Gear material grades define the classification of materials used in gear manufacturing. These grades significantly impact performance, influencing factors such as strength, durability, and wear resistance. Material properties and heat treatment play a vital role in enhancing the performance and lifespan of gears in industrial applications. For instance, the incorporation of rigid nanofillers in composites can substantially improve physical properties. Selecting the appropriate gear material grade ensures optimal functionality across various applications, from automotive to aerospace.

Key Takeaways

- Selecting the right gear material grade is crucial for optimal performance in various applications, including automotive and aerospace.

- Metals like steel and cast iron offer high strength and durability, while plastics provide affordability and lightweight options for specific uses.

- Understanding the criteria for grading gear materials, such as strength, durability, and wear resistance, helps engineers make informed decisions.

- Conducting a cost-benefit analysis is essential when choosing gear materials to balance performance with budget constraints.

- Regular maintenance practices, including proper lubrication and inspections, can significantly extend the lifespan of gears.

Types of Gear Materials

Gears can be made from various materials, each offering unique properties that influence their performance in different applications. Understanding these materials helps in selecting the right gear for specific needs.

Metals

Metals are the most commonly used materials for gear manufacturing due to their strength and durability. They dominate the market, accounting for a significant share in industries such as automotive, industrial, and energy. The following metals are frequently utilized in gear production:

- Steel: Known for its high strength and durability, steel gears can withstand heavy loads and harsh conditions.

- Cast Iron: This material offers excellent wear resistance and is suitable for heavy loads, making it ideal for industrial applications.

- Bronze: Recognized for its machinability and corrosion resistance, bronze gears are often used in marine and high-wear environments.

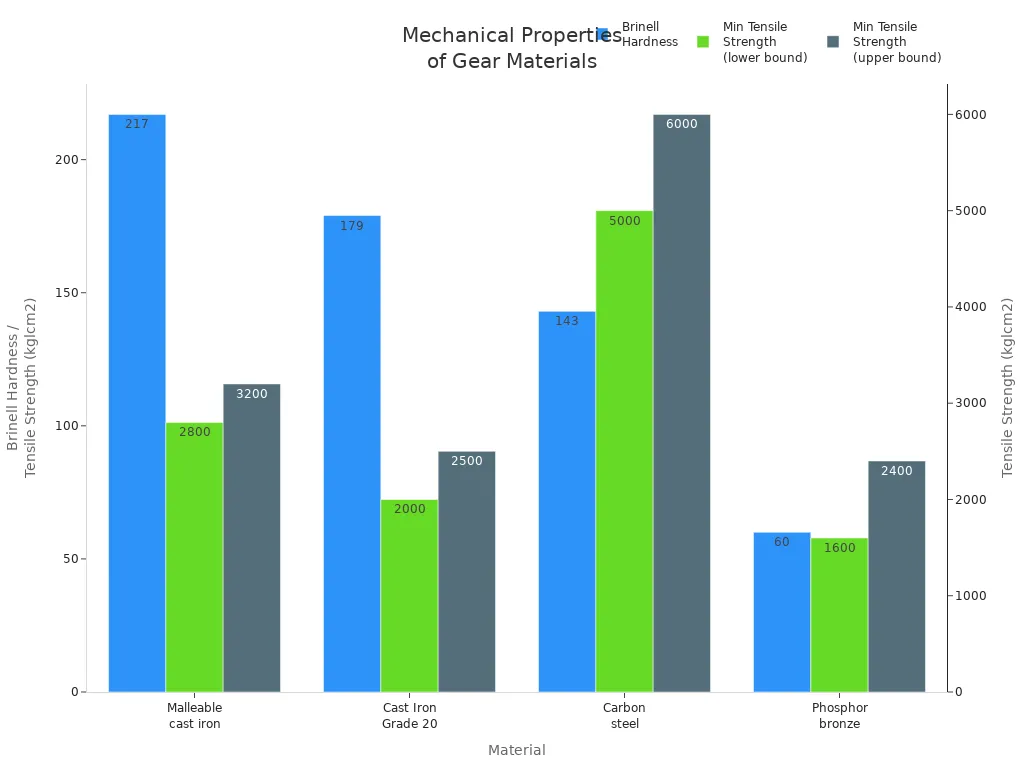

The mechanical properties of these metals vary significantly. For instance, the table below outlines the hardness and tensile strength of common gear materials:

| Material | Condition | Brinell Hardness Number | Minimum Tensile Strength (kglcm²) |

|---|---|---|---|

| Malleable cast iron | White heart castings | 217 max. | 2800 – 3200 |

| Cast Iron | Grade 20 | 179 min. | 2000 – 2500 |

| Carbon steel | 0.3% carbon | 143 | 5000 – 6000 |

| Phosphor bronze castings | Sand cast | 60 min. | 1600 – 2400 |

Plastics

Plastic gears have gained popularity in various applications, particularly in automotive and consumer electronics. They offer several advantages, including:

- Affordability: Plastic gears are less expensive to manufacture than metal gears.

- Lightweight: Their lightweight nature makes them ideal for applications requiring reduced weight.

- Silent operation: Plastic gears operate quietly, making them suitable for noise-sensitive environments.

However, they also have disadvantages. The table below summarizes the pros and cons of plastic gears:

| Advantages | Disadvantages |

|---|---|

| Lightweight | Lower load capacity |

| Corrosion resistance | Poor heat resistance |

| Noise reduction | Less durability |

| Electrical insulation | |

| Lower friction |

While plastic gears are often self-lubricating, they may not perform well under high-load conditions. Studies indicate that plastic gears can be superior in maintenance needs and operational efficiency compared to metal gears.

Composites

Composite materials combine different substances to enhance performance. They are particularly useful in low to medium load applications. Composite gears excel in environments where lubrication is challenging. However, they may not perform well under high-load and high-temperature conditions, which often necessitate the use of metal gears.

The development of advanced composite materials continues to evolve, providing opportunities for improved performance in specific applications.

Specialty Alloys

Specialty alloys play a crucial role in high-performance gear applications. These materials combine various elements to enhance specific properties, making them suitable for demanding environments. Engineers often select specialty alloys for their unique characteristics, which can significantly improve gear performance.

One of the most notable specialty alloys is C92900. This alloy exhibits a high load-bearing capacity, ensuring that gears can withstand substantial forces without failure. Additionally, C92900 provides smooth operation and reduced friction, which enhances efficiency and minimizes wear. Its durability and machinability allow for precise manufacturing, making it a preferred choice in industries requiring high-performance gears.

The table below summarizes the properties of C92900:

| Alloy Grade | Properties |

|---|---|

| C92900 | High load-bearing capacity, smooth operation, reduced friction, enhanced machinability, durability, and precise manufacturing. |

While specialty alloys offer numerous advantages, they also come with cost implications. The manufacturing processes for these materials are often complex, requiring high-quality raw materials. This complexity can lead to increased production costs. The table below outlines the various cost implications associated with using specialty alloys compared to standard metals:

| Cost Implication | Description |

|---|---|

| High Production Costs | Specialty alloys require complex manufacturing processes and high-quality raw materials, increasing costs. |

| High Manufacturing Costs | Premium alloys may be chosen unnecessarily, leading to wasted resources when standard alloys suffice. |

| Increased Processing Costs | Specialized handling or treatment for certain alloys raises manufacturing costs without proportional benefits. |

| Higher Scrap Rates | Inappropriate alloy selection can lead to more waste during production, impacting material costs and profitability. |

Criteria for Grading Gear Materials

Strength

Strength is a critical criterion for grading gear materials. It determines how much load a gear can handle without failure. The strength of gear materials is assessed through empirical testing and standardized equations, notably the Lewis Equation. This equation evaluates the necessary dimensions of a gear to transmit a specified force. It relies on pre-calculated values that correlate the maximum load per unit length to the material’s hardness.

Typical strength values for common gear materials vary based on their composition and treatment. The table below summarizes the failure probability and corresponding strength values:

| Failure Probability | Typical Strength Values |

|---|---|

| 0.01% | Derived from testing |

| 1% | Standardized methods |

| 10% | Application dependent |

Additionally, hardness tests, such as Brinell or Rockwell, are used to assess material strength. These tests provide insights into how well a material can withstand operational stresses.

Durability

Durability refers to a material’s ability to withstand wear, pressure, and damage over time. It is essential for ensuring that gears perform reliably in demanding environments. Various testing methods assess the durability of gear materials, including:

- Environmental Resistance Testing: Evaluates how materials withstand various environmental conditions.

- Vibration Testing: Assesses material response to vibrational forces, crucial in aerospace and automotive industries.

- Shock Testing: Tests material durability against sudden impacts, simulating real-world high-impact scenarios.

- High-Speed Tensile Testing: Measures tensile properties under rapid forces, important for automotive applications.

These tests ensure that gear materials meet industry standards for durability, which is vital for maintaining performance and safety.

Wear Resistance

Wear resistance is another key factor in grading gear materials. It measures how well a material can resist degradation due to friction and contact with other surfaces. High wear resistance prolongs the lifespan of gears, reducing maintenance costs and downtime.

Materials with superior wear resistance often include specialty alloys and treated metals. The ISO standards, such as ISO 6336, provide guidelines for calculating gear strength and assessing wear resistance. These standards help manufacturers ensure that their gear materials meet the necessary performance criteria.

By understanding these criteria, engineers can select the appropriate gear material grade for specific applications, ensuring optimal performance and longevity.

Cost-Effectiveness

Cost-effectiveness plays a crucial role in selecting gear materials. Manufacturers must balance performance with budget constraints. The choice of material directly impacts production costs, maintenance expenses, and overall operational efficiency.

When evaluating cost-effectiveness, consider the following factors:

- Material Costs: The price of raw materials varies significantly. Metals like steel and specialty alloys often come with higher upfront costs compared to plastics and composites. However, their durability may justify the initial investment.

- Manufacturing Costs: The complexity of the manufacturing process affects costs. For instance, specialty alloys require advanced techniques, increasing production expenses. In contrast, plastic gears typically involve simpler processes, leading to lower manufacturing costs.

- Maintenance Costs: Gears made from high-quality materials often require less maintenance. Durable materials reduce wear and tear, leading to fewer replacements and repairs. This long-term savings can offset higher initial costs.

- Operational Efficiency: Efficient gears contribute to reduced energy consumption. Selecting materials that enhance performance can lead to lower operational costs over time.

Tip: Always conduct a cost-benefit analysis when selecting gear materials. This analysis should include not only the initial costs but also the expected lifespan and maintenance requirements.

The table below summarizes the cost implications of different gear materials:

| Material Type | Initial Cost | Maintenance Cost | Lifespan |

|---|---|---|---|

| Steel | High | Moderate | Long |

| Cast Iron | Moderate | Low | Long |

| Plastic | Low | Moderate | Short |

| Specialty Alloys | Very High | Low | Very Long |

Impact of Gear Material Grade on Performance

Load Capacity

The load capacity of gears is a crucial factor in their performance, especially in heavy machinery applications. Gear steels are engineered to withstand the rigorous demands of mechanical applications. The primary alloying elements, such as carbon, chromium, and nickel, define their characteristics.

- Carbon content provides hardness and strength.

- Chromium and nickel contribute to toughness and resistance to wear and fatigue.

The material of construction (MOC) in gear manufacturing significantly influences the gear’s performance and durability. The MOC affects factors like strength, wear resistance, and fatigue life. Choosing the right material ensures the gearbox performs reliably under different loads and operational conditions.

Efficiency

Efficiency is another vital aspect influenced by gear material grade. Laboratory tests reveal significant differences between gears made from high-grade and low-grade materials. The following table summarizes these differences:

| Material Type | Load-Carrying Capacity | Performance Consistency |

|---|---|---|

| High-Grade (Clean Steel) | Significantly Better | Extremely Low Scatter |

| Low-Grade (Reference Steel) | Lower | Higher Scatter |

High-grade materials enhance load-carrying capacity and ensure consistent performance. This consistency reduces energy losses during operation, leading to improved overall efficiency.

Noise and Vibration

The choice of gear material grade also affects noise and vibration levels, particularly in automotive transmissions. Different materials exhibit varying noise levels during operation. The following table illustrates the noise level differences between various gear materials:

| Gear Material | Noise Level Difference (dB) |

|---|---|

| Austempered Ductile Iron (ADI) | 10 to 12 dB |

| Steel | 10 to 12 dB |

Materials like Austempered Ductile Iron (ADI) and steel produce similar noise levels, but the choice of material can still influence the overall vibration characteristics of the transmission. Lower vibration levels contribute to smoother operation and enhanced user experience.

Lifespan

The lifespan of gears significantly impacts their performance and reliability in various applications. Several factors influence how long gears can operate effectively before requiring replacement or maintenance. Understanding these factors helps engineers select the right materials and design for specific applications.

Key Factors Influencing Lifespan

- Material Properties:

- The inherent characteristics of the gear material play a crucial role in determining lifespan. For instance:

- Metals: Steel and specialty alloys often exhibit longer lifespans due to their strength and wear resistance.

- Plastics: While lightweight and cost-effective, plastic gears may have shorter lifespans under heavy loads.

- The inherent characteristics of the gear material play a crucial role in determining lifespan. For instance:

- Environmental Conditions:

- Gears operating in harsh environments face additional challenges. Factors include:

- Temperature: Extreme heat or cold can affect material properties, leading to premature failure.

- Moisture: Exposure to water or humidity can cause corrosion, particularly in metal gears.

- Contaminants: Dust and debris can accelerate wear, especially in unsealed gear systems.

- Gears operating in harsh environments face additional challenges. Factors include:

- Load and Stress:

- The amount of load a gear experiences directly correlates with its lifespan. Higher loads can lead to:

- Increased wear rates.

- Greater fatigue, which may result in cracks or fractures over time.

- The amount of load a gear experiences directly correlates with its lifespan. Higher loads can lead to:

- Maintenance Practices:

- Regular maintenance can significantly extend the lifespan of gears. Effective practices include:

- Lubrication: Proper lubrication reduces friction and wear, enhancing gear longevity.

- Inspection: Routine checks can identify wear patterns early, allowing for timely interventions.

- Regular maintenance can significantly extend the lifespan of gears. Effective practices include:

Lifespan Comparison Table

The following table summarizes the expected lifespan of various gear materials under typical operating conditions:

| Gear Material | Expected Lifespan (Years) | Key Considerations |

|---|---|---|

| Steel | 10-20 | High strength, susceptible to corrosion |

| Cast Iron | 15-25 | Excellent wear resistance, heavy loads |

| Plastic | 5-10 | Lightweight, limited by load capacity |

| Specialty Alloys | 20-30 | High performance, costly but durable |

Tip: Selecting the right gear material and implementing effective maintenance strategies can significantly enhance the lifespan of gears, reducing overall operational costs.

Choosing the Right Gear Material

Selecting the appropriate gear material involves careful consideration of several factors. Each factor plays a crucial role in ensuring that the gears perform effectively in their intended applications.

Application Requirements

When choosing gear materials, engineers must assess the specific application requirements. Key factors include:

- Load capacity and torque requirements: Ensure the material can withstand expected loads without deforming.

- Speed and rotational forces: Choose materials with good heat dissipation and low friction for high-speed applications.

- Operating environment: Select materials resistant to corrosion and wear based on environmental conditions.

- Desired lifespan: Balance material hardness and toughness to meet durability goals.

- Compatibility: Ensure the material works well with other components to avoid issues.

These considerations help engineers select materials that meet performance expectations while minimizing the risk of failure.

Environmental Considerations

Environmental factors significantly influence gear material selection. Temperature and humidity can affect material performance. For example, POM plastic gears perform well in medium temperature ranges but may fail under extreme conditions. High humidity can lead to material swelling or instability, which engineers must consider when selecting gear materials. Understanding these environmental impacts ensures that gears maintain functionality and longevity in various settings.

Budget Constraints

Budget constraints often dictate material choices in large-scale manufacturing projects. Cost-effective options include:

- Thermoplastics: Such as polycarbonate and polypropylene, known for high impact resistance and durability.

- Recycled Plastics: These materials are cost-effective and environmentally friendly while maintaining product integrity.

- Material Blends: Combining polypropylene with fiberglass enhances durability without significant cost increases.

Balancing performance with cost is essential. Engineers must evaluate the long-term benefits of higher-quality materials against initial expenses to make informed decisions.

Tip: Always conduct a thorough cost-benefit analysis when selecting gear materials. This analysis should include not only the initial costs but also the expected lifespan and maintenance requirements.

Manufacturer Recommendations

Leading gear manufacturers emphasize the importance of selecting the right material grade based on specific properties. Their recommendations often focus on the following key factors:

- Strength: The material must withstand operational loads without failure.

- Stiffness: Adequate stiffness ensures that gears maintain their shape under stress.

- Fatigue Resistance: Materials should resist wear over time, especially in high-cycle applications.

- Corrosion Resistance: This is crucial for components exposed to harsh environments, such as marine applications.

- Impact on Manufacturing Processes: The chosen material should facilitate efficient manufacturing and assembly.

For aerospace applications, manufacturers often recommend specific aluminum alloys and composite materials. These materials provide high strength-to-weight ratios, making them ideal for applications where weight reduction is critical. Additionally, manufacturers advise considering ultimate strength, low-velocity impact strength, and resistance to creep and corrosion. These factors become particularly important for components subjected to extreme conditions.

When selecting gear materials, manufacturers suggest conducting thorough evaluations of the operational environment. For example, gears used in marine settings require materials that can withstand saltwater exposure. Similarly, gears in high-temperature environments may need specialized alloys to prevent degradation.

Tip: Always consult with manufacturers for their recommendations tailored to specific applications. Their expertise can guide engineers in making informed decisions that enhance performance and longevity.

By adhering to these recommendations, engineers can ensure that their gear selections meet the demands of their respective industries while optimizing performance and reliability.

Gear material grades play a vital role in the performance and reliability of mechanical systems. Selecting the right material impacts durability, efficiency, and maintenance costs. Key factors to consider include strength, environmental conditions, and budget constraints.

Tip: Always verify the chemical composition and mechanical properties of materials before use. This practice ensures optimal performance and longevity.

Engineers should prioritize gear material grades in their designs to enhance safety and functionality. By doing so, they can achieve better outcomes in various applications, from automotive to aerospace.

FAQ

What are the most common materials used for gears?

The most common materials for gears include metals like steel, cast iron, and bronze, as well as plastics and composites. Each material offers unique properties suited for different applications.

How does gear material grade affect performance?

Gear material grade influences strength, durability, wear resistance, and efficiency. Higher-grade materials typically enhance load capacity and lifespan, leading to better overall performance in mechanical systems.

What factors should I consider when selecting gear materials?

Consider application requirements, environmental conditions, budget constraints, and manufacturer recommendations. These factors help ensure optimal performance and longevity of the gears in their intended use.

Are plastic gears suitable for high-load applications?

Plastic gears are generally not recommended for high-load applications due to their lower load capacity and durability compared to metal gears. They perform better in low to medium load scenarios.

How can I extend the lifespan of gears?

To extend gear lifespan, implement regular maintenance practices such as proper lubrication, routine inspections, and selecting appropriate materials based on environmental conditions and load requirements.