How the MIM Process Enables Superior Part Formation

Metal injection molding stands as a breakthrough advancement in powder metallurgy that creates complex metal parts with excellent mechanical properties. This process combines the design freedom of plastic injection molding with the material performance of wrought metals.

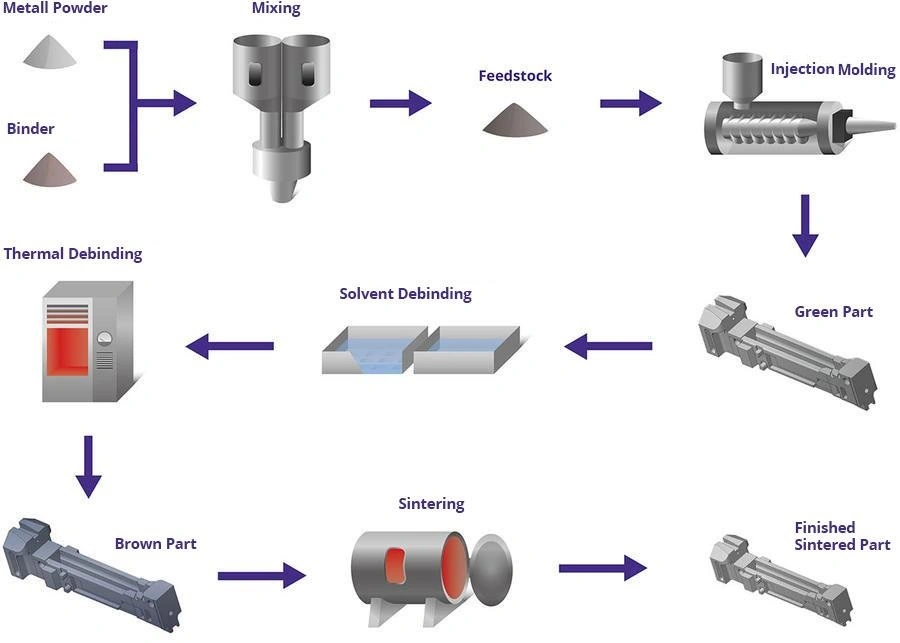

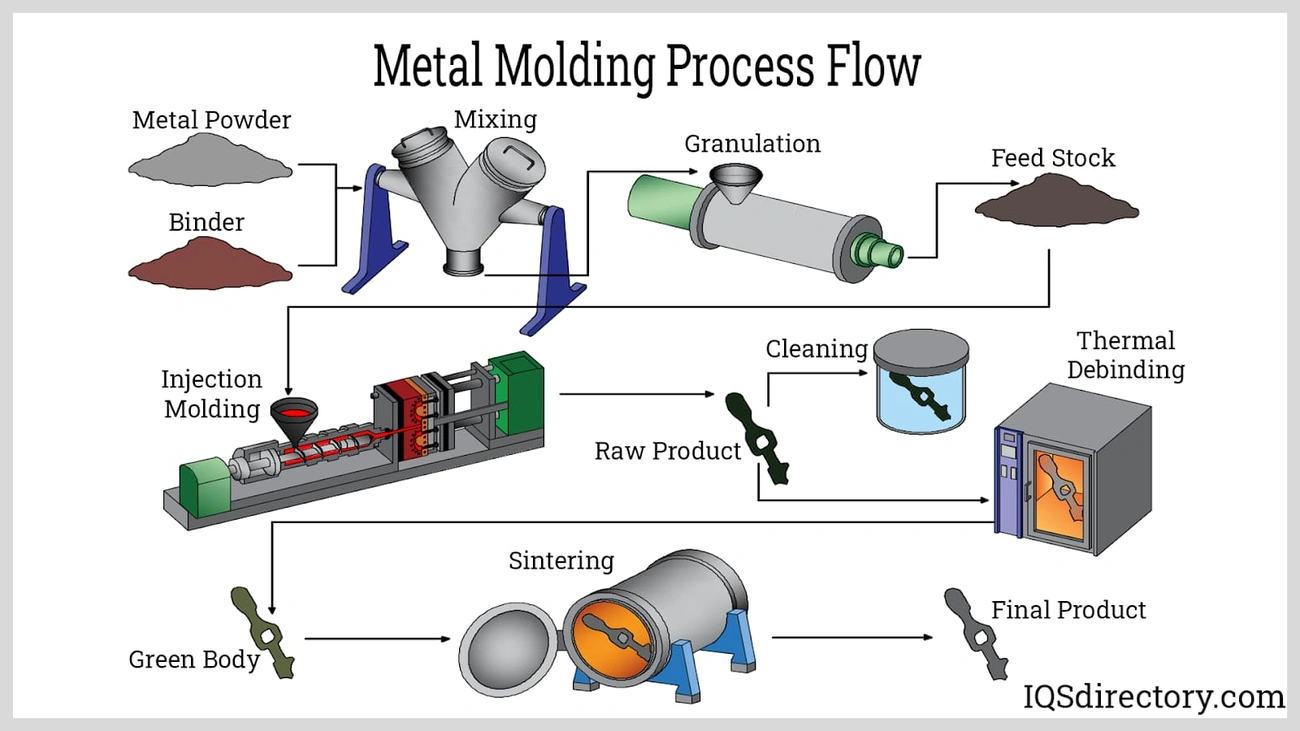

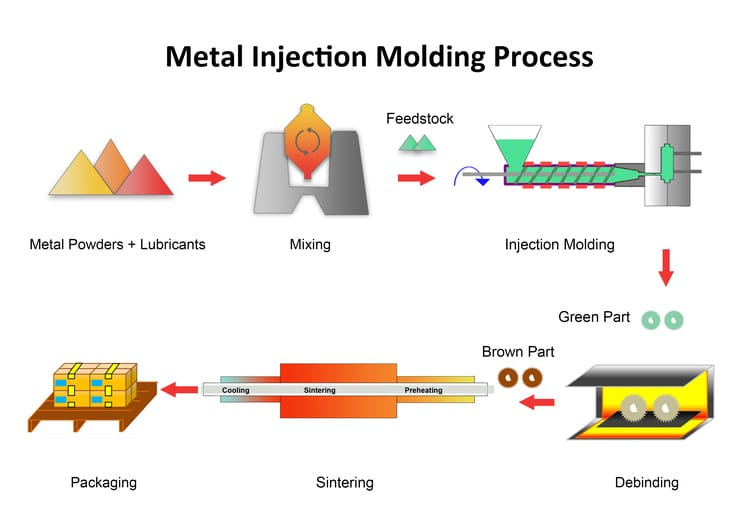

Feedstock Preparation in the MIM Process

The MIM process begins with the careful preparation of feedstock—a mixture of fine metal powders and binder materials. MIM works best with metal powder particles smaller than 45 μm, with optimal ranges of d10 > 2 μm, d50 = 9.8 μm, and d90 < 22 μm. These fine powders give a superior surface finish and better sinterability because of their larger surface area. The binder makes up about 40% of the feedstock volume and acts as a temporary carrier to help molding.

The metal powders and binders need proper blending to create an even distribution. A uniform mix prevents defects like black marks that show powder-binder separation and lead to sinking after sintering. The blended mixture becomes free-flowing pellets ready for injection molding machines.

Injection Molding of Metal-Binder Mixture

The feedstock pellets go into an injection molding machine’s heated barrel. Heat and screw forces turn the feedstock into a toothpaste-like material. High pressure pushes this plasticized mixture through gates into a mold cavity.

The cooled and molded part—known as a “green part”—comes out of the mold with its shape complete. This part contains the same metal powder and binder ratio as the original feedstock and measures about 20% larger than its final sintered form. The process creates intricate features, thin walls, and complex shapes that traditional manufacturing finds challenging.

Debinding and Formation of Brown Parts

Removing most of the binder while keeping the part’s shape marks the next vital phase. This debinding process works through several methods:

- Catalytic debinding removes the binder using gaseous acid (nitric or oxalic) at temperatures below its softening point

- Solvent debinding uses liquids like acetone, heptane, or water to dissolve the binder

- Thermal debinding uses controlled heating to melt and evaporate the binder

The part becomes a “brown part” after debinding—porous but stable from the remaining binder. These connected pores play a vital role in sintering by letting remaining binder escape and allowing uniform densification.

Sintering: The Key to Final Part Strength

Brown parts sit on ceramic setters inside a high-temperature furnace with a controlled atmosphere for the final step. The temperature rises to about 85% of the metal’s melting point. A stainless steel part might heat up to 1,350-1,400°C.

Sintering makes the remaining binder evaporate completely as metal particles fuse through diffusion. The process removes most pore volume that the binder occupied, causing 15-20% linear shrinkage. The uniform feedstock ensures even densification and excellent dimensional control despite this shrinkage.

The finished part reaches 96-99% of theoretical density and matches wrought metals in mechanical and physical properties. This remarkable change from powder to high-performance metal component shows why MIM-sintered parts perform better than traditional manufacturing alternatives.

Why Sintering Enhances Mechanical Properties

Sintering plays a key role in the metal injection molding process. It changes ordinary metal powder particles into reliable, high-performance components. This amazing transformation happens at the microscopic level and enhances mechanical properties through several mechanisms.

Uniform Microstructure from Atomic Diffusion

Metal atoms become mobile at sintering temperatures and move across particle boundaries. Their movement creates solid-state bonds between separate powder particles. The process happens in three stages. First, necks form between particles. Then, pores become rounded as grains start to grow. Finally, pores close and become isolated. Research shows that this diffusion-based process creates an even microstructure with consistent grain size. These uniform properties lead to predictable mechanical performance and eliminate weak points that often appear in cast materials.

High Density Achieved Through Controlled Shrinkage

Properly sintered MIM components stand out for their exceptional density. These materials reach impressive density levels between 95% and 99% of theoretical values. Studies show that each 1% increase in density leads to a 3-5% improvement in tensile strength. Temperature control during sintering makes a big difference. Research indicates that sintering at 1360°C for 1.5 hours in an argon atmosphere achieves 87% relative density. The same temperature with the wrong atmosphere might only reach 81% density.

Isotropic Strength vs. Directional Grain in Forging

MIM parts develop uniform properties in all directions, unlike forged components. Forged materials get “directional strength” because their grains align along specific flow paths. This directional property helps components designed for one-way stress, but creates problems for complex parts under multi-directional loads. MIM’s even strength distribution performs better for geometrically complex components that face stress from various directions.

Liquid Phase Sintering for Complex Alloys

Liquid phase sintering offers better results for challenging alloy systems. One alloy component melts during this process and improves densification through better atomic diffusion. This method works great for materials that are hard to sinter, such as aluminum alloys and superalloys. It helps create complex alloy components with better uniformity and higher final density. Recent studies prove its effectiveness – liquid phase sintering achieves nearly full densification (99.2%) in specialized 316L stainless steel compositions.

Performance Comparison: MIM vs Traditional Metalworking

Metal injection-molded parts show better performance characteristics than traditional metalworking techniques. JH MIM brings nearly 20 years of expertise in Metal injection molding and Powder metallurgy. The company delivers precision-engineered products to customers worldwide.

Tensile Strength and Hardness Benchmarks

MIM components reach impressive mechanical properties with 95-99% of theoretical density compared to traditional methods. MIM stainless steel components can achieve yield strengths of 750 MPa and tensile strengths of 900 MPa at 96% density. Heat treatment can boost these values to 1090 MPa yield and 1185 MPa tensile strength. The firearms industry notes that MIM parts show slightly lower properties than forged components, yet still reach about 90% of forged strength.

Dimensional Accuracy and Tolerance Control

MIM stands out by achieving tight tolerances between ±0.3% to ±0.5% of nominal dimensions. Die casting needs wider tolerances of ±0.5mm. Small components benefit from this precision, where traditional machining proves challenging or too expensive.

Surface Finish Quality Without Machining

MIM produces excellent surface quality without extra finishing steps. The process achieves roughness values below Ra 1.2 μm. Some manufacturers get surface finishes as smooth as Ra 0.8 μm. Surface roughness as low as 0.2μm has been achieved in mass production by using metal powder with an average particle diameter of 2μm.

Material Efficiency and Waste Reduction

MIM cuts down material waste by a lot compared to subtractive manufacturing methods. The process lets manufacturers recycle unused materials like feedstock remnants and sprues. Expensive materials like superalloys and precious metals benefit from this optimization.

Repeatability in High-Volume Production

MIM shows exceptional repeatability and consistency in high-volume manufacturing. Medical device manufacturing proves that MIM delivers consistent quality across large production runs. The automated production capabilities ensure better part-to-part consistency than many traditional manufacturing methods.

Application-Specific Advantages of MIM Sintered Parts

Metal injection molding (MIM) technology shows exceptional versatility in a variety of industries and provides tailored solutions for specialized applications. The right material selection and process optimization help MIM deliver remarkable performance advantages for critical components.

Medical Implants with Biocompatible Titanium Alloys

MIM-processed titanium alloys create highly biocompatible medical implants. These materials have become game-changers in orthopedic and dental applications because of their high specific strength, excellent corrosion resistance, and bone-like elastic modulus. MIM-manufactured Ti-6Al-4V components reach tensile strengths of 895-930 MPa while staying biocompatible and not interfering with advanced imaging methods. The technology helps create porous titanium structures that promote bone ingrowth, and studies reveal 46% bone ingrowth in just 60 days.

Aerospace Components with High-Temperature Superalloys

MIM-processed superalloys that handle extreme operating conditions are a great way to get aerospace advantages. To name just one example, Pratt & Whitney’s PurePower® PW1500G engines use metal injection molded components, which proves the technology’s acceptance in critical applications. MIM-processed Inconel 713C and Udimet 720 show promising high-temperature tensile properties up to 900°C. JH MIM brings nearly 20 years of experience to the metal injection molding industry and provides precision-engineered aerospace components to global customers.

Automotive Fuel System Parts with Tight Tolerances

Automotive fuel systems need components with exceptional dimensional precision and material performance. MIM-produced fuel injectors, pressure regulators, and pump gears keep tight tolerances while working well with various fuels. These components meet stringent international emissions standards such as Euro 6. The process also makes it easier to produce complex parts like turbocharger components that must withstand extreme operating conditions.

Miniaturized Electronics with Complex Geometries

The electronics industry now relies heavily on MIM to make miniaturized components with intricate geometries. MicroMIM technology specializes in components weighing less than 1 gram with critical features smaller than 100 microns. MIM outperforms traditional manufacturing techniques in producing electronic housings, heat sinks, microwave components, and PCB terminal blocks with superior precision. Electronics manufacturers get major advantages through MIM’s ability to create components with complex internal features and integrated channels.

Conclusion

Metal Injection Molding has revolutionized manufacturing by surpassing traditional metal fabrication methods in several ways. This piece shows how MIM creates better components by combining powder metallurgy with precision molding techniques.

MIM’s four-stage process includes feedstock preparation, injection molding, debinding, and sintering. This process lets manufacturers create complex metal parts with remarkable mechanical properties. The sintering process boosts material performance through uniform microstructure development, controlled densification, and even strength distribution.

When compared to conventional metalworking, MIM’s advantages are clear. These components show impressive tensile strength and hardness. They also maintain tighter dimensional tolerances and better surface finishes. MIM’s material efficiency and consistent repeatability make it the top choice for precision components.

MIM benefits show up in many industries. Medical implants need biocompatible titanium alloys, while aerospace parts require high-temperature superalloys. Automotive systems depend on precisely toleranced components. Electronics manufacturers need MIM for their tiny, complex geometries.

JH MIM stands out in this specialized field with almost 20 years of experience in metal injection molding and powder metallurgy. Their facilities cover more than 18,000 square meters. World-class machinery and 150 skilled workers power their operations. This blend of expertise, capacity, and precision makes JH MIM China’s leading metal injection molding manufacturer that serves customers worldwide.

Manufacturing’s future belongs to technologies that can create complex geometries with superior material properties while reducing waste. MIM keeps expanding into industries where traditional methods fall short. It has secured its place as a crucial manufacturing process for modern precision components.

Key Takeaways

Metal Injection Molding (MIM) represents a revolutionary manufacturing approach that combines powder metallurgy with precision molding to create superior metal components across diverse industries.

• MIM achieves 95-99% theoretical density through controlled sintering, delivering mechanical properties comparable to wrought metals with uniform microstructure and isotropic strength.

• Superior dimensional accuracy of ±0.3-0.5% and surface finishes below Ra 1.2 μm eliminate secondary machining operations while maintaining tight tolerances.

• Complex geometries impossible with traditional methods become feasible through MIM’s injection molding process, enabling intricate internal features and miniaturized components.

• Material efficiency reaches new heights with minimal waste generation and ability to recycle unused feedstock, particularly valuable for expensive superalloys and precious metals.

• Industry-specific advantages span critical applications from biocompatible titanium medical implants to high-temperature aerospace superalloys and precision automotive fuel system components.

The technology’s proven track record in demanding applications, combined with exceptional repeatability in high-volume production, positions MIM as the preferred manufacturing method for precision metal components where traditional metalworking methods fall short.

FAQs

Q1. What are the main advantages of Metal Injection Molding (MIM) over traditional manufacturing methods? MIM offers superior dimensional accuracy, complex geometries, excellent surface finish, and high material efficiency. It can achieve 95-99% theoretical density, resulting in mechanical properties comparable to wrought metals while minimizing waste.

Q2. How does the sintering process in MIM enhance mechanical properties? Sintering creates a uniform microstructure through atomic diffusion, resulting in high density and isotropic strength. This process eliminates weak points commonly found in cast materials and allows for consistent performance regardless of load direction.

Q3. In which industries is MIM particularly beneficial? MIM is especially advantageous in medical, aerospace, automotive, and electronics industries. It enables the production of biocompatible implants, high-temperature resistant components, precision fuel system parts, and miniaturized electronic components with complex geometries.

Q4. What level of dimensional accuracy can be achieved with MIM? MIM typically maintains tolerances of ±0.3% to ±0.5% of nominal dimensions. This precision is particularly valuable for small components where traditional machining would be challenging or cost-prohibitive.

Q5. How does MIM compare to forging in terms of material strength? While MIM parts may show slightly lower strength properties than forged components, they still achieve approximately 90% of forged strength. However, MIM offers isotropic strength, whereas forged parts have directional strength, making MIM ideal for components facing multidirectional loads.