Sintering cost reduction strategies are a vital part of today’s 3D printing market. The industry reached 13.7 billion USD in 2020, and experts predict it will hit 63.46 billion USD by 2026 at a 29.48% CAGR. This rapid growth shows how manufacturing leaders must balance new opportunities with challenges when they use additive manufacturing technologies.

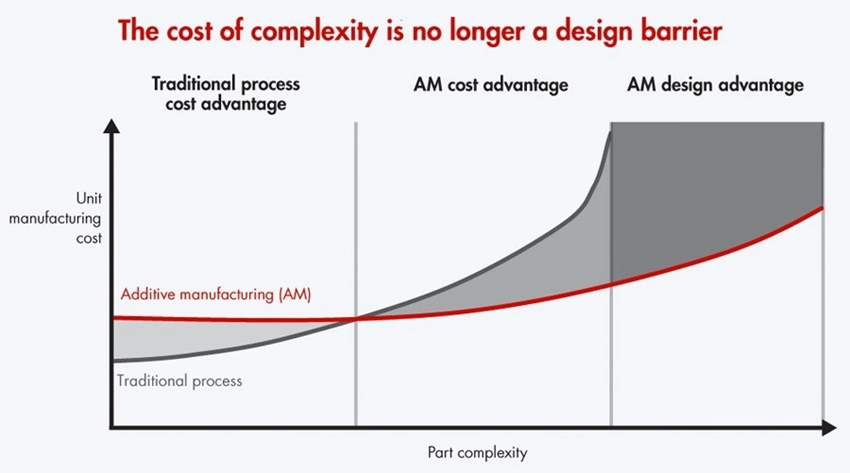

Two factors drive sintering costs in additive platforms of all types: machine time and materials. 3D printing gives manufacturers amazing advantages – they can create complex shapes that were impossible before and skip tooling costs for smaller runs. The key to managing these costs lies in smart planning. Volume plays the biggest role in determining costs, so manufacturing leaders need to create engineering strategies that match their production requirements.

This piece dives into proven ways manufacturing professionals can cut costs right away. Each section gives useful tips to reduce production expenses while maintaining quality. Readers will learn everything from picking the right infill patterns to choosing between FFF, SLA, and SLS technologies.

Understand the True Cost Drivers in Sintering

Sintering cost reduction works best when you understand where your money goes during production. Unlike traditional manufacturing, where tooling costs dominate the original expenses, sintering operations follow a different cost structure. This calls for specific ways to optimize costs.

Material usage vs. machine time

Material costs and machine operating time are the foundations of sintering economics. High-performance metal powders make up a big part of your expenses. Premium alloys cost more – titanium powder costs over $300/kg while stainless steel runs $50-60/kg. Yes, indeed, material costs often make up the biggest chunk of expenses in laser sintering processes. This differs from stereolithography and fused deposition modeling, where machine costs take the lead.

Two key factors determine how well you use materials:

- Packing density – Higher densities (up to 30% in benchtop systems) help you use build space better

- Refresh rate – Fresh powder needed for each new build, usually between 30-50%

You get the best results when packing density matches or beats the refresh rate. This creates a zero-waste printing workflow where you only need to replace sintered powder. Material utilization rates play a huge role in the economics – many cost models assume you’ll only use 50% of materials.

Hidden costs in post-processing

Post-processing costs more than the actual printing. These costs sneak up on you:

Equipment for post-processing ranges from $999 for simple depowdering kits to $50,000 for industrial solutions. Labor adds another big expense – workers spend lots of time taking parts off build plates. Parts with standard supports take 90% longer to remove than optimized ones.

Heat treatment adds another crucial cost to post-processing. Parts can warp when you skip thermal stress relief while removing them from the build plates. Aerospace applications need Hot Isostatic Pressing (HIP) equipment that costs between $1.5-3 million.

Energy consumption and labor

Energy makes up a big part of sintering expenses. The process uses 8-10% of a steel-making enterprise’s energy. Better sintering temperatures help save energy. Research shows you can cut theoretical energy use by increasing iron content in raw materials and reducing FeO in the final product.

Labor costs pile up, especially with complex systems that need dedicated technicians. You’ll spend at least a full working day cleaning and depowdering traditional industrial sintering systems before switching powder types. Better systems cut this downtime to four hours when switching between similar materials.

Running and finishing parts for one metal sintering machine can cost $150,000 yearly. Electricity adds about $3,000 per year, depending on local rates. Smart moves like optimized post-processing workflows and fewer manual steps can save you money.

Design Smarter: Reduce Volume and Complexity

Smart design principles are the lifeblood of effective sintering cost reduction. Companies can slash material usage and keep structural integrity by rethinking their manufacturing approach and reducing volume strategically.

Use lightweight structures and infill patterns

Gyroid infill patterns give you exceptional strength-to-weight ratios because of their interlocking geometry. MIT research shows that graphene compressed into a gyroid structure is 10 times stronger than steel at just 5% of the density. This principle works with sintering materials of all types, which helps manufacturers optimize structural performance and cut costs at the same time.

Most functional sintered parts work best with 15-25% infill – this sweet spot balances material savings and mechanical performance. Parts that need more rigidity can use up to 40% gyroid infill and still avoid solid interiors.

You can also try these infill options:

- Adaptive cubic: This adjusts density based on wall proximity and creates larger middle cavities. It uses about 25% less material than rectilinear patterns

- Support cubic: The density increases near the top layers. You’ll use less material than any other supported infill

- Hexagonal: You get excellent mechanical resistance with optimized material paths

Avoid overhangs and unnecessary supports

Support structures waste time, energy, and material during both construction and removal. They create many manufacturing headaches – powder waste, higher fabrication costs, and surface quality problems.

Here’s how to minimize support structures:

- Put the largest face flat on the build platform. This improves print success and sintering performance

- Add chamfers (0.5-1.0 mm) to the bottom edges so they don’t splay

- Design overhangs at gentler angles – surfaces built at angles over 45° to the build plate usually stay good without supports

Smart process parameters for overhanging areas (downskin parameters) now let you print overhanging angles to about 25° without supports. Special parameter tweaks might even get you down to 10°.

Hollow out parts where possible

Hollow structures cut material usage throughout the sintering process. Volume drives the main cost in sintering, so removing non-functional material saves money directly. This works because unsintered powder naturally supports hollow designs in selective laser sintering (SLS).

Make hollowing work better by:

- Using shell commands in CAD software that leave only essential channel walls

- Keeping wall thickness consistent (usually 2-3mm) to avoid thermal stress concentrations

- Adding multiple escape holes (at least 3.5mm wide) so powder can get out of hollow parts

- Connecting features with lightweight structures that use diamond-shaped holes to save more material

Hollowing thick parts makes wash time shorter because fluid flows through channels and dissolves binder material faster. This technique also reduces thermal stresses during sintering, which helps since big thickness changes can make parts warp or curl.

These engineering cost reduction strategies help manufacturing leaders implement cost reduction categories while keeping part functionality and quality intact.

Choose the Right Sintering Technology

The right choice of sintering technologies can lead to major cost reduction opportunities that manufacturing leaders often miss. Each technology brings specific benefits to different production scenarios and affects both upfront investment and running costs.

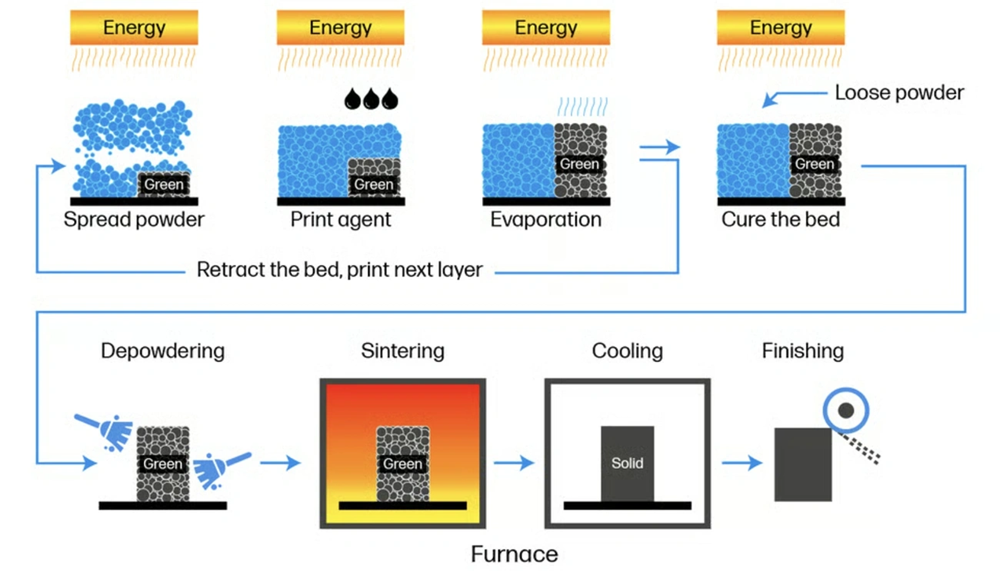

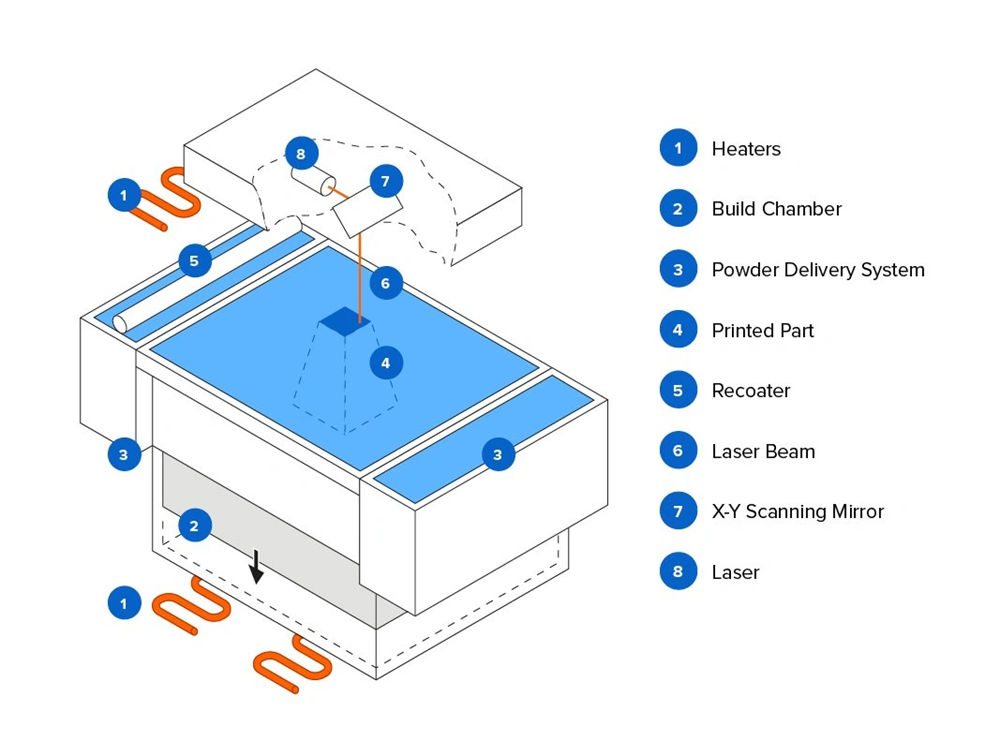

Compare DMLS, SLS, and binder jetting

Direct Metal Laser Sintering (DMLS), Selective Laser Sintering (SLS), and binder jetting come with their own cost structures:

DMLS costs range from $150-$300 per machine hour and create parts with superior mechanical properties (about 98-99% density). The need for support structures and post-processing adds to the total costs.

SLS delivers similar precision with different materials. The process works great with plastics and needs no support structures because the surrounding powder bed supports overhanging features naturally. This leads to less waste and lower post-processing needs.

The production economics of binder jetting are impressive—it runs at $100-$200 per hour, which beats DMLS rates. The process can make materials 10-100 times faster than DMLS. All the same, binder jetting reaches only 95-97% density, which might affect strength.

Match technology to part function and volume

The right match between technology and application needs will give optimal cost-efficiency:

DMLS shines in making performance-critical components that need aerospace certification or medical implants, where high strength and precision justify higher costs. The mechanical properties come close to wrought materials, making it perfect for zero-failure applications.

Binder jetting works best for medium-to-high volume production of components that don’t need maximum strength. Engine components, transmission housings, and heat management systems are perfect examples.

SLS strikes a balance—it creates detailed parts for functional testing or limited production runs at a lower cost than DMLS. The process can create lightweight structures and complex geometries without supports, making it cost-effective for specific uses.

When to switch from prototyping to production

Changing technologies as volumes grow can lead to big sintering cost reduction:

Many manufacturers start with DMLS for prototyping high-performance components. Production volumes increase, and a switch to binder jetting can cut per-part costs by a lot through faster build speeds and lower operating costs.

State-of-the-art developments have made SLS available to more users—new benchtop industrial systems need less energy and run on standard AC power instead of specialized infrastructure. Small manufacturers can now exploit engineering cost reduction strategies that only large enterprises could use before.

The final cost calculation depends on the part quantity. DMLS might still be cost-effective for small batches (1-10 pieces) despite higher hourly rates. Production scaling to hundreds or thousands makes binder jetting’s speed advantage more economical, even with extra sintering furnace time.

Optimize for Post-Processing and Finishing

Many manufacturers don’t realize how much post-processing adds to their sintering costs. You can cut production expenses by making downstream processes more efficient.

Minimize support structures

Metal additive manufacturing faces a big challenge with support structures. These structures waste materials and need lots of work to remove. The way you design supports affects both cost and quality. Studies show that regular support structures take 90% longer to remove compared to better-designed ones.

Topology-optimized support structures use 60% less material while staying strong enough to prevent distortion. This means you save on materials and spend less time on post-processing. Most supports are wasted material, but clever designs can turn them into useful features like cooling channels.

Design for easy powder removal

The quality of powder removal affects surface finish, mechanical properties, and overall part quality. So designers should remember these key features:

- Put at least two escape holes (minimum 3.5mm diameter) in hollow parts to help get all the powder out

- Stay away from small cavities or holes below 1mm that trap powder

- Make internal channels smooth instead of curved to prevent powder from getting stuck

When working with bone-inspired lightweight designs, you need architecture that lets powder flow out easily. Research shows properly designed powder-removal structures are only 10.35% weaker than solid parts, which gives great weight savings without losing much strength.

Reduce manual labor through automation

Automation changes the economics of sintering by cutting labor costs and making results more consistent. Manual work varies with operator skill, but automated systems give the same results every time.

AMT’s systems like PostPro SF100, use automated vapor smoothing, chemical polishing, and surface treatments in closed-loop systems. Their PostproDP systems are great at removing leftover powder, which makes manufacturing cleaner and requires fewer workers.

Automated systems do more than save on labor – they’re better at material recovery because they can collect unsintered powder more efficiently. This wastes less material and uses less energy. Your skilled workers can focus on complex tasks instead of repetitive manual work that might cause injuries [8].

Plan for Scale: Batch Strategy and Build Orientation

Strategic batch planning is a key method to achieve sintering cost reduction. The way parts are arranged in the build chamber plays a crucial role in production costs.

Stack and nest parts to maximize build volume

Smart nesting techniques help you fit multiple components together like pieces in a Tetris game. This maximizes machine usage and cuts down costs per part. Technicians can now prepare several builds at once with multiplatform nesting options. This lets them focus on more valuable tasks rather than spending time on repetitive arrangements. Modern software uses two powerful algorithms – bounding box nesters work with rectangular shapes while geometry nesters handle organic forms. These automated solutions complete the process in seconds.

Reduce Z-height to cut machine time

The vertical dimension makes a big difference in sintering economics. Each layer needs mechanical movement, which adds significant time to builds. Parts oriented horizontally tend to be more economical than vertical orientations. Setting specific “ceilings” for builds helps complete projects within target timeframes and boosts density.

Use cost reduction services for production planning

Production planning services help spread overhead costs across multiple parts. These services calculate the best orientation through numerical simulations. Simple geometries can see up to 100% improvement in mechanical performance. The services also optimize batch configurations. When parts are packed efficiently, the laser travels less distance between sintered regions, which saves time.

Conclusion

Cost reduction in sintering gives manufacturing leaders a competitive edge in today’s faster-growing additive manufacturing market. Material consumption and machine time remain the biggest expenses. Smart approaches can cut production costs by a lot while quality standards stay intact.

A clear understanding of the cost structure helps optimize processes better. Material selection and utilization efficiency affect profits directly, especially since high-performance metal powders cost premium prices. On top of that, hidden costs like post-processing and energy use often exceed actual printing expenses, making them key areas to improve.

Smart design principles create major savings chances without doubt. Cutting volume through lightweight structures, proper infill patterns, and hollow designs reduces material use while keeping structural strength. Parts designed without unnecessary supports and overhangs waste less material and have better surface finish.

Your choice of technology shapes cost management just as much. DMLS, SLS, and binder jetting each work best for specific part functions, production volumes, and performance needs. Leaders should review these options carefully and switch between technologies as production grows.

Post-processing improvements offer another way to save money. Fewer support structures, better powder removal designs, and automated processes cut labor costs and boost consistency. These methods also help recover more material, which helps both profits and sustainability.

Smart batch planning helps machines run at full capacity through good stacking, nesting, and orientation choices. Professional planning services spread overhead costs across multiple parts while making configurations work better.

Manufacturing leaders who use these complete strategies will definitely gain an edge over competitors. Companies that become skilled at balancing quality, performance, and budget-friendly solutions through smart sintering will succeed. The market keeps asking for complex, custom components, and these companies will lead the way.

Key Takeaways

Manufacturing leaders can achieve substantial cost savings in sintering operations by implementing strategic approaches across design, technology selection, and production planning.

• Optimize material usage through smart design – Use lightweight structures, gyroid infill patterns (15-25%), and hollow designs to reduce material consumption by up to 60% while maintaining structural integrity.

• Select the right sintering technology for your volume – DMLS for high-performance prototypes, SLS for mid-volume functional parts, and binder jetting for high-volume production at 10-100x faster speeds.

• Minimize post-processing costs through design – Eliminate unnecessary supports, include 3.5mm+ escape holes for powder removal, and implement automation to reduce manual labor by 90%.

• Maximize build efficiency with strategic batching – Stack and nest parts like Tetris, orient horizontally to reduce Z-height, and use professional planning services to distribute overhead costs across multiple components.

• Focus on hidden cost drivers – Post-processing often exceeds printing costs, energy consumption represents 8-10% of total expenses, and material utilization rates below 50% significantly impact economics.

The key to successful sintering cost reduction lies in understanding that volume drives primary costs, while strategic optimization across design, technology, and planning can deliver competitive advantages without compromising quality standards.

FAQs

Q1. What are the main cost drivers in sintering? The primary cost drivers in sintering are material usage and machine time. High-performance metal powders can be expensive, with material costs often representing the largest portion of total expenses. Additionally, energy consumption, labor, and post-processing contribute significantly to overall costs.

Q2. How can I reduce material usage in sintered parts? You can reduce material usage by implementing smart design principles. Use lightweight structures and infill patterns like gyroid (15-25% infill), avoid unnecessary overhangs and supports, and hollow out parts where possible. These strategies can dramatically decrease material consumption without compromising structural integrity.

Q3. Which sintering technology is best for high-volume production? For high-volume production, binder jetting is often the most cost-effective option. It operates at lower hourly rates compared to DMLS and can produce parts 10-100 times faster. However, it typically achieves slightly lower density (95-97%) compared to DMLS, so it’s best suited for components that don’t require maximum strength.

Q4. How can I optimize post-processing to reduce costs? To optimize post-processing, focus on minimizing support structures through strategic design, incorporate features for easy powder removal (like escape holes), and consider automating post-processing tasks. Automation can significantly reduce labor costs and improve consistency in results.

Q5. What strategies can I use to maximize build efficiency? To maximize build efficiency, employ smart batch planning strategies. Stack and nest parts to utilize the full build volume, orient parts horizontally to reduce Z-height and machine time, and consider using professional planning services to optimize part arrangements and distribute overhead costs across multiple components.