Metal Injection Molding (MIM) can reduce cnc machining costs by 30-50% during complex metal parts production at scale.

Traditional machining methods waste 30-40% of material as chips and scrap. MIM creates parts with less than 5% material waste. MIM tooling costs are 20-30% lower than comparable die casting tools, which makes it an attractive choice to optimize machining costs. The advantages go beyond saving materials – MIM parts need minimal or no secondary machining and save up to 90% on finishing costs compared to conventional methods.

These numbers make a strong case for companies looking at low cost cnc machining alternatives. The global Metal Injection Molding market will reach $4.2 billion by 2027 because manufacturers have found its cost advantages. A cnc machining costs calculator shows that MIM’s cost-per-part drops dramatically as production volume rises. MIM achieves high precision tolerances of ±0.3% to ±0.5%, which is vital for companies that produce complex, high-performance components.

This piece shows how manufacturers can use MIM technology to cut unit costs by a lot while maintaining quality and performance.

Understanding Cost Drivers in MIM

Metal Injection Molding (MIM) stands out as an economical manufacturing option for complex metal parts. Manufacturers need to understand the key factors that drive costs in this process to optimize their production expenses.

Material selection and its effects

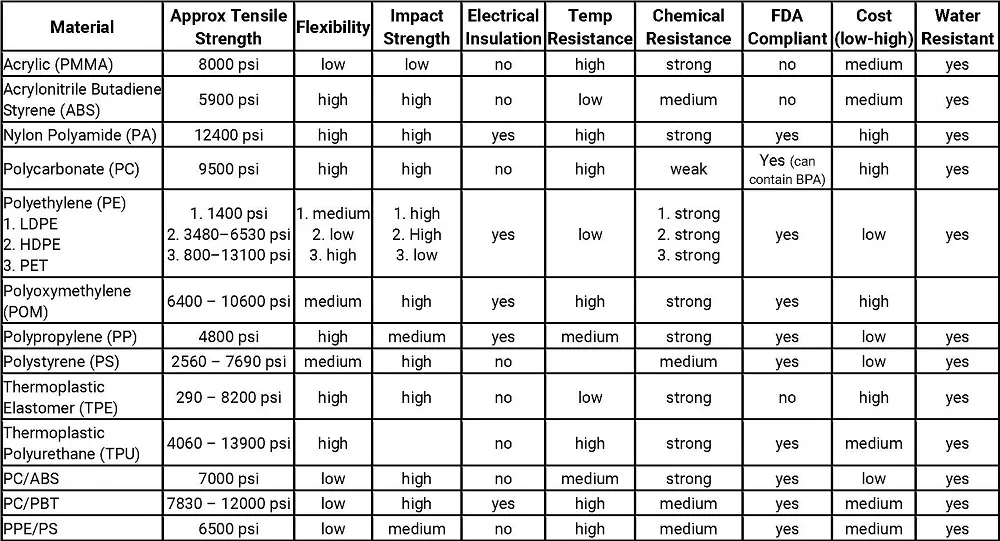

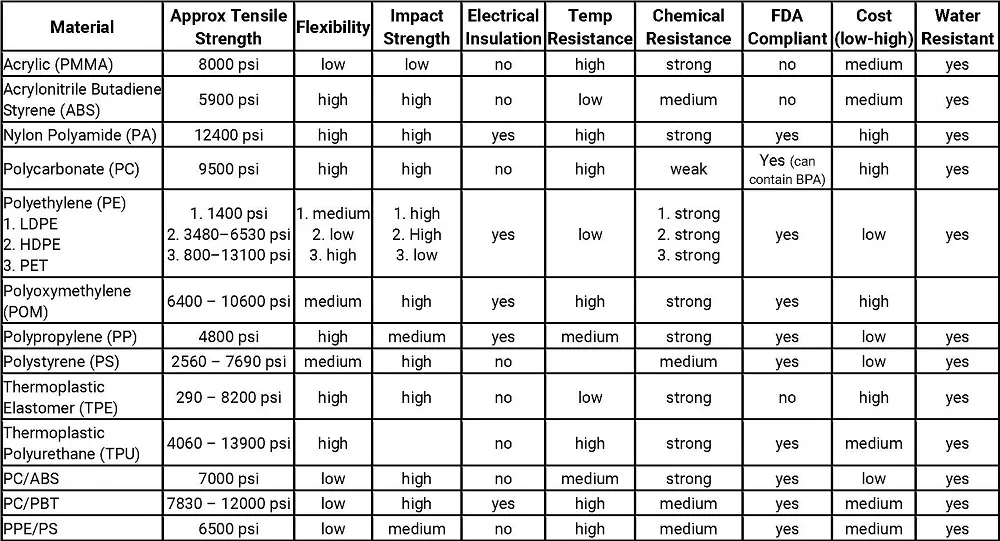

Two main factors determine how material choice affects MIM economics. Stainless steels (like 316L and 17-4PH) cost about 30% more than carbon steels (such as 42CrMo4 and FN08). This price gap exists because stainless steels cost 10-15 times more than raw materials in bar or ingot form.

Materials do more than just affect the purchase price – they influence processing time and energy use. Stainless steels need a hydrogen atmosphere during sintering, while carbon steels work with nitrogen. Carbon steels also sinter 30-40% faster than stainless steels, which improves production speed.

Size plays a big role in costs. MIM parts work best between 0.5-40 grams, though parts weighing over 150 grams can still be cheaper than other manufacturing methods. Custom powders add extra costs when standard compositions don’t fit the bill, so using common alloys helps keep expenses down.

Tooling costs and lifespan

Tooling is a vital investment in the MIM process. Professional industrial injection molding equipment ranges from $50,000 to $200,000, based on how complex and customized it needs to be. The mold price falls between $30,000 and $70,000.

These key elements affect how long tooling lasts:

- Mold material quality and construction

- Processing environment and conditions

- How often maintenance happens

- Type of plastic/metal being processed

Good maintenance makes tools last longer. Regular checks, cleaning, and repairs prevent wear and cut long-term costs. Tool life varies greatly—aluminum tools last less than 10,000 shots, but hardened steel ones can handle 500,000 to over 1 million shots.

Labor and machine cycle time factors

Cycle time shapes the cost calculations for custom cnc work and MIM production. This includes process time, material movement, inspection, and waiting time. Queue time makes up most of the manufacturing cycle.

Cycle time often gets lost due to:

- Machines breaking down or needing maintenance

- Workers waiting for materials or unclear instructions

- Quality problems that need fixes

- Supply chain delays

- Production getting backed up

Cycle time efficiency matters most when comparing cnc machining and MIM costs. Companies can cut unit costs by improving workflows, adding automation where it makes sense, and reducing wasted time.

Manufacturing cycle efficiency measures how much time adds value compared to total cycle time. This helps spot areas where companies can cut machining costs and make production better.

MIM vs CNC Machining: A Cost Comparison

The choice between Metal Injection Molding (MIM) and CNC machining depends on economic tipping points that affect production costs. A thorough cost analysis shows clear patterns about which manufacturing method provides the best value.

CNC machining’s expensive scenarios

Several factors drive up CNC machining costs. Complex parts need multiple tool changes that slow down the process and increase expenses . Deep internal cavities or pockets create problems because they need delicate tools that break easily during machining.

Precision requirements also push costs higher. You need extra manufacturing steps like grinding, honing, and polishing plus more detailed inspections to meet tight tolerances. Parts with many features that need numerical callouts (radii, hole diameters, chamfers) cost more to produce .

Material choice plays a crucial role too. Hard materials make tools wear out faster and need more upkeep. This wear directly impacts machining time – the biggest cost factor in CNC production that outweighs material, setup, and finishing costs combined.

MIM’s cost advantages

MIM shines economically with complex parts made in large numbers. The process works better for medium to high-volume production because setup times don’t change much with part complexity. The cost per part drops as production volume goes up with MIM.

Material utilization gives MIM another edge. CNC machining wastes material through cutting, while MIM creates near-net shapes with minimal waste. This makes a big difference with expensive alloys.

Cost data shows MIM and CNC machining break even at about 12,500 units for a simple 10mm cube. MIM delivers lower unit costs and better precision beyond this volume. Companies quickly recover MIM’s initial tooling investment for small, complex parts made in high volumes.

Cost calculator helps compare processes

A specialized calculator helps manufacturers compare these processes accurately. Key factors to include:

- Setup and programming costs (higher upfront for CNC)

- Production volume (determines break-even point)

- Geometry complexity (affects CNC time)

- Material costs and usage efficiency

- Labor needs (CNC needs more labor per part)

- Quality control and inspection requirements

Good calculators show that MIM’s higher tooling costs get offset by lower per-unit expenses at scale. Projects needing thousands of similar complex parts work better with MIM. Small batches or frequently changing designs suit CNC machining better.

The best manufacturing method depends on both direct costs and other factors like design flexibility, material properties, and lead times. A complete analysis helps you pick the right process for your needs.

Design Strategies to Lower MIM Unit Costs

Smart design choices are the life-blood of cost reduction in Metal Injection Molding (MIM). The way you design parts directly affects how much material you use, how complex your tools need to be, and how well production flows—these factors determine your final costs.

Simplify part geometry

Complex shapes make molding much harder and drive up production costs. Design simplification goes beyond just looks—it’s about making parts that are easier and cheaper to produce.

You might want to assess if a complex part would cost less when made as several simpler pieces. Adding assembly steps might seem counterintuitive, but the savings often make up for the extra assembly work.

Material flow inside the mold cavity needs careful planning. Good designers know how metal moves in the mold and create parts that are both innovative and practical. Sharp corners inside the part force machines to stop and adjust position, which takes more time and money. Rounded internal corners let machines work non-stop and cut down on expenses.

Avoid unnecessary features and undercuts

Undercuts make it tough to get parts out of molds in MIM production. While MIM can handle undercuts using slides or lifters, these features make tools more complex and expensive.

Designers should focus on:

- Checking if each undercut needs to be there

- Getting rid of details that might create undercuts

- Finding ways to redesign small features to eliminate undercuts

- Using proper draft angles on cores or external undercuts for better release

Cam actions help form undercuts without extra steps, but they cost more. Multiple cam actions cause real headaches because each one needs lots of space in the tool.

Optimize wall thickness and uniformity

Wall thickness plays a huge role in material costs, cycle times, and part quality. MIM parts work best with walls between 1-6mm, depending on size. Anything thicker than 12.5mm causes problems with uneven shrinkage and takes longer to sinter.

Uniform wall thickness helps fill cavities better, stops sink marks from forming, and reduces warping during sintering. Walls thinner than 0.5mm might break when parts are still green because they’re too fragile.

Whatever dimensions you choose, keeping them consistent throughout the part is vital. When wall thickness varies, cooling happens unevenly and parts can end up warped or distorted. Even wall thickness gives you better control over shrinkage.

These design approaches help manufacturers cut MIM production costs while keeping parts functional and high-quality.

Material and Process Choices for Cost Efficiency

Smart material and process choices in Metal Injection Molding can cut production costs while keeping part quality high. Your choices here will decide if MIM gives you the best value for money.

Choosing cost-effective MIM materials

The materials you pick play a big role in controlling MIM costs. Stainless steel and low alloy steels are usually your best bet for saving money, unlike titanium and tool steels, which cost much more. The material pyramid tells this story well – better performance means higher costs.

Materials affect your wallet in two main ways. Stainless steels (like 316L and 17-4PH) cost about 30% more than carbon steels (42CrMo4 and FN08). You also need hydrogen atmosphere sintering for stainless steel parts instead of nitrogen for carbon steels. This takes 30-40% more processing time.

Most MIM makers give you these standard alloy options:

- Ferrous alloys: steel, stainless steel, tool steel, low-alloy steel

- Specialty alloys: iron-nickel, Invar, Kovar

- Non-ferrous options: copper, titanium, and nickel alloys

Balancing material properties with price

Getting the best value means looking beyond just the price tag. You need to think about strength, how well it fights corrosion, and if it keeps its shape. Fe02Ni gives you better strength and finish. Heat-treating can make it even stronger and harder.

Your feedstock mix matters too. Metal powders make up 60-65% of feedstock volume, while binders fill the other 35-40%. You must control this mix carefully to get the right flow and final properties.

Pre-mixing materials can save you money. It spreads alloying elements more evenly and makes properties better. Yes, it is easier to control exactly what goes into your alloy when you pre-mix. This cuts waste and saves money.

Considering hybrid manufacturing approaches

Mixing additive techniques with regular methods opens new doors to cut costs. This way uses additive processes to make designs better while mass-producing parts the usual way to save money.

A real-world comparison showed big savings – USD 100,007.58 for hybrid versus USD 833.60 for regular milling.. The cost of hybrid manufacturing adds up additive and machining expenses.

Hybrid manufacturing works great with different materials too. You can add precise material layers to parts you already have. This helps fix expensive components. You can also mix different materials in one part to get exactly what you need. This gives you the best mix of function and value.

Batch Production and Scaling for Lower Costs

Production volume plays a decisive role in determining MIM unit costs. Manufacturers can achieve big cost reductions that affect their bottom line by planning batch sizes strategically.

How batch size affects custom cnc work cost

Batch size optimization creates a deep effect on production economics. Modern production economics assesses the relationship between batch size, transaction cost, and holding cost. This stands in stark comparison to traditional cost accounting, which focuses on the Economic Order Quantity (EOQ) model. Smaller batch sizes decrease overall costs by reducing quality issues, minimizing expediting, and cutting overtime.

Money savings happen through several channels:

- Smaller batches cut lead time and speed up customer response

- Less work-in-process inventory frees up cash

- Teams spot quality issues right away instead of after large production runs

- Customer change orders pose minimal risk with smaller batches

Tooling costs make up the biggest investment in MIM project development. Any mold design changes add to both tooling expenses and time. While setup times increase with smaller batches, the MED methodology offers the quickest way to reduce changeover tim.

Planning production volumes for best ROI

MIM technology makes financial sense only at specific production thresholds. Most applications need annual production to exceed 20,000 units to achieve good unit pricing. Production quantity becomes attractive above 5,000 units.

MIM shines with complex geometries, especially when you have small-sized components with thin walls. Companies find this technology valuable because it consolidates multiple parts into a single piece and eliminates inventory and assembly costs.

Smart batch planning balances transaction costs against holding costs. Transaction costs cover resources needed to move batches through the system. Holding costs include expenses from delayed system changes. Finding the sweet spot means calculating cost per unit for different batch sizes: (Fixed Costs + Variable Costs) / Batch Size.

Companies should update their batch sizes based on accurate demand forecasts. This helps them adjust quickly to market changes.

How batch size affects custom cnc work cost

Batch size plays a crucial role in CNC machining costs. Manufacturers need to grasp this unique cost structure to keep their expenses low. The relationship between quantity and unit cost creates a predictable pattern that has major financial implications for custom metal parts production.

The price gap between making one piece versus multiple pieces follows a distinct curve. Small batch production carries higher per-unit costs because the original setup costs get spread across fewer parts. These costs become more manageable as batch sizes grow. The biggest cost savings show up in the shift from prototype to small production runs. The unit cost can drop by half just by increasing the batch from 1 to 5 units.

Production costs keep falling as volume increases, though the savings become smaller. A part that costs $40 as a single unit drops to about $12.50 in a batch of 10. The same part costs roughly $8.79 each in a batch of 100. This means the cost per unit can fall by more than 60% between single-piece and 100-piece production. Small batch costs typically run 2-3 times higher than mass production.

Planning production volumes to best ROI

Manufacturers should take these steps to maximize their return:

- Find cost thresholds where bigger batches stop bringing major savings

- Check if combining smaller orders into larger runs saves money

- Balance inventory costs against production efficiency

- Run different scenarios through cost estimation software

Placing larger orders works better than multiple small ones. Cost simulation tools help analyze different scenarios without disrupting engineering work. This lets manufacturers quickly find the best batch size for maximum returns.

The best batch planning needs a balance between transaction and storage costs. Companies should adjust their batch sizes based on what the market needs . The sweet spot lies where production runs match market demand without creating excess inventory.

Conclusion

MIM helps manufacturers cut unit costs while maintaining quality. This piece explores how MIM provides substantial cost advantages over traditional manufacturing methods, especially when you have complex metal parts made at scale.

The economics of MIM work better as production volumes increase. A hefty upfront tooling investment spreads across thousands of units and cuts per-part costs. MIM matches CNC machining costs at around 12,500 units, and the savings grow from there.

Smart design choices boost these cost benefits even more. Simple part geometry, fewer features, and even wall thickness improve production efficiency. The right material choice balances performance needs with costs – stainless steel and low alloy steels are affordable options that work well in many cases.

Production planning can make or break cost reduction efforts. Batch sizes affect unit costs directly. Bigger volumes spread fixed costs across more parts efficiently. Companies should analyze their production numbers carefully to see where MIM gives the best ROI.

Without doubt, MIM technology saves money in several ways. It wastes less material, needs fewer tools, requires minimal secondary operations, and optimizes production. MIM isn’t just another option – it’s a competitive edge for companies making complex metal parts in medium to high volumes.

FAQs

Q1. What is Metal Injection Molding (MIM) and how does it reduce costs?

Metal Injection Molding is a manufacturing process that combines the versatility of plastic injection molding with the strength of metal materials. It reduces costs by minimizing material waste, lowering tooling expenses, and reducing the need for secondary machining operations, especially for complex metal parts produced at scale.

Q2. How does MIM compare to CNC machining in terms of cost?

MIM becomes more cost-effective than CNC machining as production volume increases. Typically, MIM reaches cost parity with CNC machining at around 12,500 units. Beyond this point, MIM offers consistently lower unit costs while maintaining high precision, particularly for small, complex parts.

Q3. What design strategies can help lower MIM unit costs?

Key strategies include simplifying part geometry, avoiding unnecessary features and undercuts, and optimizing wall thickness and uniformity. These approaches improve manufacturability, reduce material usage, and increase production efficiency, all of which contribute to lower unit costs.

Q4. How does material selection impact MIM costs?

Material choice significantly affects MIM costs. Stainless steels and low alloy steels are generally the most cost-effective options. The material impacts not only the purchase price but also processing time and energy consumption. Balancing material properties with price is crucial for optimizing costs.

Q5. At what production volume does MIM become financially viable?

For most applications, MIM becomes financially viable when annual production exceeds 20,000 units. However, production quantities above 5,000 units can start to show attractive pricing. The exact threshold depends on factors such as part complexity, material choice, and specific application requirements.