MIM mold design plays a crucial role for engineers in the manufacturing process. Effective design enhances production efficiency and significantly improves part quality. Engineers must navigate various challenges during the design phase. These challenges can include material selection, complex geometries, and the need for precise tolerances. Addressing these issues is essential for achieving optimal results in metal injection molding.

Key Takeaways

- MIM mold design is crucial for enhancing production efficiency and part quality.

- Selecting the right materials, including metal powders and binders, is essential for optimal results.

- Design parts with appropriate draft angles and uniform wall thickness to ensure efficient molding.

- Aim for tolerances within ±0.1 mm to ensure high-quality and manufacturable MIM parts.

- Consolidate multiple part designs into a single mold to reduce costs and production time.

- Utilize simulation and testing to identify potential issues before production, enhancing part quality.

- Design effective cooling systems to ensure uniform temperature distribution and minimize defects.

- Collaborate with cross-functional teams to align design with production capabilities and improve outcomes.

Understanding MIM Mold Design

Definition and Process

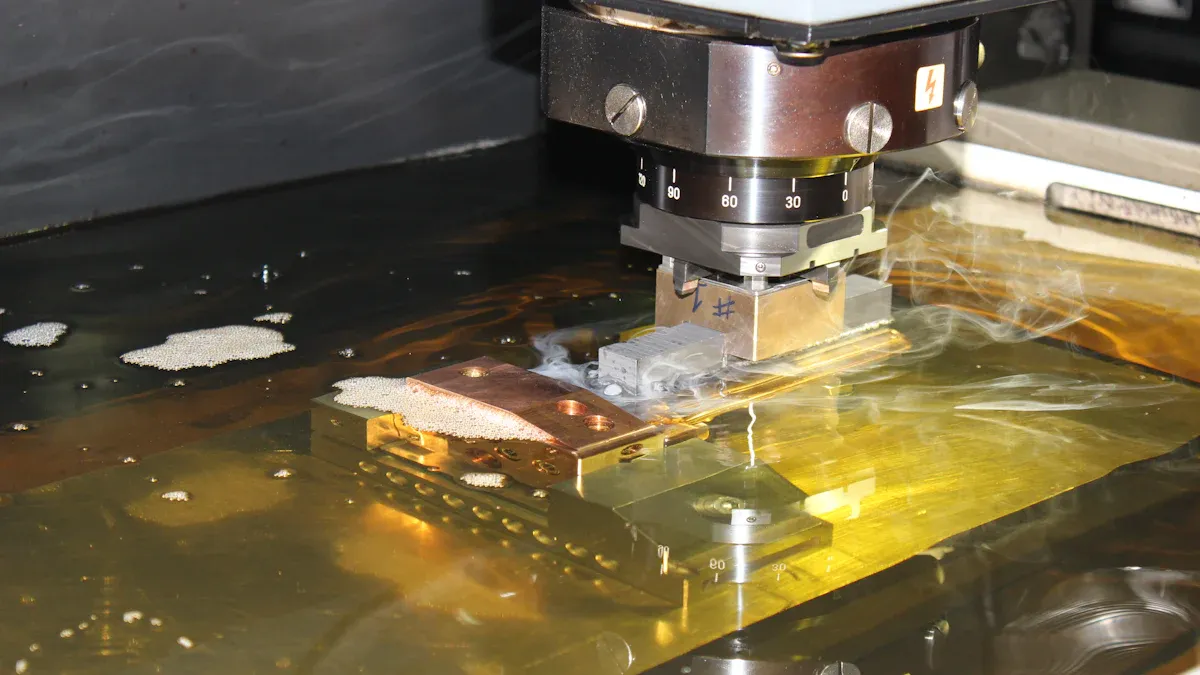

Metal Injection Molding (MIM) is a manufacturing process that combines the versatility of plastic injection molding with the strength of metal. Engineers create complex metal parts by mixing fine metal powders with a binder material. This mixture forms a feedstock, which they inject into molds under high pressure. After cooling, the molded parts undergo a debinding process to remove the binder, followed by sintering to fuse the metal particles. This process results in dense, high-quality components that meet stringent specifications.

Key Components of MIM Molds

MIM molds consist of several critical components that ensure efficient production. These include:

- Cavity and Core: The cavity forms the outer shape of the part, while the core defines the inner features.

- Ejector System: This system helps remove the finished part from the mold without damage.

- Cooling Channels: Proper cooling is essential to maintain consistent temperatures during the molding process, which affects part quality.

- Sprue and Runner System: This system channels the feedstock into the mold cavity, ensuring even distribution.

Each component plays a vital role in the overall efficiency and effectiveness of the MIM mold design.

Common Applications of MIM

MIM technology finds applications across various industries due to its ability to produce intricate and precise components. The following table highlights some of the most common industries and their typical applications:

| Industry | Typical Applications |

|---|---|

| Medical | Biocompatible implants for medical devices |

| Aerospace | Lightweight parts with complex geometries |

| Automotive | Intricate components requiring precision and durability |

| Electronics | Precision components for electronic devices |

| Consumer Goods | Detailed designs for various consumer products |

| Sporting Equipment | Innovative designs for sports-related products |

| Jewelry | Complex shapes and detailed designs for jewelry items |

These applications demonstrate the versatility and effectiveness of MIM mold design in producing high-quality parts for diverse sectors.

Essential Design Tips for MIM Mold Design

Material Selection

Selecting the right materials is crucial in MIM mold design. Engineers must consider the properties of metal powders and binders to achieve optimal results. The choice of metal powder affects the final part’s mechanical properties, density, and surface finish. Common materials include stainless steel, titanium, and various alloys. Each material has unique characteristics that influence the molding process and the performance of the final product.

When selecting binders, engineers should prioritize compatibility with the metal powder. The binder must effectively hold the metal particles together during the injection process and facilitate the debinding phase. A well-chosen binder enhances the overall quality of the molded parts.

Tip: Always consult material data sheets and conduct preliminary tests to ensure the selected materials meet the specific requirements of the application.

Part Geometry

Part geometry plays a significant role in MIM mold design. Engineers must design parts with features that can be efficiently molded while maintaining structural integrity. Complex geometries can be achieved, but they require careful consideration of draft angles, wall thickness, and undercuts.

- Draft Angles: Incorporating appropriate draft angles facilitates the ejection of parts from the mold. A typical draft angle ranges from 1 to 3 degrees, depending on the material and part complexity.

- Wall Thickness: Uniform wall thickness is essential to prevent warping and ensure consistent cooling. Engineers should aim for a thickness of 1 to 3 mm for most applications.

- Undercuts: Avoiding undercuts simplifies the mold design and reduces production costs. If undercuts are necessary, engineers can use side actions or collapsible cores.

Tolerances and Fits

Achieving precise tolerances and fits is vital for ensuring the quality and manufacturability of MIM parts. Engineers must determine optimal tolerances based on the intended application and the capabilities of the MIM process. The following factors influence tolerance selection:

| Factor | Description |

|---|---|

| Repeatability | The MIM process is highly automated and repeatable, ensuring each part produced is the same, reducing defects. |

| Consistent Raw Material Quality | Metal powders used in MIM are highly consistent in composition and particle size, reducing variability in final parts. |

| Controlled Environment | The process occurs in a controlled environment, minimizing contamination and defects, ensuring high-quality final parts. |

Engineers should aim for tolerances within ±0.1 mm for most applications. However, specific requirements may necessitate tighter tolerances. Understanding the capabilities of the MIM process allows engineers to balance manufacturability with part performance.

By focusing on material selection, part geometry, and tolerances, engineers can enhance the effectiveness of MIM mold design. Implementing these essential tips leads to improved production efficiency and higher-quality components.

Optimization Strategies in MIM Mold Design

Design Consolidation

Design consolidation is a powerful strategy in MIM mold design. It involves merging multiple part designs into a single mold. This approach streamlines the manufacturing process and enhances efficiency. Engineers can achieve significant cost savings and reduce production time by minimizing the number of parts produced.

The following table outlines best practices for consolidating multiple part designs into a single MIM mold:

| Best Practice | Description |

|---|---|

| Reduce Secondary Operations | Minimizing the need for additional processes like deburring or assembly can significantly lower costs. |

| Optimize Material Selection | Choosing the right materials can enhance part performance and accuracy, impacting overall production efficiency. |

| Consolidate Components | Merging separate parts into a single design reduces complexity and manufacturing steps, leading to faster production times and lower costs. |

The impact of design consolidation extends beyond just cost savings. It also simplifies the supply chain and improves part consistency. By integrating parts, engineers reduce the number of suppliers and logistics involved, which enhances overall production efficiency.

Simulation and Testing

Simulation and testing are critical components of MIM mold design. Engineers utilize advanced software to simulate the molding process before actual production. This approach allows them to identify potential issues and optimize the design accordingly.

The following table highlights various testing protocols used to validate MIM mold designs:

| Testing Protocol | Purpose / What it Ensures | Description / Methodology |

|---|---|---|

| Dimensional Testing | Ensures geometric precision and dimensional accuracy | Utilizes Coordinate Measuring Machines (CMM) and 3D scanning for complex geometries. |

| Mechanical Testing | Validates mechanical performance under operational stresses | Involves tensile testing, Charpy impact testing, microhardness, and fatigue testing under cyclic loads. |

| Non-Destructive Testing (NDT) | Detects internal and surface defects without damaging parts | Employs Industrial CT scanning, SEM-EDS analysis, and Dye Penetrant Testing. |

| Metallurgical Controls | Ensures material homogeneity and microstructure integrity | Controls feedstock homogeneity, binder composition, and sintering profiles. |

Through simulation, engineers can predict how the mold will perform under various conditions. Testing further validates these predictions, ensuring that the final product meets the required specifications. This proactive approach minimizes the risk of defects and enhances the overall quality of MIM parts.

Cooling System Design

Cooling system design is another vital aspect of MIM mold design. Proper cooling ensures uniform temperature distribution during the molding process. This uniformity is crucial for achieving consistent part quality and minimizing defects.

Engineers must consider several factors when designing cooling systems:

- Cooling Channel Placement: Strategically placing cooling channels can optimize heat transfer and reduce cycle times.

- Channel Size and Shape: The size and shape of cooling channels affect the flow of coolant and the efficiency of heat removal.

- Material Selection: Choosing materials with high thermal conductivity can enhance cooling efficiency.

By focusing on these factors, engineers can design effective cooling systems that improve production efficiency and part quality.

Addressing Common Challenges in MIM Mold Design

Defects in MIM Parts

Defects in MIM parts can arise from various factors during the manufacturing process. Engineers must identify and address these issues to ensure high-quality output. Common defects include:

- Dimensional Variability: Inconsistent part dimensions can result from improper cooling or inadequate mold design.

- Surface Defects: Issues such as rough surfaces or blemishes often stem from poor material handling or contamination.

- Internal Voids: These can occur due to insufficient binder removal or improper sintering conditions.

To mitigate these defects, engineers should implement rigorous quality control measures throughout the production process. Regular inspections and testing can help catch defects early, ensuring that corrective actions are taken promptly.

Cost Management

Managing costs in MIM mold design is essential for maintaining competitiveness without sacrificing quality. Engineers can adopt several strategies to optimize costs effectively:

- Early identification of design deficiencies helps avoid costly setbacks and improves part quality.

- Collaboration with manufacturing experts during the design phase ensures that design choices are validated for manufacturability and cost efficiency.

- Conducting mold flow analysis before finalizing designs helps identify potential issues, preventing failures and reducing rework.

Additionally, key cost drivers in MIM mold design include:

- Material Selection: Choosing cost-effective materials that meet specifications can significantly reduce expenses.

- Process Optimization: Streamlining production processes to eliminate inefficiencies can lower costs and increase speed.

- Scrap Reduction: Monitoring and minimizing waste during production can lead to substantial material cost savings.

By focusing on these areas, engineers can effectively manage costs while maintaining the integrity of the MIM mold design.

Collaboration with Cross-Functional Teams

Collaboration among cross-functional teams is vital in overcoming challenges in MIM mold design. Engineers, designers, and manufacturing experts must work together to ensure that all aspects of the design align with production capabilities. This collaboration fosters a comprehensive understanding of the project requirements and helps identify potential issues early in the design phase.

Effective communication among team members can lead to innovative solutions and improved product quality. Regular meetings and brainstorming sessions can facilitate knowledge sharing and enhance problem-solving capabilities. By leveraging the expertise of various team members, organizations can streamline the design process and achieve better outcomes in MIM mold design.

In summary, effective MIM mold design hinges on several key strategies. Engineers should prioritize material selection, optimize part geometry, and ensure precise tolerances. Implementing these best practices can significantly enhance production efficiency and part quality.

Tip: Continuous learning is vital in this evolving field. Engineers can explore various resources to deepen their understanding of MIM mold design. For instance, comprehensive guides and design recommendations can provide valuable insights into complex geometries and tooling features.

Case studies illustrate the benefits of adhering to best practices. For example, harmonizing wall thickness in automotive parts reduced defects and improved production yield.

By embracing these strategies and resources, engineers can excel in MIM mold design and contribute to the industry’s advancement.

FAQ

What is Metal Injection Molding (MIM)?

Metal Injection Molding (MIM) combines metal powder and binder to create complex metal parts. This process involves injecting the feedstock into molds, followed by debinding and sintering to achieve high-density components.

What are the advantages of MIM over traditional methods?

MIM offers several advantages, including the ability to produce intricate geometries, reduced material waste, and lower production costs. It also allows for high-volume manufacturing of precision parts.

How do engineers select materials for MIM?

Engineers choose materials based on mechanical properties, compatibility with binders, and application requirements. Common materials include stainless steel, titanium, and various alloys, each offering unique characteristics.

What common defects occur in MIM parts?

Common defects include dimensional variability, surface imperfections, and internal voids. These issues often arise from improper cooling, contamination, or inadequate binder removal during the manufacturing process.

How can engineers optimize cooling systems in MIM molds?

Engineers can optimize cooling systems by strategically placing cooling channels, selecting appropriate channel sizes, and using materials with high thermal conductivity. This ensures uniform temperature distribution and reduces cycle times.

What role does simulation play in MIM mold design?

Simulation allows engineers to predict mold performance and identify potential issues before production. This proactive approach helps optimize designs, minimize defects, and enhance overall part quality.

How important is collaboration in MIM mold design?

Collaboration among cross-functional teams is crucial. It fosters communication, encourages innovative solutions, and ensures that all design aspects align with production capabilities, ultimately improving product quality.

What are the typical applications of MIM technology?

MIM technology is widely used in industries such as medical, aerospace, automotive, electronics, consumer goods, sporting equipment, and jewelry. It excels in producing intricate and high-quality components for these sectors.