Metal Injection Molding in the consumer electronics field

The vigorous development of the powder injection molding process and the explosive growth of consumer electronics complement each other.

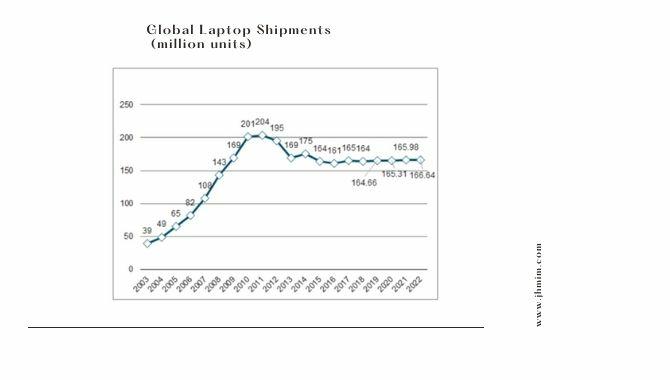

From 2000 to 2020, the consumer electronics industry has grown rapidly for 20 years, from laptops to pads, from smartphones to smart bracelets and smartwatches.

As can be seen from the table below, from 2000 to 2010, sales of notebook computers increased tenfold.

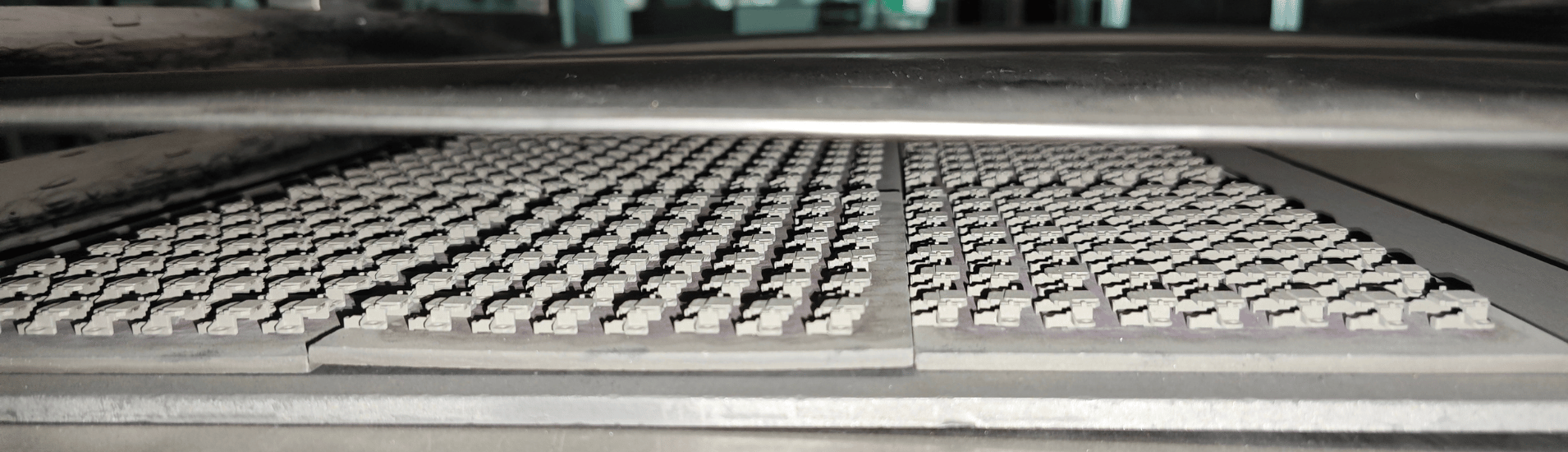

Electronic consumer products require miniaturization, high precision, and huge quantity, and electronic products are getting smaller and thinner, and the cost requirements are lower. This is the advantage of the metal powder injection molding industry, which makes the molding injection industry grow rapidly, and the proportion of the industry has soared from less than 5% to more than 50%!

Laptop hinges, metal cooling fan blades; mobile phone camera covers, SIM card trays, charging ports; electronic watch hinges, dials, clasps, etc.

Why JH MIM here>>>

Metal Injection Molding Consumer Product Solutions

JH MIM has focused on MIM manufacturing for around 20 years, and supplier of electronic equipment for Xiaomi, BBK, Huawei, etc. Rapid mold design, rapid sample provision, rapid quantitative production. Signed a strategic cooperation agreement with core customers. Grow with customers.