How Magnesium Alloy Density Shapes Modern Engineering: From Aerospace to Electronics

Magnesium alloys are among the lightest structural metals available, which makes them valuable for engineering projects where weight matters. These materials stand out as the top choice for lightweight construction, offering better specific strength and damping abilities than strong aluminum alloys and alloy steels. Their impressive strength-to-weight ratio has made them popular in industries that need to cut weight without losing performance.

The makeup of magnesium alloys includes magnesium mixed with elements like aluminum, zinc, manganese, silicon, copper, and rare earth metals. Most commercial versions contain 3 to 13 percent aluminum. These combinations create materials with unique properties, even with their distinctive hexagonal lattice structure. This crystal arrangement leads to strong anisotropy and limits how easily the material can be shaped at room temperature. Engineers see this as both a challenge and an opportunity.

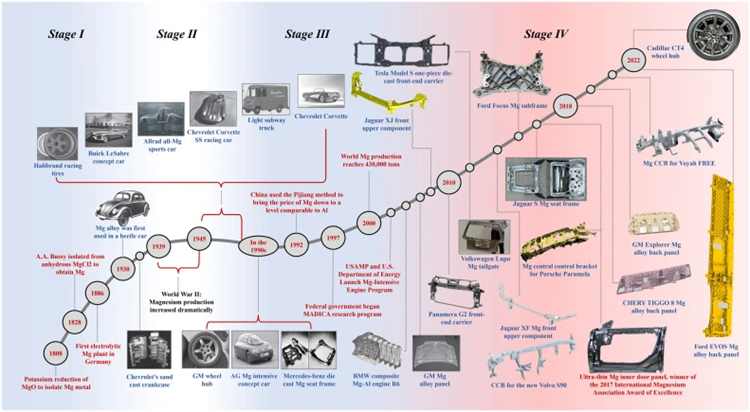

These alloys have become essential in the automotive, aerospace, and electronics industries, where lightweight but reliable materials make a difference. Adding magnesium components helps vehicles weigh less and perform better – from faster acceleration to better braking and fuel savings. The aerospace industry uses these alloys to create lighter aircraft structures that work more efficiently. The next sections will show how magnesium alloys’ density impacts modern engineering in different fields and look at specific alloy types and where they work best.

Why Magnesium Alloy Density Matters in Modern Design

Magnesium alloys’ low density revolutionizes modern engineering design approaches. These alloys weigh just 1.74 g/cm³, which is 35% less than aluminum (2.7 g/cm³) and 77% less than steel (7.8 g/cm³). This weight advantage plays a key role in industries where reduced mass affects performance, efficiency, and functionality.

Specific strength and stiffness advantages

Magnesium alloys go further than just being lightweight – they boast impressive specific strength (strength-to-density ratio). Some magnesium-lithium-aluminum alloys achieve specific yield strengths around 350 kN·m/kg, which outperforms most engineering alloys. A BCC β-phase Mg-14Li-7Al alloy combines ultralow density (1.32 g/cm³) with high yield strength to achieve a specific strength of 470-500 kN·m/kg.

Magnesium shows remarkable efficiency in stiffness when engineered correctly. A magnesium section with double the depth of a steel component provides 70% more rigidity at half the weight. Compared to aluminum, a magnesium part needs only 75% of the weight to match rigidity. This makes magnesium alloys valuable where both lightness and structural rigidity matter.

Role in lightweight structural engineering

Magnesium alloys excel at reducing weight without sacrificing performance in structural engineering. Cars become more fuel-efficient – a 10% weight reduction boosts fuel economy by 5-10%. Each kilogram saved in a 1000 kg car improves mileage by 0.016 km/l.

These materials benefit industries of all types:

- Aerospace: Lighter aircraft parts mean better maneuverability and lower launch costs

- Automotive: Parts like steering wheels, seat frames, and engine blocks reduce inertia and handle better

- Electronics: The 3C sector uses magnesium’s functional and structural benefits together

Magnesium alloys offer more than weight savings:

- High damping capacity

- Superior thermal conductivity

- Electromagnetic interference shielding

- Potential flame retardancy through proper alloying

Comparison with magnesium-aluminum alloy density

Aluminum remains magnesium’s most common alloying element, significantly affecting density and mechanical properties. Magnesium-aluminum alloys typically contain 3-13% aluminum, which improves castability and strength while keeping density low.

AZ91, the most common magnesium-aluminum alloy, balances castability and strength perfectly. AM60 alloys trade some strength for better ductility, making them ideal for car crash zones.

Magnesium alloys with rare earth elements offer even higher specific strength. These alloys stay lightweight while solving traditional magnesium problems like poor corrosion resistance and weak high-temperature performance.

Engineers can fine-tune magnesium alloy density by carefully choosing alloying elements. This allows them to balance weight, strength, stiffness, and functional properties based on specific design needs.

Aerospace Engineering: Reducing Mass Without Compromising Strength

The aerospace industry has adopted magnesium alloys as key materials to achieve “gram-by-gram optimization” in lightweight design. Magnesium alloys are ideal candidates for critical aerospace components because their density is just two-thirds of aluminum’s, which gives them unique potential for specific strength and stiffness. This weight reduction affects both the performance and economic viability of aircraft and spacecraft systems.

Use of WE43 and AE42 in high-temperature aerospace parts

High-temperature aerospace applications now rely more on specialized magnesium alloys like WE43 and AE42. WE43, which contains 4 wt%Y, 3.3 wt%RE, and 0.5 wt%Zr, shows much better mechanical properties at room and elevated temperatures. Rare-earth elements boost mechanical performance and provide better corrosion and heat resistance through solid solution strengthening and precipitation strengthening effects.

New economical die-casting magnesium alloys like DieMag633 and MRI230D show exceptional specific strength at high temperatures, going beyond traditional alloys like AZ91 and AM50/60. These materials now work in helicopter tail reduction gearboxes, fighter wing ribs, rotor lead wire pressure plates, and key components in aircraft, missiles, and spacecraft.

A game-changing moment came in 2024 when China’s Tianzhou-8 cargo spacecraft mission used a large-scale complex-structure functional integrated magnesium alloy adapter component. The team overcame many technical challenges to ensure stable equipment functionality and reliable load-bearing capacity.

Density-driven fuel efficiency improvements

Magnesium alloys’ lightweight nature brings real benefits to aerospace applications. Aircraft components weigh less, which cuts emissions and boosts fuel efficiency. This makes operations more environmentally responsible and economical. Lower weight in spacecraft reduces launch costs, and lighter payload mass in intercontinental missiles cuts the takeoff weight of launch vehicles.

Magnesium offers more than just weight reduction. These alloys have excellent damping capacity that reduces fatigue and wear in components that face constant vibrations. On top of that, they provide better electromagnetic shielding, thermal conductivity, and impact resistance than low-density plastics, especially in extreme temperatures.

Creep resistance in magnesium rare-earth alloys

Creep resistance is crucial for aerospace applications – it’s knowing how to resist time-dependent inelastic deformation at high temperatures. Magnesium-rare earth-based alloys show exceptional creep resistance at elevated temperatures, making them great candidates for critical aerospace components.

Rare earth elements boost creep resistance through several mechanisms:

- Formation of precipitates that effectively restricts dislocation movement on dominant slip systems

- Increasing dissociation energy, which hinders activated cross-slip

- Raising out-of-plane migration energy, creating greater energy penalties for dislocation climb

These improvements change the alloy’s electronic structure by adding covalent character that strengthens bonds. Zn addition to Mg-Nd-La alloy, which improved creep life by 600% in some cases, which relates to the precipitation of a new phase on critical planes of hexagonal close-packed magnesium.

Scientists continue to develop magnesium alloys for aerospace applications. Surface treatments like plasma electrolytic oxidation improve corrosion resistance, while new manufacturing processes allow more complex shapes. Without doubt, magnesium alloys will become more important in future aerospace design, where the main goal remains reducing mass without losing strength.

Automotive Sector: Enhancing Safety and Efficiency

Magnesium alloys have become a vital material choice for car manufacturers who want to reduce weight without compromising passenger safety. The automotive industry wants to use about 350 lbs (159 kg) of magnesium components in vehicles by 2020. This marks a dramatic increase from just 10 lbs (4.5 kg) used in 2005. Magnesium’s unique properties make it perfect for meeting strict emissions regulations – it weighs 75% less than steel and 33% less than aluminum.

AM60B and AZ91D in crash zones and dashboards

Two magnesium alloys stand out in automotive safety applications because of their unique properties. AM60B alloy works great in die-cast automotive safety components, particularly instrument panel structures and seat frames. The alloy provides excellent ductility and absorbs energy effectively. These properties make it a vital component in crash zones where impact absorption directly affects passenger safety. The alloy’s 10-15% elongation helps absorb impact in crush zones, while traditional steel components would simply shear.

AZ91D leads the pack as the most popular magnesium high-pressure die-casting alloy. It combines an excellent strength-to-weight ratio with superior castability. These features make it perfect for powertrain and mechanical components that need toughness more than deformation capability. General Motors now uses die-cast magnesium in steering wheels, instrument panels, and roof-panel frames in almost every vehicle they make.

Fuel economy gains from lightweight frames

Weight reduction through magnesium use leads to clear efficiency improvements. Cars that weigh 10% less can achieve 6%-8% better fuel economy. Research shows that cutting vehicle weight by 100 kg reduces fuel consumption by about 0.5 L/100 km.

Car engineers must speed up their lightweighting strategies to meet stricter fuel efficiency laws. Magnesium substitution could help reduce vehicle weight by 20% after 2020. These benefits go beyond fuel savings – lighter vehicles accelerate better, handle more smoothly, and brake more effectively.

Corrosion resistance in underbody components

Corrosion resistance remains a key challenge for magnesium in cars, but engineers have made great progress. Regular magnesium alloys are prone to corroding easily, especially in humid conditions or when exposed to salt water. Modern magnesium alloys now feature fewer impurities and better properties, often paired with REACH-compliant protective coatings.

A new magnesium-calcium alloy shows remarkable corrosion resistance. It stays intact even after six months in a 3.5wt% NaCl solution. This breakthrough lets manufacturers use magnesium in underbody parts that were previously off-limits. Plasma electrolytic oxidation (PEO) offers another solution by improving corrosion and wear resistance for automotive components and sub-assemblies.

Car manufacturers continue pushing for lighter vehicles, and magnesium alloy use should grow from 3.6 kg per vehicle in 2016 to 11.5 kg by 2030.

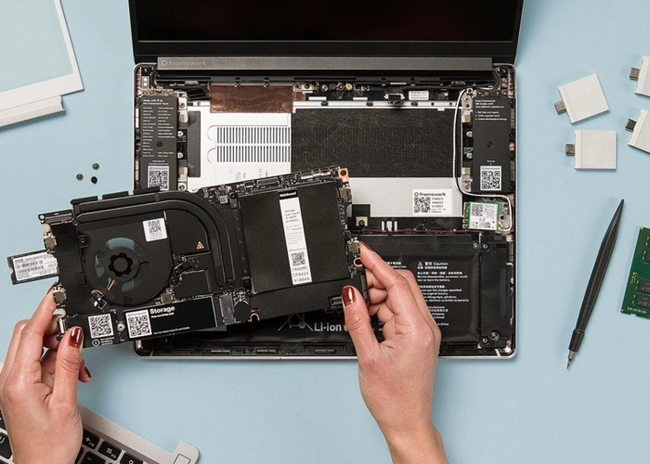

Consumer Electronics: Compact, Durable, and Lightweight

Magnesium alloys help consumer electronics manufacturers solve a constant challenge: creating devices that are lighter, stronger, and more functional. The remarkably low density of magnesium materials makes them perfect for portable devices where weight matters.

Magnesium alloy products in smartphones and laptops

Electronics companies use magnesium alloys for casings and structural components in smartphones, tablets, and laptops because of their exceptional strength-to-weight ratio. Magnesium laptop parts are 20 times stronger than typical thermoplastics. Major manufacturers have embraced these materials extensively. Lenovo’s ThinkPad T14 now features keyboard frames made from 90% recycled magnesium. The 2024 LG Gram stands out as the world’s lightest 16-inch laptop at just 1.36 kg, which is 30% lighter than its competitors.

Electromagnetic shielding and heat dissipation

Magnesium alloys offer more than structural benefits for electronic device performance. These alloys shield against electromagnetic interference without needing fillers or additives. Their natural EMI shielding capabilities protect sensitive electronic components from external electromagnetic radiation effectively.

Heat management adds another significant advantage. Specialized high-conductivity magnesium alloys like ZC0505 reach thermal conductivity values of 160.1 W/(m·K). This performance surpasses common structural materials such as iron (80 W/(m·K)) and titanium (22 W/(m·K)). Electronic devices become more powerful and compact each year, making efficient heat dissipation vital to prevent thermal stress and extend component life.

Thin-wall casting for miniaturized components

The exceptional thin-wall casting capabilities of magnesium alloys allow manufacturers to produce intricate components with complex geometries. These thin-walled structures maintain their strength, unlike many other materials. New manufacturing techniques now help with the cold stamping of magnesium alloy sheets as thin as 0.5 mm. This advancement supports the ongoing trend toward miniaturization in consumer electronics.

Electronic devices keep evolving toward greater integration and smaller sizes. Magnesium alloys are pioneering this progression by combining structural integrity with functional benefits. Their naturally low density continues to provide the vital lightweight advantage needed in modern devices.

Material Selection and Processing Challenges

Manufacturing magnesium alloys comes with unique processing challenges. Safety and performance requirements need specialized approaches. Engineers must think about several critical factors before they choose the right manufacturing methods.

Surface treatment for corrosion protection

Magnesium alloy’s biggest problem remains its vulnerability to corrosion. Surface treatments like anodizing, plating, and powder coating help alleviate this issue. Health concerns led to a ban on hexavalent chromium, which made chemical conversion coatings less popular. Plasma electrolytic oxidation (PEO) has emerged as a better option that provides exceptional protection compared to traditional chrome-based methods. Self-healing coatings with inhibitors are a great way to get long-term protection. These coatings can repair damaged layers on their own. Recent studies showed how electron beam or glow discharge can turn native magnesium oxide films into protective magnesium carbonate scales at room temperature.

Machining safety and chip ignition risks

Sharp safety protocols are essential when machining magnesium alloys because fine chips and powders can catch fire without warning. Thin chips reach ignition temperatures during finishing operations, which significantly raises the risk. Research on helical hole milling of AZ31 magnesium alloy revealed that cutting speed affects machining temperature the most. Safe machining requires sharp tools with large clearance angles. Operators should avoid tool dwelling on workpieces and use heavy feeds to create thicker chips. Mineral oil coolants work better than water-based options that can produce flammable hydrogen gas. Class D fire extinguishers with sodium chloride or graphite-based powder should be within reach since water makes magnesium fires worse.

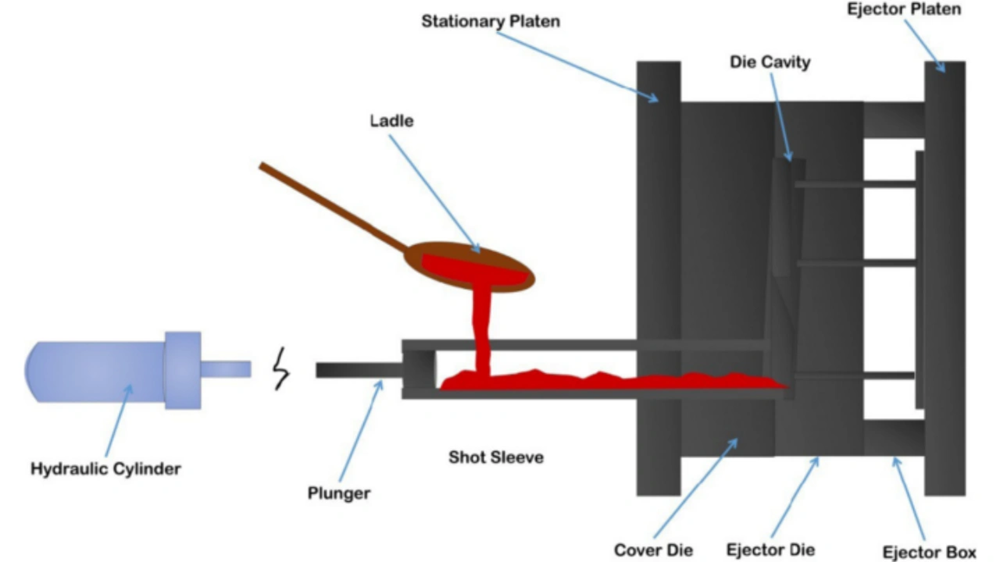

Die casting vs. extrusion for density-sensitive parts

Die casting and extrusion are the foundations of magnesium component manufacturing. Each process offers unique benefits for density-sensitive applications. Die casting creates complex shapes with irregular cross-sections in one step. Extrusion produces uniform cross-sectional parts that can be more ductile. Extrusion dies cost less than die-casting molds, but die-cast parts are stiffer and need fewer secondary operations. High-volume production favors die casting despite higher upfront tooling costs. Extrusion typically creates stronger products with smoother surfaces, making it ideal for smaller production runs that need consistent cross-sections.

Conclusion

Magnesium alloys are reshaping modern engineering practices in many industries. These materials are 35% lighter than aluminum and 77% lighter than steel, making them essential where weight matters most. Engineers value magnesium beyond its lightweight nature. Its specific strength, damping capacity, and thermal conductivity make it a standout choice.

The aerospace industry uses specialized alloys like WE43 and AE42 that work great in high temperatures. These materials help reduce aircraft weight, save fuel, and cut operating costs. The automotive sector benefits from magnesium, too. AM60B and AZ91D alloys boost safety and efficiency in crash zones, dashboards, and structural parts. Lower weight leads to better fuel economy and vehicle performance naturally.

Electronics makers know the great advantages of magnesium alloys. These materials often show up in smartphones and laptops. They shield against electromagnetic interference and dissipate heat well while providing structural support. Their thin-wall casting properties help create the tiny components needed in modern portable devices.

The biggest problems with magnesium are its tendency to corrode and complex processing needs. Engineers must carefully select surface treatments and machining methods to work with these materials effectively. The choice between die casting and extrusion greatly changes the final properties of magnesium parts.

Without doubt, magnesium alloys will become more important as industries seek better efficiency and performance. Their unique mix of low weight and high strength makes them leaders in lightweight design. The future looks promising for magnesium alloys. Research teams are developing specialized formulations for specific industry needs. These groundbreaking materials are not just today’s solution but tomorrow’s foundation for technological progress.

Key Takeaways

Magnesium alloys are revolutionizing modern engineering with their exceptional lightweight properties and versatile applications across critical industries.

• Unmatched weight advantage: Magnesium alloys are 35% lighter than aluminum and 77% lighter than steel, delivering superior specific strength for weight-critical applications.

• Aerospace breakthrough: Specialized alloys like WE43 and AE42 enable high-temperature performance while reducing aircraft mass, improving fuel efficiency by 5-10% per 10% weight reduction.

• Automotive safety enhancement: AM60B and AZ91D alloys excel in crash zones and dashboards, combining energy absorption with significant fuel economy improvements.

• Electronics miniaturization: Magnesium enables thin-wall casting for compact devices while providing electromagnetic shielding and superior heat dissipation compared to plastics.

• Processing requires expertise: Safe machining protocols and proper surface treatments are essential to address ignition risks and corrosion challenges inherent to magnesium alloys.

The strategic selection of magnesium alloys based on density requirements continues to drive innovation in lightweight design, making these materials indispensable for future engineering solutions where performance and efficiency are paramount.

FAQs

Q1. What are the main advantages of using magnesium alloys in engineering? Magnesium alloys offer exceptional lightweight properties, being 35% lighter than aluminum and 77% lighter than steel. They provide high specific strength, excellent damping capabilities, good electromagnetic shielding, and superior thermal conductivity. These properties make them ideal for applications where weight reduction and performance are crucial.

Q2. How are magnesium alloys used in the aerospace industry? In aerospace, magnesium alloys like WE43 and AE42 are used for high-temperature components such as gearboxes, helicopter transmissions, and aircraft wheels. They help reduce aircraft mass, improve fuel efficiency, and enhance overall performance. For every 10% reduction in weight, fuel efficiency can improve by 5-10%.

Q3. What role do magnesium alloys play in automotive safety and efficiency? Magnesium alloys, particularly AM60B and AZ91D, are used in automotive crash zones and dashboards. They provide excellent energy absorption capabilities and contribute to significant weight reduction, leading to improved fuel economy. A 10% reduction in vehicle weight can result in a 6-8% improvement in fuel efficiency.

Q4. How are magnesium alloys beneficial in consumer electronics? In electronics, magnesium alloys are used for casings and structural components in smartphones, tablets, and laptops. They allow for thin-wall casting, enabling the creation of miniaturized components. Additionally, these alloys provide effective electromagnetic shielding and superior heat dissipation compared to plastics, which is crucial for modern portable devices.

Q5. What are the main challenges in working with magnesium alloys? The primary challenges include corrosion susceptibility and processing complexities. Special surface treatments are required for corrosion protection, and strict safety protocols must be followed during machining due to the risk of chip ignition. The choice between manufacturing processes like die casting and extrusion also significantly impacts the final properties of magnesium components.