options. Manufacturers adjust length, diameter, wall thickness, alloy selection, and media grade to meet filtration, flow, and chemical compatibility needs.

Standard lengths come in 254mm, 508mm, 762mm, and 1016mm, with custom sizes available. Size specs include both internal and external diameter measurements. Outer diameters start at 4mm, while inner diameters can be as small as 2.5mm. Wall thickness ranges from 1mm to 6mm. High-precision manufacturing can achieve tolerances of 0.1mm.

Sintered metal’s flexibility makes it easy to modify through welding or soldering. This adaptability allows the creation of complex shapes while maintaining enough mechanical strength to handle fluid pressure.

Surface Finishing: Sandblasting, Buffing, and Lapping

Surface treatment processes are crucial for both the look and the function of sintered metal tubes. Here are some finishing options that boost appearance and properties:

- Sandblasting creates a matte, uniform surface texture perfect for applications needing less glare or better coating adhesion

- Polishing techniques like lapping and buffing create smooth, reflective surfaces that are easier to clean and resist corrosion better

- Mass finishing methods include vibratory finishing and tumble finishing which work well with complex shapes

- Grinding techniques like honing improve dimensional accuracy and surface quality

Quality control remains strict at every customization stage. JH MIM brings nearly 20 years of powder metallurgy expertise to produce precision-engineered sintered powder metal ultrafine tubes. Their products feature exact dimensional control and surface quality. These customization capabilities serve many industries, from petrochemical processing to semiconductor manufacturing.

Engineers can optimize filtration performance for almost any industrial application thanks to the many customization options available for sintered metal powder tubes. These options range from basic configurations to precise dimensions and surface treatments.

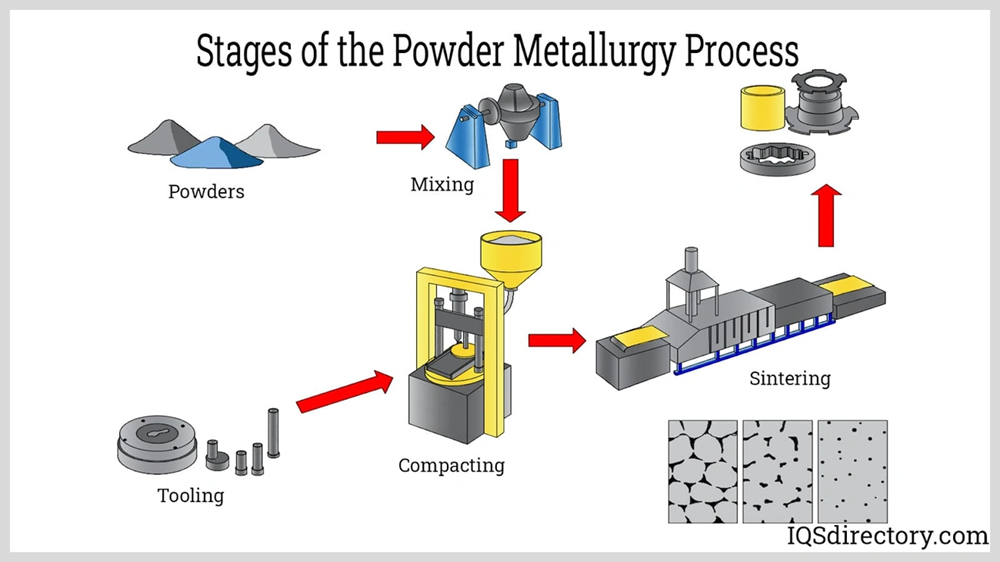

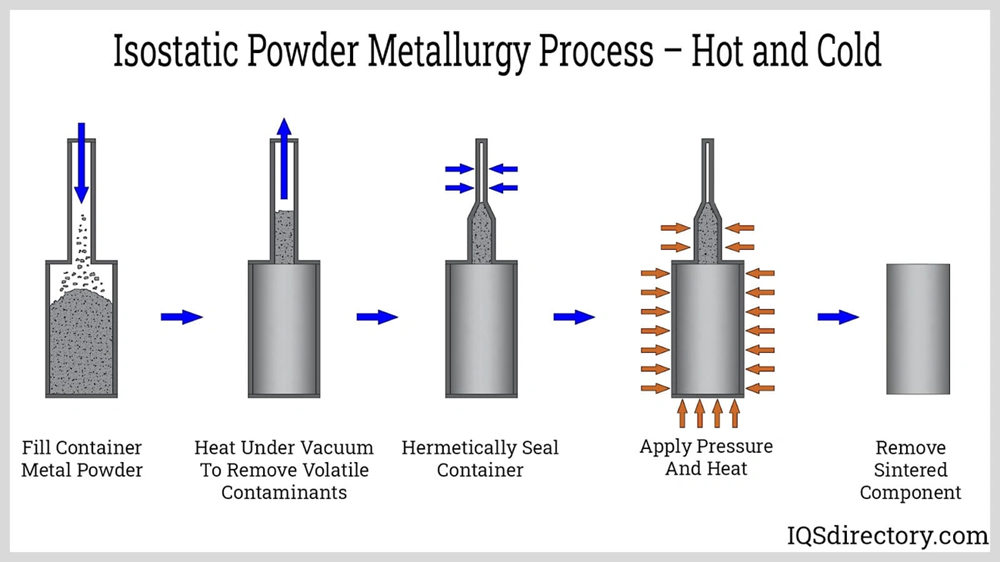

Manufacturing Workflow from Powder to Tube

Manufacturing sintered metal powder tubes needs careful control at each step. The process turns raw metal powders into high-performance filtration components. Each production stage shapes the product’s porosity, strength, and filtration abilities.

Powder Metallurgy: Atomization and Blending

The transformation from raw material to finished sintered tube starts with powder production through atomization. This process breaks molten metal into droplets that quickly solidify into powder. Two main atomization methods create powders with unique features:

Gas atomization creates spherical particles with low oxygen content. This makes it perfect for metals like titanium and stainless steel that oxidize easily. High-pressure gas jets break up molten metal streams into fine droplets that become solid while falling.

Water atomization yields irregularly shaped particles containing more oxygen. This cost-effective process produces larger volumes and works best to make iron powder.

The powder’s properties shape how well the final sintered tube performs. Particles usually measure between 1-1000 microns. Scientists use laser scattering, sieving, and microscopy to measure them. Common shapes include granular, spherical, flake, and dendritic forms.

After atomization, manufacturers blend powders with precision to get the right chemical mix. This vital step determines the tube’s final traits—including strength, corrosion resistance, and heat stability. Powder blends often mix structural parts (like nickel at 1450°C melting point) with binding materials (such as bronze melting around 850°C).

Tube Forming via Pressing and Rolling

The forming process begins once the powder blend is ready. Die pressing leads the way in creating shapes from metal powders. The process follows these steps:

- A measured amount of powder fills a die cavity

- Punches from both ends compact the powder to create even density

- The “green” part comes out of the die

- Automated systems remove the compact

Pressure forces metal particles to join at room temperature. This creates a solid but delicate “green” part. These compacted pieces need more processing because they’re too fragile to use.

Tubular shapes need specific handling. Manufacturers measure exact amounts of powdered metal based on the tube size they want. The powder goes into a molding machine. Compression fuses the metal particles into solid plates of different thicknesses that will become tubes.

Sintering and Post-processing Techniques

Sintering turns fragile green parts into strong components through three heating stages:

Preheating starts at 500-900°C. This removes lubricants and binders while reducing surface oxides on metal particles. The furnace’s atmosphere needs careful control to prevent carbon deposits that could cause surface problems.

High-temperature sintering happens at 70-90% of the metal’s melting point. Copper-based parts need 820°C, iron-based ones require 1120°C, and stainless steel needs 1250°C. This key phase has three distinct parts:

- Powder particles start forming neck contacts with slight densification

- Necks grow larger as grains expand and porosity drops

- Pores become isolated while grains grow faster

The controlled cooling phase solidifies and stabilizes the sintered tube. Cooling speed affects how the microstructure develops. Slower cooling usually creates better mechanical properties.

Final operations often include infiltration to improve surface properties. One method fills tin into the pores using materials like Sn60PbAg as infiltration liquid. Temperature and timing directly affect how deep the material penetrates.

JH MIM brings 20 years of expertise in Metal injection molding and Powder metallurgy. Their mastery of precise manufacturing techniques helps them create precision-engineered sintered powder metal ultrafine tubes. They provide top-quality filtration solutions to customers in a variety of industries worldwide.

Material Science Behind Sintered Powder Metal Tubes

Material selection plays a key role in determining how sintered metal powder tubes perform. The base material you choose affects everything from filtration efficiency to pressure handling and how long the tubes last in different industrial settings.

Nickel-Based Alloys for Harsh Environments

Nickel and its alloys are top choices for sintered filter tubes that need to work in extreme conditions. These materials can handle temperatures between 800-1200°C. This is a big deal as it means that they work better than stainless steel, which only handles up to 600°C. Their excellent heat resistance makes nickel-based sintered tubes perfect for high-temperature industrial processes.

Nickel alloys also shine when it comes to chemical durability. They resist corrosive fluids well, even harsh substances like hydrochloric and sulfuric acids. You’ll find several nickel-based options like nickel-chromium, nickel-molybdenum, and nickel-chromium-iron alloys. Each type works best in specific corrosive environments.

Stainless Steel for General Industrial Use

Stainless steel grades 304 and 316L are the most common materials used in sintered metal powder tubes. The 316L grade gives you the perfect mix of strength and corrosion resistance. Manufacturers can fine-tune the pore size by adjusting compaction pressure and powder particle dimensions.

These stainless steel types work great in many industries. You’ll find them in petroleum, natural gas, chemical processing, and pharmaceutical equipment. They’re so versatile because they have smooth walls inside and out, plus their pores are evenly distributed.

Bronze for Cost-Effective Applications

Bronze offers the most economical option for sintered filter tubes. It’s a great choice when you have budget constraints. Bronze resists corrosion well enough, especially when it’s not exposed to strong acids.

The material does have its limits. Bronze isn’t strong enough for high-pressure applications, so you’ll need to use it in less demanding environments. Still, you can adjust its porosity between 28-50%. This flexibility lets engineers find the right balance between air flow and filtration needs.

JH MIM can help if you need expert material guidance. They’ve spent nearly 20 years in the Metal injection molding and Powder metallurgy industry. The company creates precision-engineered sintered powder metal ultrafine tubes that match their global customers’ specific material needs.

Maintenance, Cleaning, and Lifecycle Management

Sintered metal powder tubes in industrial applications last much longer with proper care protocols. A regular cleaning schedule removes built-up contaminants and helps the system maintain peak filtration efficiency without disruptions.

Backwashing and Ultrasonic Cleaning Methods

Backflushing stands out as the simplest yet most effective way to clean sintered filter tubes regularly. The process pushes fluid or gas against the normal flow direction and dislodges trapped particles without taking the system apart. Ultrasonic methods work exceptionally well for deeper cleaning by using high-frequency sound waves to create microscopic bubbles. These bubbles collapse and release tiny energy jets that remove contaminants from even the smallest pores. A typical ultrasonic cleaning cycle takes 10-15 minutes, though heavily soiled filters might need multiple cycles. Chemical soaking removes tough residues like polymers or scaling. The process usually needs weak acids or alkaline detergents, depending on the contaminant type.

Monitoring Pressure Drop for Performance

The pressure drop across sintered metal tubes shows how well they perform. The pressure difference grows as contaminants fill the pores, which points to reduced filtration efficiency. Quick detection of clogging becomes possible through regular monitoring before system performance suffers. Flow rate measurements also offer valuable insights—restored flow rates after cleaning show successful maintenance work. Well-maintained filters show steady pressure patterns throughout their service life.

Replacement Guidelines and Service Life Estimation

Sintered metal powder tubes need replacement even with careful maintenance. Most filters last 3-5 years under normal conditions. You should consider replacement when you notice constant clogging after cleaning, major damage to the porous structure, or poor filtration performance. Good maintenance records that track cleaning frequency and performance help predict the best time for replacement.

Conclusion

Sintered metal powder tubes showcase remarkable engineering achievements that span many industries. These specialized components blend exceptional filtration capabilities with outstanding mechanical strength, thermal resistance, and customizable designs. This piece explores these tubes’ versatility, from their microscopic pore structures to their strength in extreme industrial environments.

The performance characteristics of sintered metal tubes make them essential in critical operations. Their controllable porosity enables filtration precision between 1 and 250 micrometers, while their mechanical strength supports operation under pressures up to 3000 psi. Their thermal stability also shines through – some compositions can withstand temperatures up to 950°C, which guarantees reliable performance in demanding environments.

Material choice forms the foundation when using sintered metal tubes. Stainless steel delivers balanced performance for general industrial use, while nickel-based alloys excel in harsh, corrosive environments. Bronze offers affordable options for less demanding applications. The manufacturing process – from powder atomization through compaction to sintering – shapes these performance attributes directly.

Regular maintenance substantially extends these tubes’ operational lifespan. Backwashing, ultrasonic cleaning, and pressure differential monitoring help maintain peak filtration efficiency. Most filters last 3-5 years under normal conditions, but proper care can extend this timeframe further.

Organizations looking for reliable filtration solutions gain value from working with experienced manufacturers. JH MIM brings nearly 20 years of powder metallurgy expertise to deliver precision-engineered sintered metal tubes. These tubes meet exact specifications across petrochemical, semiconductor, and power generation applications. Their technical knowledge ensures optimal material selection, manufacturing processes, and design configurations that match specific industrial needs.

Advances in sintered metal tube technology promise greater filtration precision, material performance, and application versatility. These vital components will remain crucial infrastructure elements that support industrial processes worldwide.

Key Takeaways

Understanding sintered metal powder tubes reveals their critical role in industrial filtration, from manufacturing processes to maintenance strategies that maximize performance and longevity.

• Precision filtration capabilities: Sintered metal tubes offer controllable porosity from 1-250 micrometers, withstanding pressures up to 3000 psi while maintaining consistent flow rates across diverse industrial applications.

• Material selection drives performance: Stainless steel provides balanced general-purpose performance, nickel alloys excel in harsh environments up to 950°C, while bronze offers cost-effective solutions for less demanding applications.

• Manufacturing precision determines quality: The atomization-to-sintering workflow controls final tube properties, with powder blending, pressing parameters, and thermal treatment directly impacting filtration efficiency and mechanical strength.

• Customization enables optimal solutions: Design options including pleated configurations, dimensional variants, and surface treatments allow engineers to tailor filtration systems for specific industrial requirements and performance metrics.

• Proactive maintenance extends service life: Regular backwashing, ultrasonic cleaning, and pressure drop monitoring can extend operational lifespan to 3-5 years, preventing costly system disruptions and maintaining filtration efficiency.

The success of sintered metal tube implementation depends on matching material properties to application demands while establishing robust maintenance protocols that preserve performance throughout the component’s operational lifecycle.

FAQs

Q1. What are the key advantages of sintered metal powder tubes? Sintered metal powder tubes offer precision filtration (1-250 micrometers), high mechanical strength (withstanding up to 3000 psi), excellent thermal resistance (up to 950°C for some materials), and customizable designs. These properties make them ideal for demanding industrial applications in petrochemical, semiconductor, and power generation industries.

Q2. How long do sintered metal powder tubes typically last? Under normal operating conditions, sintered metal powder tubes generally have a service life of 3-5 years. However, with proper maintenance including regular cleaning and monitoring, this lifespan can potentially be extended.

Q3. What materials are commonly used for sintered metal powder tubes? The most common materials are stainless steel (particularly grades 304 and 316L) for general industrial use, nickel-based alloys for harsh environments, and bronze for more cost-effective applications. The choice depends on specific performance requirements and operating conditions.

Q4. How are sintered metal powder tubes cleaned and maintained? Maintenance typically involves backwashing (reversing flow to dislodge particles), ultrasonic cleaning (using high-frequency sound waves), and chemical soaking for stubborn residues. Regular monitoring of pressure drop across the filter is crucial to assess performance and determine when cleaning or replacement is necessary.

Q5. What factors influence the porosity of sintered metal powder tubes? The porosity of sintered metal powder tubes is primarily controlled during the manufacturing process. Key factors include the size and shape of the metal powder particles, the compaction pressure used during forming, and the sintering conditions (temperature, time, and atmosphere). These parameters allow manufacturers to achieve precise pore sizes and distributions.