Tungsten alloy is one of the most valuable MIM materials to produce high-quality medical components, with its exceptional density of approximately 18.5 g/cm³. This remarkable metal injection molding (MIM) material brings great advantages to healthcare applications. Its unique blend of strength, biocompatibility, and antibacterial properties reduces infection risks and body rejection effectively.

Medical device manufacturing depends heavily on MIM material properties to ensure optimal performance. Engineers combine tungsten with precision engineering and create intricate components that meet tight tolerances—vital for surgical instruments and medical implants. Tungsten in MIM procedures saves substantial costs for manufacturing processes and healthcare providers. To cite an instance, tungsten surgical tools need fewer replacement tips during operations, so procedure times decrease, and efficiency improves. JH MIM has delivered precision-engineered tungsten alloy products to global customers in sectors of all sizes for nearly 20 years. The company serves aerospace, electronics, and especially medicine as a trusted MIM material supplier.

Why Tungsten Alloys Are Ideal for Medical MIM

Tungsten’s exceptional material properties make it the best choice for metal injection molding in medical applications. Tungsten alloys offer unique performance characteristics that other standard MIM materials don’t match, meeting critical healthcare needs effectively.

High Melting Point and Structural Integrity

Tungsten stands out with the highest melting point among metals at 3,422°C (6,192°F). Medical devices keep their structural integrity under extreme conditions because of this property. The material’s remarkable thermal resistance helps medical devices work perfectly even during high-temperature sterilization. Tungsten’s exceptional tensile strength makes it perfect for surgical instruments that need to handle stress without breaking or changing shape.

Tungsten’s thermal conductivity (173 W/(m·K) at 22°C) keeps sensitive medical components from overheating. Surgical tools benefit from this feature as it protects nearby tissues from heat damage. JH MIM brings 20 years of experience as a MIM material supplier and creates precision-engineered medical components that last through repeated use cycles.

Low Thermal Expansion for Dimensional Stability

Tungsten’s coefficient of thermal expansion matches glass, making it one of the most valuable MIM materials for medical use. Complex medical instruments need precise tolerances, and tungsten’s dimensional stability under thermal stress delivers exactly that.

Temperature changes barely affect MIM components’ dimensions and fit specifications. This stability makes tungsten alloys perfect for applications that need micro-feature replication and uniform density throughout. The risk of distortion during sintering drops significantly compared to other MIM materials.

Resistance to Corrosive Sterilization Environments

Medical devices must withstand repeated exposure to harsh sterilization environments and corrosive body fluids. Tungsten alloy resists corrosion well and maintains its integrity without degrading. This quality prevents harmful substances from being released.

Tungsten shows excellent biocompatibility, unlike some nickel-containing stainless steel variants that can trigger adverse reactions. The material’s non-toxic and inert properties minimize tissue reactions while its antibacterial features reduce infection risks. Surgical instruments made from tungsten-based MIM materials handle frequent autoclave sterilization well. They also resist harsh chemicals like chlorine wipes and ultrasonic cleaning solutions effectively.

Material Selection and Customization for Medical Use

Medical device manufacturers need to pick the right tungsten alloy composition that works best for their specific needs. They must find the right balance between hardness, how well it resists corrosion, and how compatible it is with the human body.

W-Ni-Fe vs W-Ni-Cu Alloys in Surgical Tools

The choice between tungsten-nickel-iron (W-Ni-Fe) and tungsten-nickel-copper (W-Ni-Cu) alloys will affect how surgical tools work and their performance. W-Ni-Cu alloys are better at conducting heat, which makes them perfect for tools that need to stay cool during procedures. W-Ni-Fe alloys, on the other hand, are denser and hold their shape better – a vital feature for tools that need to stay precise under pressure.

These alloy systems work well with the human body and fight bacteria effectively. This means there’s less risk of infection or rejection by the body. Surgeons can rely on these tungsten heavy alloys because they keep their shape even after sterilization and provide the perfect weight and balance needed for precise control.

MIM 4605 Material vs 440C MIM Material in Implants

MIM 4605 and 440C stainless steel each have their own strengths for medical implants. 440C MIM material is harder (49HRC) but barely stretches (1%), which isn’t ideal when movement is needed. MIM 4605 is more flexible – engineers can adjust its properties from 36HRC with 3% stretch to 48HRC with 2% stretch. This helps them find the right mix of strength and flexibility for each implant.

440C resists corrosion well but needs careful heat treatment and thorough cleaning. It’s best for special cases where maximum hardness is needed, while 4605 gives more options for adjusting material properties.

Role of MIM Material Supplier in Alloy Optimization

Quality MIM material suppliers are vital in making tungsten alloys work better for medical uses. Mi-Tech Metals gets the best raw materials and delivers consistent, high-quality products that meet exact specifications. Their quality control goes beyond simple standards. They run many tests to check material properties, sizes, and accuracy.

AMT and similar companies let customers choose from various alloys, including stainless steel, tungsten, and superalloys. These suppliers’ expertise helps manufacturers get exactly what they need for their specific uses. This kind of teamwork becomes more important as medical technology grows more complex and needs more specialized materials with exact properties.

Precision Engineering in Medical MIM Components

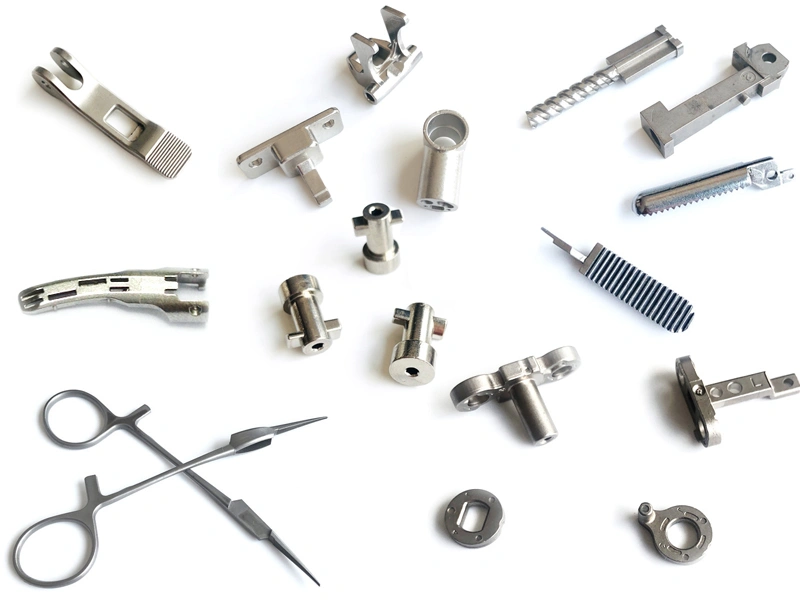

Precision engineering is central to medical tungsten alloy manufacturing through metal injection molding (MIM). This advanced manufacturing process provides clear benefits for complex medical components that need exact specifications and consistent performance.

Micro-Feature Replication in Tungsten MIM

MIM technology creates intricate tungsten components with complex geometries that would be impossible to make through regular machining methods. You can produce detailed features such as thin walls, internal cavities, and textured surfaces with high precision. The process combines the benefits of powdered metal technology with injection molding’s flexibility. Manufacturers can replicate micro-features consistently in large production runs. This precision becomes valuable for medical devices like surgical instruments and imaging equipment components.

Uniform Density and Non-Deforming Properties

Tungsten MIM components reach 98% theoretical density and deliver 67% higher tensile strength. They also provide 300% better wear resistance than conventional powder metallurgy’s 92% limit. The density-strength relationship follows an exponential curve instead of a linear progression:

- 92% density: 650 MPa tensile strength, large interconnected pores act as crack initiation sites

- 95% density: 850 MPa tensile strength (+31%), pores becoming isolated but still significant

- 98% density: 1,090 MPa tensile strength (+67%), minimal isolated pores, stress concentration eliminated

JH MIM has nearly 20 years of experience as a MIM material supplier. The company creates non-deforming components that keep their shape under stress – a vital requirement for medical applications.

Tight Tolerances in Complex Mold Designs

Precision in MIM mold design plays a vital role for medical components, with tolerances measured in microns. These tight dimensional requirements affect the quality of sintered parts. Advanced machining and metrology technologies help achieve these requirements. MIM produces small, high-performing precision products with tight tolerances consistently across high-volume runs. The process removes pressure gradients through fluid-phase pressure transmission and achieves ±0.5% pressure uniformity across complex geometries. This uniformity before sintering leads to consistent shrinkage, helping manufacturers meet strict medical device specifications.

Real-World Applications in Medical Devices

Tungsten MIM components play vital roles in healthcare because of their unique material properties. Medical professionals use these precision-engineered tungsten parts to solve complex challenges in healthcare.

Tungsten Ejector Pins in Injection Molding Systems

Crafts Technology produces high-precision CraftAlloy™ tungsten carbide ejector pins that excel in medical device molding. Their hardness and rigidity reduce core movement by a lot, which results in better precision for molded parts. These pins maintain uniform density and resist abrasion while staying non-deforming even in challenging molding conditions.

Tungsten Carbide Nozzles in Drug Delivery Devices

Drug delivery systems rely on tungsten carbide nozzles because they resist wear extremely well. These components can handle high operational temperatures and resist corrosion. Tungsten carbide provides the structural strength needed for precise medicine delivery in micronozzle applications.

Tungsten Needle Tips in Biopsy and Endoscopy Tools

Valleylab™’s tungsten microsurgical needle electrode delivers better cutting and coagulation with minimal heat spread. The ultra-sharp design, combined with fine tungsten wire, gives doctors precise control when they need to analyze tissue carefully. These needles maintain their shape throughout surgical procedures.

Tungsten Shielding in Radiation Therapy Equipment

Tungsten alloy’s density makes it perfect for radiation shielding in medical equipment – it’s almost twice as dense as lead. These components keep patients and healthcare workers safe from harmful radiation during treatments. Experts predict the North American medical tungsten alloy collimator market will grow 6-8% yearly over the next five years.

Conclusion

Tungsten alloy components made through Metal Injection Molding represent a breakthrough in medical device engineering. In this piece, we got into how tungsten’s exceptional properties make it perfect for demanding medical applications. Its remarkable density of 18.5 g/cm³, high melting point, and low thermal expansion set it apart. The material’s corrosion resistance and biocompatibility meet critical requirements for surgical instruments and implantable devices.

Choosing the right material plays a crucial role in designing tungsten MIM components. Manufacturers can customize specific properties by carefully balancing W-Ni-Fe and W-Ni-Cu alloys based on what they need. Surgical tools can then benefit from either better thermal conductivity or stronger structural integrity depending on their use.

MIM’s precision engineering capabilities boost tungsten’s value in medical applications. Manufacturers can create complex micro-features with uniform density and tight tolerances that traditional machining can’t achieve. This leads to medical devices that perform better and maintain consistent quality in every production run.

Ground applications show the real benefits of tungsten MIM components. These components deliver outstanding performance in demanding conditions – from ejector pins in molding systems to needle tips in surgical instruments. Maybe even more importantly, tungsten’s density makes it an excellent radiation shield that protects patients and healthcare professionals during treatment.

JH MIM brings 20 years of expertise to making precision-engineered tungsten alloy products. Their knowledge will give medical device manufacturers components that meet strict quality standards while leveraging tungsten’s unique properties. As medical technology keeps evolving, tungsten alloy components made through metal injection molding will definitely remain key to developing innovative, high-performance medical devices.

Key Takeaways

Medical tungsten alloy components manufactured through Metal Injection Molding (MIM) offer exceptional performance advantages for healthcare applications, combining superior material properties with precision engineering capabilities.

• Tungsten alloys provide unmatched density (18.5 g/cm³) and biocompatibility, making them ideal for surgical instruments and radiation shielding applications.

• MIM technology achieves 98% theoretical density in tungsten components, delivering 67% higher tensile strength than conventional powder metallurgy methods.

• Material customization between W-Ni-Fe and W-Ni-Cu alloys allows optimization for specific medical applications, balancing thermal conductivity and structural integrity.

• Precision engineering through MIM enables complex micro-features and tight tolerances essential for medical devices like needle tips and drug delivery nozzles.

• Real-world applications span from ejector pins in medical device molding to radiation therapy shielding, demonstrating tungsten’s versatility in healthcare technology.

The combination of tungsten’s exceptional material properties with MIM’s precision manufacturing capabilities creates medical components that deliver superior performance, durability, and safety in critical healthcare applications.

FAQs

Q1. What makes tungsten alloys ideal for medical applications? Tungsten alloys offer exceptional density, high melting point, low thermal expansion, and excellent corrosion resistance. These properties make them perfect for surgical instruments, implants, and radiation shielding in medical equipment.

Q2. How does Metal Injection Molding (MIM) enhance the production of medical tungsten components? MIM allows for the creation of complex geometries with tight tolerances and uniform density. This process achieves 98% theoretical density in tungsten components, resulting in higher tensile strength and better wear resistance compared to conventional manufacturing methods.

Q3. What are some real-world applications of tungsten MIM components in the medical field? Tungsten MIM components are used in various medical applications, including ejector pins for medical device molding, carbide nozzles in drug delivery devices, needle tips for biopsy and endoscopy tools, and radiation shielding in therapy equipment.

Q4. How do different tungsten alloys compare for medical use? W-Ni-Fe alloys offer greater density and structural integrity, ideal for tools requiring precise dimensions under stress. W-Ni-Cu alloys provide superior thermal conductivity, making them suitable for instruments needing heat dissipation during procedures. Both demonstrate excellent biocompatibility and antibacterial properties.

Q5. What role does a MIM material supplier play in medical component manufacturing? A quality MIM material supplier ensures the use of high-grade raw materials, maintains strict quality control, and offers expertise in alloy selection and optimization. They collaborate with manufacturers to select ideal solutions based on specific material properties required for medical applications.