Modern vehicles use up to 600 sintered parts manufactured components in each car, with 10 to 15 kg of powder metal parts per vehicle. These numbers show how crucial powder metallurgy is in today’s automotive industry. Global leaders make over 10 million sintered components daily, and these precisely engineered parts are the foundations of automotive design.

Sintered steel components deliver excellent strength properties. Their tensile strength can reach 1,300 MPa, matching wrought structural steels or alloyed cast iron. On top of that, sintered metal products use over 97% of starting raw materials, which means minimal waste. These engineered sintered components need nowhere near as much energy to process compared to traditional metalworking technologies.

Making sintered metal parts allows high-volume production of complex shapes with fewer steps. The process saves energy and preserves natural resources because it often uses recycled metals. Automotive manufacturers looking for performance and sustainability need an experienced sintered parts manufacturer as their partner.

Overview of Sintered Parts in Automotive Engineering

Powder metallurgy (PM) is the lifeblood of manufacturing technology in modern vehicles. U.S. automobiles typically contain sintered parts weighing between 13 to 45 kg. This process has become crucial to creating precision automotive components that meet tough performance standards.

Definition of sintered metal parts and powder metallurgy

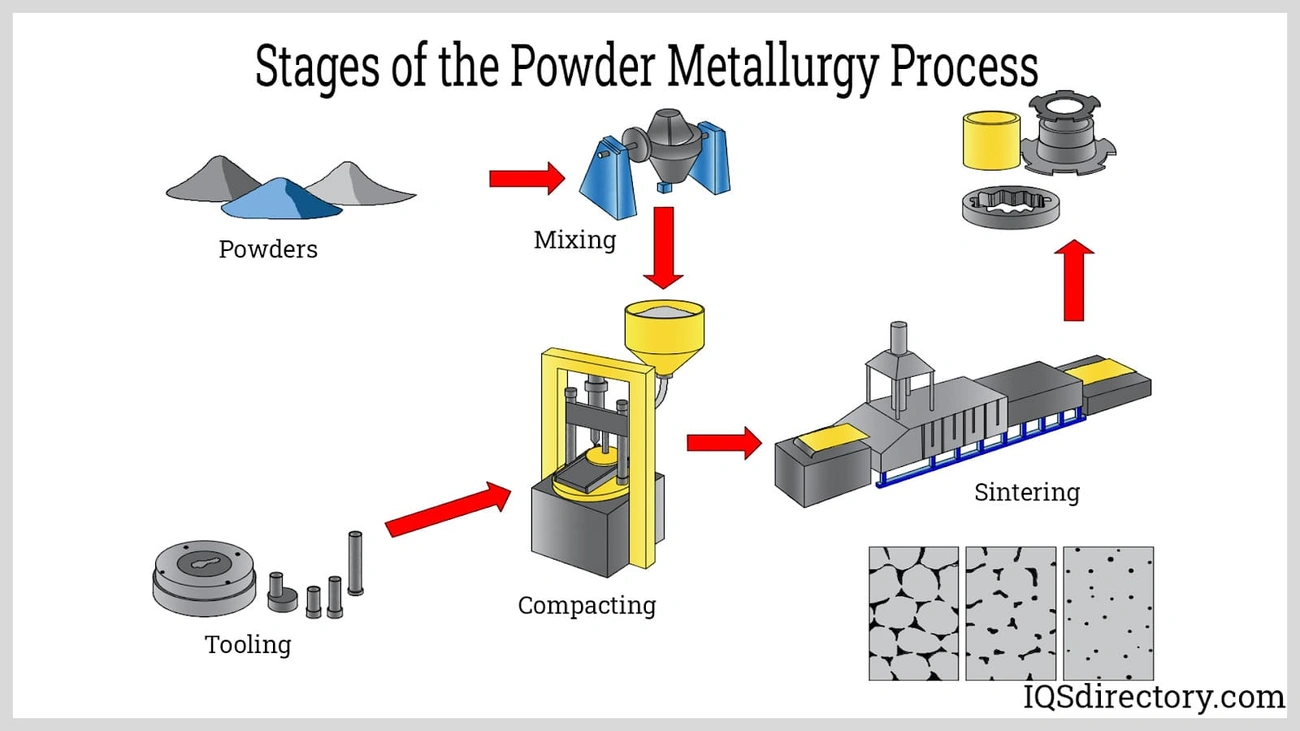

Powder metallurgy creates parts from metal powders through compression and heat treatment. The process compacts fine metal particles into a shape and heats them to a temperature below their melting point—a crucial thermal treatment called sintering. Metal powder particles fuse through intermetallic bonding without complete liquefaction. Sintering creates strong, dense parts through solid-state diffusion at about 70-90% of the metal’s melting temperature. This key difference—building parts from powder instead of melting or cutting solid metal—gives unique advantages to engineered sintered components.

Why is sintered steel ideal for automotive applications

Sintered steel stands out in automotive engineering because it uses materials so well. The process reaches 95-99% material utilization, which makes it valuable for expensive metals. Sintered metal parts also deliver remarkable dimensional accuracy with tight tolerances right from production. These components stay consistent in large production runs—a must-have for automotive assembly.

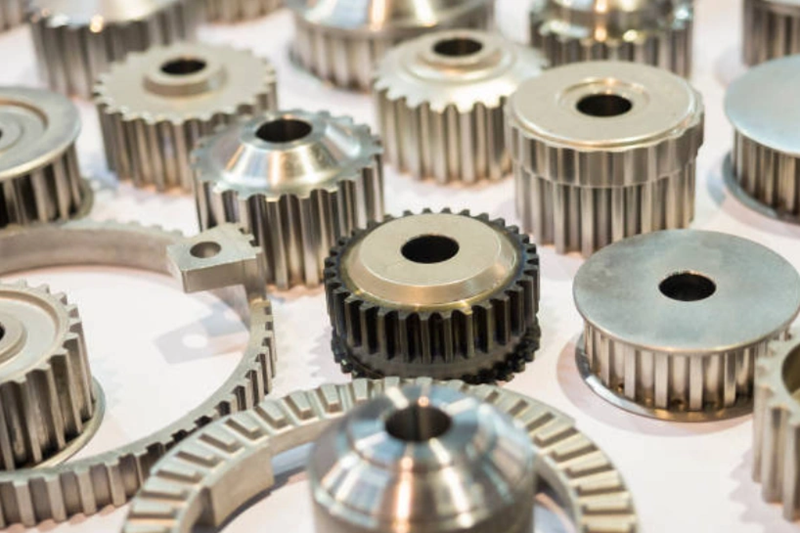

Powder metallurgy works with many raw materials like iron, steel, alloy steels, stainless steel, copper, aluminum, titanium, and soft magnetic materials. Engineers can pick the best compositions for specific uses, from engine parts to transmission systems. Yes, it is remarkable that modern automobiles use more than 1,000 powder metallurgy parts, ranging from camshaft gears to planetary assemblies.

Comparison with traditional machining and casting

Sintered parts manufacturing beats traditional machining in several ways. Traditional machining wastes 40-60% of raw materials through chips and shavings, while powder metallurgy reaches 97% efficiency. This huge difference saves money on premium materials like titanium and tool steel.

Sintering uses less energy because it heats materials below their melting points, unlike casting, which needs complete liquefaction. The powder metal process uses about half the energy per kilogram compared to machining. Sintered metal products also excel at making complex shapes with intricate features that would be nowhere near affordable through traditional machining.

Automotive manufacturers looking for affordable high-volume production find that sintered metal parts minimize or eliminate secondary operations. This efficiency, plus knowing how to create components with controlled porosity and unique material properties, makes powder metallurgy essential in modern automotive engineering.

Key Automotive Applications of Sintered Metal Components

The automotive industry leads the use of sintered metal components in vehicles. These components work effectively in transmission, engine, chassis, and exhaust systems. Their precision engineering delivers outstanding results in key vehicle operations.

Shift-by-Wire Actuators with sinter-hardened nickel steel

Electronic control systems have replaced mechanical transmission shifting through Shift-by-Wire (SBW) actuators. The assemblies contain compound AGMA 8 gears, trigger arms, links, and couplings made from sinter-hardened nickel steel. Each component goes through complete non-destructive testing to guarantee reliability. Sintered parts in SBW systems save more than 25% in costs compared to traditional manufacturing methods like turning, milling, or EDM.

Brake System Balancing Weights with tight tolerances

High-performance vehicles use a sintered steel brake system, balancing weights that make rotors last three times longer. These parts meet precise geometric tolerances that go beyond industry standards, which allows multiple versions from one toolset. This precision helps reduce temperatures and vibration, keeping drag minimal during critical braking.

Four-Wheel Drive Shifting Assemblies using planetary gears

Four-wheel drive shifting systems use planetary gear assemblies that help switch between two-wheel and four-wheel drive modes in trucks and SUVs. Each system typically has 16 AGMA 8 planet gears made from hybrid low-alloy sintered steel . The output shaft that connects the actuator motor to the transmission uses proprietary high-impact copper steel. It reaches a density of 7.7 g/cm³ with a tensile strength of 65 MPa (95,000 psi).

Minivan Door Clutch Assemblies with hybrid low alloy steel

Engineered sintered components make automatic operation possible for sliding doors and tailgates in minivans. The clutch assembly combines four parts: an armature, rotor blank, bearing, and pinion gear. These components use phosphorous iron material with a density of 7.0 g/cm³. They achieve an ultimate tensile strength of 45,000 psi and a yield strength of 32,000 psi. Smart tooling design ensures proper density that meets both magnetic and strength needs.

Material Science Behind Engineered Sintered Components

The science of materials is the foundation of sintered parts manufacturing. Specialized metal compositions enable the delivery of precise automotive performance characteristics.

Hybrid low-alloy steel vs. copper-infiltrated steel

Hybrid low-alloy steel powders combine nickel, molybdenum, and manganese as their key alloying elements. They use admixed graphite to provide carbon content. These formulations are most effective in medium- to high-density applications that require heat treatment to enhance strength and wear resistance. These hybrid low-alloy materials flow and compact better, which helps cut process costs.

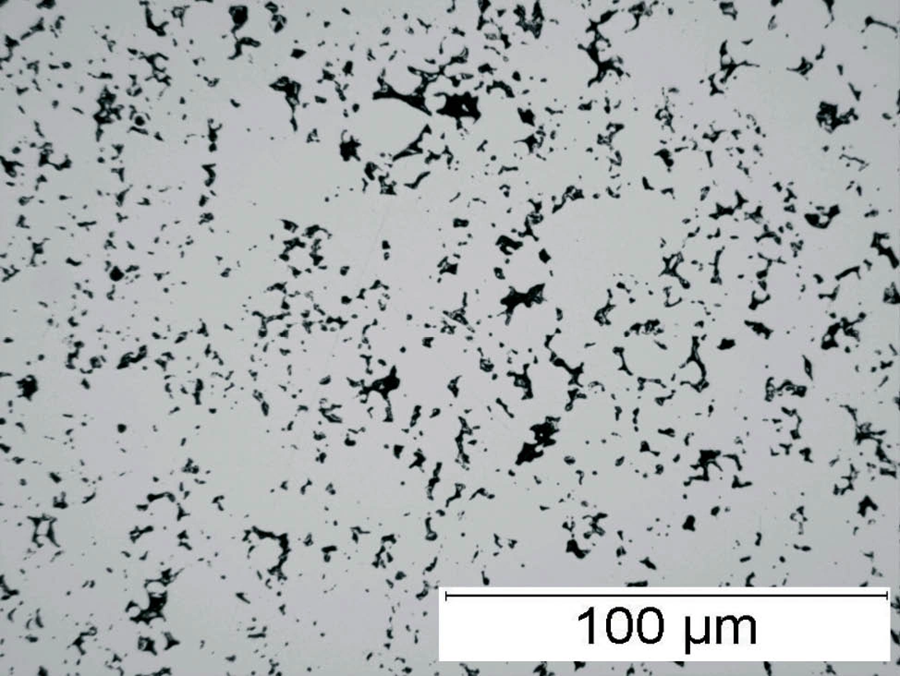

Steel components made with copper infiltration start as iron or iron-copper powder that’s compacted into shape before sintering. During this process, molten copper-based material fills surface-connected pores through capillary action. The result is a unique steel-copper structure that works great for medium-pressure hydraulic systems. Sealed-off pores make these parts easier to machine since there are fewer interrupted cuts from porosity.

300 and 400 series stainless steel in exhaust systems

The 300 series (austenitic) stainless steels contain chromium (16-18%) and nickel (8-10.5%). They resist corrosion well and excel in high-temperature applications. All the same, their oxide scales peel off easily, which makes them less suitable for some exhaust components.

The 400 series (ferritic) stainless steels mainly contain chromium (11.5-18%) with very little nickel. While they don’t resist corrosion as well as the 300 series, they handle oxidation better. SUS 436L is the go-to choice for most main mufflers. Cost factors have led more manufacturers to use SUS 436J1L, which contains less molybdenum.

Soft magnetic alloys for electric motor applications

Hiperco® alloys lead the pack among commercial soft magnetic materials. They show high permeability and low core loss. These iron-cobalt formulations deliver 25% higher induction and 30% lower losses compared to standard electrical steel. High Permeability 49 stands out with its excellent magnetic permeability, making it perfect for efficient, high-speed motor designs.

Alphaloy for high-temperature resistance in hot-end parts

Alphaloy is an iron-based powder metal alloy created specifically for hot-end exhaust applications. It replaces expensive materials like stainless steel. You can weld this specialized formulation without any post-welding heat treatment. Alphaloy also resists cyclic hot oxidation remarkably well, and its thermal expansion properties match those of stainless steels.

Benefits of Precision Sintered Metal Products in Automotive

Sintered metal products provide great value in automotive applications by balancing performance with cost benefits. JH MIM brings nearly 20 years of expertise in Metal injection molding and Powder metallurgy, serving global customers with precision-engineered products.

Dimensional accuracy and repeatability in mass production

Sintered parts hit tight dimensional tolerances consistently. These tolerances typically range from IT8 to IT9 and can improve to IT5-IT7 after sizing. Parts match each other perfectly, which leads to better product quality. The components stay remarkably consistent during high-volume production runs and come with excellent surface finish right off the line. This level of precision becomes particularly valuable for complex shapes that traditional machining doesn’t deal with very well.

97% material utilization and reduced machining waste

Powder metallurgy wastes very little material – it uses more than 97% of the starting raw materials. Traditional machining wastes much more, losing 40-60% of materials as chips and shavings. The higher utilization rate cuts production costs and makes powder metallurgy a truly green manufacturing process.

Lean manufacturing and cost savings over CNC

Sintered metal parts cost less than CNC machining once you make more than 40-50 units. The energy savings are impressive too – PM needs about 6.8 kWh/kg while traditional machining uses 8.4-11.4 kWh/kg. Sintering also removes the need for extra steps, which cuts costs by roughly 13.68% compared to CNC machining.

High fatigue strength and wear resistance in critical parts

Sintered steel components can handle extreme temperatures, corrosive environments, and heavy loads. Higher compacting density improves their fatigue resistance, especially when using techniques like sinter hardening. The right material choice can improve mechanical properties by a lot, with tensile strength going up 15-25% through specialized compositions.

Conclusion

Modern automotive engineering relies heavily on sintered metal parts as core components that outperform traditional manufacturing methods. Precision-engineered components deliver exceptional mechanical properties and maintain dimensional accuracy consistently. Raw metal powders transform into complex, high-performance parts through powder metallurgy to meet strict automotive standards.

Sintered components excel at material efficiency. Powder metallurgy uses over 97% of starting materials, while conventional machining wastes up to 60%. This conserves valuable resources and reduces production costs substantially. These versatile parts let manufacturers create specialized components for critical applications – from shift-by-wire actuators to high-performance brake systems and four-wheel drive assemblies.

Material science makes these components even more valuable. Sintered parts can meet specific performance requirements through hybrid low-alloy steel, copper-infiltrated steel, or specialized formulations like Alphaloy. JH MIM’s expertise spans nearly 20 years in Metal injection molding and Powder metallurgy, delivering precision-engineered products to customers worldwide.

Reduced energy consumption, fewer secondary operations, and streamlined production steps make sintered parts manufacturing beneficial for automotive manufacturers. Sintered metal components will remain crucial to automotive design and production as vehicles evolve with higher performance demands and stricter efficiency standards. Powder metallurgy’s combination of material efficiency, dimensional accuracy, and exceptional mechanical properties makes it an irreplaceable technology for today’s and tomorrow’s automotive industry.

Key Takeaways

Modern automotive manufacturing relies heavily on sintered metal components, with each vehicle containing up to 600 sintered parts totaling 10-15 kg per car. Here are the essential insights for understanding this critical manufacturing technology:

• Material efficiency advantage: Sintered parts achieve 97% material utilization versus 40-60% waste in traditional machining, significantly reducing costs and environmental impact.

• Superior dimensional precision: Powder metallurgy delivers IT8-IT9 tolerances directly from manufacturing, ensuring consistent part-to-part accuracy in high-volume production.

• Cost-effective for volume production: Sintered components become more economical than CNC machining after 40-50 units, with 13.68% lower production costs overall.

• Exceptional mechanical properties: Sintered steel achieves tensile strength exceeding 1,300 MPa while offering high fatigue resistance and wear performance in critical applications.

• Energy-efficient manufacturing: The sintering process requires approximately 6.8 kWh/kg compared to 8.4-11.4 kWh/kg for traditional machining methods.

The powder metallurgy process has become indispensable for automotive manufacturers seeking to balance performance, sustainability, and cost-effectiveness in modern vehicle production.

FAQs

Q1. What are the main advantages of using sintered parts in automotive manufacturing? Sintered parts offer high material efficiency (97% utilization), excellent dimensional accuracy, cost-effectiveness in high-volume production, superior mechanical properties, and energy-efficient manufacturing compared to traditional methods.

Q2. How do sintered metal components compare to traditionally machined parts in terms of cost? Sintered metal parts become more economical than CNC machining once production exceeds 40-50 units, with overall cost savings of about 13.68%. They also require less energy to produce, using approximately 6.8 kWh/kg compared to 8.4-11.4 kWh/kg for traditional machining.

Q3. What types of automotive components are commonly made using powder metallurgy? Common automotive applications for sintered parts include shift-by-wire actuators, brake system balancing weights, four-wheel drive shifting assemblies, and minivan door clutch assemblies. These components are found in transmission, engine, chassis, and exhaust systems.

Q4. How does the material science behind sintered parts contribute to their performance? The material science of sintered parts allows for specialized metal compositions that deliver precise performance characteristics. For example, hybrid low-alloy steels offer enhanced strength and wear resistance, while soft magnetic alloys provide high magnetic induction for electric motor applications.

Q5. What level of dimensional accuracy can be achieved with sintered metal products? Sintered parts typically achieve tight dimensional tolerances ranging from IT8 to IT9, which can be further improved to IT5-IT7 after sizing. This high level of accuracy ensures excellent part-to-part uniformity and consistency across high-volume production runs.

Pingback: A Review of the Top 5 High-Precision China Sintered Parts Factories