Metal powder products

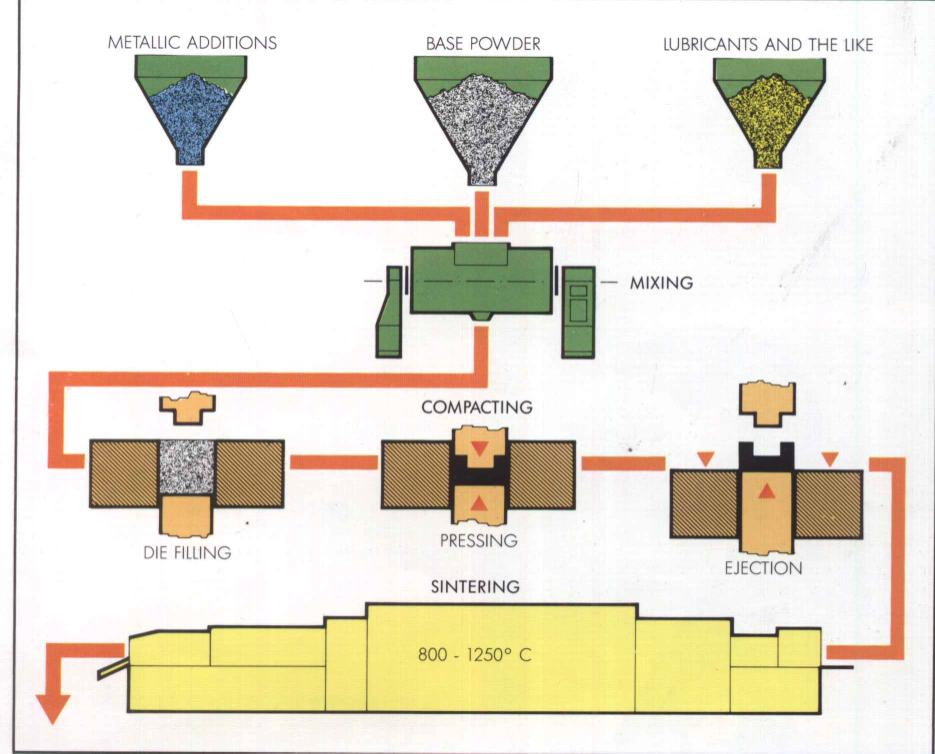

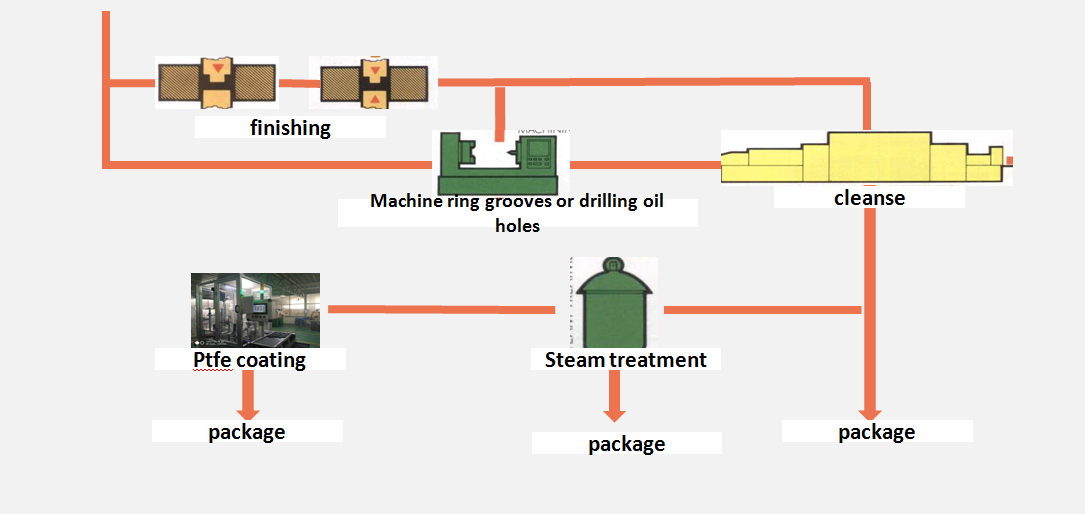

The metal powder product MPP is by mixing the required base powder (reduced iron powder or atomized iron powder) and additives, and then mixed powder is filled in the mold cavity with the required shape for pressing forming, and then forming body is sintered in a protective atmosphere to form a metallurgical combination of various particles, and the final powder metal product is obtained after finishing or post-processing.

Powder Metal Process

Advantages:

- Near net forming

- Complex shape

- Excellent dimensional accuracy.

- Desired mechanical properties

- Large scale production and good repeatability

- Surface finish

- Different material combinations are allowed

- Porosity and porosity control (self-lubricating materials)

- Good magnetic properties (soft magnetic materials)

Powder Metal Parts

JH MIM as a manufacturer of powder metal products, has 300 tons of press and 500 tons of press, please send your CAD drawings, we will provide you with a comprehensive solution for metal powder parts.

powdered metal sintering

Sintering process in powder metallurgy is a process in which the powder compact is heated and held at a temperature lower than the melting point of its main components, and then cooled in a certain way and speed to obtain the required strength and various physical and mechanical properties.

Classification of sintering furnace: push-rod sintering furnace mesh belt sintering furnace, at this stage, all enterprises are using mesh belt sintering furnace.

Structure of mesh belt sintering furnace:

Pre-burning stage: Preheat powder to crush and burn off lubricant

High temperature holding stage: The compact is held at the specified temperature for a long enough time to obtain the physical and mechanical properties required for the sintered part

Cooling stage: The compact is cooled slowly from high temperature to recrystallization temperature, and then cooled rapidly to obtain the final organizational structure of the sintered metal products.