Related Resources

- Powder metal injection molding process

- Powder metallurgy gears

- Powder materials

When you research how powder metallurgy products are manufactured, are your custom parts suitable for powder metal manufacturing? Understanding the sintering of metal is an essential link, powder metallurgy metal products need sintering process.

What is sintered metal? What material is suitable for sintering? How does the powder sintered metal process produce high strength parts? Sintered metals are widely used in various fields.

What Is a Sintered Metal Part?

The sintering process in powder metallurgy PM refer to the process of metal powder or powder compact, which is heated to a temperature lower than the melting point of the main component, and obtains the required strength and characteristics of materials or products due to physical and chemical interactions such as bonding between particles. JH MIM has a wide range of stainless steel powder sintered parts in various sizes, including filters, filter cups, filter columns, filter plates, sintered mesh, etc

Powder Metal Sintering Process

The sintering process in powder metallurgy involves heating and pressing metal materials at high temperatures to cause the powder particles to fuse and solidify, resulting in a solid overall structure. Below, the specific steps of the sintering process are discussed.

1. Preparation of raw materials

Prepare the raw ingredients needed for sintering. Typically, the basic material is metal powder, which can be either a single metal or an alloy powder. To guarantee that the materials produced after sintering have optimum qualities, the raw materials chosen should be appropriately matched to the performance requirements of the required products and process requirements.

2. mixing and preparation

To ensure the final product’s composition is homogeneous, the necessary metal powder is combined thoroughly in a specific ratio. A ball mill or similar piece of machinery can be used to further refine the combined powder to increase its activity and fluidity.

3. forming

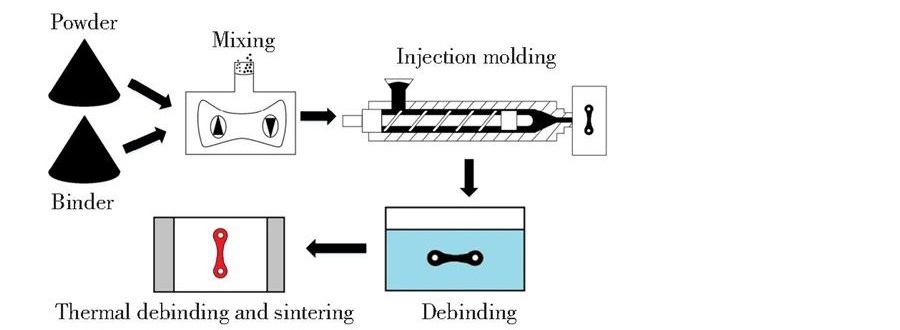

Forming is an important step in the sintering process. Commonly used molding methods are pressing and injection molding. The pressing method is to put the mixed metal powder into the mold and apply a certain pressure to form it. The injection molding method is to mix the mixed metal powder with organic matter and inject it into the injection molding machine, and make it shape by heating and pressure.

4. Sintering

The manufactured metal parts must be sintered. Sintering is the technique of using heat and pressure to melt and cure between metal powder particles. To ensure that the powder particles may completely fuse and create a solid structure during the sintering process, variables including temperature, time, and pressure must be under control.

5. Cooling and treatment

The sintered product needs to be cooled. The cooling process can be accelerated by natural cooling or the use of cooling media. After cooling, the product can be further treated, such as removing the surface oxide layer, heat treatment, etc., to further improve the performance of the product.

6. Processing and inspection

After sintering and treatment, the product can be processed, such as cutting, grinding, grinding, etc. At the same time, it is also necessary to carry out strict inspection of the product to ensure that the quality of the product meets the requirements. The commonly used inspection methods include appearance inspection, dimension measurement, mechanical property testing and so on.

7. Surface treatment and packaging

Surface preparation and packaging are necessary for processed and examined products. Depending on the product’s purpose and requirements, the surface treatment can be chosen from coating, painting, etc. To prevent damage and make transit and storage easier, the product must be packaged properly.

In SUMMARY:

The metal sintering process includes steps such as raw material preparation, mixing and preparation, forming, sintering, cooling and treatment, processing and inspection, surface treatment and packaging. Each step requires strict control of process parameters to ensure that product quality and performance meet the requirements. Sintering process is widely used in the preparation of metal materials, and can obtain materials with high strength, high hardness, wear resistance, corrosion resistance and other excellent properties.

Metal Sintering Vs. Metal Melting

The difference between metal sintering and metal melting

1. Different processing methods

Metal sintering and melting are processed in different ways. Metal sintering is the pressing of metal powder in the mold, without the need to heat the metal to the melting state; Metal melting, on the other hand, requires heating the metal above the melting point to make it a liquid state.

2. Different metal states

The metal billet created through the metal sintering process is mixed directly with metal powder, and the joint between the metals is solid. The metal billet created through the metal melting process is cooled by liquid metal and formed into solid. As a result, it is simpler to process and form the metal sintering processing billet material because it is more uniform; The microstructure and characteristics of the metals produced by the metal melting process vary in some ways.

3. Different fields of application

The application of metal sintering mainly focuses on the manufacture of high-strength, high-precision, complex shape parts and devices, such as vehicle engine cylinder block, gas turbine guide vane, Marine brake, etc. Metal melting is widely used, both for the manufacture of large parts, such as steel Bridges, steel buildings, and can be used to manufacture basic parts with complex structure and size, such as aircraft engines.

PLEASE CONTACT US