Powder metallurgy process adds about 10kg of components to today’s average modern car. This manufacturing method has become crucial to automotive production. The use of these highly precise components grows 6% to 7% each year per vehicle. Manufacturers worldwide use almost a million tons of iron and steel powder annually. About 90% goes into sintered component production, while 75% to 80% serves the automotive industry specifically.

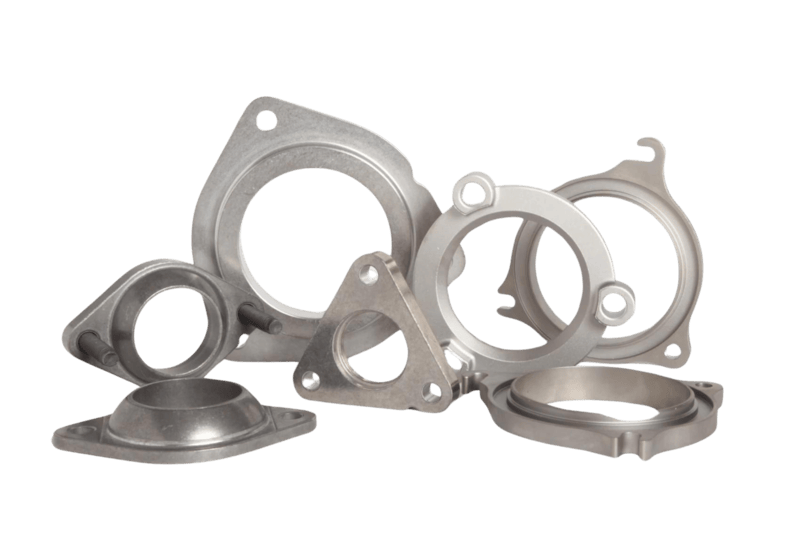

Exhaust systems present some of the most challenging applications for powder metallurgy processes. Many automotive companies and exhaust manufacturers have approved and now produce several powder metallurgy stainless steel exhaust components. These include coupling flanges and oxygen sensor bosses. Powder metallurgy’s benefits shine through its exceptional thermal stability, vibration resistance, and dimensional precision. Companies like JH MIM bring a unique experience with 20 years in Metal injection molding and powder metallurgy. They provide precision-engineered products to global customers that help advance this technology. This piece shows how powder metallurgy process steps solve complex exhaust flange designs by looking at material choices, production techniques, and real-life performance advantages.

Challenges in Designing Automotive Exhaust Flanges

Automotive exhaust flange design comes with many engineering hurdles because these parts must work in harsh conditions. Engineers use innovative methods like powder metallurgy to tackle these challenges.

Thermal Expansion and Vibration Resistance Requirements

Exhaust flanges face extreme thermal cycling from high-temperature exhaust gases as engine speeds change. This cycling creates thermal strain when parts are held by stays and other components. Over time, this leads to thermal fatigue failure. Studies show that bigger temperature differences (ΔT) and higher constraint rates mean shorter thermal fatigue life.

The cycles of heating and cooling can wear down or break flange fasteners, which leads to exhaust leaks. Vibration adds another tough challenge. Each cylinder makes similar periodic, complex vibration patterns that don’t sync with each other. This creates a demanding durability test.

Material Compatibility with Exhaust Gasses

AISI 321 and AISI 347 stainless steels barely hold up when exposed to 1500-1600°F for long periods. Materials at these temperatures suffer from high-temperature oxidation, carburization, and damage from combustion products.

Exhaust gases don’t flow evenly, which creates temperature differences of 300-400°F on certain parts. This makes distortion and cracking worse. That’s why exhaust flanges need steel or stainless steel (304L/316L) that meets AWWA C207-13 standards for heat and corrosion resistance.

Dimensional Tolerances in Multi-part Assemblies

Manufacturing always has some uncertainty, so making parts with exact measurements isn’t possible. This means engineers must carefully specify tolerances, especially for parts that touch each other.

The right tolerances balance function, manufacturing precision, and cost. Tighter tolerances improve performance, but this is a big deal as it means that production costs rise, particularly below certain limits. Standard dimensional tolerances for exhaust systems usually allow ±1/8″ linear changes and ±½° angular variations.

The pipe and flange connection must fit perfectly because gaps cause welding problems like “blow-through”. Powder metallurgy helps manufacturers achieve needed precision while keeping costs reasonable for these challenging parts.

Powder Metallurgy Process Steps for Exhaust Flange Production

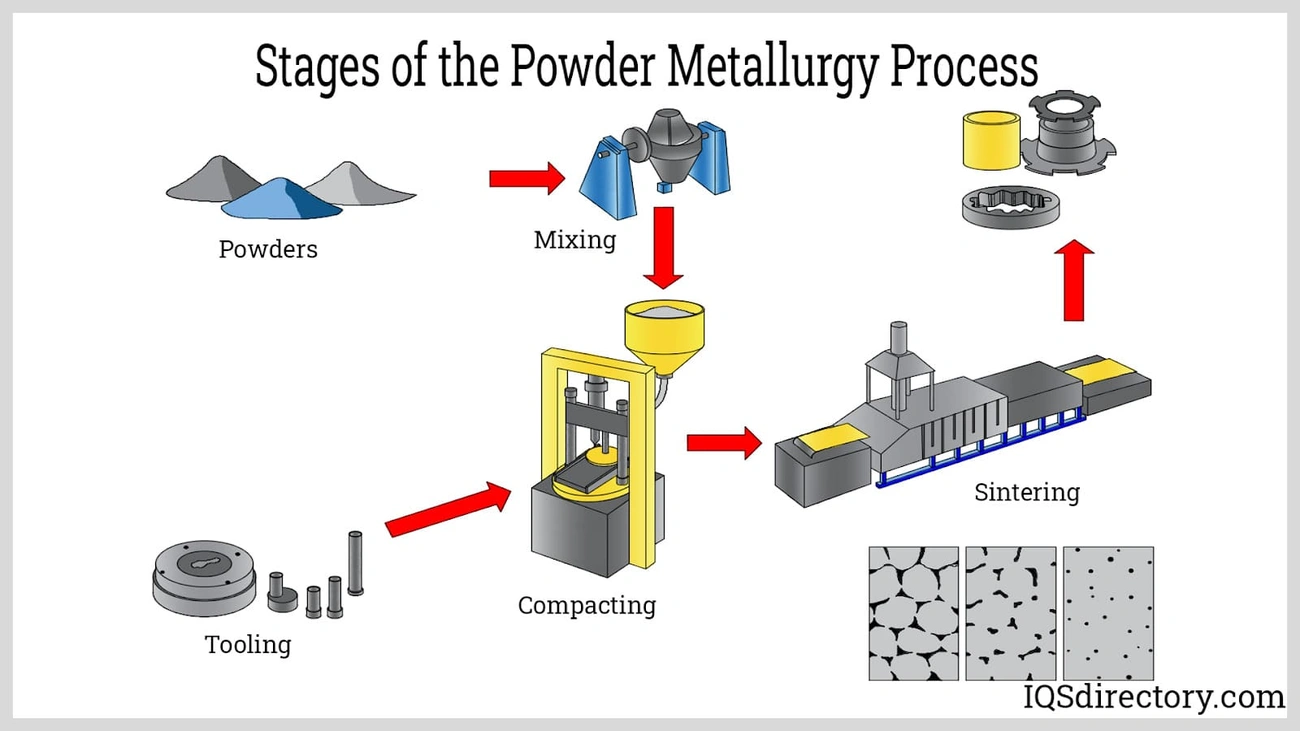

The production of exhaust flanges through powder metallurgy uses four manufacturing stages that create components with excellent dimensional accuracy and mechanical properties. Each step plays a vital role in determining how the final product performs.

Iron Powder Mixing with Graphite and Lubricants

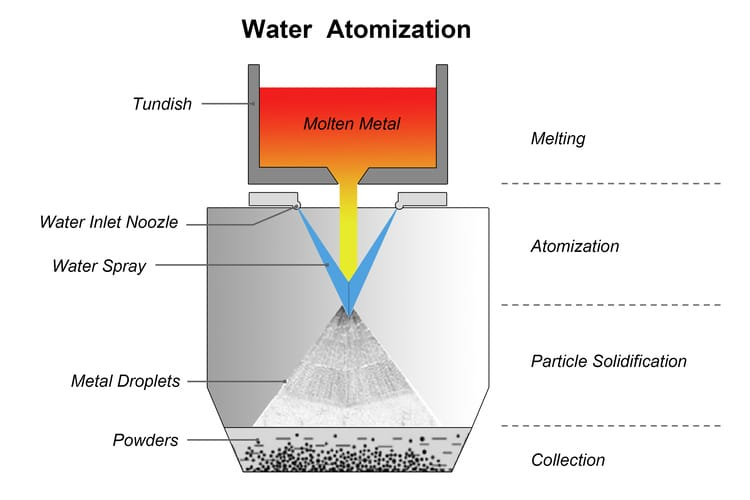

The process starts when manufacturers prepare metal powder, usually iron or steel powder. They mix these base materials with alloying elements like copper powder, graphite, and solid lubricants such as zinc stearate or amide wax. The mixture must be completely uniform because any variations will affect the component’s dimensional accuracy and physical properties. Manufacturers either bond the alloying elements to iron particles or create uniform particles by adding alloying elements before atomization. This prevents different powder particles from separating. Graphite serves as a key additive that will give maximum compression during later processing stages.

High-Pressure Compaction Using Precision Dies

The mixed powder goes through compaction in specialized presses. These machines use upper and lower punches to apply exact, high pressure that forms the powder into a “green compact”. Steel and other hard metals need compaction pressures between 400 and 800 MPa. The pressure must be high enough and last long enough to create mechanical bonds between metal particles. The final density and physical properties depend substantially on factors like pressure distribution, particle size, and lubricant content.

Sintering at 1100–1250°C in Controlled Atmosphere

The green compacts then undergo sintering at temperatures between 1100°C and 1250°C in controlled furnace environments. This heat treatment happens below the metal’s melting point and creates metallurgical bonds between particles. Stainless steel components need sintering in pure hydrogen atmosphere for 45 minutes to reach minimum density requirements of 7.20 g/cm³. The process typically achieves material density between 90% and 95% of theoretical density. The temperature control must be exact to make proper alloying and microstructural development possible.

Post-Sintering Treatments: Coining and Impregnation

Sintered parts often need secondary operations to improve their properties and dimensional accuracy. Manufacturers use sizing or coining to repress components, which improves dimensional precision and surface finish. This step also helps seal the powder metal part’s surface. Some applications use vacuum or oil impregnation techniques to increase density and strength. The exhaust flange components might also get heat treatments like induction hardening or carburizing to improve surface hardness and wear resistance.

Material Engineering in Powder Metallurgy for Exhaust Systems

Material selection is a vital factor when applying powder metallurgy processes to exhaust systems. Engineers need to assess material properties to get optimal performance in high-temperature environments.

Ferritic vs Austenitic Stainless Steel Powders

Ferritic stainless steels (400 series) give you specific advantages for exhaust flange applications. These materials contain 11-18% chromium and provide good corrosion resistance, among other low thermal expansion coefficients. Ferritic grades deliver better oxidation resistance during heat cycling and heat transfer rates that are nowhere near what austenitic alternatives offer.

Austenitic stainless steels (300 series) contain higher levels of chromium (16-26%) and nickel (6-22%). Their face-centered cubic structure creates excellent ductility but lacks the thermal properties that make ferritics better for exhaust applications. These austenitic grades shine in aggressive environments where you need superior corrosion resistance.

Porosity Control for Corrosion Resistance

The biggest problem in preventing corrosion lies in porosity management. Sintered stainless steels show corrosion rates that are two orders of magnitude worse than wrought counterparts. Interconnected pores let corrosive substances penetrate components, which creates this challenge.

Your manufacturing process directly affects porosity levels. Higher compaction pressures (750-1000 MPa) can reduce porosity to about 7%. Lower pressures (250 MPa) lead to porosity levels around 23%. Engineers can balance mechanical strength with other functional requirements through careful porosity control.

Prealloyed Powders for High-Temperature Stability

Prealloyed powders are the foundations of uniform composition throughout each particle. Manufacturers create these by adding elements like molybdenum, manganese, and chromium to molten iron before atomization. You get consistent properties and improved microstructure from this homogeneity.

Specialized alloys like Alphaloy show exceptional performance in hot-end exhaust applications. This iron-based powder metal alloy contains similar alloying constituents to ductile cast iron while keeping a ferritic microstructure. It resists cyclic hot oxidation better and has thermal expansion properties like stainless steels.

Case Study: Powder Metallurgy Exhaust Flange by Hoeganaes Europe

Höganäs Europe shows how powder metallurgy works in real-world applications through their exhaust flange production. This technology meets complex automotive needs effectively.

Component Geometry and Tooling Design

Gt. B Components Ltd in St Helens, UK, makes a simple yet effective exhaust flange using Hoeganaes Europe powder. The component’s design takes advantage of powder metallurgy’s ability to create complex shapes with undercuts and internal cavities. Their tooling design shows precision engineering that produces highly accurate dimensions – something traditional manufacturing methods can’t match. Each flange needs its own precision tool, which means substantial upfront costs.

Production Volume and Cost Efficiency

The exhaust flange production shows why powder metallurgy works best in high-volume manufacturing scenarios. Production becomes cost-effective at volumes of 100,000 similar parts or more, often reaching into millions. The process wastes very little material with scrap rates of just 3%, while machining operations waste about 50%. These parts roll off the production line at rates from several hundred to thousands per hour.

Performance Comparison with Machined Flanges

Performance tests show that powder metallurgy flanges are just as strong as machined versions, even with their natural porosity. Despite that, they dampen vibrations better because of their microstructure. The flanges stay dimensionally stable during thermal cycling, so they meet all the strict requirements for automotive exhaust systems.

Conclusion

Powder metallurgy is a game-changing manufacturing method for complex exhaust flange designs in automotive applications. This technique helps overcome major challenges that exhaust components face, especially when you have thermal cycling, vibration, and corrosion resistance requirements. The four-stage production process combines mixing, compaction, sintering, and post-processing to deliver exceptional dimensional accuracy while remaining economical at high volumes.

Material selection is vital, and ferritic stainless steels provide better thermal properties than austenitic alternatives. Proper porosity control boosts corrosion resistance, while prealloyed powders ensure the high-temperature stability needed for exhaust system performance. The Hoeganaes Europe case study shows these benefits through ground application, demonstrating both economic and performance advantages over traditional manufacturing methods.

Companies like JH MIM, with nearly 20 years of expertise in metal injection molding and powder metallurgy, keep advancing this technology. Their precision-engineered products for global customers have established powder metallurgy as the preferred manufacturing method for complex exhaust components.

Powder metallurgy offers a compelling solution for exhaust flange production by delivering components with excellent thermal stability, vibration-damping properties, and dimensional precision. These features, combined with cost efficiency at scale, are a great way to get durable, high-performance exhaust system solutions in the automotive industry.

Key Takeaways

Powder metallurgy offers a superior manufacturing solution for complex exhaust flange designs, delivering precision components that withstand extreme automotive conditions while maintaining cost-effectiveness at scale.

• Powder metallurgy achieves 90-95% material density through a controlled four-stage process: mixing, high-pressure compaction, sintering at 1100-1250°C, and post-processing treatments.

• Ferritic stainless steels outperform austenitic grades for exhaust applications due to lower thermal expansion coefficients and superior heat transfer properties.

• Production becomes economically viable at 100,000+ parts with material waste as low as 3% compared to 50% in traditional machining operations.

• Porosity control is critical for corrosion resistance – higher compaction pressures (750-1000 MPa) reduce porosity to 7% versus 23% at lower pressures.

• Prealloyed powders ensure uniform composition throughout particles, providing consistent high-temperature stability essential for exhaust system durability.

The technology addresses three major exhaust flange challenges: thermal cycling fatigue, material compatibility with corrosive gasses, and maintaining tight dimensional tolerances in multi-part assemblies. With powder metallurgy contributing 10kg of components per modern vehicle and growing 6-7% annually, this manufacturing method has become indispensable for automotive exhaust systems requiring exceptional thermal stability and vibration resistance.

FAQs

Q1. What are the main advantages of using powder metallurgy for exhaust flange production? Powder metallurgy offers exceptional thermal stability, vibration resistance, and dimensional precision for exhaust flanges. It also provides cost-effectiveness at high production volumes, with material waste as low as 3% compared to 50% in traditional machining.

Q2. How does the powder metallurgy process work for creating exhaust flanges? The process involves four main steps: mixing iron powder with additives, high-pressure compaction using precision dies, sintering at 1100-1250°C in a controlled atmosphere, and post-sintering treatments like coining and impregnation to enhance properties.

Q3. What materials are best suited for exhaust flanges made through powder metallurgy? Ferritic stainless steels are preferred for exhaust flanges due to their lower thermal expansion coefficients and better heat transfer properties compared to austenitic grades. Prealloyed powders are also used to ensure uniform composition and high-temperature stability.

Q4. How does powder metallurgy address the challenges of designing automotive exhaust flanges? Powder metallurgy tackles key challenges by producing components with excellent thermal cycling resistance, material compatibility with corrosive exhaust gasses, and the ability to maintain tight dimensional tolerances in multi-part assemblies.

Q5. At what production volume does powder metallurgy become economically viable for exhaust flange manufacturing? Powder metallurgy typically becomes cost-effective when producing at least 100,000 identical parts, often extending into millions. This high-volume capability, combined with low scrap rates, makes it an attractive option for automotive exhaust system components.