Feedstock composition plays a crucial role in determining the mechanical properties of metal injection molded components. Understanding the nuances of feedstock allows manufacturers to optimize performance effectively. Variations in composition can lead to significant differences in outcomes, influencing factors such as strength, density, and overall durability. For instance, studies show that the rheological behavior of feedstocks is affected by temperature and shear rate, impacting moldability and the quality of the final product.

Key Takeaways

- Feedstock composition is vital for determining the mechanical properties of MIM components.

- Different metal powders and binders influence strength, hardness, and fatigue resistance.

- Uniform particle size distribution enhances flowability and reduces defects in molded parts.

- Quality control of feedstock ensures consistency and reliability in final products.

- Optimizing feedstock can lead to improved performance in applications like medical devices and aerospace.

- Understanding the role of additives can enhance the properties of MIM components.

- Future trends include using recyclable materials and optimizing grain size for better mechanical properties.

- Manufacturers should prioritize feedstock quality to achieve superior results in MIM processes.

Understanding Feedstock Composition in MIM

Definition of Feedstock

Feedstock in metal injection molding refers to the mixture of metal powders and binders that form the basis for producing components. This combination allows for the shaping of complex geometries that traditional manufacturing methods may struggle to achieve. The metal powders serve as the primary raw material, while the binder acts as a temporary adhesive, facilitating the injection molding process. After molding, the binder is removed, leaving behind a compacted metal part ready for sintering.

Types of Feedstock Materials

Metal injection molding utilizes various feedstock materials, each with distinct properties that cater to specific applications. Common types include:

| Material Family | Application | Specific Features |

|---|---|---|

| Stainless Steel | Medical, electronic, hardware, aerospace | Strength, heat treatable, corrosion resistance |

| Low-alloy Steel | Hardware, bearings, consumer goods | Case hardenable, high wear resistance |

| Tool Steel | Wood and metal cutting tools | High hardness, wear resistance |

| Titanium | Aerospace applications | High strength-to-weight ratio |

| Soft Magnetic Alloys | Electrical components | Excellent magnetic properties |

Each material family offers unique advantages, making them suitable for various industries. For example, stainless steel is favored for its corrosion resistance, while titanium is ideal for lightweight applications in aerospace.

Importance of Feedstock Quality

The quality of feedstock significantly impacts the consistency and reliability of MIM outcomes. Manufacturers must ensure that the metal powders used are uniform in composition and particle size. This consistency reduces variability in the final parts, leading to improved quality.

- Consistent raw material quality is essential for the MIM process.

- Effective quality control measures help avoid defects or inconsistencies in the final product.

- Proper selection and preparation of materials are crucial to meet desired specifications.

Challenges in selecting feedstock composition often arise, such as achieving the right combination of metal powders and binders. Manufacturers address these challenges through careful research and advanced mixing techniques to ensure uniformity and desired flow characteristics.

MIM Manufacturing Processes and Feedstock Composition

Metal Injection Molding (MIM) is a sophisticated manufacturing process that combines the principles of plastic injection molding with powder metallurgy. This method allows for the production of complex metal parts with high precision and efficiency. Understanding the role of feedstock composition is essential, as it directly influences the quality and mechanical properties of the final product.

Overview of Metal Injection Molding

MIM involves several key stages, each requiring careful consideration of feedstock composition. The process begins with the preparation of a feedstock that consists of a mixture of metal powders and binders. This combination is crucial for achieving the desired flow characteristics and ensuring that the material fills the mold cavity effectively.

Steps in MIM Production

The MIM production process can be broken down into several distinct steps:

- Feedstock Preparation:

- Fine metal powders are mixed with a binder to create a homogeneous mixture. Typically, this mixture contains about 60% metal and 40% polymer by volume.

- The use of fine metal powders, often under 20 microns, differentiates MIM from traditional powder metallurgy processes.

- Injection Molding:

- The prepared feedstock is heated until it reaches a molten state and then injected into molds. This forms what are known as green parts, which are fragile yet retain the necessary shape for further processing.

- Debinding:

- In this step, the binder is removed from the green parts, resulting in brown parts. These parts are porous but maintain their geometry, which is crucial for the next stages of production.

- Sintering:

- The brown parts undergo heating to bond the metal particles together. This step is vital for achieving the desired density and mechanical properties, which are critical for the performance of the final product.

Role of Feedstock in Each Step

The composition of the feedstock plays a significant role at each stage of the MIM process:

- Feedstock Preparation: The quality of the mixture influences mechanical properties and dimensional accuracy. A homogeneous mixture ensures smooth flow during injection.

- Injection Molding: The feedstock’s rheological properties, such as viscosity, must remain consistent across various temperatures. This consistency prevents segregation during molding.

- Debinding: The choice of binder affects contamination levels and the final properties of the sintered part. A well-designed binder system minimizes defects.

- Sintering: The feedstock composition directly impacts the final density and mechanical properties of the part. Properly sintered components exhibit enhanced strength and durability.

By understanding how feedstock composition affects each step, manufacturers can optimize their processes to produce high-quality MIM components that meet industry-specific requirements.

Particle Size and Distribution Effects

Impact on Flowability

Particle size and distribution significantly influence the flowability of MIM feedstock. Research highlights the importance of differentiating the effects of powder shape and size on flow performance. For instance, wall slip, a critical factor in flowability, varies with the size and shape of metal powders. Larger, round-shaped particles tend to experience more wall slip. In contrast, using conical dies can reduce slip by up to 60% for fine, round particles.

Additionally, studies indicate that smaller particles, such as those measuring 10 μm, lead to a slight increase in viscosity. The highest viscosity increase occurs when powder content rises from 60% to 65% by volume. Feedstocks with 10 μm particles achieve complete filling in microtextures across all mold variations. However, 22 μm particles demonstrate decreased filling capabilities as powder content increases. This variation in flowability directly affects the quality of the final molded parts.

Influence on Density

The distribution of particle sizes also plays a crucial role in determining the final density of MIM components. A narrow particle size distribution enhances flow characteristics, which leads to better mold filling. This improvement reduces defects such as voids and sink marks in the final product.

Uniform packing density is achieved with an ideal particle size distribution. This uniformity minimizes defects like cracks and segregation during the sintering process. The sintering process itself is influenced by particle size, affecting bonding and the final mechanical properties of the molded part. Therefore, manufacturers must carefully consider the particle size distribution to optimize the density and overall quality of the components.

Effects on Sintering Behavior

The relationship between particle size and sintering behavior is critical for achieving desired mechanical properties in MIM parts. The following table summarizes experimental data that illustrates this relationship:

| Material | Particle Size | Sintering Driving Force | Degree of Densification | Porosity | Shrinkage Rate |

|---|---|---|---|---|---|

| 17-4PH | Smallest | Greater | Better | Higher | Higher |

| 316L | Medium | Moderate | Moderate | Moderate | Moderate |

| 304 | Largest | Lower | Poor | Lower | Lower |

As shown, smaller particle sizes generally lead to a greater sintering driving force, resulting in better densification. Conversely, larger particles exhibit lower densification and higher porosity. Understanding these dynamics allows manufacturers to tailor their feedstock compositions for optimal sintering behavior, ultimately enhancing the mechanical properties of the final products.

By focusing on particle size and distribution, manufacturers can significantly improve the performance and reliability of MIM components, meeting the demands of various applications.

Effects of Different Feedstock Compositions on Mechanical Properties

Metal Powder Types

The type of metal powder used in feedstock significantly influences the mechanical properties of MIM components. Different powders exhibit unique characteristics that affect flowability, density, and strength. The following table summarizes key factors related to metal powder types:

| Evidence Type | Description |

|---|---|

| Particle Size Distribution | Affects flowability, packing density, and green strength; fine powders improve mold filling. |

| Surface Characteristics | Influences interaction with binder and final surface finish; optimized surfaces enhance bonding. |

| Chemical Composition | Determines properties of sintered parts; alloy powders provide specific mechanical and thermal traits. |

For instance, finer powders tend to enhance mold filling and reduce defects in the final product. Conversely, coarser powders may lead to lower packing density and increased porosity. Manufacturers must carefully select metal powders to achieve the desired mechanical properties in their components.

Binder Materials

Binder materials play a crucial role in the MIM process, affecting the shaping and final properties of the molded parts. The choice of binder can significantly impact the density and hardness of the final product. The following table illustrates the performance of different binder systems:

| Binder System | Shaping Method | Relative Density (%) | Vickers Microhardness (HV) | Maximum Stress (MPa) |

|---|---|---|---|---|

| Soluble Binder | MEX | 88 – 94 | 32 | 79 ± 3.2 |

| Soluble Binder | MIM | 93 – 95 | 36 | N/A |

The data indicates that soluble binders yield higher relative densities and microhardness in MIM compared to other methods. Additionally, the binder composition can influence shrinkage rates during the sintering process. For example, an organic binder mix typically results in a shrinkage rate of 10-15%, leading to high-quality sintered elements with minor flaws.

Additives and Their Roles

Additives are essential in modifying the properties of feedstock, enhancing the performance of MIM components. They serve various functions, from improving flowability to increasing mechanical strength. The following table outlines the roles of different additives:

| Additive Type | Effect on Feedstock Properties |

|---|---|

| Surface Modifiers | Improve powder-binder compatibility, reduce agglomeration, enhance mechanical strength and shape retention. |

| Stearic Acid (SA) | Increases fluidity of the feedstock; optimal mechanical properties at 9 vol%. |

| Silane Coupling Agent | Increases melting index, bending strength, and debinding rate of the feedstock. |

| General Surfactants | Change powder polarity, reduce agglomeration, enhance interaction with binder. |

For example, stearic acid enhances the fluidity of the feedstock, which is crucial for achieving uniform filling during the injection molding process. Similarly, silane coupling agents improve the overall mechanical properties by promoting better bonding between the metal powders and the binder.

By understanding the effects of different feedstock compositions, manufacturers can optimize their MIM processes to produce components that meet specific mechanical property requirements.

Mechanical Properties Influenced by Feedstock Composition

Tensile Strength

Tensile strength is a critical mechanical property that reflects a material’s ability to withstand pulling forces without breaking. The composition of feedstock significantly impacts the tensile strength of MIM components. For instance, the Co-Cr-Mo-Si alloy demonstrates a maximum sintering density of 99.2% when using gas atomized (GA) powder. In contrast, water atomized (WA) powder achieves a lower density of 98.8%. This difference in density directly correlates with tensile strength. The GA feedstock exhibits a notably higher ultimate tensile strength due to its larger symmetry, which results in lower porosity and reduced stress concentration.

- Higher sintering density leads to improved tensile strength.

- The processing characteristics of feedstocks, analyzed through torque and capillary rheometers, reveal differences in flow performance that can affect the final mechanical properties.

Hardness

Hardness is another essential property influenced by feedstock composition. Research indicates that the type and concentration of binder and metal powder in the feedstock play significant roles in determining hardness levels. An increase in solid loading enhances mechanical properties and sintering density. However, higher solid loading can also raise friction between powders, complicating the extrusion process.

- An increase in the polypropylene (PP) fraction within the binder enhances hardness due to the incorporation of residual carbon into the metallic lattice.

- The combination of powder loading and binder systems is crucial for achieving desired hardness levels in MIM components.

Fatigue Resistance

Fatigue resistance refers to a material’s ability to endure repeated loading and unloading cycles without failure. The composition of feedstock directly influences the fatigue resistance of MIM products. A study focusing on titanium alloys, specifically Ti6Al4V, highlights the impact of feedstock composition on fatigue performance. The research utilized a feedstock composition of HDPE/LDPE/wax (40/0/60) with a solid load of 60 vol% and 5 wt% stearic acid. This composition was instrumental in comparing MIM parts with those produced by other methods.

- The choice of feedstock significantly affects the mechanical properties, including fatigue resistance, of the final molded products.

- Optimizing feedstock composition can lead to enhanced durability and performance in applications subjected to cyclic loading.

By understanding the relationship between feedstock composition and these mechanical properties, manufacturers can tailor their processes to produce components that meet specific performance requirements.

Applications and Performance Based on Feedstock Composition

Industry-Specific Requirements

Different industries impose unique requirements that dictate the selection of feedstock composition for metal injection molding applications. The following table outlines key properties that influence feedstock selection:

| Property | Importance in Feedstock Selection |

|---|---|

| Melting Point | Ensures compatibility with metal alloys |

| Thermal Expansion Coefficient | Affects dimensional stability during processing |

| Density | Influences the final part’s weight and strength |

| Viscosity | Affects flowability during the injection process |

| Shrinkage | Impacts dimensional accuracy of the final product |

Manufacturers must consider these properties to ensure that the final products meet specific end-use requirements. Different metals and alloys provide varied properties, and the selection process often focuses on strength, thermal properties, and corrosion resistance.

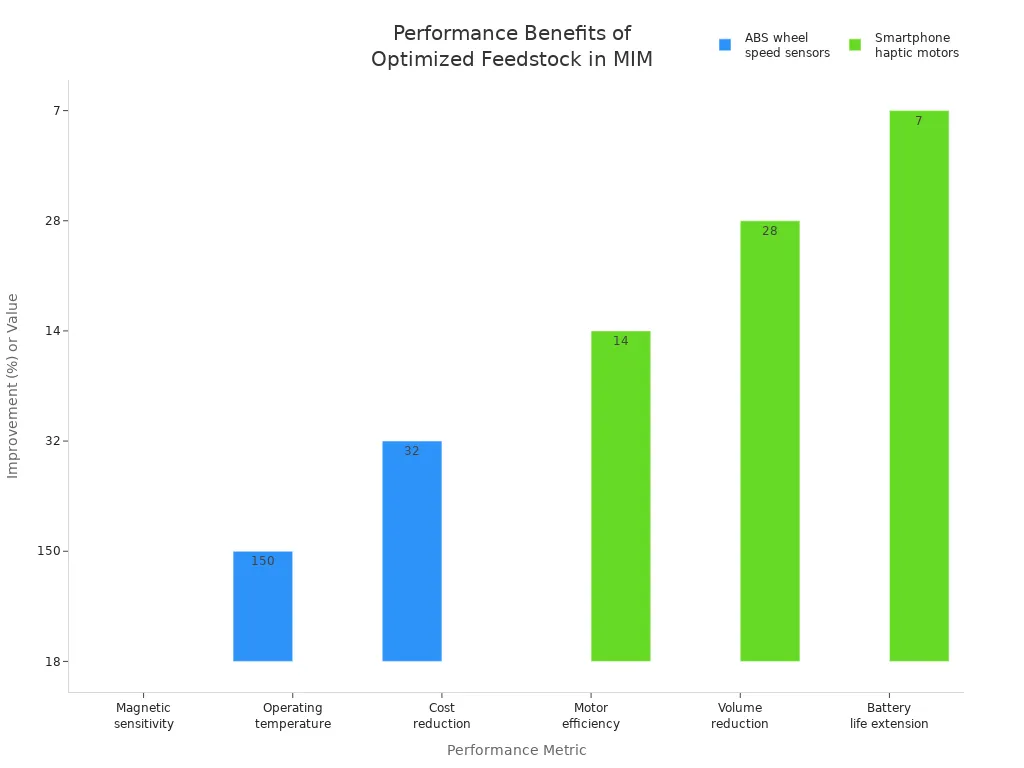

Case Studies of Successful MIM Parts

Several case studies illustrate the successful use of tailored feedstock compositions in producing high-performance metal injection molded parts. The following table summarizes notable examples:

| Case Study Title | Description |

|---|---|

| MIM for Medical Components | Illustrates the use of tailored feedstock in medical applications. |

| The Cadence Tablet Core Plate | Highlights a MIM innovation for accessibility in medical devices. |

| Machined to MIM Conversion | Demonstrates the transition from traditional machining to MIM. |

| Plastic to MIM Conversion | Shows the adaptation of plastic components to MIM processes. |

| MIM 17-4 PH Metal Injection Molding Door Lock Hinge | Focuses on a specific application in security components. |

These case studies showcase how optimized feedstock compositions lead to improved performance metrics, such as enhanced strength and durability, which are critical in demanding applications.

Future Trends in Feedstock Development

The ongoing developments in feedstock for metal injection molding are leading to improved properties, including higher strength and corrosion resistance. Recent advancements focus on the development of new materials that enhance mechanical properties. These innovations are crucial for expanding the applications of MIM components.

Emerging trends include:

- Recyclable and Biodegradable Materials: Manufacturers are increasingly adopting eco-friendly binders and low-impact metal alloys to reduce environmental footprints.

- Optimizing Grain Size: This is essential for enhancing mechanical properties such as tensile strength and ductility. Careful selection of metal powders and processing parameters plays a vital role.

- Sustainability Practices: The industry is moving towards minimizing raw material usage and energy consumption, aligning with broader sustainability goals.

These advancements not only improve the functionality of MIM components but also contribute to the overall sustainability of the manufacturing process.

In summary, feedstock composition significantly influences the mechanical properties of MIM components. Key points include:

- Material Selection: Different metal powders and binders affect strength, hardness, and fatigue resistance.

- Process Optimization: Understanding particle size and distribution enhances flowability and density.

Implications: Optimizing feedstock composition is crucial for meeting industry-specific requirements. This optimization leads to improved performance across various applications, from medical devices to aerospace components.

By prioritizing feedstock quality, manufacturers can achieve superior results in their MIM processes.

FAQ

What is feedstock in metal injection molding?

Feedstock refers to the mixture of metal powders and binders used in metal injection molding. This combination allows for the shaping of complex geometries in the manufacturing process.

How does particle size affect MIM components?

Particle size influences flowability, density, and sintering behavior. Smaller particles generally enhance mold filling and reduce defects, while larger particles may lead to increased porosity.

Why is binder selection important in MIM?

The choice of binder affects the shaping, density, and final properties of molded parts. A suitable binder ensures better flowability and minimizes defects during the injection process.

What mechanical properties are influenced by feedstock composition?

Feedstock composition impacts tensile strength, hardness, and fatigue resistance. Different metal powders and binders contribute to these properties, affecting overall performance.

How can manufacturers optimize feedstock for MIM?

Manufacturers can optimize feedstock by selecting appropriate metal powders, binders, and additives. They should also focus on achieving uniform particle size distribution for better flowability.

What industries benefit from MIM technology?

Industries such as aerospace, medical, automotive, and electronics benefit from MIM technology. The ability to produce complex, high-precision parts makes MIM suitable for various applications.

Are there any future trends in feedstock development?

Yes, future trends include the use of recyclable materials, optimizing grain size, and adopting sustainable practices. These advancements aim to enhance mechanical properties and reduce environmental impact.

How does feedstock quality affect MIM outcomes?

High-quality feedstock ensures consistency and reliability in MIM outcomes. Uniform composition and particle size reduce variability, leading to improved mechanical properties and overall product quality.