Binder Selection for Tungsten Alloy MIM

Tungsten alloys processed through metal injection molding machines deliver exceptional density of about 18.5 g/cm³, making them perfect for weight-critical applications. These high-density materials pack remarkable strength with durability. They excel in defense, military, aerospace, and nuclear applications. Tungsten alloys’ unique physical properties like high melting points and low thermal expansio,n need specialized binder systems to achieve the best molding results.

Metal injection molding boosts design flexibility while optimizing material usage, especially when you have complex tungsten components. The industrial metal injection molding machine process depends heavily on choosing the right binder. Typical binder choices include polymeric organic systems such as paraffin wax, polyethylene, polypropylene, polyoxymethylene, and stearic acid. Yes, it is possible to create high-strength products with intricate geometries through metal injection molding, but success largely depends on how well the tungsten alloy works with the chosen binder system.

This piece dissects the key factors that influence binder selection for tungsten alloy metal molding machines and shows how different binder systems work with tungsten’s unique properties. On top of that, it helps metal injection molding services optimize their processes for tungsten applications of all types while achieving maximum sintered density and uniform microstructures.

Binder Role in the Metal Injection Molding Process

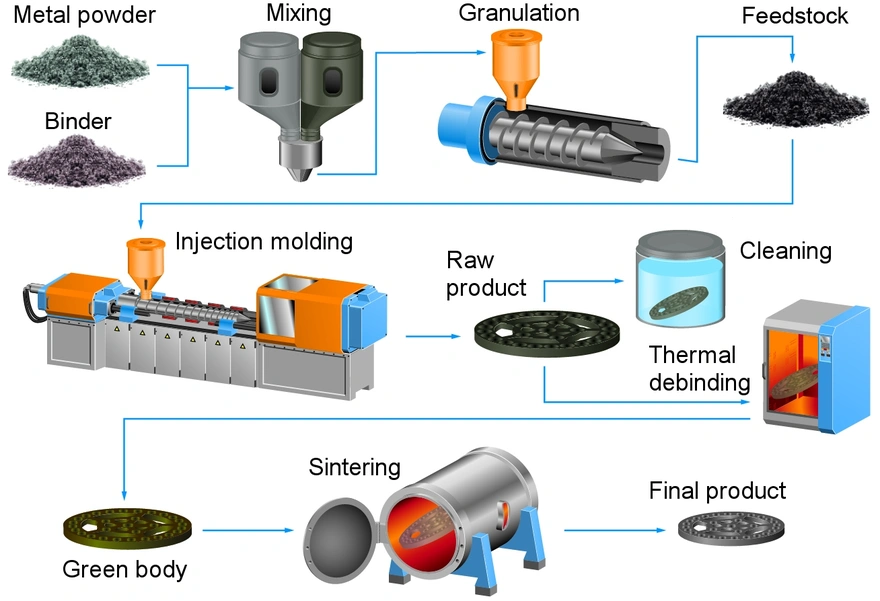

Binders are the foundations of the metal injection molding process. These temporary organic materials are vital components in metal injection molding. They act as carriers that hold fine metal powders together during processing stages. The evolution of metal injection molding technology largely parallels the development of binder compositions and their debinding technologies.

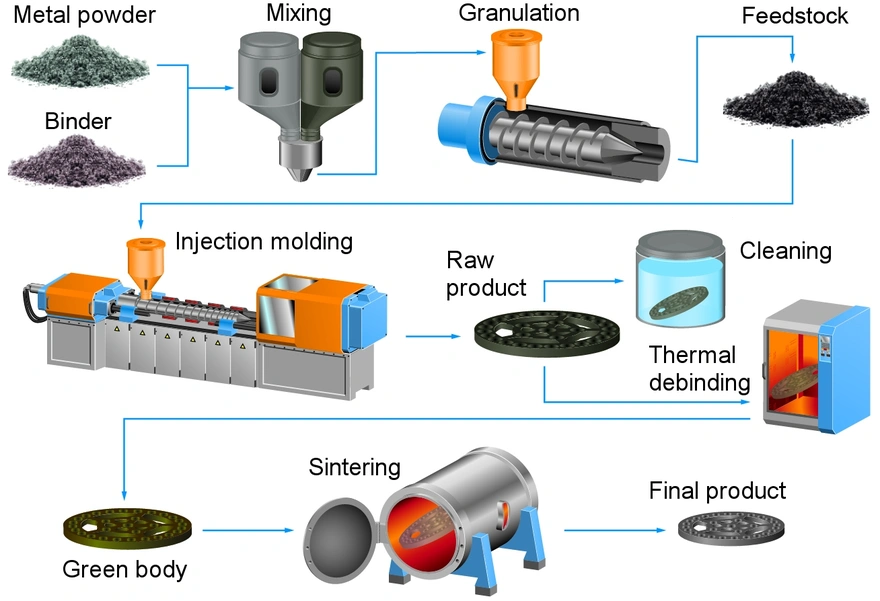

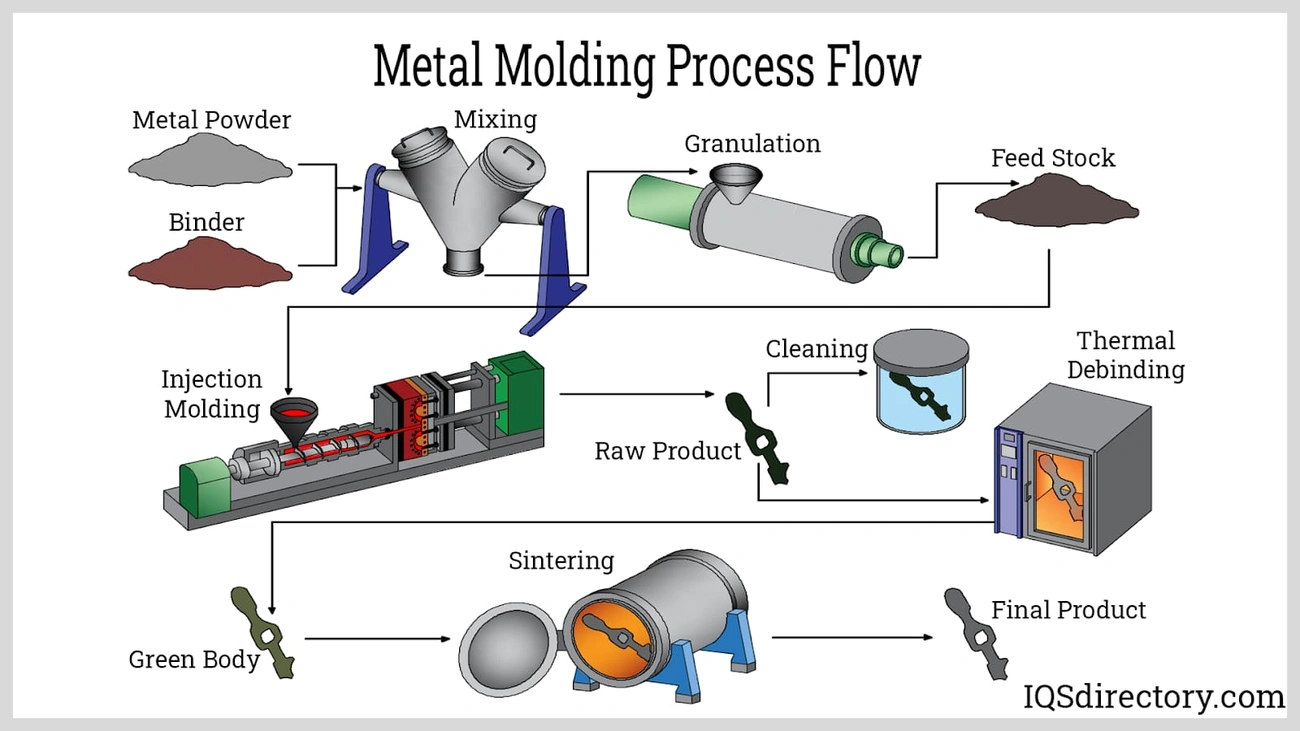

Feedstock Formation in Metal Molding Machine

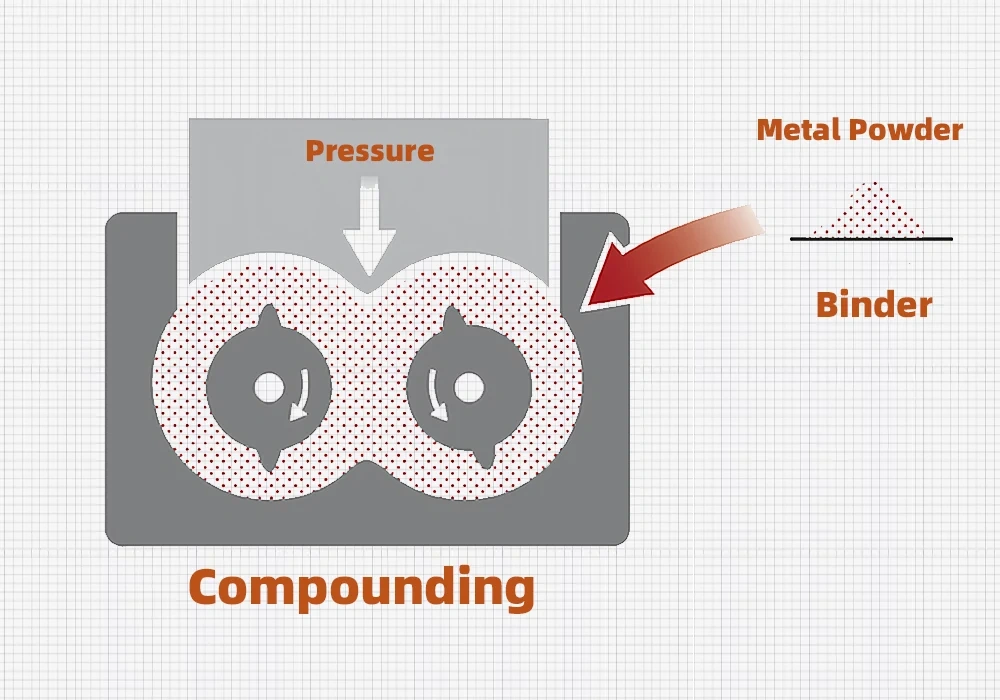

Metal powders blend with binders to create a uniform mixture suitable for injection during feedstock preparation. Research shows a powder-to-binder ratio of 93:7 works best for the metal injection molding process. This ratio has a slight excess of binder that prevents separation and maintains uniformity throughout the molded part. The binder helps reduce friction between particles, which leads to better particle packing density and streamlines processes.

Standard binder systems combine multiple components that each serve a specific purpose. You’ll typically find mixtures of polymers (polyethylene or polypropylene), synthetic or natural waxes, and stearic acid. Newer systems like polyoxymethylene (POM)-based binders have become popular because they mold well and keep their shape. Teams usually prepare the composite feedstock using twin-screw extruders or high-temperature blenders.

Powder loading substantially affects the final component quality. Many factors influence this vital parameter, including the binder system and process variables. Poor feedstock preparation or improper recycling can lead to product defects. That’s why thorough blending matters so much for successful metal molding operations.

Binder’s Role in Injection and Mold Flow

A good binder system should meet several needs. It needs to work with high volumes of fine metal powders (60% or more by volume), form a solid mass for plastification, and allow eco-friendly debinding. The system should also provide enough strength through the “backbone binder,” keep properties consistent, support recycling, and stay budget-friendly.

The binder mix directly shapes several key aspects of metal injection molding. These include the relative density after sintering (93-95%), shrinkage after sintering (10-18%), microhardness values (about 36 HV), and mechanical strength (maximum stress of 79 ± 3.2 MPa).

The pressure during injection molding should stay moderate. Too much pressure can cause defects like flash or feedstock sticking to the die. Many operations now use low-pressure injection molding machines. These machines reduce mold wear and use less energy.

Debinding Stage and Residue Removal

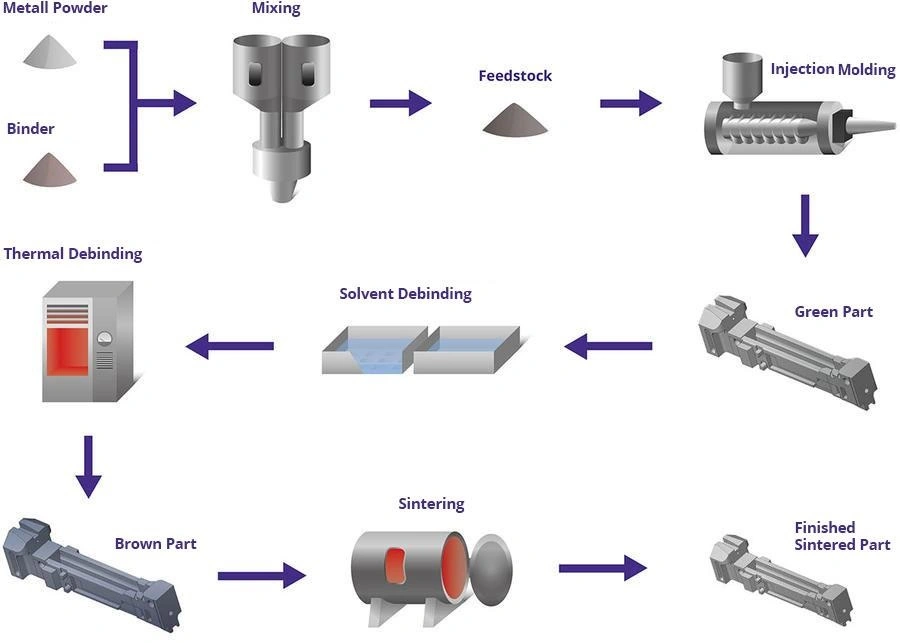

The debinding phase is vital in metal injection molding. It removes the main binding material from the molded component before sintering can begin. This step changes the “green” part into a porous “brown” part that’s ready for sintering. The process can take up to 40% of the total production cycle, often creating a bottleneck.

The metal injection molding industry uses three main debinding techniques: thermal, solvent, and catalytic. Thermal debinding heats green parts in a controlled atmosphere to melt and evaporate the binder based on thermal properties. Solvent debinding soaks parts in organic solvents like heptane or acetone to dissolve the binder and create pores. Catalytic debinding uses gas catalysts at around 120°C to break down the binder into volatile molecules.

Getting rid of all the binders is essential for quality components. Any leftover binder can cause cracks, distortion, or contamination during sintering. These issues can hurt the final product’s mechanical properties and looks. Research shows longer heating and holding times during thermal debinding can cut final part porosity from 23% to 12%.

Modern metal injection molding usually involves two-stage debinding. The first stage removes the soluble, low-molecular-weight portion of organic binders. The second stage takes care of what’s left. This approach stops rapid gas formation during later debinding stages. Without it, stresses, cracks, or internal voids might form, especially in complex or thin-walled shapes.

Material Compatibility and Binder Selection

The right binder systems for tungsten alloys need careful material compatibility assessment. Tungsten creates unique challenges because of its high density (19.3 g/cm³), melting point (3422°C), and particle characteristics that set it apart from standard metal powders. The success of the metal injection molding process relies on how well these specialized binders work with tungsten’s physical properties.

Binder Interaction with Tungsten Particle Size

Tungsten particle size shapes binder selection and mixing behavior. Research shows that fine tungsten powder with a 1–2 μm grain size produces the best results in metal injection molding feedstock preparation. Particle size also affects the critical powder loading (CPL) – the maximum powder amount that fits into the binder system. Regular formulations reach 58-60 vol% powder loading, while better formulations can hit 62-65 vol%.

This small 3-4% difference in powder loading matters a lot:

- At 58% powder loading: Green density hits 11.2 g/cm³ (58% of theoretical) with 10-15% reject rate

- At 64% powder loading: Green density reaches 12.3 g/cm³ (64% of theoretical) with only 2-5% reject rate

Bimodal powder distributions help improve packing efficiency in industrial metal injection molding machines.

Thermal Behavior with High-Density Alloys

Binder systems’ thermal characteristics must match tungsten’s unique properties. Good tungsten-compatible binders use a three-component structure:

- Primary binder (paraffin wax): 38-42% of binder mass, melting point 58-64°C

- Backbone polymer (HDPE): 50-55% of binder mass, softening point 125-135°C

- Surfactant (stearic acid): 5-8% of binder mass

Wax-based binders work best for tungsten heavy alloys in metal injection molding. Incomplete debinding can restrict final density to 94-96% since leftover binder leaves 0.1-0.5 wt% carbon contamination that reacts with tungsten at sintering temperatures (1,475°C) to form tungsten carbide.

Binder-Binder Phase Transition Considerations

Different binder components create complex interactions during the metal injection molding services production cycle. Regular multi-component binder systems need complex multi-step processes for mixing and debinding. New approaches use solid binder mixing at room temperature instead of traditional liquid binder mixing at high temperatures (around 150°C).

Research on tungsten-based composites reveals that mechanical milling of sub-micron tungsten-based composite and paraffin wax powders at room temperature can cut the needed paraffin wax volume fraction to 0.2 while making solid compacts. This method eliminates dimensional changes after thermal debinding. The volumetric decreases match the original binder volume fraction, with equal shrinkage in all directions.

Adding rare earth oxide nanoparticles through the binder marks another breakthrough. These particles stop tungsten grain growth during high-temperature sintering without hurting densification.

Evaluating Binder Systems for Industrial MIM Machines

Selecting the right binder systems for industrial MIM applications requires careful evaluation of flow characteristics, burnout profiles, and long-term stability. These elements streamline processes and determine the final part quality in metal injection molding operations.

Binder Flow Behavior in Industrial Metal Injection Molding Machine

The processability during injection molding depends on the rheological properties of the MIM feedstock. The core team must evaluate these parameters carefully:

- Viscosity and shear sensitivity

- Melt flow index

- Temperature-dependent flow characteristics

A well-designed binder system combines multiple components like primary polymers (polyethylene, polypropylene), secondary polymers, waxes, and surfactants. This combination creates balanced rheological properties during molding. The powder loading needs optimization to achieve proper flow while maximizing metal content, with ranges typically between 55-65% by volume.

Manufacturers use additives such as plasticizers and flow modifiers to adjust rheological behavior. These ensure complete mold filling without separating powder and binder components during injection [3]. JH MIM brings exceptional expertise with 20 years in Metal injection molding and Powder metallurgy. They deliver precision-engineered products to global customers using optimized binder formulations.

Binder Burnout Profiles in High-Volume Production

Multi-component binder systems need precise control during sequential debinding steps. Defects like blistering or cracking occur when primary binders remain before thermal debinding. The original standardized protocols posed challenges for optimizing debinding cycles across different powder-binder combinations.

Research shows a powder-to-binder ratio of 93:7 provides the best flowability and enables complete debinding. This ratio adds slightly more binder to prevent separation and maintain uniform distribution throughout the molded part. High-quality components require complete binder removal since leftover binder can affect mechanical properties and appearance.

Binder System Stability in Long Cycle Times

Temperature changes during processing can separate powder and binder components. This creates powder-binder segregation, leading to density gradients in molded parts. The segregation becomes more noticeable during long production runs or when feedstock goes through multiple reprocessing cycles.

Studies on binder recycling reveal that the biggest changes happen by the fourth recycling cycle. After this point, material viscosity and processability start declining. Melt flow index measurements support this four-cycle limit for maintaining quality. TGA results show specific decomposition stages, where early material loss comes from slip agents and wax breaking down.

Particles with a D50 of 20 μm show higher chances of flow-induced defects. Water-atomized particles with irregular shapes help minimize these issues.

Performance-Driven Binder Phase Engineering

Selecting the right binder phase is crucial for the metal injection molding process success. This choice shapes how tungsten alloy components perform. Different binder phases bring unique benefits that match specific uses.

Ni-Fe vs Ni-Cu Binder Phase: Mechanical Trade-offs

Nickel-based systems lead the way in tungsten-based heavy alloy applications. Ni-Fe binders work exceptionally well with tungsten during sintering. They create continuous metallic matrices that deliver the perfect balance of strength and plasticity for structural and protective components. Ni-Cu systems shine differently. Their non-magnetic properties and resistance to corrosion make them ideal for precision instruments in specialized settings. You’ll find nickel and copper in solid solution across all non-magnetic grades.

Cobalt-Based Binder Phase in Abrasive Applications

Cobalt remains the top choice for cemented tungsten carbides compared to alternatives like nickel. Its high melting point of 1493°C and great high-temperature strength make it stand out. Cobalt can form a liquid phase with WC at 1275°C. The material dissolves about 10% WC at this temperature. This creates a eutectic that brings exceptional hardness while keeping enough toughness. Lower cobalt levels boost hardness but reduce rupture strength and fracture toughness. Microstructures below submicrometer size deliver better hardness, toughness, and resistance to abrasion.

Copper Binder Phase for Electrical Conductivity

Tungsten-copper materials uniquely use copper. It connects the tungsten skeleton and handles core electrical functions. These systems focus on managing heat and electrical performance rather than maximum strength in metal injection molding machines.

Binder Phase Selection for Radiation Shielding Parts

Radiation shielding components made from tungsten alloys absorb 30-40% more X-rays than lead. They need just one-third of the space. Ningbo Jiehuang Chiyang’s expertise in metal injection molding services helps create these specialized parts for medical and nuclear applications.

Case-Based Binder Selection for Tungsten MIM Parts

Case studies show how choosing the right binder affects component performance in tungsten MIM applications. Each application comes with its own challenges that need specific binder solutions.

Binder Choice for Tungsten Ejector Pins

Wax-based binders boost sinterability and create uniform microstructures in tungsten ejector pins used under high stress. These binders help form an even grain structure during production. This structure is crucial for pins that take repeated impact and wear. The best binder systems contain 4-10% metallic phase by weight. This ratio maximizes hardness while keeping the toughness needed.

Binder Phase in Tungsten Carbide Nozzles

Cobalt stands out as the preferred binder material for tungsten carbide nozzles because it delivers excellent toughness and durability. Cobalt creates the perfect balance between hardness and structural strength for nozzles that face abrasive materials. The binder content typically ranges from 4-25% by weight. Lower concentrations give greater hardness when extreme wear resistance is needed.

Binder System for 5G Micro-Hole Components

5G micro-hole components need ultra-precise dimensional control. Binderless WC systems or minimal binder formulations let manufacturers create components with microfeatures as small as 0.1mm. Co-Ni-Cr alloy binders are a great choice because they resist oxidation better – a must-have for these precision applications.

Binder Selection for Medical Needle Holder Tips

Tungsten carbide needle holder tips used in medical settings need top-quality binders that ensure long-lasting durability and sharpness. These surgical instruments work best with TC (Tungsten Carbide) tips that have precise binder ratios. This precision helps maintain reliable performance during surgery.

Conclusion

The right binder can make or break the success of tungsten alloy metal injection molding processes. This piece shows how various binder systems work with tungsten’s unique properties to get the best results. A good binder needs to handle several tasks – it must support high powder loading, provide the right flow characteristics, and allow clean and quick debinding. The end use of the product, whether it’s radiation shielding, electrical parts, or medical instruments, plays a key role in picking the best binder system.

Research clearly shows that the right powder-to-binder ratios make a big difference in part quality. Tests point to a 93:7 ratio as ideal for tungsten alloys. The choice between wax-based, polymer-based, or multi-component systems shapes both how easy the material is to work with and the final part’s features like density, size accuracy, and strength. Three-component systems that use primary binders, backbone polymers, and surfactants work exceptionally well with tungsten’s challenging physical properties.

Working with tungsten alloys requires careful attention to material compatibility. Engineers must think over how binder systems interact with tungsten particle size, deal with thermal behavior in high-density alloys, and manage phase transition patterns. These elements determine whether the final sintered parts will meet tough performance standards in industries from defense to healthcare.

JH MIM brings nearly 20 years of expertise in Metal injection molding and Powder metallurgy. The company delivers precision-engineered products to customers worldwide using optimized binder formulations. This knowledge helps manufacturers achieve the highest sintered density and uniform microstructures their tungsten alloy parts need.

Picking the right binder system for tungsten alloy MIM parts isn’t easy, but it pays off with better design options, smarter material use, and superior part performance. As technology grows, binder systems will keep evolving to offer more precision and efficiency in this specialized manufacturing process. Companies that become skilled at choosing the right binders will gain a real edge in making high-quality tungsten parts that meet tough specs in many industries.

Key Takeaways

Understanding the critical role of binder selection in tungsten alloy MIM processes can significantly improve manufacturing outcomes and component performance across diverse industrial applications.

• Optimal powder-to-binder ratio of 93:7 maximizes flowability while achieving 64% powder loading for superior green density and reduced reject rates in tungsten MIM operations.

• Multi-component binder systems with wax, polymer, and surfactant provide balanced rheological properties essential for complete mold filling without powder-binder separation.

• Complete binder removal through controlled debinding prevents defects like cracking and contamination that compromise final part mechanical properties and dimensional accuracy.

• Application-specific binder selection drives performance – cobalt binders excel in abrasive applications, while Ni-Fe systems optimize structural strength for tungsten components.

• Thermal compatibility between binder and tungsten’s unique properties determines sintering success, requiring specialized formulations for high-density alloys with elevated melting points.

The success of tungsten alloy MIM depends heavily on matching binder chemistry to both material properties and end-use requirements, making informed binder selection a competitive advantage in precision manufacturing.

FAQs

Q1. What is the optimal powder-to-binder ratio for tungsten alloy metal injection molding? The optimal powder-to-binder ratio for tungsten alloy MIM is 93:7. This ratio provides the best flowability and supports complete debinding while maximizing metal content, typically achieving 62-65% powder loading by volume.

Q2. Why are multi-component binder systems preferred for tungsten alloy MIM? Multi-component binder systems are preferred because they provide balanced rheological properties during molding. They typically consist of primary polymers, secondary polymers, waxes, and surfactants, which together ensure complete mold filling without separation of powder and binder components during injection.

Q3. How does binder selection affect the final properties of tungsten alloy components? Binder selection significantly impacts the final properties of tungsten alloy components. It influences factors such as sintered density, dimensional accuracy, mechanical strength, and microstructure. The right binder system can optimize these properties for specific applications, whether it’s radiation shielding, electrical components, or precision medical instruments.

Q4. What are the key considerations when choosing a binder for tungsten carbide parts? For tungsten carbide parts, key considerations include the ability to form a liquid phase with WC at high temperatures, provide sufficient toughness, and contribute to the final hardness. Cobalt is often preferred as it dissolves WC at high temperatures, creating a eutectic that contributes to exceptional hardness combined with sufficient toughness.

Q5. How does the debinding process affect the quality of tungsten alloy MIM parts? The debinding process is critical for the quality of tungsten alloy MIM parts. Incomplete removal of binders can cause defects like blistering, cracking, or contamination during sintering. A properly controlled debinding process, often involving multiple stages, ensures complete binder removal without compromising the part’s structural integrity or final properties.