The demand for ultra-tiny components has surged, driven by advancements in technology across various industries. The global market for thin and ultrathin films reached $18.3 billion in 2022 and is projected to grow to $38.8 billion by 2028, with a compound annual growth rate (CAGR) of 13.5% from 2023 to 2028. However, traditional manufacturing methods face significant challenges, which is where Micro-MIM Technology comes into play.

| Limitation Type | Description |

|---|---|

| Limited Geometric Freedom | Traditional subtractive micromanufacturing restricts designs to 2/2.5D structures. This limitation makes it difficult to achieve high-aspect ratio ‘true-3D’ structures with feature sizes below tens of microns, a challenge that Micro-MIM Technology aims to overcome. |

| Limited Materials Processing | Non-metallic materials encounter issues such as crystallographic anisotropy and material defects, hindering the integration of functional properties into microscale products. Micro-MIM Technology offers innovative solutions to these processing limitations. |

| Limited Feature-Size Resolution | The resolution of fabrication processes is constrained by physical laws and tooling limitations, affecting the production of ultra-tiny components effectively. Micro-MIM Technology enhances feature-size resolution, enabling the creation of more precise components. |

As semiconductor nodes shrink, the challenges blend physical laws with economic constraints, complicating the scaling of transistors. Micro-MIM Technology provides a promising avenue to address these complexities in the manufacturing landscape.

Key Takeaways

- Micro-MIM Technology combines metal injection molding with microfabrication to produce ultra-tiny components with high precision.

- This technology overcomes limitations of traditional manufacturing methods, allowing for complex geometries and intricate designs.

- Micro-MIM achieves up to 98% material conversion efficiency, significantly reducing waste and enhancing sustainability.

- The technology is ideal for industries like medical devices, automotive, and electronics, where precision and reliability are crucial.

- Micro-MIM can produce components with tolerances as tight as ±0.010 mm, ensuring high dimensional accuracy.

- The streamlined production process of Micro-MIM allows for faster turnaround times, meeting the demands of modern manufacturing.

- As the market for ultra-tiny components grows, Micro-MIM Technology is positioned to play a key role in future innovations.

- Investing in Micro-MIM can lead to cost savings and improved profitability, especially in high-volume production scenarios.

What is Micro-MIM Technology?

Definition of Micro-MIM Technology

Micro-MIM Technology, or Micro Metal Injection Molding, represents an advanced manufacturing technique designed for producing ultra-tiny metal components. This method combines the principles of traditional metal injection molding (MIM) with microfabrication techniques. According to industry literature, Micro-MIM allows for the creation of intricate geometries and fine details that are often unattainable through conventional manufacturing methods.

| Aspect | Description |

|---|---|

| Definition | Metal injection molding (MIM) is a near-net shape manufacturing approach for fabricating metal components with excellent mechanical properties. |

| Advantages | High production rate, good mechanical properties, good dimensional control, and good shape complexity. |

| Disadvantages | High sintering temperature, part size limitation, and product with residual pores. |

| Process Steps | Mixing, injection molding, de-binding, and sintering. |

| Materials Used | Zirconia, 316L stainless steel, tungsten carbide, titanium, copper, chrome steel, and nickel. |

How Micro-MIM Technology Works

The Micro-MIM process involves several critical steps that transform raw materials into finished components. The fundamental principles guiding this technology include:

- Mixing: Manufacturers blend metal powders with plastic and wax binders to create a feedstock.

- Injection Molding: The feedstock is heated and injected into a mold cavity, forming a ‘green’ part.

- Debinding: The binder is removed from the ‘green’ part, resulting in a ‘brown’ part using catalytic or solvent techniques.

- Sintering: The ‘brown’ part is heated in a furnace, transforming it into a dense solid component.

This systematic approach enables the production of components with high precision and complex geometries, making Micro-MIM Technology a preferred choice in various industries.

Key Materials Used in Micro-MIM Technology

Micro-MIM Technology utilizes a range of materials, each selected for its unique properties that enhance the performance of the final product. Common materials include:

| Material | Properties |

|---|---|

| Stainless Steel | Excellent corrosion resistance, high strength, good elasticity, superb mechanical properties. |

| Low-Alloy Steels | Affordable, heat-treatable, high-strength, good ductility, and machinability. |

| Tool Steels | High hardness, wear resistance, ideal for cutting tools and molds. |

| Titanium | Strength, low weight, corrosion resistance, and suitable for demanding applications. |

| Tungsten | Extraordinary density, strength, and hardness, ideal for high-density applications. |

| Copper Alloys | Excellent conductivity, flexibility, suitable for electrical and thermal applications. |

These materials contribute to the overall effectiveness of Micro-MIM Technology, allowing manufacturers to meet the stringent demands of modern applications.

Advantages of Micro-MIM Technology

Precision and Tolerances in Micro-MIM Technology

Micro-MIM Technology excels in achieving high precision and tight tolerances, making it a preferred choice for industries requiring intricate components. The technology can produce fine structures under 1 mm, which is a significant advantage over traditional methods.

| Manufacturing Method | Precision Level | Tolerance Level |

|---|---|---|

| Micro-MIM | High density, smooth surface finish | Capable of producing fine structures under 1 mm |

| CNC | Approaches industry standards | Varies, may require additional polishing |

| Micro Machining | ±0.001 mm to ±0.005 mm | As tight as ±0.0001 mm in specialized applications |

Micro-MIM can mass-produce thin-wall designs that stamping cannot achieve. This capability allows manufacturers to create components with complex geometries while maintaining high dimensional accuracy.

Design Flexibility with Micro-MIM Technology

Micro-MIM Technology offers remarkable design flexibility, enabling the production of very small and intricate metal components that traditional machining cannot achieve. This technology removes the limitations of machining, allowing for the creation of parts with tight tolerances and complex shapes.

- Micro-MIM is particularly beneficial in modern medical device applications, where specifications are critical.

- The ability to produce complex geometries enhances the potential for innovation in various industries, including electronics and automotive.

This flexibility not only meets the demands of contemporary designs but also opens new avenues for product development.

Reduced Waste and Material Efficiency in Micro-MIM Technology

Micro-MIM Technology significantly reduces material waste, achieving up to 98% material conversion efficiency. This efficiency is crucial, especially when working with expensive materials like titanium alloys and superalloys.

- Compared to traditional machining processes, Micro-MIM generates significantly less material waste.

- The technology’s ability to utilize materials effectively contributes to cost savings and sustainability in manufacturing.

By minimizing waste, Micro-MIM Technology not only enhances profitability but also aligns with the growing emphasis on environmentally friendly manufacturing practices.

Achievable Tolerances with Micro-MIM Technology

Dimensional Accuracy in Micro-MIM Technology

Micro-MIM Technology achieves remarkable dimensional accuracy, making it suitable for applications requiring precise specifications. The technology can produce components with tolerances as tight as ±0.010 mm. This level of precision is particularly beneficial for small parts, often measuring less than 5 mm.

| Technique | Tolerance | Notes |

|---|---|---|

| Micro-MIM | ±0.010 mm | High accuracy for components < 5mm |

| Conventional MIM | ±0.5% | Lower accuracy compared to Micro-MIM |

| Machining | Varies, generally better than ±0.010 mm | Can achieve high precision but less efficient for mass production |

This table illustrates how Micro-MIM outperforms conventional methods in terms of dimensional accuracy. The ability to maintain such tight tolerances enhances the reliability of components in critical applications, such as medical devices and precision instruments.

Surface Finish Quality in Micro-MIM Technology

Surface finish quality plays a crucial role in the performance of components produced using Micro-MIM Technology. A smooth surface reduces friction and minimizes the risk of bacterial growth, especially in medical applications. Manufacturers often aim for specific surface roughness metrics to ensure optimal functionality.

Typical surface finish metrics include:

- Ra (roughness average): Average value of peak heights above the mean line.

- Rz: Average difference between the five highest peaks and lowest valleys.

- RMS: Root mean square average of the difference between profile height and the mean line.

To achieve these metrics, various surface treatment methods are employed:

| Surface Treatment Method | Description |

|---|---|

| Chemical surface treatment | Includes etching, pickling, polishing, and chemical deburring. |

| Organic coatings | Involves adhesive bonding and painting. |

| Heat treatment | Enhances strength, wear resistance, and hardness through tempering and quenching. |

| Mechanical surface treatment | Comprises shot blasting, carving, polishing, finishing, deburring, and grinding. |

| Metal coating | Encompasses galvanizing, chrome plating, PVD coating, and chemical metal coating. |

These treatments ensure that components meet stringent quality standards, enhancing their performance in various applications.

Comparison with Other Manufacturing Methods

When comparing Micro-MIM Technology to other manufacturing methods, several factors come into play, including cost, speed, and quality. Micro-MIM proves to be cost-effective for production volumes exceeding 10,000 units annually, offering savings of 20-50% compared to precision machining and investment casting.

Additionally, Micro-MIM significantly reduces material waste to 1-3%, while traditional machining often results in 40-60% waste. This efficiency not only lowers costs but also aligns with sustainability goals in manufacturing.

In terms of quality, Micro-MIM parts maintain mechanical properties comparable to those produced through traditional methods, ensuring high performance in small to medium-sized complex parts.

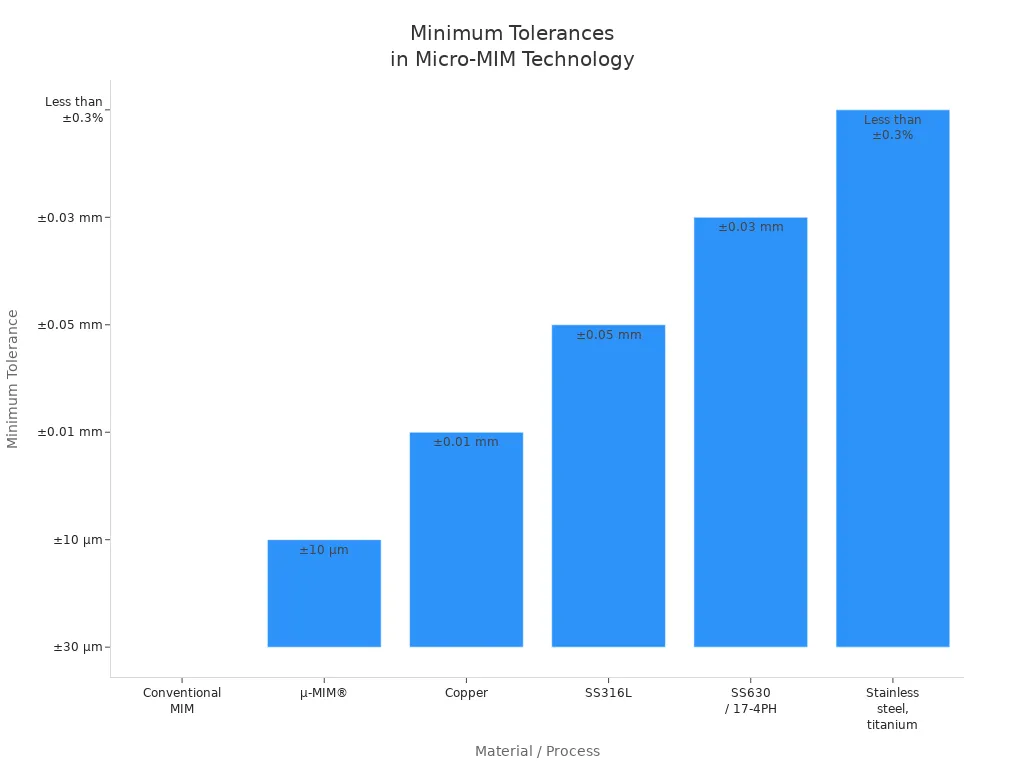

This chart visually represents the minimum tolerances achievable with various materials and processes, further emphasizing the advantages of Micro-MIM Technology.

Types of Components Produced with Micro-MIM Technology

Medical Devices from Micro-MIM Technology

Micro-MIM Technology plays a crucial role in the production of various medical devices. This technology enables manufacturers to create intricate and precise components essential for modern healthcare. Commonly produced medical devices include:

- Complex surgery tools

- Medical implants

- Dental parts

These components benefit from Micro-MIM’s ability to produce precision parts while reducing production costs and minimizing waste. The technology also enhances the speed of manufacturing, which is vital in the medical field. Surgical instruments, implants, and diagnostic equipment are just a few examples of how Micro-MIM Technology meets the stringent demands of medical applications.

Automotive Parts from Micro-MIM Technology

In the automotive industry, Micro-MIM Technology is revolutionizing the production of critical components. Key automotive parts manufactured using this technology include:

- Sensor housings

- Internal components for LiDAR systems

- Injector nozzles

- Turbocharger vanes

- Components for fuel systems and powertrains

The performance advantages of these parts are significant. Micro-MIM offers design flexibility, high precision, and reduced material waste. Additionally, the ability to produce complex geometries allows for innovative designs that enhance vehicle performance and efficiency. As the automotive sector continues to evolve, Micro-MIM Technology will likely play an increasingly important role in component manufacturing.

Electronics Components from Micro-MIM Technology

Micro-MIM Technology also finds extensive applications in the electronics sector. It enables the production of various components that are integral to modern electronic devices. The following table outlines some common electronics components produced using this technology and their typical applications:

| Component Type | Typical Applications |

|---|---|

| Semiconductor Packaging | High-end semiconductor devices, lead frames, heat dissipation substrates |

| Electronic Substrates | Power modules, LED packaging |

| Sensor Housings | Automotive electronics, industrial control |

| RF Components | Communications, filters, antennas |

Additionally, Micro-MIM Technology is used to manufacture SIM slot parts, drone brackets, earphone frames, and connectors for smart devices. The technology’s ability to produce high voltage power connectors, PCB terminal blocks, and micro switches further illustrates its versatility in the electronics industry. As demand for compact and efficient electronic assemblies grows, Micro-MIM Technology will continue to be a key player in meeting these needs.

Applications of Micro-MIM Technology in the Medical Field

Surgical Instruments Made with Micro-MIM Technology

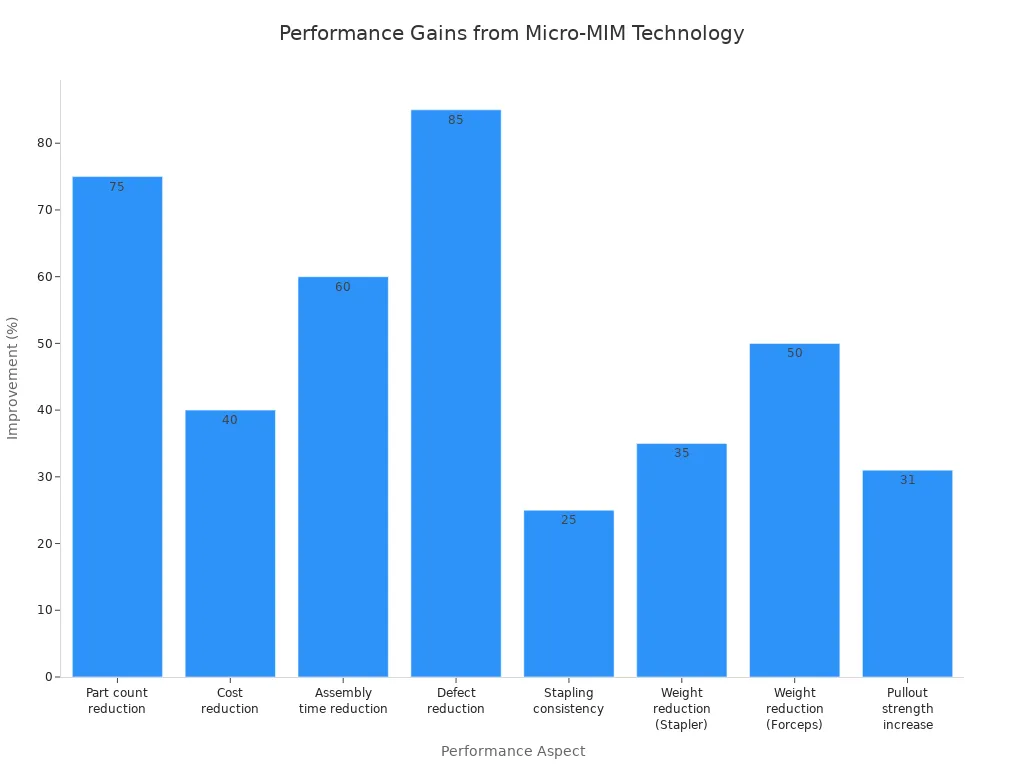

Micro-MIM Technology significantly enhances the performance and reliability of surgical instruments. By consolidating components, manufacturers can reduce the part count in devices like surgical staplers from 12 parts to just 3. This consolidation leads to a 40% reduction in manufacturing costs and a 60% decrease in assembly time. The following table summarizes key performance improvements:

| Performance Aspect | Improvement / Feature | Example / Metric |

|---|---|---|

| Component Consolidation | Reduction in part count | From 12 parts to 3 parts (Surgical Stapler) |

| Manufacturing Cost | Cost reduction | 40% reduction (Surgical Stapler) |

| Assembly Time | Time reduction | 60% reduction (Surgical Stapler) |

| Quality Defects | Defect reduction | 85% reduction (Surgical Stapler) |

| Stapling Consistency | Performance improvement | 25% improvement (Surgical Stapler) |

| Weight Reduction | Weight savings | 35% reduction (Surgical Stapler), 50% (Biopsy Forceps) |

| Mechanical Properties | Pullout strength increases | 850N vs. 650N (31% increase) (Orthopedic Screws) |

| Fatigue Resistance | Endurance cycles | >5 million cycles without failure (Orthopedic Screws) |

| Dimensional Accuracy | Thread accuracy | ±0.02 mm consistency (Orthopedic Screws) |

| Surface Finish | Optimization for reduced tissue adhesion | <1 μm Ra surface finish (Biopsy Forceps) |

| Complex Geometries | Internal channels, undercuts | Channels as small as 0.3-0.4 mm diameter; 0.5 mm wall thickness |

| Biocompatibility & Corrosion Resistance | Material selection enhances reliability | Titanium alloys (ISO 10993 certified), Cobalt-Chrome alloys with corrosion rate <0.1 mm/year |

These advancements lead to improved surgical outcomes and enhanced patient safety.

Implants and Prosthetics from Micro-MIM Technology

Micro-MIM Technology plays a vital role in producing implants and prosthetics. This technology allows for the creation of orthopedic implants, such as hip and knee joint components. The materials used, including 316L stainless steel and titanium alloys (e.g., Ti-6Al-4V), are recognized for their excellent biocompatibility and corrosion resistance. Key benefits include:

- The ability to create intricate geometries with tight tolerances, essential for optimal fit and function in joint replacements.

- Enhanced mechanical properties that improve the longevity and performance of implants.

Diagnostic Equipment Utilizing Micro-MIM Technology

Micro-MIM Technology is crucial for manufacturing components in diagnostic equipment. It contributes to various applications, including:

- Drug Delivery Systems: MIM technology is essential for producing components in these systems, ensuring precise dosages and reliable performance.

- Infusion Pumps: Internal components manufactured using Micro-MIM enhance the efficiency and reliability of these devices.

- Medical Imaging: MIM provides radiation shielding and precision alignment components, improving the accuracy of diagnostic imaging.

Additionally, Micro-MIM creates sophisticated parts for diagnostic tools, such as housings for endoscopy equipment and micro-surgical tools. This technology ensures that medical professionals have access to reliable and efficient diagnostic equipment, ultimately improving patient care.

Scalability and Business Benefits of Micro-MIM Technology

Cost Efficiency of Micro-MIM Technology

Micro-MIM Technology provides significant cost savings for manufacturers. By minimizing material waste and enhancing production efficiency, this technology proves especially beneficial in high-volume production scenarios. In sectors like aerospace and defense, the initial tooling costs become less burdensome as production scales up. As manufacturers produce larger quantities, the per-unit costs decrease substantially. This reduction occurs because the fixed costs of tooling are distributed over a greater number of parts, leading to improved profitability.

Production Speed with Micro-MIM Technology

Production speed is another critical advantage of Micro-MIM Technology. The streamlined process, which includes mixing, injection molding, debinding, and sintering, allows for rapid turnaround times. Manufacturers can produce complex components in a fraction of the time required by traditional methods. This efficiency is vital in industries where time-to-market is crucial. The ability to quickly adapt to changing demands further enhances the appeal of Micro-MIM Technology, enabling companies to respond swiftly to market needs.

Market Demand and Growth Potential for Micro-MIM Technology

The market demand for Micro-MIM Technology continues to grow, driven by its applications across various sectors. The automotive industry, which accounts for approximately 41.50% of the market, significantly influences this demand. The need for lightweight and high-strength components in vehicles propels the adoption of Micro-MIM Technology. Additionally, the increasing electrification of vehicles necessitates compact and precise metal components.

Advancements in material science and process automation further fuel this growth. These innovations enable manufacturers to produce intricate geometries, meeting the evolving requirements of industries such as medical devices and electronics. As the demand for Micro-MIM Technology expands, manufacturers must remain vigilant about potential challenges, including high initial tooling investment costs and the need for specialized expertise. Addressing these challenges will be essential for capitalizing on the growth potential of this transformative technology.

Future Potential of Micro-MIM Technology

Innovations on the Horizon for Micro-MIM Technology

The future of Micro-MIM Technology looks promising, with several innovations on the horizon. As industries demand more complex and precise components, manufacturers are exploring advanced techniques to enhance production capabilities. The integration of Industry 4.0 technologies, such as automation and real-time data analytics, is set to revolutionize the Micro-MIM landscape. These innovations will improve operational efficiency and enable the production of intricate designs that meet the evolving needs of sectors like aerospace and medical devices.

Expanding Industry Applications of Micro-MIM Technology

Micro-MIM Technology is rapidly expanding into high-precision sectors, including aerospace, medical devices, and automotive. This trend reflects a growing recognition of the technology’s ability to produce small, complex components with high accuracy. Regulatory changes promoting sustainability and digital traceability are driving innovation within the MIM sector. As manufacturers adopt these practices, they can enhance product quality while reducing environmental impact. The versatility of Micro-MIM allows it to adapt to various applications, making it a valuable asset across multiple industries.

Environmental Impact Considerations of Micro-MIM Technology

Micro-MIM Technology presents several environmental advantages compared to traditional manufacturing methods. Key points include:

- Micro-MIM is considered environmentally friendly and energy-saving compared to conventional injection molding methods.

- While it generates waste and consumes energy, it does so at a lower rate than many traditional processes.

- The injection molding process can produce byproduct waste, including defective products and plastic residues.

- The use of chemicals in injection molding poses environmental hazards.

- Traditional injection molding is energy-intensive, contributing to greenhouse gas emissions and air pollution.

- Sustainable practices, such as using renewable materials and optimizing production processes, can mitigate negative environmental impacts.

By focusing on sustainability, Micro-MIM Technology not only meets the demands of modern manufacturing but also aligns with global efforts to reduce environmental footprints. As the industry continues to innovate, the potential for Micro-MIM to contribute positively to both economic and ecological goals remains significant.

Micro-MIM Technology plays a pivotal role in modern manufacturing. Its advantages include:

| Advantage | Description |

|---|---|

| High Density | Micro-MIM enables the production of components with high density. |

| Smooth Surface Finish | The technology provides a smooth surface finish for the parts produced. |

| High Design Flexibility | Micro-MIM allows for greater design flexibility in mass production. |

As industries prioritize sustainability, Micro-MIM aligns with the demand for efficient manufacturing practices. The future of ultra-tiny component manufacturing looks promising. The micro-manufacturing equipment market is projected to grow at a CAGR of 5.9% from 2025 to 2034. Additionally, the integration of AI and automation technologies enhances micro-manufacturing processes, improving efficiency and reducing downtime. Industries such as medical devices, electronics, and automotive will continue to drive the demand for miniaturized components, necessitating high-precision micro-manufacturing tools.

FAQ

What is Micro-MIM Technology?

Micro-MIM Technology, or Micro Metal Injection Molding, is a manufacturing process that produces ultra-tiny metal components with high precision and complex geometries.

What industries benefit from Micro-MIM Technology?

Industries such as medical devices, automotive, and electronics benefit significantly from Micro-MIM Technology due to its ability to create intricate and precise components.

How does Micro-MIM Technology reduce waste?

Micro-MIM Technology achieves up to 98% material conversion efficiency, minimizing waste compared to traditional manufacturing methods, which often generate significant scrap.

What materials are commonly used in Micro-MIM?

Common materials include stainless steel, titanium, tungsten, and various alloys. These materials enhance the performance and durability of the final components.

What are the key advantages of Micro-MIM Technology?

Key advantages include high precision, design flexibility, reduced material waste, and the ability to produce complex geometries that traditional methods cannot achieve.

How does Micro-MIM Technology compare to traditional manufacturing methods?

Micro-MIM Technology offers superior precision, reduced waste, and faster production speeds compared to traditional methods like CNC machining and investment casting.

What is the future potential of Micro-MIM Technology?

The future of Micro-MIM Technology looks promising, with innovations in automation and material science driving growth across various industries, particularly in high-precision applications.

Can Micro-MIM Technology produce components for the aerospace industry?

Yes, Micro-MIM Technology can produce components for the aerospace industry, including lightweight and high-strength parts that meet stringent performance requirements.