Metal Injection Molding (MIM) serves as an innovative technique for producing Tang Buckles. This process combines fine metal powders with a binder to create a feedstock. Manufacturers then inject this feedstock into molds, shaping it into precise components. The result is a highly efficient production method that ensures dimensional accuracy and complex geometries.

The advantages of using Metal Injection Molding for Tang Buckles are significant. MIM allows for the mass production of intricate designs while maintaining high strength and durability. Additionally, it reduces material waste compared to traditional machining methods.

Key Takeaways

- Metal Injection Molding (MIM) combines fine metal powders with a binder to create precise components, making it ideal for producing Tang Buckles.

- MIM offers high precision and the ability to create complex geometries, allowing for innovative designs that enhance both functionality and aesthetics.

- The process achieves up to 97% material utilization, significantly reducing waste and promoting sustainability in manufacturing.

- MIM enables rapid production, allowing manufacturers to quickly respond to market demands while maintaining high-quality standards.

- Choosing MIM can lead to cost savings due to reduced material waste and the ability to produce multiple parts in a single cycle.

Understanding Metal Injection Molding

Metal Injection Molding (MIM) is a sophisticated manufacturing process that combines the principles of plastic injection molding with powder metallurgy. This technique allows manufacturers to produce complex metal parts with high precision and efficiency. The MIM process involves several key steps:

- Feedstock Preparation: Fine metal powders are mixed with a binder to create a feedstock. This mixture is essential for achieving the desired properties in the final product.

- Injection Molding: The feedstock is heated and injected into molds under high pressure. This step shapes the material into the desired form, such as a Tang Buckle.

- Debinding: After molding, the binder is removed through a debinding process. This step is crucial for ensuring that the metal retains its integrity.

- Sintering: The final step involves heating the molded part in a controlled atmosphere. This process fuses the metal particles together, resulting in a solid, dense component.

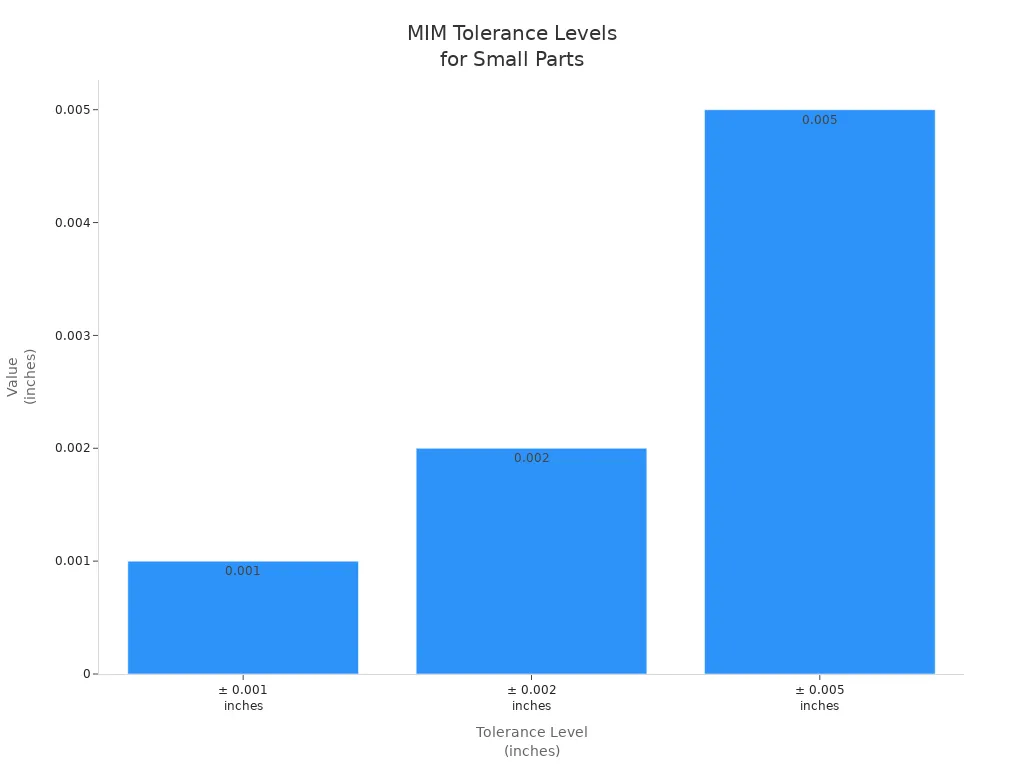

MIM is particularly advantageous for producing small, intricate components like Tang Buckles. The tolerances achievable with this method are impressive. For instance, typical tolerances include:

| Tolerance Level | Description |

|---|---|

| ± 0.002 inches | Generally recognized tight tolerance for parts. |

| ± 0.001 inches | Very tight tolerance, often for critical components. |

| ± 0.005 inches | Typical machining tolerance when tighter is not specified. |

These tolerances are essential for applications requiring precise fitting, such as in medical, industrial, and automotive sectors.

Moreover, MIM stands out for its environmental benefits. The process achieves up to 97% material utilization, leading to minimal waste. It utilizes recyclable metal powders and reusable tooling, promoting sustainability. Additionally, energy consumption in MIM is lower than in traditional metalworking processes, resulting in fewer greenhouse gas emissions.

As the global market for Metal Injection Molding continues to grow, it is projected to reach approximately $4.65 billion by 2024, with a compound annual growth rate (CAGR) of 8.60%. This growth reflects the increasing demand for efficient and sustainable manufacturing solutions.

Application of Metal Injection Molding for Tang Buckles

Metal Injection Molding (MIM) plays a crucial role in the production of Tang Buckles, particularly due to its ability to create intricate designs with high precision. This manufacturing method allows for the production of complex geometries that traditional methods struggle to achieve. The following points highlight how MIM enhances the design and functionality of Tang Buckles:

- MIM enables the production of intricate shapes and features without the need for secondary machining.

- The process can create detailed designs, such as those found in Tang Buckles, with high precision and tight tolerances.

- MIM imposes few design restrictions, allowing manufacturers to produce complex geometries that are difficult or costly to achieve using conventional techniques.

The versatility of Metal Injection Molding makes it an ideal choice for Tang Buckles used in various applications, including outdoor gear, safety equipment, and industrial machinery. The ability to produce parts with complex features means that manufacturers can design buckles that not only meet aesthetic requirements but also enhance functionality.

Moreover, MIM’s efficiency in mass production significantly reduces lead times. Manufacturers can produce large quantities of Tang Buckles quickly, ensuring that they meet market demands without compromising quality. This efficiency is particularly beneficial in industries where time-to-market is critical.

In addition to speed, MIM offers cost-effectiveness. The reduction in material waste and the ability to produce multiple parts in a single cycle contribute to lower production costs. This advantage allows companies to offer competitive pricing while maintaining high-quality standards.

Overall, the application of Metal Injection Molding for Tang Buckles exemplifies how modern manufacturing techniques can meet the evolving needs of various industries. As technology advances, the potential for even more innovative designs and applications continues to grow.

Advantages of Metal Injection Molding for Tang Buckles

Metal Injection Molding offers several advantages for the production of Tang Buckles. These benefits make it a preferred choice among manufacturers. Here are some key advantages:

- High Precision: MIM allows for the creation of intricate designs with tight tolerances. This precision is essential for components like Tang Buckles, which require exact fitting and functionality.

- Cost-Effectiveness: The efficiency of Metal Injection Molding reduces production costs. Manufacturers can produce multiple parts in a single cycle, minimizing waste and maximizing output.

- Complex Geometries: MIM enables the production of complex shapes that traditional methods cannot achieve. This capability allows for innovative designs that enhance both aesthetics and functionality.

- Material Utilization: The process achieves up to 97% material utilization. This high efficiency leads to less waste and a more sustainable manufacturing approach.

Tip: When considering manufacturing methods, evaluate the specific requirements of your product. Metal Injection Molding may provide the best solution for intricate designs and high-volume production.

- Rapid Production: MIM significantly reduces lead times. Manufacturers can quickly respond to market demands, ensuring the timely delivery of Tang Buckles.

- Versatility: The process accommodates various materials, allowing manufacturers to select the best metal for their specific application. This versatility enhances the performance of the final product.

Comparison with Other Manufacturing Methods

When evaluating manufacturing methods for Tang Buckles, Metal Injection Molding (MIM) stands out against traditional techniques such as machining, casting, and stamping. Each method has its unique advantages and limitations. Here’s a comparison of MIM with these common manufacturing processes:

1. Machining

- Process: Machining involves removing material from a solid block to achieve the desired shape.

- Advantages:

- High precision for simple geometries.

- Suitable for low-volume production.

- Limitations:

- Generates significant material waste.

- Time-consuming for complex designs.

2. Casting

- Process: Casting involves pouring molten metal into a mold to create a part.

- Advantages:

- Cost-effective for large parts.

- Capable of producing complex shapes.

- Limitations:

- Longer lead times due to cooling and solidification.

- Potential for defects like porosity.

3. Stamping

- Process: Stamping uses dies to cut or shape metal sheets.

- Advantages:

- Fast production rates for flat parts.

- Low cost for high-volume runs.

- Limitations:

- Limited to flat or simple shapes.

- Requires extensive tooling for new designs.

MIM Advantages

MIM combines the benefits of these methods while minimizing their drawbacks. Here are key advantages of MIM over traditional techniques:

| Feature | Metal Injection Molding | Machining | Casting | Stamping |

|---|---|---|---|---|

| Material Utilization | Up to 97% | Low | Moderate | Moderate |

| Design Complexity | High | Low | Moderate | Low |

| Production Speed | Fast | Slow | Moderate | Fast |

| Waste Generation | Minimal | High | Moderate | Moderate |

Case Studies and Real-World Applications

Metal Injection Molding (MIM) has proven its value across various industries through numerous case studies and real-world applications. Here are some notable examples:

- Outdoor Equipment: A leading manufacturer of outdoor gear utilized MIM to produce Tang Buckles for backpacks. The intricate designs allowed for lightweight yet durable buckles. This innovation improved the overall performance of their products while reducing production costs.

- Automotive Industry: An automotive parts supplier adopted MIM for producing Tang Buckles used in seatbelt systems. The precise tolerances ensured safety and reliability. The company reported a significant reduction in lead times, allowing them to meet increasing market demands swiftly.

- Medical Devices: A medical device company implemented MIM to create Tang Buckles for surgical instruments. The complex geometries achieved through MIM enhanced the functionality of the instruments. Additionally, the high material utilization minimized waste, aligning with the company’s sustainability goals.

- Industrial Machinery: An industrial equipment manufacturer turned to MIM for Tang Buckles used in machinery assembly. The ability to produce multiple parts in a single cycle reduced production time and costs. This efficiency allowed the company to maintain competitive pricing in a challenging market.

Note: These case studies illustrate how MIM enhances product design and manufacturing efficiency. Companies across various sectors benefit from the precision and cost-effectiveness of this innovative process.

Metal Injection Molding offers numerous advantages for producing Tang Buckles. This method ensures high precision, cost-effectiveness, and the ability to create complex geometries. Manufacturers benefit from reduced lead times and minimal material waste.

As the industry evolves, several trends are emerging in Tang Buckle production:

- Growth of e-commerce facilitating global B2B trade

- Resurgence of vintage and western fashion styles

- Increased demand for customization, including logos and unique finishes

These trends highlight the importance of adopting Metal Injection Molding for future manufacturing needs. Companies should consider this innovative method to stay competitive and meet the demands of a changing market.

FAQ

What materials are commonly used in Metal Injection Molding for Tang Buckles?

Metal Injection Molding typically uses stainless steel, titanium, and other alloys. These materials provide strength, durability, and resistance to corrosion, making them ideal for Tang Buckles in various applications.

How does Metal Injection Molding compare to traditional manufacturing methods?

Metal Injection Molding offers higher precision, reduced waste, and the ability to create complex geometries. Traditional methods like machining and casting may not achieve the same level of detail or efficiency.

What industries benefit from Metal Injection Molding Tang Buckles?

Industries such as outdoor equipment, automotive, medical devices, and industrial machinery benefit from MIM Tang Buckles. The precision and cost-effectiveness of MIM meet the demands of these sectors.

Can Metal Injection Molding accommodate custom designs?

Yes, Metal Injection Molding can accommodate custom designs. Manufacturers can create intricate shapes and features tailored to specific requirements, enhancing both functionality and aesthetics.

What is the typical lead time for producing Tang Buckles using MIM?

Lead times for producing Tang Buckles using Metal Injection Molding vary based on order size and complexity. However, MIM generally offers faster production times compared to traditional methods, allowing for quicker market response.