Tungsten is the most heat-resistant metal in aerospace applications. It has an extraordinary density of 19.3 g/cm³, which makes it almost 70% denser than lead. Its melting point reaches 3410°C, and tungsten alloys can handle extreme temperatures that break down other materials. These properties make them a great way to get high-performance aircraft and spacecraft components.

These alloys serve two important roles in aerospace – they work as counterweights and vibration dampeners. Tungsten’s impressive density (16.5-18.75 g/cm³) helps manufacturers build compact, high-mass components that improve flight stability by a lot. Rocket propulsion systems with tungsten can run at temperatures from 1760°C to over 3320°C. This leads to more powerful and optimized engines. Tungsten alloys perform better than traditional materials like lead or steel, and they help reduce oil consumption while improving thermal efficiency in natural gas turbines.

Tungsten Alloy Counterweights in Aircraft Systems

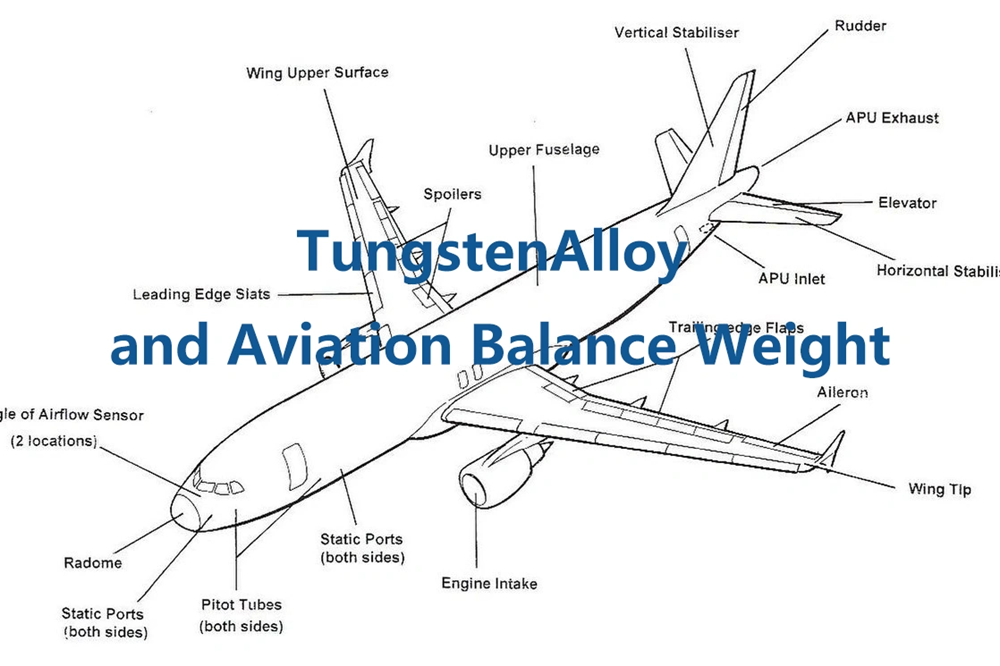

Tungsten alloy counterweights play vital roles in modern aircraft by delivering maximum mass in minimal space. Aircraft designs now feature streamlined fuselages and thinner wings. The internal volume available for counterweights keeps shrinking, which makes tungsten’s exceptional density even more valuable.

Flight surface balancing in ailerons and rudders

Control surface balancing stands out as one of tungsten alloys’ key applications in aviation. These dense materials fit perfectly into ailerons, elevators, and rudders to prevent dangerous aerodynamic flutter at high speeds. Tungsten counterweights’ compact nature lets designers maintain maximum surface area for control and prevent dynamic instability. The high strength of tungsten allows optimal positioning to get the most efficient weight effect, so designers can use minimal material. These weights, when placed in precise locations, help aircraft maintain proper center of gravity and give smooth operation of flight controls.

Rotor blade calibration for helicopters

Helicopter rotor blades just need perfect balance to work safely. Tungsten alloys are a great match for compensating imbalances built into individual blades during manufacturing. These high-density metals enable both static and dynamic balancing of rotor blades. Incorrect balancing can cause excessive vibration throughout the aircraft that might degrade flying qualities and reduce component lifetime. Tungsten counterweights with precise trimming will give stable flight dynamics and proper Center of Gravity (CG) maintenance.

Comparison with lead and steel for compact mass

Tungsten offers significant advantages over traditional counterweight materials in aerospace:

- Density advantage: Tungsten alloys (17-18.5 g/cm³) are approximately 41% more dense than lead (11.3 g/cm³) and over twice as dense as steel (7.8 g/cm³)

- Mechanical performance: Unlike lead, which exhibits creep at ambient temperatures, tungsten alloys remain stable in mechanically stressed positions

- Space efficiency: The higher density allows smaller components to be used, often reducing overall system weight

- Structural integrity: Tungsten provides tensile strength between 700-1000 MPa along with excellent fatigue resistance

Tungsten has replaced other materials, including depleted uranium, which aircraft manufacturers previously used in wide-body aircraft for rudders and wing assemblies. Boeing has provided customers with tungsten replacement counterweights since 1981 and installed them in new Boeing 747 aircraft.

Vibration Damping and Inertial Control Applications

Vibration control is a vital area where tungsten alloys shine in aerospace applications. These alloys have exceptional density that gives them superior damping capabilities in multiple aircraft systems. This quality helps reduce harmful vibrations that could damage both equipment and crew members.

Tungsten bucking bars in riveting operations

Aircraft assembly requires extensive riveting that creates harmful vibrations. Tungsten bucking bars with high density have become important tools that absorb these vibrations during riveting work. These bars are twice as dense as steel and absorb shock effectively. This protects workers from developing conditions like carpal tunnel syndrome or vibration white finger that harm the hand’s nerves, muscles, and bones. A major airframe manufacturer’s tests showed that workers saved about three seconds per rivet with tungsten bars. This is a big deal as it means that productivity improved significantly. These bars also work better in tight spaces because they pack substantial mass into a compact size.

Fly-by-wire joystick inertia improvement

Modern aircraft mostly use fly-by-wire systems instead of traditional mechanical control linkages. In spite of that, pilots need tactile feedback when flying. Engineers solve this by adding small amounts of tungsten alloy to flight control joysticks. This recreates the familiar “feel” of conventional elevator and aileron controls by increasing inertia. Tungsten’s high density provides enhanced momentum in minimal space. This makes it valuable especially when you have limited cockpit space where every centimeter counts.

Vibration suppression in avionics and engines

Tungsten alloys do more than help with riveting and control systems – they protect sensitive aerospace parts from operational vibrations. Engineers design these alloys to meet high standards in a variety of shapes. This allows them to work with different aircraft components like wings, rotor blades, and combustion engines. Aerospace companies face constant challenges with damage to critical mechanical parts from unavoidable operational vibrations. Tungsten-based vibration dampeners solve this problem by limiting harmful movement. This extends component lifespan and makes aircraft systems more reliable.

Thermal and Structural Roles in Spacecraft and Rockets

Tungsten alloys stand out as thermal and structural components in extreme space environments where other materials fail. The metal becomes indispensable for spacecraft elements facing intense thermal challenges due to its exceptional melting point of 3,422°C.

Is tungsten used in spacecraft propulsion systems?

Spacecraft propulsion technology relies heavily on tungsten. The material plays a vital role in rocket nozzles, thruster components, and advanced propulsion systems. Arcjet thrusters employ tungsten-copper components that maintain structural integrity and dissipate heat effectively during plasma generation. Scientists are exploring tungsten’s potential for ion engines and nuclear thermal propulsion systems because its radiation-shielding properties offer additional benefits.

W-Cu composites in hypersonic vehicle shielding

The combination of tungsten’s heat resistance and copper’s superior thermal conductivity creates ideal materials for hypersonic applications. These composites can reduce surface temperatures from 2000°C to 1650°C during ablation. The materials act as both active and passive protection systems against extreme temperatures. American hypersonic aircraft’s structure contains approximately 400 kilograms of tungsten.

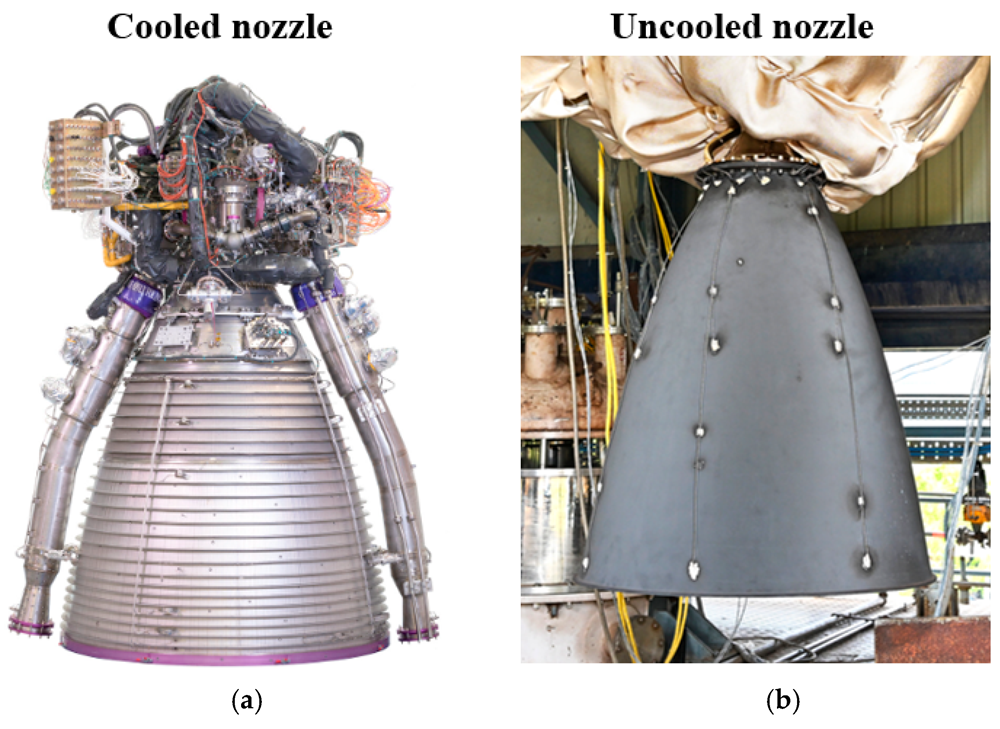

Tungsten-rhenium nozzles for solid rocket motors

Tungsten-based nozzle inserts show superior performance in solid rocket motors at temperatures reaching 5500°F. Pressed, sintered, and forged tungsten remains the most reliable nozzle material accessible to engineers. Rhenium additions enhance tungsten’s high-temperature properties, resulting in alloys with tensile strengths up to 3260MPa. These properties make the alloys perfect for rocket engine applications that face severe thermal and mechanical stresses.

Aerospace navigation systems just need materials with exceptional precision and reliability, which makes tungsten alloys essential components. These high-density materials improve critical control systems through their unique physical properties.

Gyroscope rotors using tungsten alloy

Tungsten alloy has become the go-to material for outer rotors in aviation gyroscopes. These precision instruments are the foundations of navigation and guidance systems in aerospace applications. Gyroscopes with tungsten rotors stay remarkably stable even in extreme dynamic conditions. A rotor’s weight directly affects the system’s stability, so tungsten’s high density significantly improves control precision. These components now guide satellites, missiles, rockets, aircraft, submarines, and torpedoes with impressive accuracy. Metal injection molding creates these intricate parts within aerospace’s strict tolerance requirements.

Nutation damping in satellite attitude systems

Satellites must maintain precise attitude control to work effectively. High-density tungsten alloy balls solve satellite sloshing problems by providing nutation damping in attitude instruments. This technology reduces residual chapter angles to below 0.1℃ and meets international advanced standards. Most nutation dampers use a tube filled with viscous fluid that contains a tungsten mass attached to springs. These systems help stabilize spinning spacecraft through energy dissipation from fluid friction.

Tungsten aircraft parts in Spey engine controllers

Spey engines extensively use high-density tungsten alloy, particularly in counterweight components. Tungsten elements work as counterweights in brackets, rocker speed controllers, and fuel regulating controllers. Tungsten’s exceptional density-to-volume ratio makes it perfect for precision applications where engineers must balance space and weight requirements.

Conclusion

Tungsten alloys are without doubt the life-blood materials of modern aerospace engineering because of their exceptional properties. Our examination shows how tungsten’s remarkable density—nearly 70% greater than lead—helps create compact, high-mass components that aircraft need for stability and control. The material’s unmatched heat resistance, with a melting point of 3410°C, makes these alloys irreplaceable in extreme thermal environments during spaceflight.

These alloys serve many critical aerospace systems. Dense materials prevent dangerous aerodynamic flutter in flight surface balancing and maintain optimal control surface effectiveness. Helicopter rotor blades need tungsten’s density to achieve perfect balance and stability during operation.

Tungsten-based solutions improve vibration control by a lot. High-density tungsten bucking bars boost productivity and protect workers during riveting operations. These alloys make the tactile feedback better in fly-by-wire joystick systems and reduce harmful vibrations in sensitive avionics and engines.

Space vehicles need tungsten for thermal protection and structural integrity. W-Cu composites protect hypersonic vehicles from extreme temperatures. Tungsten-rhenium alloys create nozzles that withstand intense conditions inside solid rocket motors. Space exploration would face severe limitations without these specialized materials.

Precision navigation systems need tungsten components to work properly. Tungsten alloy gyroscope rotors provide exceptional stability for guidance systems on aerospace platforms. Satellite attitude control systems use tungsten masses for nutation damping to ensure precise positioning during orbit.

Companies that have extensive experience in metal injection molding play a vital role in manufacturing these precision-engineered tungsten components. JH MIM, with its nearly 20-year industry experience, has specialized knowledge to produce complex tungsten parts that meet strict aerospace requirements.

Tungsten alloys will definitely remain essential materials as aerospace technology advances, thanks to their unique combination of density, heat resistance, and mechanical stability. Future flight and space exploration depends on these exceptional materials and the specialized manufacturing processes that create critical components.

Key Takeaways

Tungsten alloys are revolutionizing aerospace engineering through their exceptional density and thermal properties, enabling more efficient and reliable aircraft and spacecraft systems.

• Unmatched density advantage: Tungsten alloys (19.3 g/cm³) are 70% denser than lead, allowing compact counterweights that enhance flight stability in minimal space.

• Extreme heat resistance: With a melting point of 3,410°C, tungsten withstands temperatures that destroy other materials, making it essential for rocket nozzles and spacecraft shielding.

• Superior vibration control: Tungsten bucking bars reduce worker injury during aircraft assembly while improving productivity by three seconds per rivet compared to steel alternatives.

• Critical navigation precision: Tungsten gyroscope rotors and satellite damping systems provide exceptional stability for guidance systems across all aerospace platforms.

• Thermal efficiency boost: Tungsten components can increase rocket operating temperatures from 1,760°C to over 3,320°C, enabling more powerful and efficient propulsion systems.

The aerospace industry’s future depends on tungsten alloys’ unique combination of density, heat resistance, and mechanical stability. As aircraft designs become more streamlined and space missions more demanding, these materials will remain indispensable for achieving optimal performance in extreme environments.

FAQs

Q1. What are the main uses of tungsten alloys in aerospace? Tungsten alloys are primarily used as counterweights in aircraft systems, vibration dampeners, thermal protection in spacecraft, and precision components in navigation systems. Their high density and heat resistance make them ideal for these applications.

Q2. How do tungsten alloys improve aircraft stability? Tungsten alloys are used as compact, high-mass counterweights in flight control surfaces like ailerons and rudders. Their exceptional density allows for effective balancing in minimal space, preventing aerodynamic flutter and ensuring smooth operation of flight controls.

Q3. Why is tungsten preferred for spacecraft components? Tungsten’s extremely high melting point (3410°C) makes it ideal for spacecraft components exposed to extreme temperatures. It’s used in rocket nozzles, thruster components, and thermal shielding for hypersonic vehicles, where few other materials can withstand the intense heat.

Q4. How do tungsten alloys contribute to vibration control in aerospace? Tungsten alloys are used in bucking bars for riveting operations, reducing harmful vibrations and protecting workers. They’re also incorporated into fly-by-wire joysticks for tactile feedback and used in vibration dampeners for sensitive avionics and engines.

Q5. What role does tungsten play in aerospace navigation systems? Tungsten alloys are crucial in gyroscope rotors for navigation and guidance systems. Their high density improves the stability and precision of these instruments. Tungsten is also used in satellite attitude control systems for nutation damping, ensuring accurate positioning in orbit.