The choice between PVD and DLC coating technologies puts manufacturers at a crossroads that affects their product’s performance and durability. These advanced surface treatments and anodizing represent innovative technology in metal component protection. Each brings unique advantages to metal injection molding (MIM) applications.

Specific performance needs and budget limits often determine the choice between DLC and PVD coating. The PVD vs DLC coating debate focuses on hardness and wear resistance. PVD DLC hybrid solutions could provide the best of both worlds. The comparison between PVD and anodizing brings up important points about corrosion protection and aesthetic options.

This piece breaks down each coating technology’s unique properties. You’ll learn about hardness ratings – DLC reaches 2000-3000 HV while anodizing stays between 300-500 HV. We’ll get into coating thickness, friction coefficients, durability, visual features, and costs.

The information here will help you pick the right coating technology for your MIM applications. This applies to medical instruments, aerospace components, and automotive parts. Let’s tuck into the technical details that set these coating options apart.

Understanding the Coating Methods for MIM

MIM components just need specialized surface treatments to improve their performance. Three main coating methods have become industry standards, each with its own unique properties and application processes.

What is PVD Coating and How It Works

Physical Vapor Deposition (PVD) is a sophisticated, dry, vacuum-based coating technique that is different from conventional methods. The process vaporizes solid material in a vacuum chamber and deposits it onto the target surface. This creates a thin, durable layer of metal and ceramic elements. This careful procedure creates coatings that improve both the aesthetic appeal and durability of MIM components.

PVD coatings work especially well in molding applications because their chemically saturated functional surface reduces adhesive wear and stops deposit build-up. This surface treatment then improves how materials flow during the molding process, making it perfect for MIM applications where precision matters most.

DLC Coating: Process and Properties

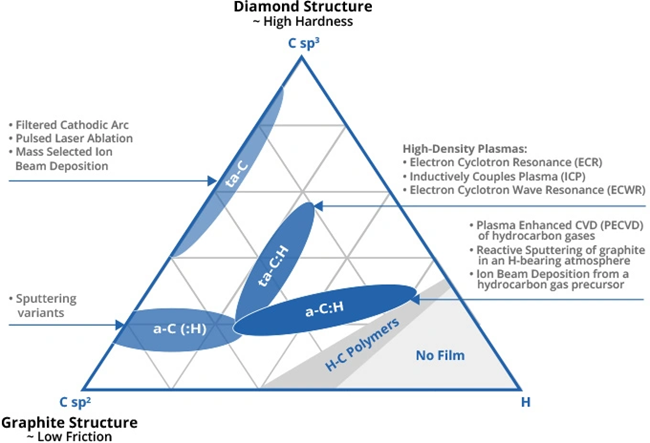

Diamond-Like Carbon (DLC) coating is a trailblazing surface treatment that combines diamond and graphite to create a thin polycrystalline diamond coating. This hybrid nature lets DLC show off the best properties of both materials. The result is exceptional hardness, low friction, and excellent resistance to abrasion and chemicals.

DLC coatings are usually applied through Physical Vapor Deposition (PVD) or Plasma Assisted Chemical Vapor Deposition (PACVD) technology. Some manufacturers also use High Power Impulse Magnetron Sputtering (HiPIMS) and Plasma Immersion Ion Deposition (PIID). PACVD is different from PVD because it uses chemical reactions to form the coating instead of physically depositing solid material.

Anodizing Explained: Electrochemical Surface Treatment

Anodizing offers a unique approach as both an electrochemical and mechanical surface treatment. The process starts by immersing the metal component in an electrolyte solution with sulfuric acid and applying an external electric current. The metal part acts as the anode while oxygen ions from the solution combine with metal atoms to create a tough oxide layer.

The anodizing procedure follows these steps:

- Surface preparation through cleaning with alkaline solutions

- Etching with sodium hydroxide to create the desired finish textures

- Desmutting using acid solutions to remove residues

- The actual anodizing process using 10-15% sulfuric acid concentration at 12-21 volts

- Final sealing with hot deionized water (85-100°C for 20-30 minutes) or nickel acetate

This process makes the natural oxide layer on the metal surface thicker into an anodic oxide film, which provides better protection. Unlike PVD and DLC, anodizing doesn’t add any metal to create the protective layer. Instead, it changes the existing surface through a conversion coating that alters the metal’s chemical character.

Material Properties: Hardness, Thickness, and Friction

The properties you can measure in coating materials show how well they’ll work in specific MIM applications. Each coating technology brings its own benefits in hardness, thickness, and friction characteristics that affect how components perform.

Hardness Ratings: 2000-3000 HV (DLC) vs 300-500 HV (Anodized)

A coating’s hardness shows how well it resists wear and abrasion. Diamond-like carbon coatings excel with their exceptional hardness and improve abrasion resistance by a lot. Si-DLC multilayer films deliver the highest nano-hardness and elastic modulus compared to anodized coatings.

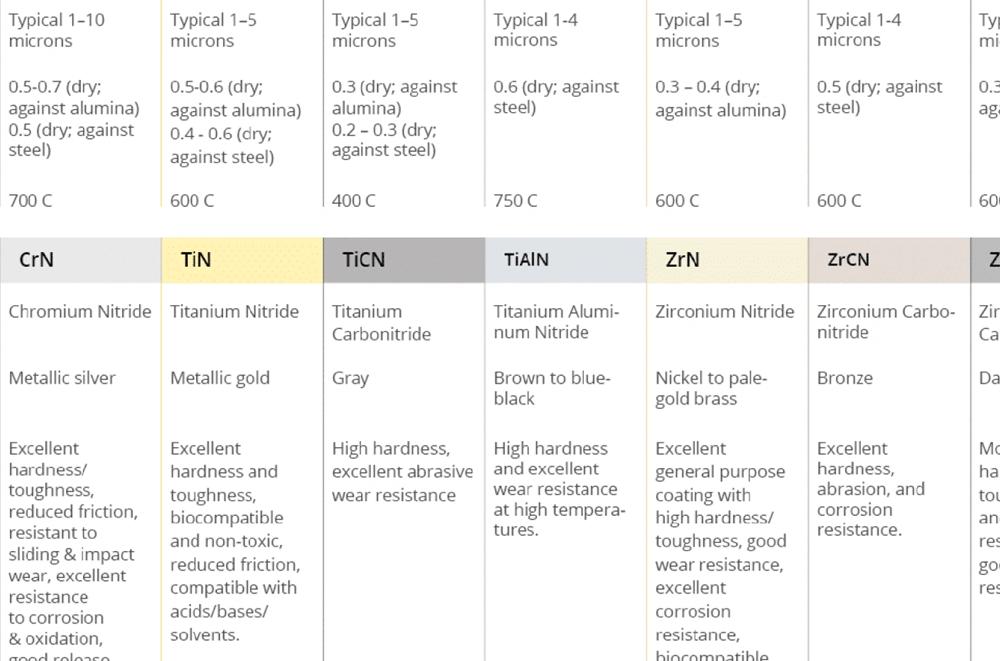

PVD coatings provide hardness values between 1400 and 2400 HV, which puts them between DLC and anodized treatments. Research proves that PVD coating’s hardness affects cutting performance. This becomes more evident with thinner coatings, where lower hardness reduces performance.

DLC clearly works better than PVD and anodizing solutions when you need maximum surface hardness. This makes it perfect for components that face extreme wear conditions.

Coating Thickness: 0.5–3μm (DLC) vs 10–25μm (Anodized)

Coating thickness is a vital factor in protective capabilities and dimensional precision. Research shows that mechanical properties decrease as coatings get thicker. The coating’s surface hardness and strength drop with increased thickness.

PVD coating thickness ranges from 3 to 10 μm. Thinner coatings often work better when they keep their hardness. The way thickness relates to mechanical strength and hardness affects how coated components wear and last.

DLC’s thinner profile works better than thick anodized layers for precision components with tight tolerances. This allows better dimensional accuracy while keeping superior hardness.

Friction Coefficient: 0.1 (DLC) vs 0.4–0.8 (Anodized)

The biggest difference between these coating technologies lies in their friction coefficients. DLC coatings show very low friction values between 0.05 and 0.1, which creates a self-lubricating effect. This is a big deal as it means that anodized aluminum has much higher friction coefficients between 0.48 and 0.8.

Research confirms that heating DLC coatings beforehand can lower friction even more. DLC heated to 500°C shows the lowest friction among tested variants. PVD coatings with higher hardness and smoother surfaces tend to have lower friction coefficients.

DLC’s better friction characteristics make it the clear choice over PVD and anodized surfaces for components that need smooth movement or galling resistance. This feature makes DLC ideal for moving parts in precision mechanical systems where you need energy efficiency and less wear.

Durability and Corrosion Resistance

Coating technologies show their real value when MIM components face stress. Each coating method works best under specific demanding conditions, and picking the right one is vital for component longevity.

Wear Resistance: DLC vs PVD vs Anodizing

DLC coatings perform better than anodized aluminum oxide coatings in wear tests because of their hardness and low friction coefficients. This makes DLC-coated parts the best choice for applications with moving parts or abrasive environments.

DLC coatings are harder than PVD coatings, though PVD still resists wear effectively. This difference matters a lot to manufacturers choosing between PVD and DLC coatings, especially for high-cycle applications where parts must last longer.

Corrosion Resistance in Harsh Environments

These coatings prove their worth in corrosive environments. Anodization adds a protective layer to the base metal, but MIM steels don’t resist corrosion as well as conventional steels. This makes choosing the right coating critical.

The protective phases in deposited coatings help them resist harsh oxidizing environments. DLC coatings have shown excellent corrosion resistance, which helps biomedical devices and implants last longer in physiological conditions.

Thermal Stability: Up to 500°C for DLC

Non-hydrogenated DLC coatings like tetrahedral amorphous carbon stay stable up to 500°C thanks to their high sp3 content. This makes them perfect for high-temperature applications.

New research has pushed these limits further. Tests show DLC films keep their tribomechanical performance stable when heated to 500°C. Adding 50% neon in plasma helps DLC films stay stable beyond 700°C, and some versions resist graphitization up to 800°C.

The debate between PVD and DLC coating continues as manufacturers match their specific needs against what each coating technology can do best.

Visual and Esthetic Differences

The selection of coatings for MIM components goes well beyond technical specs. Different coating methods create unique visual effects that shape product design and how consumers perceive the final product.

Color Options: PVD’s Versatility vs DLC’s Matte Black

PVD coating stands out because it offers remarkable color options. The coating provides a wide range of colors, including gold, rose gold, bronze, blue, dark red, and black. Manufacturers who need gold-plated finishes have PVD as their only real choice.

DLC coating gives you a distinctive black or dark gray look. The colors range from anthracite to deep black, and many people see it as sophisticated and modern. Since DLC has limited color choices, companies that want variety usually pick PVD solutions.

Surface Finish: Glossy vs Matte vs Textured

Surface finish shapes both looks and performance. PVD coatings create reflective surfaces with medium to high-gloss finishes showing 40-80% reflectivity. These finishes look premium and luxurious – perfect for decorative uses.

DLC coating adds a matte-like look to parts. This reduces glare and creates an understated, sophisticated appearance. Military or sporty designs benefit from this finish, where shine might not be wanted.

MIM components can get different textures through several post-treatments:

- Sandblasting adds texture variation and tactile feel

- Polishing creates high-gloss finishes that look appealing

- Brushing techniques create elegant matte finishes

Impact on Final Product Appearance

The visual effect goes beyond just color. PVD coatings are slightly thicker than DLC, which subtly changes how components look and their dimensions. MIM sintered parts naturally have a uniform texture, so coating choice plays a vital role in creating product identity.

Companies should think about how coating affects brand image. Products that need a premium look often benefit from high-gloss PVD finishes. Products focusing on durability and technical excellence might work better with DLC’s distinctive matte black finish.

Cost, Scalability, and Use Cases

The choice between coating technologies for MIM components often comes down to practical factors. Manufacturers need to understand the costs, production capabilities, and ideal uses to make smart decisions.

Cost Comparison: PVD vs DLC vs Anodizing

A look at costs shows anodizing as the most economical choice, with Type II processes ranging from $65 to $125 per piece. PVD coating serves as a middle-ground option at about $22 per batch for large-sized systems. DLC coating ended up commanding premium prices because of its superior hardness and wear-resistant properties.

Anodized coatings remain the most economical solution for mass production and are available for high-volume manufacturing. Notwithstanding that, PVD and DLC coatings often justify their higher costs through longer component life and better performance when evaluated for long-term value rather than the original investment.

Scalability for Mass Production

MIM excels at producing complex shapes that other methods would find too expensive. This advantage carries over to coated components. The process makes micro-sized parts in high volumes, which proves exceptionally efficient for mass production.

JH MIM brings nearly 20 years of expertise to the Metal Injection Molding industry. Their facilities span more than 18,000 square meters with world-class equipment run by 150 skilled workers. The company stands as China’s leading Metal Injection Molding manufacturer, delivering precision-engineered products to global customers who need expandable coating solutions.

Best Use Cases: Medical, Aerospace, Automotive

Each coating technology shows its strengths in specific fields:

- Medical Industry: DLC and PVD coatings give the chemical and wear resistance needed for dental tools, orthopedic implants, and surgical instruments.

- Automotive Applications: These coatings shine in engine components, fuel injection systems, and transmission parts where precision and durability matter most.

- Aerospace Components: All but one of these coatings find their place in aerospace, especially for fuel injectors, valves, actuators, and electronic connectors that need high-quality materials and tight tolerances.

The choice between PVD vs DLC coating depends on specific performance needs, with DLC showing particular value for tooling components, engine parts, and medical devices.

Comparison Table

| Characteristic | DLC Coating | PVD Coating | Anodizing |

|---|---|---|---|

| Hardness Rating | 2000-3000 HV | 1400-2400 HV | 300-500 HV |

| Coating Thickness | 0.5-3 μm | 3-10 μm | 10-25 μm |

| Friction Coefficient | 0.05-0.1 | Not mentioned | 0.4-0.8 |

| Color Options | Limited (black to anthracite) | Versatile (gold, rose gold, bronze, blue, dark red, black) | Not mentioned |

| Thermal Stability | Up to 500°C (some variants up to 800°C) | Not mentioned | Not mentioned |

| Surface Finish | Matte-like appearance | Reflective, medium to high-gloss (40-80% reflectivity) | Not mentioned |

| Relative Cost | Highest | Medium | Lowest ($65-125 per piece) |

| Main Advantages | – Best hardness rating – Minimal friction – Outstanding wear resistance – Strong protection against corrosion |

– Many color choices – Resists wear well – High-end look |

– Most cost-effective – Perfect for high-volume production |

Conclusion

This complete analysis shows the unique properties and applications of DLC, PVD, and anodizing technologies for metal injection molded components. Each coating method is a chance to get specific advantages based on performance needs and budget limits. DLC excels with its exceptional hardness of 2000-3000 HV, low friction coefficient of 0.05-0.1, and superior wear resistance. These properties make it perfect for parts under extreme mechanical stress. PVD coating delivers a great balance of performance with hardness ratings of 1400-2400 HV and matches any coating for color options in esthetic applications. Anodizing remains the budget-friendly choice for high-volume production where moderate performance specs work well.

Your application’s specific needs will determine which coating technology works best. Medical devices work well with DLC’s biocompatibility and wear resistance. Aerospace parts might need either PVD or DLC based on environmental exposure and mechanical requirements. Automotive applications use all three coating types for different component categories.

Manufacturers should think about performance specs, visual requirements, cost limits, and production volumes to pick the right coating technology. The comparison table we shared earlier sums up these key differences and helps with decision-making. JH MIM brings 20 years of experience in Metal Injection Molding. The company’s facilities span over 18,000 square meters with 150 skilled workers. They deliver precision-engineered products globally as China’s leading Metal Injection Molding manufacturer.

Without doubt, MIM component coating technology will keep evolving. Hybrid solutions might soon combine benefits from different coating types. In spite of that, knowing the basic differences between DLC, PVD, and anodizing technologies forms the foundation for smart decisions. These choices help optimize component performance, durability, and create budget-friendly solutions in demanding applications.

Key Takeaways

Understanding the fundamental differences between DLC, PVD, and anodizing coating technologies enables manufacturers to make informed decisions that optimize MIM component performance and cost-effectiveness.

• DLC delivers superior performance: With hardness ratings of 2000-3000 HV and friction coefficients as low as 0.05-0.1, DLC outperforms other coatings in wear resistance and durability.

• PVD offers esthetic versatility: Unlike DLC’s limited black finish, PVD provides extensive color options including gold, bronze, and blue while maintaining good hardness (1400-2400 HV).

• Anodizing remains most cost-effective: At $65-125 per piece, anodizing provides the most economical solution for high-volume production despite lower hardness ratings (300-500 HV).

• Coating thickness affects precision: DLC’s thin profile (0.5-3μm) maintains dimensional accuracy better than anodizing’s thicker layers (10-25μm), crucial for precision MIM components.

• Application-specific selection is critical: Medical devices benefit from DLC’s biocompatibility, aerospace requires thermal stability up to 500°C, while automotive applications utilize all three based on component requirements.

The key to successful coating selection lies in balancing performance requirements, esthetic needs, and budget constraints while considering the specific demands of your industry and application environment.

FAQs

Q1. What are the main differences between PVD and DLC coatings? PVD (Physical Vapor Deposition) and DLC (Diamond-Like Carbon) are both advanced coating technologies, but they differ in several aspects. PVD offers a wide range of color options and good wear resistance, while DLC provides superior hardness, lower friction, and excellent wear resistance. DLC typically has a black or dark gray appearance, whereas PVD can produce various colors like gold, bronze, and blue.

Q2. How does anodizing compare to PVD and DLC coatings in terms of cost and performance? Anodizing is generally the most cost-effective option, especially for high-volume production. However, it offers lower hardness (300-500 HV) compared to PVD (1400-2400 HV) and DLC (2000-3000 HV). While anodizing provides good corrosion resistance, PVD and DLC coatings often offer superior wear resistance and durability, justifying their higher costs in certain applications.

Q3. Which coating technology is best suited for medical devices? DLC coating is often preferred for medical devices due to its biocompatibility, superior wear resistance, and excellent corrosion resistance. Its low friction coefficient and high hardness make it ideal for surgical instruments, dental tools, and orthopedic implants where precision and durability are crucial.

Q4. How do these coating technologies affect the dimensional accuracy of MIM components? DLC coatings, being the thinnest (0.5-3μm), maintain the highest dimensional accuracy for MIM components. PVD coatings are slightly thicker (3-10μm), while anodized layers are the thickest (10-25μm). For precision components with tight tolerances, DLC’s thinner profile offers significant advantages in maintaining dimensional accuracy while providing superior hardness.

Q5. What factors should be considered when choosing between these coating technologies for automotive applications? When selecting a coating for automotive applications, consider factors such as wear resistance, friction coefficient, and cost-effectiveness. DLC coatings excel in engine components and fuel injection systems due to their high hardness and low friction. PVD coatings offer a balance of performance and aesthetic options, suitable for both functional and decorative parts. Anodizing might be preferred for high-volume, cost-sensitive components where moderate performance is acceptable.