Powder metallurgy and machining casting are two completely different ways to produce metal parts, each with its own efficiency profile. A look at material usage shows powder metallurgy creates minimal waste with just 3% scrap rates. CNC machining processes tell a different story – they waste up to 50% of materials, which raises big questions about resources and costs.

Powder metallurgy and machining casting are two completely different ways to produce metal parts, each with its own efficiency profile. A look at material usage shows powder metallurgy creates minimal waste with just 3% scrap rates. CNC machining processes tell a different story – they waste up to 50% of materials, which raises big questions about resources and costs.

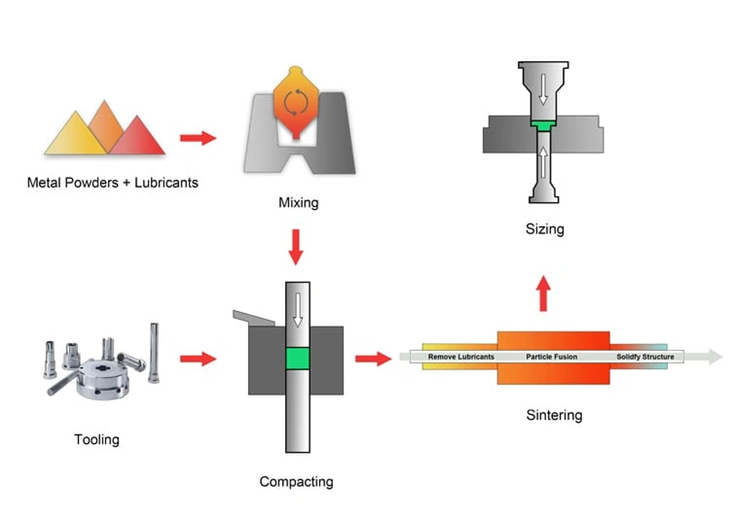

Manufacturers need to think beyond material waste to choose between casting and forging or machining casting processes. Powder metallurgy lets you create parts using endless alloy combinations, which works great for specialized applications. The machining vs casting choice isn’t simple because each method shines in different production scenarios. Traditional machining castings still lead the way in many metal fabrication areas, even though newer technologies like additive manufacturing are great for prototypes. These processes affect the environment differently, too. Some powder metallurgy finishing techniques now give us eco-friendly options that skip harmful substances.

Manufacturers heading into 2025 need a complete analysis of factors beyond just material use to figure out which process saves more. This comparison will show how casting vs forging vs machining match up in precision, speed, costs, and sustainability. These insights help pick the best option for the manufacturing needs of all types.

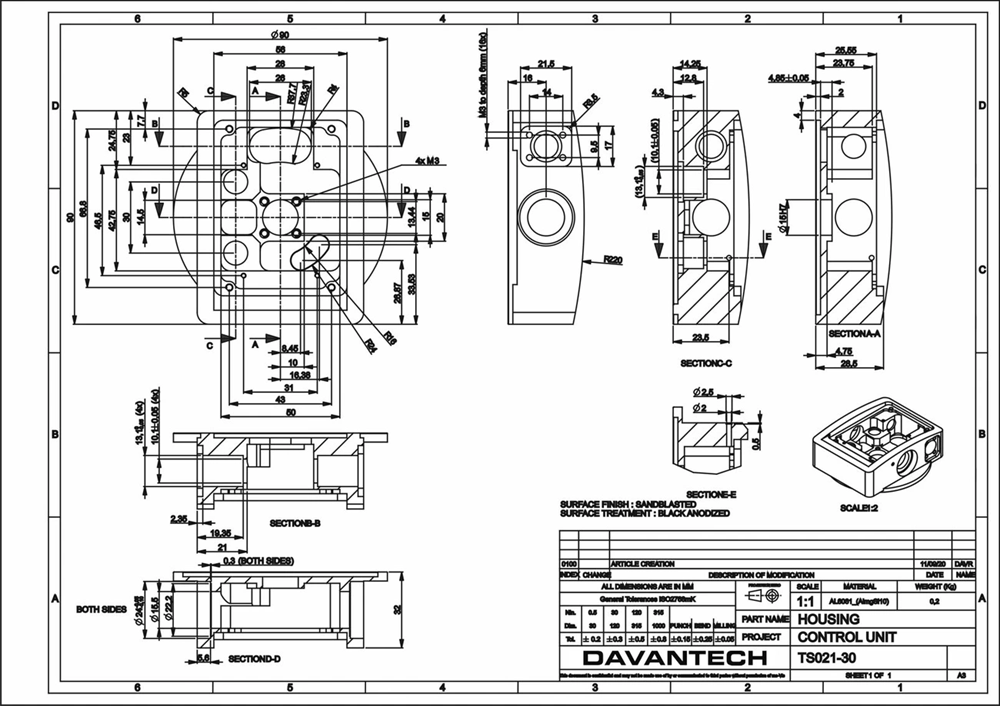

Precision and Tolerances

Tolerances play a crucial role in precision manufacturing by determining how usable components are in different industries. CNC machining produces remarkable dimensional accuracy and achieves tolerances as precise as ±0.0025 mm. This exceptional precision makes it the top choice when components need exact specifications. Powder metallurgy delivers good dimensional accuracy but falls short of CNC’s ultra-fine tolerances.

Dimensional Accuracy: CNC Machining vs Powder Metallurgy

Automated processes help CNC machining maintain consistent accuracy and precision with tight tolerances. Aerospace and medical equipment manufacturers prefer this capability. Powder metallurgy creates parts with minimal errors, but achieving similar precision usually requires additional machining steps.

Repeatability in High-Volume Production

Part-to-part repeatability shines in powder metallurgy, particularly for large production runs. The process can create thousands or even millions of similar components efficiently once the tooling is set up. CNC machining matches this repeatability but costs more than powder metallurgy when volumes increase.

Impact of Sintering on Final Dimensions

The sintering process causes slight changes in powder metallurgy parts’ dimensions. Parts become more dimensionally precise at higher sintering temperatures (1200°C-1250°C) due to more uniform microstructures and rounder pores. Cooling speeds influence the final dimensions significantly. Faster cooling creates larger roundness variations because of increased distortion and martensite formation.

Material Efficiency and Waste

Material waste plays a key role in manufacturing costs. PM and CNC machining show a remarkable difference – PM achieves impressive 3% scrap rates while machining creates about 50% material waste. This is a big deal as it means that production costs and environmental impact are vastly different.

Scrap Rates: 3% vs 50%

Near-net-shape approach in powder metallurgy uses the exact amount of material needed for each part, and this helps achieve over 95% material utilization. Traditional machining cuts away much of the solid blocks, which leads to major material losses. PM’s efficiency comes from its additive nature – it just needs the exact amount of material that the design calls for.

Material Utilization in Additive vs Subtractive Processes

Powder metallurgy, being an additive manufacturing process, works better than subtractive methods like CNC machining when it comes to using materials wisely. The main difference is simple – machining removes extra material to create parts, while powder metallurgy builds them by adding only what’s needed. On top of that, it takes less time to set up additive processes compared to the extensive preparation and machining needs.

Recyclability of Machining Castings

We can recycle the waste from machining castings, which mostly comes as chips and shavings. These materials can go into solid-state recycling systems, but it’s nowhere near as good as not creating waste in the first place. Metal casting foundries often use closed-loop systems where they recycle scrap internally – this cuts down the need for new materials by up to 50%. Recycling magnesium alloys is a great way to save energy since it only uses 5% of what’s needed to make new materials.

Production Speed and Scalability

Production speed and scalability determine manufacturing efficiency. The differences between powder metallurgy and CNC machining become clear when we analyze their throughput metrics.

Setup Time: Tooling vs Programming

These processes have very different original setup needs. CNC machining takes 1-2 hours to set up because we focused on programming and calibration. In contrast, powder metallurgy just needs 2-4 hours to prepare dies and configure equipment. Manufacturers can cut setup times with Single-Minute Exchange of Die (SMED) by moving internal tasks (done while machines are offline) to external tasks (completed during production). Quick-change tooling systems help reduce downtime between production runs.

Batch Production: Which Scales Faster?

Production rates show a big difference – powder metallurgy makes about 1,800 parts per hour, while CNC produces 20-60 parts. Yes, powder metallurgy indeed shows better efficiency for large-scale manufacturing once the tooling is 10 years old. Production data suggests CNC machining works better economically for short runs where flexibility matters more than high-volume output. Therefore, many manufacturers choose powder metallurgy to mass-produce parts that need consistent quality.

Lead Times for Prototypes and Final Parts

CNC machining delivers prototypes in 3 days, with rush options ready in 24 hours. This quick turnaround helps speed up iterations during early development. Powder metallurgy takes 7-10 days to make prototypes, but transitions naturally to full production compared to machining processes.

Cost Breakdown and ROI

Money plays a crucial role in choosing the right manufacturing process. Let’s look at how powder metallurgy and CNC machining stack up financially based on production volume and operations.

Tooling Costs: One-Time vs None

You’ll need a big upfront investment for powder metallurgy tooling. Dies and molds make up 20-30% of total manufacturing costs. This one-time expense makes PM expensive at first, but it works well for high-volume production. CNC machining doesn’t need any tooling costs. Manufacturers can start production right away with minimal investment.

Per-Part Cost in Low vs High Volume

The number of parts you make really affects the cost per piece. CNC machining costs less for small batches under 40-50 units. PM becomes cheaper once production goes beyond this point. The math is simple – more parts mean the initial tooling cost gets spread out, which brings down the cost per unit.

Energy Consumption and Operational Costs

These processes use different amounts of energy. PM uses about 1.8 kWh/kg to make iron powder and 5.0 kWh/kg for component manufacturing. Similar parts made through traditional machining need 8.4-11.4 kWh/kg. This makes PM much more energy-efficient. The sintering process uses most of the energy in PM operations.

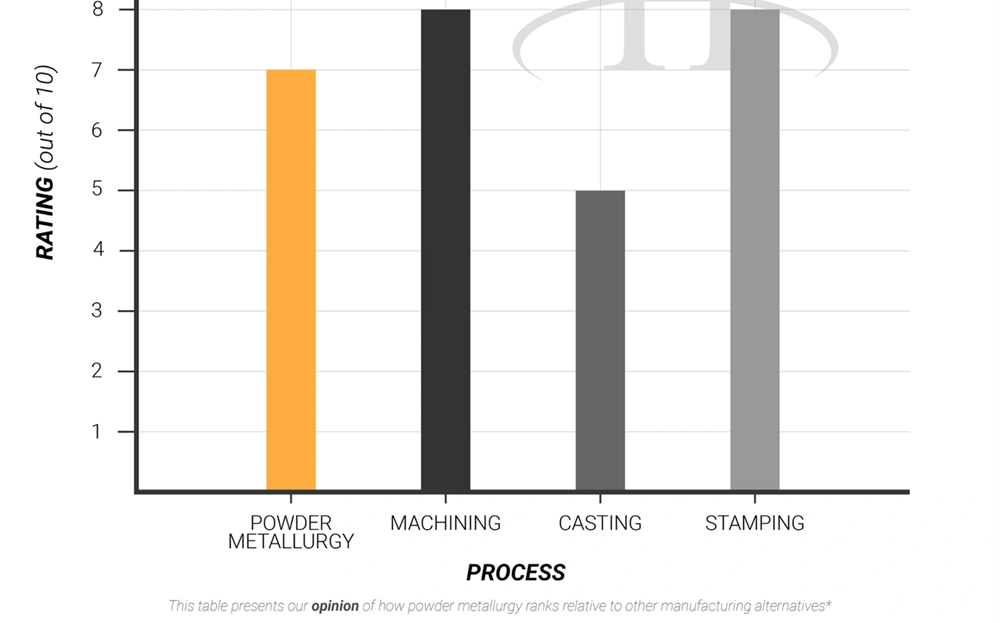

Machining vs Casting vs Powder Metallurgy: Cost Trends

Die-casting starts with expensive molds but gives you cheap per-unit costs for big batches. CNC machining has moderate setup costs and works well for small to medium runs. PM strikes a balance – the equipment costs a lot but gives you high production efficiency with minimal extra work. The cost advantage moves from machining to casting to powder metallurgy as you make more parts.

Environmental and Sustainability Factors

Manufacturing decisions in metalworking industries now heavily depend on environmental effects. A closer look at powder metallurgy and machining casting processes reveals their unique environmental footprints.

Energy Use: Sintering vs CNC Cutting

Recent sustainability studies show powder metallurgy uses 20-30% less energy than standard manufacturing methods. CNC machining operations, on the other hand, use nowhere near as little energy. Material removal processes make them much more energy-intensive. The numbers tell the story clearly – machining processes use 8.4-11.4 kWh/kg, while powder metallurgy components need only 5.0 kWh/kg.

Waste Management and Recycling

These technologies handle waste in completely different ways. CNC machining creates large amounts of metal chips, and thin-walled components can waste up to 17 times more material than the final product. The good news is that recycling these chips saves about 80% of the energy while losing just 5-7% of the material. Powder metallurgy’s net-shape capabilities make it a more material-efficient option.

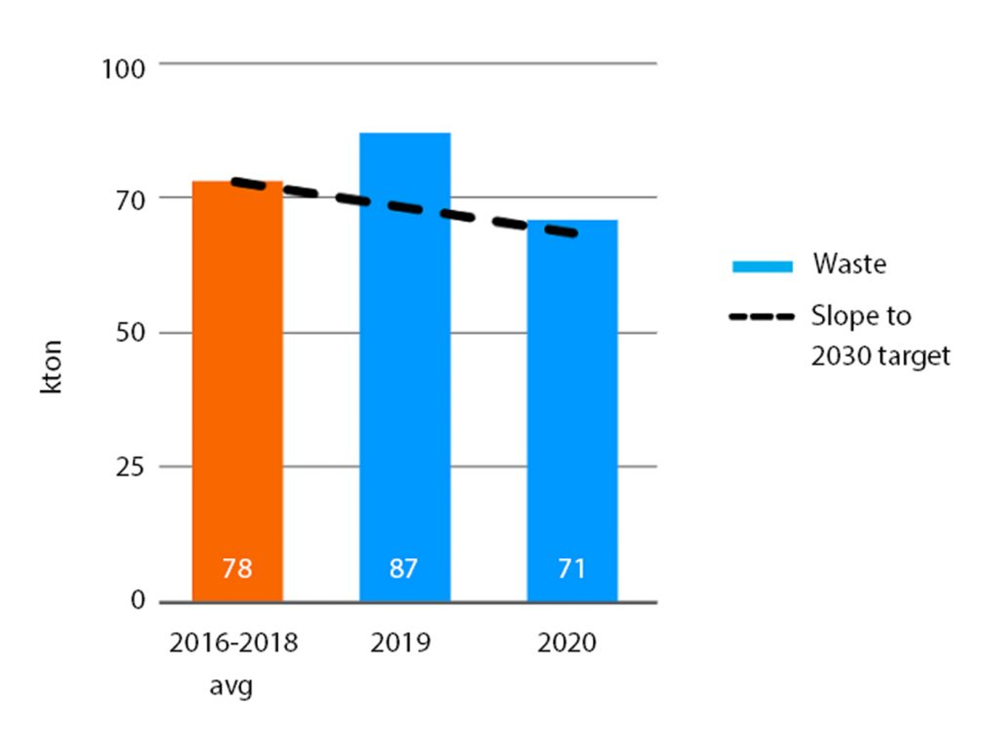

Eco-Friendliness of Powder Metallurgy in 2025

Powder metallurgy manufacturers have set bold sustainability targets for the future. To cite an instance, see GKN Powder Metallurgy’s commitment to cut absolute scope 1 and 2 greenhouse gas emissions by 42% by 2030. The industry wants a 90% reduction in emissions by 2050. They also plan to adopt a circular economy model through better recycling practices.

Comparison Table

| Comparison Factor | Powder Metallurgy | CNC Machining |

|---|---|---|

| Dimensional Accuracy | Good, but needs finishing operations | ±0.0025 mm tolerance |

| Material Waste | ~3% scrap rate | ~50% scrap rate |

| Production Speed | 1,800 parts per hour | 20-60 parts per hour |

| Setup Time | 2-4 hours to prepare dies | 1-2 hours to program |

| Prototype Lead Time | 7-10 days | 3 days (24 hours rush) |

| Original Investment | High (20-30% tooling costs) | Low (no tooling costs) |

| Energy Consumption | 5.0 kWh/kg | 8.4-11.4 kWh/kg |

| Volume Efficiency | Best value for high volume | Makes sense for small batches (<40-50 units) |

| Part Repeatability | Perfect for large production runs | Perfect but costlier at high volumes |

| Environmental Effect | Uses 20-30% less energy than standard methods | Uses more energy with lots of material waste |

Conclusion

The choice between powder metallurgy and CNC machining comes down to specific manufacturing needs, though clear cost patterns show up based on production volumes. Powder metallurgy shines with just 3% material waste compared to CNC’s 50%, making it a much more efficient choice. It also pumps out 1,800 parts per hour while CNC manages only 20-60 parts, which makes PM the clear winner for high-volume manufacturing.

Production scale plays a big role in cost decisions. CNC machining needs no tooling costs upfront, so it stays economical for small batches under 50 units. PM’s costs work better as quantities go up since the original tooling investments spread across more parts.

PM’s energy usage looks better too at 5.0 kWh/kg versus CNC’s 8.4-11.4 kWh/kg. These numbers add up to big operational savings and a smaller environmental footprint over long production runs. PM’s green advantages show up in reduced carbon emissions and match the industry’s push toward eco-friendly manufacturing.

Some projects still need CNC machining, especially when you have very strict tolerances of ±0.0025 mm in aerospace and medical parts. PM delivers good accuracy, but getting super-fine tolerances often needs extra processing steps.

Manufacturers should look at their specific needs carefully to find the most economical approach for 2025. Small batch projects with complex shapes and tight tolerances will do better with CNC machining. Medium to high-volume runs with standard precision requirements save more through PM, especially when you factor in material, energy, and long-term running costs. The final choice goes beyond basic material math to cover the whole production cycle, including lead times, extra processing steps, and green goals.

Key Takeaways

Manufacturing efficiency in 2025 depends heavily on production volume, with each process offering distinct advantages at different scales.

• Powder metallurgy achieves 97% material efficiency with only 3% waste versus CNC machining’s 50% material loss, dramatically reducing raw material costs.

• Production volume determines cost-effectiveness: CNC machining saves money for batches under 50 units, while powder metallurgy becomes more economical for higher volumes.

• Energy consumption favors powder metallurgy at 5.0 kWh/kg compared to CNC’s 8.4-11.4 kWh/kg, offering 20-30% energy savings for sustainable manufacturing.

• CNC machining delivers superior precision with ±0.0025 mm tolerances, making it essential for aerospace and medical applications requiring ultra-tight specifications.

• Speed advantages vary by application: Powder metallurgy produces 1,800 parts per hour for mass production, while CNC offers faster prototyping with 24-hour turnaround times.

The optimal choice requires balancing production volume, precision requirements, material efficiency, and long-term operational costs rather than focusing solely on upfront investment differences.

FAQs

Q1. How do powder metallurgy and CNC machining compare in terms of material efficiency? Powder metallurgy is significantly more efficient, with only about 3% material waste compared to CNC machining’s approximately 50% waste. This makes powder metallurgy a more resource-efficient option, especially for high-volume production.

Q2. Which process is more cost-effective for small batch production? CNC machining is generally more cost-effective for small batches, typically under 40-50 units. It requires no tooling costs, allowing manufacturers to begin production with minimal initial investment.

Q3. How do the energy consumption rates differ between powder metallurgy and CNC machining? Powder metallurgy consumes less energy, requiring about 5.0 kWh/kg for component manufacturing. In contrast, CNC machining typically demands 8.4-11.4 kWh/kg, making powder metallurgy more energy-efficient.

Q4. Which manufacturing process offers better precision and tolerances? CNC machining offers superior precision, achieving tolerances as strict as ±0.0025 mm. While powder metallurgy provides good dimensional accuracy, it often requires secondary operations to match CNC’s ultra-fine tolerances.

Q5. How do production speeds compare between powder metallurgy and CNC machining? Powder metallurgy excels in high-volume production, capable of producing approximately 1,800 parts per hour. CNC machining, on the other hand, typically produces 20-60 parts hourly, making it more suitable for smaller production runs or custom parts.

Pingback: The Process in Powder Metallurgy A 2025 Look at Its Advantages