AI transforms process control in metal injection molding by optimizing efficiency and minimizing defects. Facilities that embrace AI-Powered Process Control experience significant improvements. For instance, real-time adjustments and predictive maintenance lead to reduced machine downtime and extended equipment lifespan. Moreover, AI systems surpass traditional inspection methods, detecting defects earlier and preventing costly errors. Reports indicate that companies adopting advanced monitoring systems see defect rates drop by nearly 50%, underscoring the technology’s potential to enhance product quality and reduce waste.

Key Takeaways

- AI enhances efficiency in metal injection molding by optimizing processes and reducing defects.

- Real-time data analysis allows manufacturers to make immediate adjustments, improving product quality.

- Continuous feedback loops help teams identify and address issues before defects occur, fostering a culture of quality.

- Machine learning algorithms and image recognition techniques significantly improve defect detection accuracy.

- Predictive maintenance reduces unplanned downtime by identifying equipment issues before they escalate.

- AI-driven resource management leads to reduced waste and improved energy efficiency in production.

- Successful implementation of AI requires high-quality data and effective integration with existing systems.

- Companies that adopt AI technologies can expect measurable improvements in production quality and operational performance.

AI-Powered Process Control in Process Monitoring

Real-Time Data Analysis

Real-time data analysis plays a pivotal role in AI-Powered Process Control within metal injection molding. By leveraging advanced technologies, manufacturers can monitor critical parameters continuously. This capability allows for immediate adjustments, enhancing both process stability and product quality.

Key types of data that are essential for effective process monitoring include:

| Type of Data | Application |

|---|---|

| High-resolution cameras | Detect defects in real time with high accuracy, surpassing human inspection capabilities. |

| IoT sensors | Monitor spindle vibrations, nozzle temperature, and hydraulic pressure for predictive maintenance. |

| AI algorithms | Optimize debinding parameters like temperature and solvent flow to ensure quality control. |

AI systems analyze spindle vibrations, nozzle temperature, and hydraulic pressure. They can anticipate failures up to 48 hours in advance, significantly reducing unplanned downtime by 40%. This proactive approach ensures that manufacturers maintain optimal operational efficiency.

Moreover, AI technology in Generation 5 molding machines enhances efficiency, precision, and cost savings. The HT-XTEND system enables predictive maintenance and optimizes processing parameters. Real-time power monitoring improves operational transparency and aids in making informed manufacturing decisions. Adaptive control of fill and hold during injection maintains consistent parts and stable product weight, significantly reducing part weight variation.

Continuous Feedback Loops

Continuous feedback loops are integral to AI-Powered Process Control. They facilitate ongoing improvement by integrating Statistical Process Control (SPC) into the quality culture. This integration connects data, people, and processes, fostering a proactive quality management approach.

Immediate feedback enables quicker decision-making. Teams can address issues before defects occur, which is crucial in maintaining high quality. Real-time data contributes to ongoing process refinement, identifying areas for improvement over time. Continuous feedback loops help reduce scrap and accelerate learning in the manufacturing process.

By regularly reviewing process performance data, teams can identify trends and variations that may signal potential issues. This proactive approach leads to enhanced product quality and a culture of accountability. As a result, organizations can achieve significant improvements in their manufacturing processes, ensuring that they remain competitive in the evolving landscape of metal injection molding.

AI-Powered Process Control for Defect Detection

AI-Powered Process Control significantly enhances defect detection in metal injection molding through advanced machine learning algorithms and image recognition techniques. These technologies enable manufacturers to identify defects more accurately and efficiently than traditional methods.

Machine Learning Algorithms

Machine learning algorithms have emerged as powerful tools for detecting defects during the metal injection molding process. These algorithms analyze vast amounts of data to identify patterns and anomalies that may indicate defects. The accuracy of these algorithms varies, but many achieve impressive results. For instance, the following table summarizes the reported accuracy of different machine learning algorithms used in defect detection:

| Algorithm Type | Accuracy (%) | Notes |

|---|---|---|

| Decision Tree | >90 | Most accurate with little training data. |

| MLP Neural Network | 94 | Used quality indices from pressure curves. |

| Linear Regression | 84 | Predicted quality of micro-injection parts. |

These algorithms can process data from various sources, including sensors and historical production data. By doing so, they help manufacturers detect defects early in the production process, reducing waste and improving overall product quality.

Image Recognition Techniques

Image recognition techniques play a crucial role in identifying surface and internal defects in metal injection molding. These methods utilize advanced algorithms to analyze images of molded parts, allowing for precise defect detection. The following table outlines some common image recognition techniques and their applications:

| Technique | Description |

|---|---|

| Texture Analysis | Classical methods based on texture and local intensity analysis to detect defects in metal surfaces. |

| Deep Neural Networks | Utilized for defect classification, localization, and segmentation in industrial applications. |

| Faster R-CNN | Proposed for quasi-real-time detection of multiple damage types in structural visual inspections. |

These techniques often involve preprocessing steps to enhance image quality and defect visibility. For example, manufacturers may convert datasets to binary formats to improve defect pattern recognition. They might also apply morphological operations, Gaussian blur, and Otsu thresholding to refine images before analysis. The MobileNetV2 model, trained on a carefully curated dataset, has demonstrated high accuracy in classifying defects.

Comparative studies show that image recognition techniques outperform traditional defect detection methods in several aspects:

| Aspect | Image Recognition (Deep Learning) | Traditional Methods |

|---|---|---|

| Accuracy | Higher recognition rates | Subjective and variable accuracy |

| Speed | Faster processing | Slower, manual diagnosis |

| Robustness | More robust against noise | Sensitive to light and noise |

| Feature Extraction | Automated, with less manual input | Manual feature extraction is required |

| Adaptability | Adapts to unknown patterns | Requires model parameter adjustments |

By leveraging AI-Powered Process Control, manufacturers can significantly enhance their defect detection capabilities, leading to improved product quality and reduced production costs.

Predictive Maintenance with AI-Powered Process Control

Anomaly Detection

Anomaly detection serves as a cornerstone of predictive maintenance in metal injection molding. This process identifies subtle changes in equipment behavior that may signal impending failures. By analyzing historical and real-time sensor data, manufacturers can detect deviations from normal operating patterns. For instance, increased vibration or temperature fluctuations often indicate potential issues.

Key benefits of anomaly detection include:

- Timely maintenance interventions that help prevent costly downtime.

- Early identification of equipment degradation allows for proactive maintenance scheduling.

- Enhanced operational efficiency through reduced unplanned stops.

Predictive analytics programs can lead to a 30–50% reduction in unplanned stops. The financial impact of unplanned outages can be significant, with costs of around $125,000/hour. By implementing AI-Powered Process Control, manufacturers can minimize these risks and maintain smoother operations.

Maintenance Scheduling

AI optimizes maintenance scheduling by detecting early signs of equipment failure or performance degradation. This capability enables maintenance teams to schedule activities before breakdowns occur. The result is a significant reduction in unplanned downtime and an overall enhancement in operational efficiency.

The advantages of optimized maintenance scheduling include:

- Ensuring maintenance tasks are performed at the most opportune times.

- Extending the lifespan of machinery through timely interventions.

- Reducing operational costs associated with degraded equipment, which can consume 12-18% more energy.

Moreover, AI-driven predictive maintenance can reduce downtime by up to 50%. For example, a textile mill saved $320K annually after AI identified inefficiencies in its HVAC systems. This not only leads to uninterrupted operation but also enhances product quality and provides a competitive edge in the market.

By integrating AI-Powered Process Control into maintenance strategies, manufacturers can achieve substantial cost savings and improve overall productivity.

Waste Reduction Strategies through AI-Powered Process Control

Process Optimization

AI-Powered Process Control significantly enhances process optimization in metal injection molding. By implementing various strategies, manufacturers can achieve substantial waste reduction. The following table outlines key optimization strategies enabled by AI:

| Strategy | Description |

|---|---|

| Mold design optimization | AI predicts material behavior in the mold, reducing errors and improving product quality. |

| Real-time production monitoring | AI systems collect data to identify and correct anomalies promptly during production. |

| Predictive maintenance | Machine learning predicts maintenance needs, preventing breakdowns and production stops. |

| Waste reduction | AI identifies defects and problems, improving efficiency and reducing material consumption. |

These strategies collectively contribute to a more efficient production process. For instance, AI assists in reducing waste and improving product quality by identifying potential quality issues before they escalate. This proactive approach decreases scrap rates and ensures part quality. Additionally, AI systems improve product uniformity, which leads to increased productivity and reduced scrap rates.

Quantitative results demonstrate the effectiveness of AI-powered process optimization. The following table summarizes the improvements observed in key metrics:

| Metric | Result |

|---|---|

| Reduction in Scrap Rates | 23% |

| Reduction in Unplanned Machine Downtime | 10% |

| Reduction in Routine Maintenance Expenditures | 8-12% |

These metrics highlight the significant impact of AI on operational efficiency and waste reduction in metal injection molding.

Resource Management

AI-driven resource management plays a crucial role in enhancing sustainability within metal injection molding. By optimizing production processes, manufacturers can reduce waste and improve energy efficiency. Real-time data analysis and predictive analytics enable consistent quality maintenance while minimizing environmental footprints.

The integration of AI in resource management leads to notable improvements in material utilization. The following table illustrates the economic efficiency achieved through advanced techniques:

| Improvement Area | Result |

|---|---|

| Raw Material Consumption | Significant reductions observed |

| Energy Usage | Decreased energy consumption |

These advancements showcase how AI-Powered Process Control not only benefits production efficiency but also contributes to sustainable practices in the industry. By leveraging AI, manufacturers can optimize their resource management strategies, leading to a more environmentally friendly operation.

Case Studies of AI-Powered Process Control Implementations

Industry Examples

Several companies have successfully implemented AI-Powered Process Control in metal injection molding, showcasing the technology’s transformative potential. Notable examples include:

- Arburg: This company introduced the aXw Control FillAssist technology. This innovation supports mold setup and reduces setup time and costs by over 40%. The technology allows for real-time simulation of the filling process, enhancing setup efficiency.

- LS Mtron: They developed an AI Process Setup Assistant that has reduced initial process stabilization time by an average of 23% among customers. This AI system aims to replicate the expertise of skilled workers, streamlining the initial setup process.

- Milacron: This company utilizes AI and machine learning to optimize process controls and enhance machine maintenance through IoT data. Milacron is exploring AI for various applications, including training and performance improvement.

These examples illustrate how AI can enhance operational efficiency and reduce costs in metal injection molding.

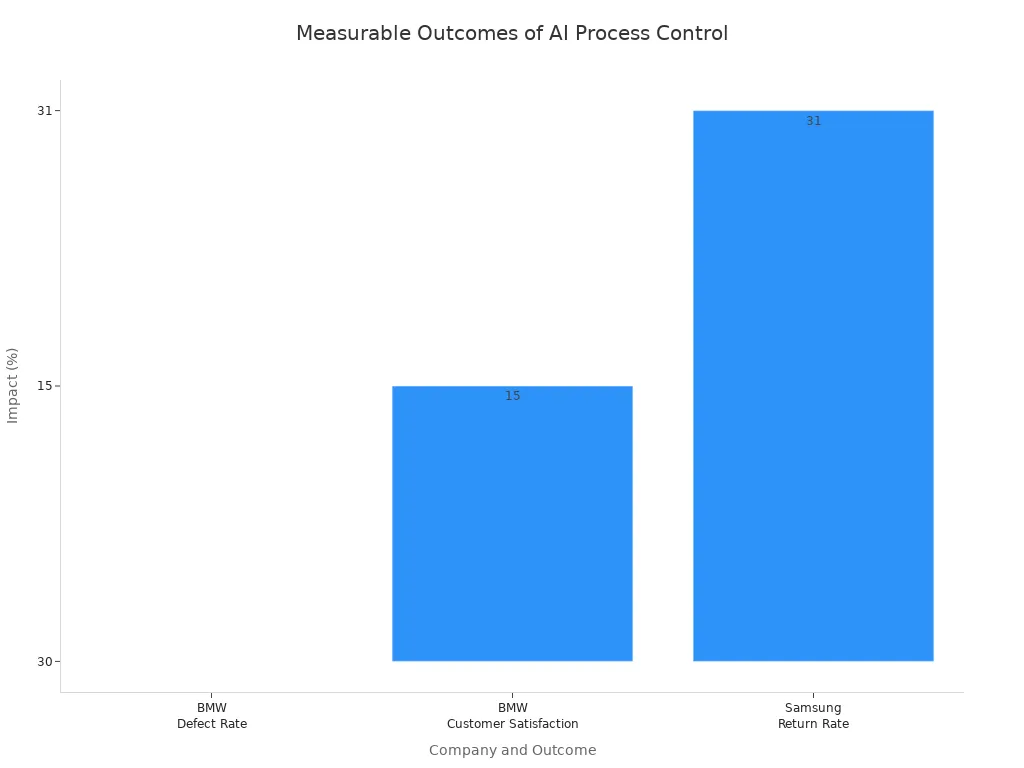

Measurable Outcomes

The implementation of AI-Powered Process Control has led to significant measurable outcomes across various companies. The following table summarizes some of these results:

| Company | Outcome Description | Measurable Impact |

|---|---|---|

| BMW | Reduction in defect rates | 30% reduction within a year |

| Increase in customer satisfaction | 15% increase reported | |

| Samsung Electronics | Reduction in customer return rates | 31% reduction within 18 months |

These outcomes highlight the effectiveness of AI-Powered Process Control in improving product quality and customer satisfaction while reducing waste and operational costs. The integration of AI technologies not only enhances production efficiency but also fosters a culture of continuous improvement within organizations.

Challenges of AI-Powered Process Control Implementation

Data Quality Issues

Data quality stands as a significant challenge in the implementation of AI-Powered Process Control. Inaccurate or incomplete data can lead to erroneous conclusions and ineffective decision-making. Manufacturers must prioritize data integrity to ensure successful AI outcomes. Key factors affecting data quality include:

- Inconsistent Data Formats: Variations in data formats can complicate analysis and integration.

- Incomplete Data Sets: Missing information can skew results and hinder predictive capabilities.

- Outdated Information: Relying on stale data can lead to misguided strategies and operational inefficiencies.

To address these issues, organizations should establish robust data governance practices. This includes regular audits and validation processes to maintain high data quality standards. By ensuring accurate and reliable data, manufacturers can enhance the effectiveness of their AI systems.

Integration with Existing Systems

Integrating AI with legacy systems presents another challenge for manufacturers in the metal injection molding industry. Many facilities rely on established systems that may not easily accommodate new technologies. Successful integration requires careful planning and execution. Best practices for this process include:

- Conduct a Legacy System Assessment: Identify system dependencies and compatibility issues to focus on core areas for modernization.

- Prioritize Data Quality and Governance: Ensure high-quality data to improve AI outcomes and maintain compliance.

- Adopt an Incremental Integration Approach: Implement AI gradually to minimize disruption and validate results.

- Leverage Cloud and Hybrid Architectures: Use cloud solutions for scalability and integration with modern tools.

- Ensure Security and Compliance: Implement robust security measures to protect legacy systems during AI integration.

- Invest in Middleware and Integration Tools: Use middleware to bridge legacy systems and AI models, enhancing compatibility and data flow.

By following these best practices, manufacturers can mitigate integration challenges and enhance the overall effectiveness of AI-Powered Process Control. A well-planned integration strategy not only streamlines operations but also maximizes the return on investment in AI technologies.

Future Trends in AI-Powered Process Control and Metal Injection Molding

Advancements in AI Technologies

Recent advancements in AI technologies are set to revolutionize process control in metal injection molding (MIM). These innovations enhance efficiency, precision, and overall production quality. The following table highlights some key advancements:

| Advancement | Description |

|---|---|

| AI-driven process optimization | Enhances efficiency and precision in the manufacturing process of metal injection molding. |

| Generative design tools | Enables rapid exploration of design permutations, optimizing for material usage and manufacturability. |

| Integration with advanced machines | Collaboration between Atomic Industries and LS Mtron to optimize mold features for production. |

These advancements not only streamline operations but also pave the way for more adaptive manufacturing processes. As manufacturers adopt these technologies, they can expect significant improvements in production timelines and product quality.

Evolving Industry Standards

The metal injection molding industry is witnessing evolving standards that shape the adoption of AI-Powered Process Control. These standards focus on enhancing quality, efficiency, and sustainability. The following table outlines some technological advancements impacting MIM:

| Technological Advancement | Impact on MIM |

|---|---|

| Advanced atomization techniques | Produces powders with tighter particle size distributions and enhanced flow characteristics. |

| Computational fluid dynamics | Simulates powder behavior under thermal and mechanical stresses, accelerating material qualification. |

| Real-time quality control systems | Ensures consistency from feedstock preparation through sintering, driving yield improvements. |

Additionally, several trends are emerging that will further influence process control in the coming years:

- AI algorithms predict defect patterns and fine-tune feedstock compositions.

- Automated mixing systems ensure consistent batch quality.

- Real-time analytics from AI monitoring tools ensure adherence to critical tolerances.

The Metal Injection Molding Association (MIMA) plays a crucial role in establishing rigorous quality benchmarks. Their certification programs enhance regulatory compliance and operational efficiency. MIMA’s global training modules keep industry experts informed, fostering innovation and collaboration across borders. Furthermore, MIMA promotes sustainable manufacturing practices, setting benchmarks for waste reduction and energy efficiency, which not only meet but exceed regulatory requirements.

As these advancements and standards evolve, manufacturers can expect to see enhanced operational efficiencies and improved product quality in metal injection molding.

AI-Powered Process Control revolutionizes metal injection molding. It enhances efficiency, reduces waste, and enables predictive capabilities. Manufacturers can expect significant improvements in production quality and operational performance. As the industry embraces these technologies, they pave the way for future innovations. The integration of AI not only streamlines processes but also fosters a culture of continuous improvement. This transformation positions companies to remain competitive in an evolving market.

FAQ

What is AI-Powered Process Control in Metal Injection Molding?

AI-Powered Process Control utilizes artificial intelligence to optimize manufacturing processes in metal injection molding. It enhances efficiency, reduces defects, and enables real-time monitoring.

How does AI improve defect detection?

AI improves defect detection through machine learning algorithms and image recognition techniques. These technologies analyze data and images to identify defects more accurately than traditional methods.

What are the benefits of predictive maintenance?

Predictive maintenance minimizes unplanned downtime and extends equipment lifespan. AI detects early signs of failure, allowing manufacturers to schedule maintenance proactively.

Can AI reduce waste in metal injection molding?

Yes, AI reduces waste by optimizing processes and improving resource management. It identifies inefficiencies and defects, leading to lower scrap rates and better material utilization.

What challenges exist in implementing AI-Powered Process Control?

Challenges include data quality issues and integration with existing systems. Manufacturers must ensure accurate data and develop strategies for seamless integration.

How can companies measure the success of AI implementation?

Companies can measure success through key performance indicators (KPIs) such as defect rates, production efficiency, and cost savings. Tracking these metrics provides insights into AI’s impact.

What future trends should manufacturers watch for?

Manufacturers should watch for advancements in AI technologies, evolving industry standards, and increased automation. These trends will shape the future of metal injection molding.

Is training necessary for staff using AI systems?

Yes, training is essential for staff to effectively use AI systems. Proper training ensures that employees understand the technology and can leverage its capabilities for improved outcomes.