Are you struggling to find a manufacturing process that can produce complex, high-precision metal parts without skyrocketing costs and excessive waste? Traditional manufacturing methods often fall short when it comes to creating intricate designs efficiently. This is where Metal Injection Molding (MIM) comes into play, offering a revolutionary solution for producing detailed and durable metal parts. By understanding what MIM parts are and their benefits, you can transform your manufacturing process, reduce costs, and improve product quality.

What Are MIM Parts?

MIM parts, or Metal Injection Molded parts, are components produced through the metal injection molding process, a sophisticated manufacturing technique that combines the versatility of plastic injection molding with the strength and integrity of powdered metallurgy. Here’s a breakdown of what MIM parts are:

Definition: MIM parts are created by mixing fine metal powders with a binder material to form a feedstock, which is then injected into a mold to shape the part. The molded part, called a “green part,” undergoes debinding to remove the binder, followed by sintering at high temperatures to fuse the metal particles together, resulting in a solid, high-density metal part.

Materials: MIM parts can be made from a variety of metals, including stainless steel, titanium, copper, and alloys such as nickel-chromium. The choice of material depends on the desired properties of the final part, such as strength, corrosion resistance, or thermal conductivity.

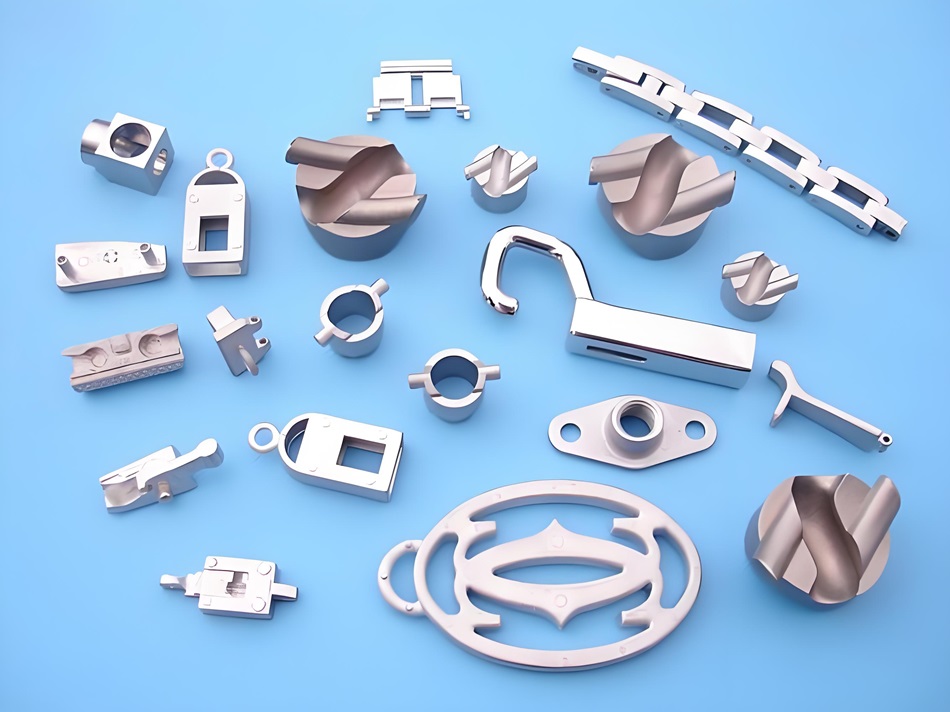

MIM PARTS

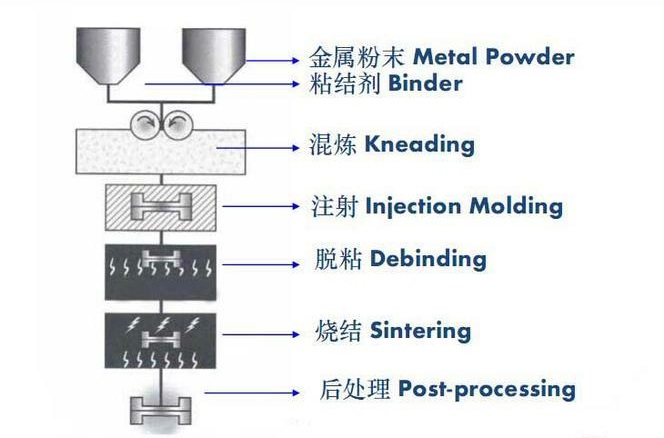

Process:

- Feedstock Preparation: Fine metal powders are mixed with a thermoplastic binder to create a homogeneous feedstock.

- Injection Molding: The feedstock is injected into a mold cavity to form the desired shape.

- Debinding: The binder is removed from the molded part, typically through a solvent or thermal process.

- Sintering: The debound part is heated in a controlled atmosphere to a temperature below the melting point of the metal, causing the metal particles to bond and form a dense, solid part.

MIM Parts Process

Advantages:

- Complex Shapes: MIM can produce parts with complex geometries that would be difficult or impossible to achieve with traditional manufacturing methods.

- Precision: The process allows for high precision and tight tolerances, often achieving tolerances as small as ±0.3% of the dimension.

- Material Efficiency: MIM uses up to 98% of the raw material, significantly reducing waste compared to subtractive manufacturing methods.

- Cost-Effective: Ideal for high-volume production, MIM reduces the need for extensive machining and minimizes material waste, lowering overall costs.

Applications:

MIM parts are used in various industries, including:

- Automotive: Components such as gearboxes, fuel injectors, and turbochargers.

- Medical: Surgical instruments, orthodontic brackets, and implantable devices.

- Consumer Electronics: Connectors, housings, and structural components.

- Aerospace: Turbine blades, sensors, and fasteners.

Now that we have a clear understanding of what MIM parts are and the advantages they offer, it’s important to delve deeper into how MIM parts stand out compared to traditional manufacturing methods. This comparison will highlight why MIM is becoming a preferred choice in various industries for producing high-precision, complex metal parts.

Differences Between MIM and Traditional Manufacturing

Process and Material Utilization

MIM Manufacturing:

- Involves injecting a metal-binder mixture into molds, allowing for the creation of intricate shapes with high material efficiency.

- Utilizes up to 98% of the input material, making it a more sustainable process with minimal waste.

Traditional Manufacturing:

- Includes processes like casting, forging, and machining, where metal is either melted and poured into molds or shaped by hammering or cutting.

- Typically generates more waste material and requires extensive post-processing to achieve final dimensions.

Energy and Cost Efficiency

MIM Manufacturing:

- Consumes less energy compared to traditional methods as it avoids melting metals and reduces extensive machining.

- Lower upfront costs due to process efficiency and reduced material waste, making it cost-effective for high-volume production.

Traditional Manufacturing:

- More energy-intensive, especially in processes like casting and forging that require high temperatures and significant mechanical work.

- Higher initial costs due to the need for more raw material and additional processing steps.

|

The compared results of important parameters in the production process |

||||

| Argument | MIM | Powder metallurgy process | Machining | Investment casting |

| Relative density (%) | 98 | 88 | 100 | 98 |

| Tensile strength | High | Low | High | High |

| Elongation | High | Low | High | High |

| Hardness | High | Low | High | High |

| Complexity | High | Low | High | Medium |

| Surface roughness | High | Medium | High | Medium |

| Production capacity | High | High | Low | Medium |

| Material range | Big | Big | Big | Medium-Big |

| Cost | Medium | Low | High | Medium |

Material Properties and Applications

MIM Manufacturing:

- Produces parts with tailored properties by mixing different metal powders, optimized for specific applications like wear resistance or high-temperature performance.

- Ideal for small, intricate parts with high dimensional accuracy, commonly used in automotive, aerospace, medical, and consumer electronics industries.

Traditional Manufacturing:

- Produces parts with superior mechanical properties due to processes like forging that align the metal’s grain structure.

- Suited for large, high-stress components where maximum strength and impact resistance are critical.

Common Metals Used in MIM Parts

The most common metals used in MIM include:

- Stainless Steel: For corrosion-resistant parts in medical, automotive, and consumer applications.

- Titanium: Used in aerospace and medical applications for its high strength-to-weight ratio and biocompatibility.

- Copper: For electrical and thermal applications due to its excellent conductivity.

- Nickel-Chromium Alloys: Known for their strength and resistance to high temperatures and corrosion.

- Tungsten Carbide: Essential for cutting tools and wear-resistant parts.

These metals are chosen based on the desired characteristics of the final component, such as strength, wear resistance, or corrosion resistance.

| Dimension(mm) | Standard Tolerance(mm) | Special Tolerance(mm) |

| 0~5 | ±0.05 | ±0.025 |

| 5~10 | ±0.07 | ±0.03 |

| 10~20 | ±0.10 | ±0.05 |

| 20~50 | ±0.30 | ±0.10 |

| 50~100 | ±0.50 | ±0.2 |

| Characteristic | Best(±) | General (±) |

| Angle | 0.1° | 2° |

Conclusion

Metal Injection Molding (MIM) is a revolutionary manufacturing process that combines the strengths of plastic injection molding and powdered metallurgy to produce high-precision, complex metal parts. MIM parts offer significant advantages in terms of material efficiency, precision, and cost-effectiveness, making them ideal for a wide range of applications in automotive, medical, aerospace, and consumer electronics industries. By leveraging the benefits of MIM, manufacturers can achieve greater design flexibility, reduce waste, and improve product quality. Whether you are looking to enhance your production capabilities or seek innovative solutions for complex metal components, MIM provides a versatile and efficient option.