Metal Injection Molding (MIM) materials have revolutionized the manufacturing of complex metal components for high-end eyewear. Eyewear manufacturers who use MIM technology can produce between 80,000 to 100,000 frames each month. This impressive production capability shows why MIM has become a crucial part of our industry.

Metal Injection Molding represents an innovative powder metallurgy near-net forming technology that brings modern plastic injection molding techniques into metal manufacturing. MIM materials prove especially valuable for eyewear by knowing how to create parts with incredibly complex shapes. The technology can apply virtually all structures achievable through injection molds to MIM products. The choice of MIM materials’ properties also shapes the final product’s performance, durability, and application.

This piece explores how MIM metals like stainless steel, titanium alloys, and other specialized alloys are revolutionizing high-end eyewear manufacturing. We’ll get into their unique mechanical properties, applications in different eyewear components, and the reasons leading manufacturers increasingly choose this versatile technology.

Understanding MIM in Eyewear Manufacturing

The manufacturing world has welcomed a revolutionary process that works wonders when creating complex metal components. Let’s look at how this technology works and why high-end eyewear production can’t do without it.

What is Metal Injection Molding (MIM)?

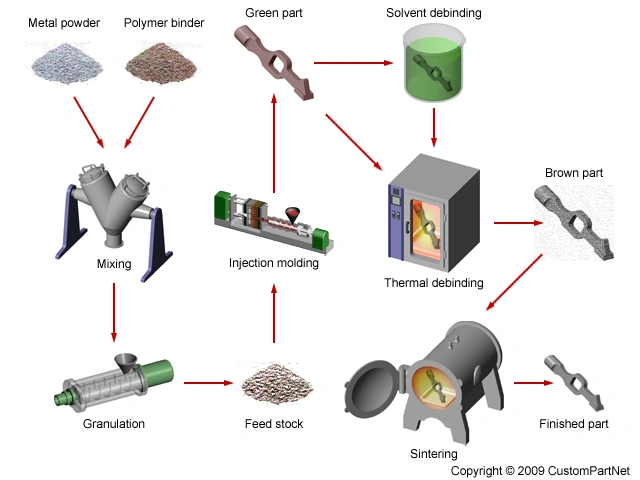

Metal Injection Molding brings together the best of plastic injection molding’s design flexibility with traditional metal manufacturing’s strength and integrity. The process starts when fine metal powders (typically 1-20 μm in size) mix with thermoplastic binders. The mix ratio sits at about 60% metal by volume (90% by weight). This blend creates a feedstock that behaves like plastic during injection but ends up as solid metal components.

MIM happens in several key stages. The feedstock heats up and flows into precision molds. Once it cools, you get what’s called a “green part.” The next step removes the binder material. The final stage, sintering, happens at temperatures close to the metal’s melting point (typically 1,200–1,400°C). This fuses the metal particles. The part shrinks evenly by 15-20% in every direction and reaches an impressive 96-99% of theoretical full metal density.

How MIM Is Different from Traditional Metal Forming

MIM stands out from regular metal forming techniques with unique benefits that make it perfect for specialized jobs. The technology lets designers create complex 3D shapes that would be impossible any other way. You can easily add intricate features, such as threads, cavities, and holes, to designs.

The quality stays consistent thanks to several factors. Automation runs through the whole process, so each part comes out the same. The metal powders used keep their composition and size super consistent, which means less variation in the final parts. The controlled environment also keeps contamination and defects away.

Money-wise, MIM makes sense too. Automation cuts labor costs compared to old-school metal forming. Everything gets used, so there’s hardly any waste or extra expenses. Traditional methods often require parts to be made separately and then assembled, but MIM accomplishes this in one step.

Why MIM Is Perfect for Eyewear Components

Spectacle frames have become a huge market for Metal Injection Molding. The technology opens up new design possibilities and lets manufacturers produce high volumes at good prices. Yes, it is great at making metal parts with complex structures and small sizes – exactly what modern eyewear needs.

To name just one example, see the rotating MIM spring hinges. These game-changers just can’t be made cost-effectively any other way. Picture two rotating disks at a 27° angle that give the spectacle temple a spring effect. They weigh just 2.6g and use 316L stainless steel.

MIM shines in eyewear production because it:

- Gets very precise with tolerances down to ±0.1% (though ±0.5% happens more often)

- Works with many metals, including stainless steel, titanium alloy, and aluminum alloy

- Makes precision hinges, spring mechanisms, decorative metal inlays, and nose pad armatures

- Uses less material and energy than traditional methods

The optical industry sees higher production efficiency with MIM technology in lens components, optical instruments, camera modules, and laser accessories. Luxury eyewear brands can now explore unprecedented design possibilities while keeping the premium material quality their customers expect.

Key MIM Materials Used in High-End Eyewear

Material selection in Metal Injection Molding plays a vital role in how well high-end eyewear performs and lasts. The eyewear manufacturing industry has seen several specialized MIM materials emerge as leaders, each bringing unique benefits to specific uses.

MIM 316L Stainless Steel for Corrosion Resistance

MIM 316L stainless steel shines as an austenitic, food-grade material that gives exceptional protection against corrosion in eyewear parts. This alloy works great when exposed to acids, which makes it perfect for frames that come into contact with sweat and environmental elements. The material’s impressive elongation properties of ≥40% and tensile strength of ≥450 MPa deliver both toughness and flexibility.

MIM 316L’s high sintered density reduces surface porosity, which stops contaminants from building up. This is a big deal as it means that the eyewear stays hygienic where it touches the skin. High-end eyewear manufacturers often employ this material for parts that need superior polish and excellent ductility.

MIM 17-4 PH for High Strength Applications

17-4 PH stainless steel gives the best results for eyewear parts that need exceptional strength. This precipitation-hardening martensitic stainless steel contains about 17% chromium and 4% nickel, striking a perfect balance between strength and corrosion resistance. Manufacturers can achieve various hardness levels from 25-30 HRC (as-sintered) to 40 HRC (heat-treated) through different heat treatments.

17-4 PH’s versatility makes it especially valuable for eyewear hinges and parts that bear weight. Heat treatment to H900 condition pushes its tensile strength to an impressive 1206 MPa while keeping good elongation at 9%. The H1100 treatment offers a balanced 1000 MPa strength with 12% elongation for applications needing better toughness.

Titanium Alloys (Ti-6Al-4V) for Lightweight Frames

Ti-6Al-4V alloy is the lifeblood of premium lightweight eyewear. This alloy weighs just 4.5g/cm³ – nowhere near as heavy as stainless steel – which makes it super comfortable for wearing all day. Notwithstanding that, it keeps impressive mechanical properties with 950 MPa tensile strength and 920 MPa yield strength.

The material combines high strength-to-weight ratio, excellent corrosion resistance, and biocompatibility perfectly for luxury eyewear frames. It also lets frames bend without breaking, which adds comfort and helps them handle daily stress better.

Cobalt-Chromium Alloys for Biocompatibility

Cobalt-chromium alloys bring special benefits to eyewear that sits against the skin for long periods. These non-magnetic alloys are great for people with metal sensitivities because they’re highly biocompatible. Co-Cr alloys like ASTM F75 keep looking good even after lots of contact with sweat, thanks to their superior corrosion resistance and wear properties.

Co-Cr alloys typically score above 38 on the Pitting Resistance Equivalent Number, suggesting they resist corrosion exceptionally well. Luxury eyewear designed for long-term use in different environments benefits greatly from this feature.

BASF MIM Materials vs Indo MIM Materials

Different suppliers bring their strengths to MIM materials for eyewear manufacturing. BASF’s Catamold evo line has specialized 17-4PH and 316L stainless steel feedstocks that work great for things like smartphone frames and connectors. Indo-MIM offers a complete range of materials, including stainless steels, titanium alloys, and specialized copper alloys that deliver exceptional material integrity.

JH MIM brings nearly 20 years of expertise in Metal injection molding and Powder metallurgy. Their factories span more than 18000 square meters and house world-class equipment. With 150 skilled workers, they deliver precision-engineered products to customers worldwide, making them China’s best Metal Injection Molding manufacturer.

Mechanical Properties of MIM Materials in Eyewear

Physical performance of MIM materials determines high-end eyewear quality and durability. Testing these components mechanically reveals performance characteristics that you cannot detect through visual inspection alone. The data shows how parts perform in ground conditions.

Tensile Strength and Flexural Modulus in Frame Components

Daily stress on eyewear frames depends heavily on tensile properties. MIM creates parts with 96-99% density, which is much higher than other metal forming processes. This results in a strength that matches wrought metals. Lab tests show impressive results:

- MIM 316L stainless steel delivers tensile strength ≥450 MPa and stretches remarkably by ≥40%

- MIM 17-4 PH stainless steel (sintered) reaches ≥950 MPa tensile strength with 730 MPa yield strength

- Ti-6Al-4V titanium alloy hits 880 MPa tensile strength and stretches by 12%

Standardized tests show that MIM titanium alloys can reach ultimate tensile strength up to 800 MPa and stretch above 15%. These properties help eyewear frames keep their shape under stress while staying flexible enough for comfort.

Impact Resistance in Hinges and Temples

Eyewear hinges deal with constant stress from opening and closing. MIM technology has changed everything here. Reports show MIM components boost impact resistance by 62% and tensile strength by 33% compared to regular alternatives.

Italian design engineer Guido Medana created innovative “Spine” eyeglass hinges with MIM technology. These hinges use interlocking “vertebrae” with a spun wire cable running through springs. This tough, self-closing hinge absorbs shocks from all angles and reduces breakage by a lot.

Dimensional Accuracy and Surface Finish

Precision is vital for eyewear components. MIM maintains tolerances of ±0.3% (minimum of ±0.075mm/0.003″). Some manufacturers typically achieve ±0.5%. This accuracy ensures complex components like spring hinges fit and work properly.

Surface quality stands out as another benefit. As-sintered MIM parts come with smooth surfaces that need minimal finishing. The uniform structure and high density (over 98% of theoretical density) create exceptional physical properties, including strength, hardness, and stretch capability.

Wear Resistance in High-Contact Areas

Areas with frequent contact and friction need special attention. Hardness testing reveals how MIM materials resist permanent deformation. Common testing methods include:

- Rockwell: Quick production control test with direct readout

- Vickers: Versatile test that works on all solid materials

- Knoop: Choice for brittle materials and thin layers

- Brinell: Best for larger samples with coarse-grain structures

MIM 17-4 PH stainless steel shows 25-30 HRC hardness when sintered. MIM 440C stainless steel (heat-treated) reaches an impressive 655 HBS hardness value. These properties make it perfect for high-wear components like hinges and adjustment mechanisms.

Applications of MIM in Eyewear Components

Metal injection molding revolutionizes high-end eyewear design by creating precise, innovative components. MIM materials bring sophisticated functionality to modern frames through tiny mechanical elements and eye-catching decorative features.

Precision Hinges and Spring Mechanisms

The rotating MIM spring hinge stands out as a breakthrough application. It consists of two rotating disks at a 27° angle that help swivel the spectacle temple with a spring effect. These lightweight components weigh just 2.6g and are made from 316L stainless steel. The innovative “Spine” hinge system takes this further by using micro-injected metal vertebrae that flex in every direction without needing adjustments. The design absorbs impacts by moving in multiple directions, which makes breakage much less likely. Some MIM hinge components are incredibly light at 0.028g, yet manufacturers produce over 4 million parts yearly.

Decorative Metal Inlays and Logos

Luxury eyewear brands set themselves apart with metal inlays and logos. To name just one example, premium frames feature custom metal inlays on temples and metal plates on acetate ends. These decorative elements show off MIM’s precision capabilities as intricate logos and patterns blend naturally into frame designs.

Bridge and Nose Pad Armatures

MIM technology produces sophisticated bridge components and nose pad armatures that balance structural strength with comfort. Premium nose pads use MIM components made from titanium. These components undergo ion plating to create skin-friendly, hypoallergenic surfaces.

Temple Tips and End Pieces

Temple tips – the arms extending across the wearer’s temples – play a crucial role in comfort. MIM processes create precise metal core components that manufacturers cover with silicon, acetate, or plastic. These tips create a comfortable barrier between the wearer and the metal core. Replacement tips come in various colors and materials with standard inner core diameters of 1.35mm, 1.45mm, and 1.60mm.

Advantages of MIM for Luxury Eyewear Brands

Luxury eyewear brands are happy to adopt MIM materials technology to expand their design capabilities beyond traditional constraints. MIM processes give distinct competitive advantages that optimize both esthetic and production concerns.

Design Freedom for Complex Geometries

MIM gives unmatched design freedom to create intricate metal components. Designers can add complex shapes, internal features, and tight tolerances that would cost too much or be impossible through conventional machining. Luxury brands can develop distinctive elements like microscopic details, artistic textures, and signature patterns that separate their products in the high-end market. Features that typically need multiple machining operations can be produced in a single MIM process.

High Volume Production with Consistent Quality

Premium eyewear manufacturers face a big challenge to scale production without losing quality. MIM works best in high-volume scenarios where components from thousands to millions of parts are needed annually. The automated MIM process will give exceptional repeatability, and each part shows consistent tolerance control and structural integrity. Manufacturers can scale faster from producing a few hundred pieces daily to more than hundreds of thousands per day with minimal adjustments.

Material Efficiency and Minimal Waste

MIM shows remarkable material efficiency. This is a big deal as it means that utilization rates are above 95% in many applications. The controlled powder metallurgy process minimizes excess and discarded materials. Sprues and runners can be reground and reused as feedstock without compromising final properties. These green manufacturing practices deliver cost advantages through optimized material usage.

Integration with Acetate and Titanium Frames

MIM components blend naturally with other premium frame materials. The technology works especially well when you have decorative inlays for acetate frames and functional components for titanium structures. Matrix, a leading MIM manufacturer, developed the patented Easyflex screwless hinge to maximize MIM benefits while offering greater customization options to eyewear designers. This integration capability helps luxury brands combine the aesthetic appeal of traditional materials with the functional advantages of precision-engineered MIM parts.

Conclusion

Metal Injection Molding has altered the map of high-end eyewear manufacturing completely. This piece explores how MIM materials deliver exceptional performance characteristics that traditional manufacturing methods cannot match. Creating intricate components with remarkable precision while retaining structural integrity has become a game-changer for luxury eyewear brands.

MIM materials deserve recognition for their versatility. Manufacturers now have unmatched options to balance esthetics, comfort, and durability – from corrosion-resistant 316L stainless steel to lightweight titanium alloys. The mechanical properties achieved through MIM create eyewear that performs better and lasts longer, with superior tensile strength, impact resistance, and dimensional accuracy.

MIM’s value lies in its consistent quality at scale. Luxury brands maintain their exacting standards while meeting growing market needs. Many high-end manufacturers now prioritize sustainability, which makes material efficiency and minimal waste aspects perfect for their initiatives.

JH MIM stands as your best Metal Injection Molding manufacturer in China. The company brings nearly 20 years of experience in Metal Injection Molding and Powder Metallurgy, with 18,000 square meters of facilities and 150 skilled workers, delivering precision-engineered products to global customers.

Revolutionary spring hinges and decorative inlays showcase how MIM makes designs possible that would otherwise remain conceptual. This technology connects artistic vision with technical feasibility, letting designers challenge boundaries while ensuring practical wearability.

MIM materials represent more than manufacturing advancement – they mark a radical alteration in high-end eyewear possibilities. Brands that accept new ideas gain competitive advantages in design differences, production optimization, and product performance. State-of-the-art Metal Injection Molding technology will, without doubt, keep shaping luxury eyewear.

Key Takeaways

MIM technology is revolutionizing high-end eyewear manufacturing by enabling complex designs, superior materials, and efficient production that traditional methods cannot achieve.

• MIM enables production of 80,000-100,000 frames monthly with 96-99% metal density, delivering strength comparable to wrought metals in complex geometries.

• Key materials like 316L stainless steel, 17-4 PH steel, and Ti-6Al-4V titanium offer superior corrosion resistance, strength, and lightweight properties for premium eyewear.

• MIM components achieve exceptional precision with ±0.3% tolerances while improving impact resistance by 62% and tensile strength by 33% over conventional alternatives.

• Revolutionary applications include 2.6g rotating spring hinges, microscopic “Spine” vertebrae systems, and decorative inlays impossible to manufacture economically through traditional methods.

• Luxury brands gain 95%+ material efficiency, seamless integration with acetate and titanium frames, and scalable high-volume production without compromising quality.

The technology bridges artistic vision with technical feasibility, allowing designers to create distinctive, durable eyewear components that enhance both performance and esthetics while supporting sustainable manufacturing practices.

FAQs

Q1. What is Metal Injection Molding (MIM) and how does it benefit eyewear manufacturing? Metal Injection Molding is a process that combines the design flexibility of plastic injection molding with the strength of traditional metal manufacturing. It allows for the creation of complex metal components with high precision, making it ideal for producing intricate eyewear parts like hinges and decorative elements.

Q2. Which materials are commonly used in MIM for high-end eyewear? Common MIM materials for high-end eyewear include 316L stainless steel for corrosion resistance, 17-4 PH stainless steel for high strength applications, titanium alloys (Ti-6Al-4V) for lightweight frames, and cobalt-chromium alloys for biocompatibility.

Q3. How does MIM improve the durability of eyewear components? MIM components demonstrate superior mechanical properties, including high tensile strength and impact resistance. For example, MIM parts can improve impact resistance by 62% and tensile strength by 33% compared to conventional alternatives, resulting in more durable eyewear.

Q4. What unique design possibilities does MIM offer for luxury eyewear brands? MIM allows for the creation of complex geometries and intricate details that would be difficult or impossible to achieve with traditional manufacturing methods. This enables luxury brands to incorporate distinctive elements like microscopic details, artistic textures, and signature patterns into their eyewear designs.

Q5. How does MIM contribute to sustainable manufacturing in the eyewear industry? MIM demonstrates remarkable material efficiency, with utilization rates exceeding 95% in many applications. The process minimizes waste, as excess materials can often be reground and reused as feedstock without compromising final properties. This supports sustainable manufacturing practices while also providing cost advantages.