Allied Sinterings has expertly crafted powdered and sintered metal goods since 1959, building a rich tradition in this specialized manufacturing process. Sintered metal production starts with iron powder as its foundation. Manufacturers combine this base with specific alloying elements and additives to achieve desired properties. The particles bond together under intense pressure to create what’s known as a ‘green’ part.

The next step takes these green parts through a heating process in controlled conditions that prevent any oxidation or contamination. This technique results in sintered iron components and metal parts with exceptional qualities. The finished products deliver remarkable dimensional precision that meets customers’ strict tolerances and quality requirements. The biggest advantage lies in knowing how to produce complex-shaped components that other manufacturing methods struggle to create. These parts are a great way to get self-lubricating properties, which means they need less maintenance. Modern sintered metal production equipment works efficiently and cleanly. The process creates no harmful emissions like volatile organic compounds or greenhouse gases.

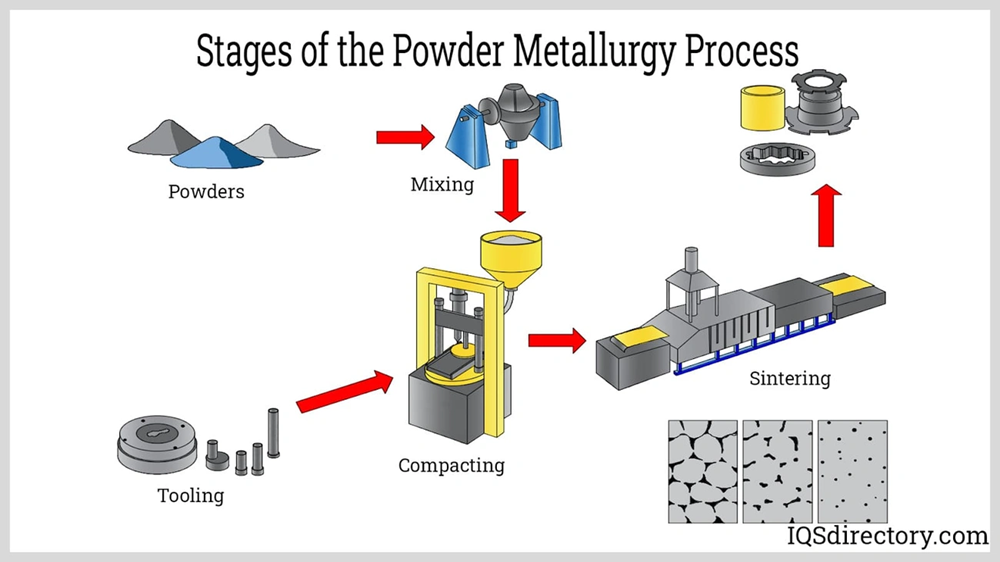

Powder Metallurgy Process for Sintered Iron Parts

Powder metallurgy turns raw metal powders into durable sintered iron components through multiple manufacturing stages. This precise process creates high-performance parts that have exceptional properties needed for automotive and industrial applications.

Iron Powder Selection and Blending Techniques

The process starts with the careful selection of metal powders. Three main types exist: atomized iron powder (produced by spraying molten iron into fine droplets), reduced iron powder (derived from iron ore reduced in hydrogen), and carbonyl iron powder (manufactured via thermal decomposition). Each powder type has unique characteristics that affect sinterability and final mechanical properties.

The blending process combines powders with alloying elements such as nickel, chromium, molybdenum, and manganese to improve corrosion resistance and mechanical strength. V-mixers uniformly blend materials at controlled speeds. Lubricants like zinc stearate help reduce friction between particles and improve powder flow during later processing stages.

Compaction Process Using Hydraulic Presses

The powder mixture then goes through compaction in hydraulic presses at pressures between 400-800 MPa. Hydraulic systems work better than mechanical alternatives because they offer precise control of pressure, dwell time, and ram speed throughout the compaction cycle. This level of control results in consistent density with minimal porosity, which directly improves structural strength and dimensional accuracy.

Sintering Furnace Parameters for Iron Alloys

Sintering furnaces heat the compacted “green” parts below their melting point—usually between 1120°C and 1300°C for iron-based materials. This vital process takes 15-60 minutes based on the application and allows atomic diffusion across particle boundaries. A controlled atmosphere (usually hydrogen-rich or inert nitrogen) prevents oxidation and maintains alloying elements.

Post-Sintering Treatments: Impregnation and Heat Treatment

Sintered components typically need additional treatments to boost performance. Impregnation adds materials into the component’s porous structure—oil for self-lubrication, resin for sealing, or copper to increase mechanical strength and toughness. Heat treatments such as quenching and case hardening change the microstructure to improve the finished parts’ hardness and strength.

JH MIM has nearly 20 years of experience in the Metal Injection Molding and Powder Metallurgy industry. We provide precision-engineered products to global customers who rely on these sophisticated manufacturing processes.

Performance Benefits of Sintered Iron in Automotive and Industrial Use

Sintered iron components stand out in many performance areas. They are perfect choices for automotive and industrial applications that just need reliable parts. These precision-engineered parts offer unique advantages that traditional manufacturing methods can’t match.

Dimensional Accuracy in High-Volume Production

Sintered steel components keep tight dimensional tolerances from IT8 to IT9 in as-sintered condition and improve to IT5-IT7 after sizing. The precision stays consistent through high-volume runs because tungsten carbide tooling defines part geometry. This tooling changes shape very slowly over hundreds of thousands of cycles. Electric vehicle planetary gears just need a strict 0.075mm runout tolerance, and powder metallurgy shows process capability (Cpk) of 1.33 in production.

Self-Lubricating Properties in Rotating Components

Self-lubrication capabilities work great thanks to the controlled porosity of sintered components. Manufacturers create a built-in lubrication system by forcing lubricant into microscopic cavities under pressure. The oil expands during operation due to heat and reaches the surface through capillary action. This creates a thin lubricating film between moving parts. The excess oil goes back to the pores when the components cool after the operation stops. This ensures continuous lubrication without any maintenance needed.

Reduced Material Waste Compared to Machining

Material utilization in powder metallurgy reaches an impressive 97% of starting raw materials. Traditional machining wastes 40-60% of materials as chips and shavings in comparison. The process just needs the exact powder amount for the final part. This makes it affordable and better for the environment.

Thermal Stability in High-Load Environments

Sintered bronze bushings work well in temperatures from 10°F to 200°F. Their porous structure spreads loads evenly. The bushings act like tiny shock absorbers that reduce stress on both the bushing and matching components.

Corrosion Resistance with Alloyed Iron Powders

Sintered iron alloys don’t resist corrosion as well as their wrought counterparts. Adding chromium, silicon, and other elements creates protective surface layers that substantially improve this property. The resistance to corrosion gets better as density increases, no matter what alloy you use.

JH MIM brings nearly 20 years of unmatched experience in Metal Injection Molding and Powder Metallurgy. We provide precision-engineered sintered metal products to global customers who rely on these advanced manufacturing processes.

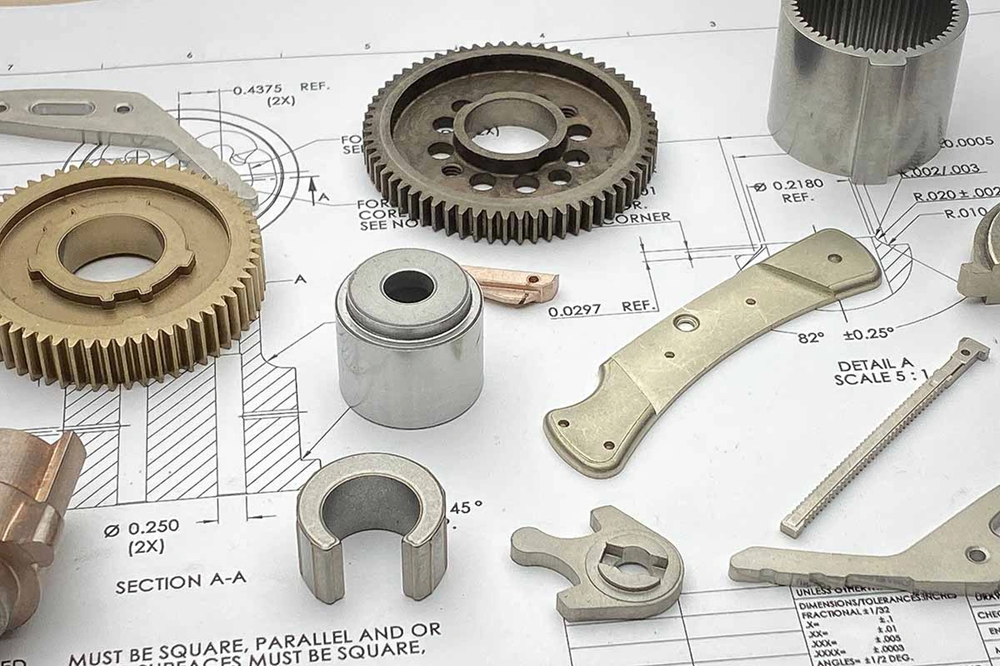

Automotive Applications of Sintered Iron Components

Sintered iron components are the backbone of many automotive systems. They deliver precise engineering with economical manufacturing benefits.

Transmission Gears and Synchronizer Hubs

Powder metallurgy creates synchronizer hubs that excel in both manual and dual-clutch transmissions. These components have precise internal and external splines with tooth profile accuracy of 0.022mm. The high-frequency quenching process helps them reach hardness levels above 40 HRC and tensile strength up to 550 MPa. These hubs can withstand constant torque transfer between components throughout a vehicle’s life.

ABS Sensor Rings and Brake System Parts

ABS rings play a crucial role in vehicle safety by sending wheel speed data to anti-lock braking systems. The powder metallurgy process creates these rings with a dimensional tolerance of ±0.02mm. These sintered ABS rings use F-0000 powder and reach 7.0g/cm³ density. The material usage rates go up to 95%, which removes the need for secondary processing.

Electric Motor Cores and Rotor Components

EV manufacturers choose sintered materials to make stator and rotor cores. These parts combine silicon iron, phosphorus iron, and electrical copper materials to achieve up to 99% IACS conductivity. You’ll find these sintered components mostly in e-axle transmissions and power electronics.

Engine Timing Sprockets and Oil Pump Gears

Timing gears keep the crankshaft and camshaft moving at precise 2:1 ratios. Oil pump gears need excellent strength and wear resistance due to tough operating conditions. Materials like FC-O2O8 help these components deliver reliable performance through thousands of cycles.

JH MIM brings 20 years of expertise in Metal Injection Molding and Powder Metallurgy. The company delivers precision-engineered products to customers worldwide.

Industrial Use Cases for Sintered Iron Parts

Sintered iron parts shine in many industrial settings that demand both durability and precision, well beyond their automotive uses.

Pump and Valve Components in Fluid Systems

Industrial fluid systems depend heavily on sintered iron components to deliver consistent results under pressure. These parts range from valve bodies and sealing housings to custom hydraulic manifolds. The components achieve leak-proof performance in high-pressure settings through copper infiltration or resin impregnation. These sintered iron parts ensure exact fluid transfer while maintaining dimensional stability.

Bearings and Bushings for Conveyor Systems

Self-lubricating sintered iron bushings deliver outstanding results in conveyor applications. The oil-impregnated design cuts down maintenance needs and optimizes operations. These components run continuously for 5,000-30,000+ hours without external lubrication. Their sintered structure acts like tiny shock absorbers by spreading loads evenly.

Gear Assemblies in Power Tools and Robotics

Power tools like angle grinders, chainsaws, and nail guns benefit from sintered iron gears’ reliable performance. These components excel in robotics where precision drives smooth, accurate movements. Robot joints, precision actuators, and end effectors all gain from these parts’ dimensional stability and wear resistance.

Compressor and Coupling Parts in HVAC Equipment

Air conditioners, refrigerators, and coolers use sintered pistons in their hermetic compressors. Sintered couplings excel at transferring torque between connected shafts. These parts reduce vibrations and absorb shock loads to protect connected equipment.

Custom Structural Parts for Agricultural Machinery

Agricultural equipment makers choose sintered iron for parts that must endure harsh field conditions. These components resist corrosion and need minimal maintenance. The range includes mounting brackets engineered to handle mechanical loads and structural frames.

JH MIM brings nearly 20 years of Metal Injection Molding and Powder Metallurgy expertise to global customers needing precision-engineered products.

Conclusion

Sintered iron components are the life-blood of modern manufacturing for automotive and industrial applications. These precision-engineered parts provide outstanding dimensional accuracy, self-lubricating properties, and remarkable material efficiency that traditional manufacturing methods can’t match. Manufacturers can create components with complex geometries and specialized performance characteristics through the powder metallurgy process – from powder selection through compaction and sintering to post-processing treatments.

Sintered parts play a vital role in critical automotive systems like transmissions, braking systems, electric motors, and engine timing mechanisms. The durability and precision of these components are essential in industrial applications of all types, including fluid systems, conveyors, power tools, HVAC equipment, and agricultural machinery.

Manufacturers looking for budget-friendly options in demanding applications choose sintered iron parts because of their technical and economic benefits. These parts have become essential elements in modern engineering due to their reduced material waste, dimensional stability, and consistent performance. JH MIM’s 20-year experience in Metal Injection Molding and Powder Metallurgy helps deliver precision-engineered products to global customers who rely on these sophisticated manufacturing processes.

Sintered iron components will keep playing a vital role in advancing automotive and industrial technologies. They deliver the performance, reliability, and efficiency that modern applications just need. The ongoing refinement of powder metallurgy processes will expand these benefits further and create many more possibilities for manufacturers in any discipline.

Key Takeaways

Sintered iron parts offer superior manufacturing advantages through powder metallurgy, delivering exceptional precision and performance for demanding automotive and industrial applications.

• Exceptional precision: Sintered iron maintains tight tolerances (IT8-IT9) with 97%+ material utilization, eliminating waste from traditional machining processes.

• Self-lubricating performance: Built-in oil impregnation creates maintenance-free operation for 5,000-30,000+ hours in rotating components and bearings.

• Versatile automotive applications: Critical components include transmission gears, ABS sensor rings, electric motor cores, and timing sprockets requiring precise dimensional accuracy.

• Industrial reliability: Pump components, conveyor bushings, power tool gears, and HVAC parts benefit from corrosion resistance and thermal stability.

• Cost-effective manufacturing: Near-net-shape production reduces secondary processing while achieving complex geometries impossible with conventional methods.

The powder metallurgy process transforms raw iron powders into high-performance components through controlled compaction, sintering, and post-treatments, making sintered iron parts essential for modern automotive and industrial systems requiring durability, precision, and efficiency.

FAQs

Q1. What are the main advantages of using sintered iron parts in automotive and industrial applications? Sintered iron parts offer exceptional dimensional accuracy, self-lubricating properties, reduced material waste, and the ability to create complex shapes. They also provide thermal stability in high-load environments and can be engineered for improved corrosion resistance.

Q2. How does the powder metallurgy process work for creating sintered iron components? The powder metallurgy process involves selecting and blending iron powders with alloying elements, compacting the mixture under high pressure, sintering the compacted parts in a controlled atmosphere furnace, and often applying post-sintering treatments like impregnation or heat treatment to enhance performance.

Q3. What are some common automotive applications for sintered iron parts? Sintered iron components are widely used in automotive applications such as transmission gears, synchronizer hubs, ABS sensor rings, brake system parts, electric motor cores, engine timing sprockets, and oil pump gears.

Q4. How do sintered iron bearings and bushings benefit industrial machinery? Sintered iron bearings and bushings offer self-lubricating properties, reducing maintenance requirements and enhancing operational efficiency. They can operate continuously for thousands of hours without external lubrication and help distribute loads evenly, acting as miniature shock absorbers in machinery.

Q5. What makes sintered iron parts environmentally friendly compared to traditional manufacturing methods? Sintered iron parts are environmentally friendly due to their high material utilization rate (over 97%) compared to traditional machining, which can waste 40-60% of materials. The powder metallurgy process also produces no harmful emissions like volatile organic compounds or greenhouse gasses and is highly energy-efficient with modern equipment.