Metal Injection Molding (MIM) in Aerospace drives the production of lightweight, high-precision components essential for advanced defense systems. Manufacturers use MIM to produce complex geometries and achieve exceptional material performance for mission-critical applications. The market for MIM in Aerospace and defense reached USD 4.5 billion in 2023, with strong demand for lightweight, durable, and miniaturized parts.

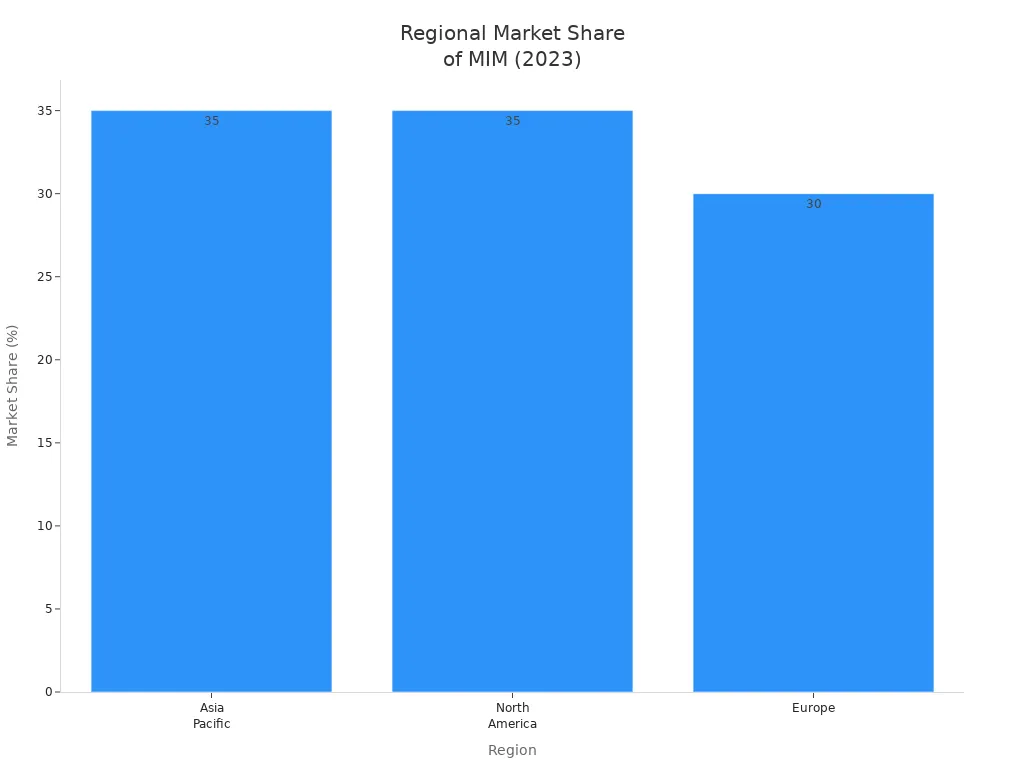

| Aspect | Details |

|---|---|

| Industry Segment | Aerospace Defense expected to hold largest market share in 2023 |

| Key Drivers | Demand for lightweight, durable, high-precision, complex, miniaturized components |

| CAGR | 11.2% (SkyQuest), 4.26% (Market Research Future) over forecast periods |

| Regional Market Share | Asia Pacific leads; North America (~35%), Europe (~30%) significant shares |

| Application Segment | High-Strength Applications largest share in 2023, critical for aerospace and automotive |

| Production Volume Segment | High-volume segment largest share due to mass production demand |

| Market Size (2023) | USD 4.5 billion (SkyQuest) |

| Market Size (2032/34) | Projected USD 11.7 billion (SkyQuest) |

Key Takeaways

- Metal Injection Molding (MIM) produces lightweight, precise metal parts that improve aerospace and defense systems by reducing weight and enhancing performance.

- MIM allows complex shapes and tight tolerances that traditional methods cannot easily achieve, saving time and cutting production costs.

- The process supports a wide range of strong, durable materials like titanium and superalloys, ensuring parts withstand extreme conditions.

- MIM offers cost efficiency and faster production for high-volume manufacturing, making it ideal for mission-critical aerospace and defense components.

- Advanced design and sustainable practices in MIM help manufacturers create reliable, eco-friendly parts that meet strict industry standards.

MIM in Aerospace: Technology and Relevance

What is Metal Injection Molding

Metal Injection Molding (MIM) combines the versatility of plastic injection molding with the strength and integrity of metal. This advanced manufacturing process enables the production of small, intricate metal parts with high precision and consistency. The technology follows a series of well-defined steps:

- Feedstock Preparation: Fine metal powders, such as stainless steel or titanium, are mixed with thermoplastic binders to form a uniform feedstock. Manufacturers granulate this mixture into pellets.

- Injection Molding: The feedstock pellets are heated until they become viscous. The material is then injected at high pressure into precision molds, forming what is known as the “green part.”

- Binder Removal: Specialized processes remove the binders, resulting in a fragile “brown part” that retains the desired shape.

- Sintering: The brown part is heated just below the metal’s melting point. This step bonds the metal particles, eliminates porosity, and achieves near-full density and mechanical strength.

MIM in Aerospace allows for the creation of complex geometries and thin-walled structures that traditional machining cannot achieve. The process also minimizes material waste and reduces the need for secondary operations.

Meeting Aerospace and Defense Demands

Aerospace and defense industries impose some of the most stringent requirements on component manufacturing. These sectors demand exceptional precision, reliability, and material performance. MIM in Aerospace addresses these challenges by delivering parts with tight tolerances, high density, and excellent mechanical properties.

- Manufacturers must comply with rigorous standards such as AS9100 for quality management and NADCAP for special processes.

- Regulatory requirements like ITAR and DFAR ensure secure handling of sensitive data and materials.

- Components often require traceability, advanced material certifications, and environmental controls.

MIM in Aerospace meets these demands through controlled sintering environments, advanced mold design, and robust process controls. The technology produces mission-critical components that withstand extreme conditions, resist corrosion, and maintain structural integrity. As a result, MIM in Aerospace supports the production of lightweight, high-precision parts essential for modern aircraft, defense systems, and space vehicles.

Key Benefits of MIM in Aerospace and Defense

Lightweight Component Manufacturing

Weight reduction remains a top priority in aerospace and defense engineering. Metal Injection Molding enables the production of lightweight components by using advanced metal powders such as titanium and aluminum alloys. Engineers design intricate, near-net-shape parts that optimize material usage and minimize excess weight. This approach reduces the need for heavy machining or the assembly of multiple parts. As a result, aircraft and defense systems benefit from lighter, stronger, and more fuel-efficient components. The aerospace industry often describes the strength-to-weight ratio achieved through MIM as a game-changer for lightweight design. By supporting the creation of lighter structures, MIM in Aerospace advances the development of next-generation aircraft and defense platforms.

Tip: Lighter components not only improve fuel efficiency but also increase payload capacity and operational range for both aircraft and defense vehicles.

High Precision and Complex Geometries

Aerospace and defense applications demand components with tight tolerances and intricate features. Metal Injection Molding excels in producing highly detailed parts with complex geometries, including thin walls, internal cavities, and fine surface details. The process typically achieves dimensional accuracy within ±0.3–0.5%, with even tighter tolerances possible through post-processing. MIM is ideal for small to medium-sized components that require detailed features and consistent quality.

- Engineers use MIM to manufacture actuator housings, micro connectors, pins, and sealing components for high-pressure systems.

- The process delivers near-net shape parts with minimal machining, reducing production time and cost.

- MIM offers higher accuracy than die casting, making it suitable for mission-critical aerospace and defense parts.

This capability allows manufacturers to create parts that traditional machining cannot easily produce, ensuring reliable performance in demanding environments.

Material Versatility and Performance

Metal Injection Molding supports a wide range of materials tailored to the specific needs of aerospace and defense. The process accommodates ferrous alloys, tungsten alloys, hard metals, and special materials such as titanium and nickel-based superalloys. Each material offers unique performance characteristics, including high strength, corrosion resistance, fatigue resistance, and the ability to withstand extreme temperatures.

| Material Category | Examples of Materials | Performance Characteristics |

|---|---|---|

| Ferrous Alloys | Tool steels, stainless steels, iron-nickel alloys, Kovar, Invar | High strength, corrosion resistance, fatigue resistance, magnetic permeability |

| Tungsten Alloys | Tungsten, tungsten-copper blends | High hardness, wear resistance, durability under intense use |

| Hard Metals | Cemented carbides (WC-Co), cermets (Fe-TiC) | Extremely hard, fracture resistant, suitable for high-wear applications |

| Special Materials | Titanium alloys, nickel-based superalloys, cobalt-chromium alloys, molybdenum alloys | High strength, corrosion resistance, fatigue resistance, high-temperature capability, precision and repeatability |

MIM-produced parts achieve high density—typically 95% to 98% of theoretical density—resulting in excellent strength and ductility. The uniform internal microstructure ensures consistent density and weight, while the high-quality surface finish reduces the need for additional processing. These attributes make MIM a preferred choice for producing high-performance aerospace and defense components that must meet strict reliability and durability standards.

Cost and Production Efficiency

Metal Injection Molding (MIM) delivers significant advantages in cost and production efficiency for aerospace and defense manufacturers. These industries often require small, complex parts made from high-performance metals such as Inconel and titanium. Traditional manufacturing methods like CNC machining or casting can drive up costs due to material waste, labor intensity, and the complexity of part geometries.

Cost Savings Compared to Traditional Methods

MIM stands out by reducing both direct and indirect manufacturing costs. While initial tooling investments for MIM are higher—often ranging from $15,000 to $70,000 per design—these costs become more economical as production volumes increase. The process leverages automation, which lowers labor expenses and ensures consistent quality across large batches.

- MIM minimizes material waste by producing near-net-shape parts, which reduces the need for extensive machining.

- Automation in MIM streamlines production, decreasing per-unit costs, especially for intricate or high-precision components.

- The ability to use advanced alloys in MIM enhances part performance and lifespan, justifying the upfront investment.

- For small to medium batch sizes with complex designs, MIM often proves more cost-effective than CNC machining or casting.

Note: MIM enables the production of parts that would be difficult or expensive to manufacture using traditional methods, offering both design flexibility and economic viability for aerospace applications.

Production Lead Times and Scalability

Aerospace and defense programs frequently operate under tight schedules and require rapid delivery of mission-critical components. MIM addresses these needs by shortening production lead times and supporting scalable manufacturing.

| Feature | Benefit |

|---|---|

| Shorter lead times | Faster delivery of finished aerospace/defense parts |

| Elimination of post-processing | Reduced production time and costs |

| High precision and consistency | Increased productivity and cost savings |

MIM produces components in near-final form, which reduces or eliminates the need for secondary operations. This approach accelerates time-to-market and allows manufacturers to respond quickly to changing demands. Although tooling lead times can range from 6 to 10 weeks, the process becomes highly efficient for large-scale production—often exceeding 100,000 parts—where economies of scale justify the initial investment.

- MIM supports the production of intricate, high-precision parts with reduced lead times compared to traditional methods.

- The process enables customization and rapid adaptation to new designs, which is essential for aerospace and defense innovation.

- By minimizing post-processing, MIM further reduces overall production costs and streamlines supply chains.

Tip: For aerospace and defense manufacturers, MIM offers a strategic advantage by combining cost efficiency, scalability, and the ability to deliver complex, high-performance components on tight deadlines.

MIM in Aerospace: Real-World Applications

Aircraft Components

Aircraft manufacturers rely on Metal Injection Molding to produce a wide range of critical components. MIM enables the creation of lightweight, corrosion-resistant parts with complex geometries and tight tolerances. These features help improve fuel efficiency and extend flight range by reducing overall aircraft weight. The process also supports high-volume production, ensuring consistent quality and cost savings.

| Aircraft Components Manufactured Using MIM | Description/Notes |

|---|---|

| Fasteners | High volume use in commercial and military aircraft |

| Screws | Common small parts benefiting from MIM durability and cost savings |

| Seatbelt Components | Includes assemblies and adjustment levers |

| Wing Flap Screw Seals | Specialized sealing components |

| Bushings | Durable, high-density parts |

| Latches | Used in various aircraft mechanisms |

| Fittings | Precision components for assembly |

| Seat Belt Assemblies | Complex assemblies produced efficiently |

| Adjustment Levers | Functional parts with complex geometry |

Manufacturers also use MIM to produce turbine blades, fuel system components, and hydraulic parts. These components must withstand extreme conditions and deliver reliable performance in engines, landing gear, and cockpit systems. The use of advanced alloys like titanium and Inconel further enhances mechanical strength and durability.

Defense System Parts

Defense systems demand components that combine durability, precision, and reliability. MIM produces small, complex metal parts that meet strict performance standards under extreme conditions. The process supports the manufacture of fire control group components, such as triggers, hammers, sears, and sear housings. Magazine catch and lock components, fire suppression parts, and sight plates also benefit from MIM’s ability to achieve tight dimensional tolerances and high material density.

- Fire control group components (triggers, hammers, sears, sear housings)

- Magazine catch and lock components

- Fire suppression parts

- Sights and sight plates

- Stock components and accessories

MIM in Aerospace and defense applications allows for the combination of multiple components into a single part, reducing assembly complexity and improving manufacturability. The process also enables the use of difficult-to-machine materials, resulting in parts with superior mechanical properties and corrosion resistance.

Satellite and Spacecraft Components

Satellite and spacecraft systems require high-precision, lightweight components that can withstand harsh environments. Metal Injection Molding enables the production of intricate parts for propulsion, communication, and navigation subsystems. Manufacturers use high-strength stainless steel and specialized magnetic alloys to ensure components maintain performance during extended space missions.

- MIM provides excellent dimensional accuracy and repeatability, which is critical for reliable satellite operation.

- Components exhibit high strength-to-weight ratios, supporting lightweight yet durable satellite structures.

- The process allows for complex geometries and tight tolerances, optimizing subsystem functionality.

Corrosion resistance and mechanical strength contribute to the longevity of satellite and spacecraft components. MIM offers design flexibility and production efficiency, making it a preferred choice for manufacturing reliable, high-performance parts for space applications.

Case Studies: MIM in Aerospace and Defense

Overcoming Weight and Precision Challenges

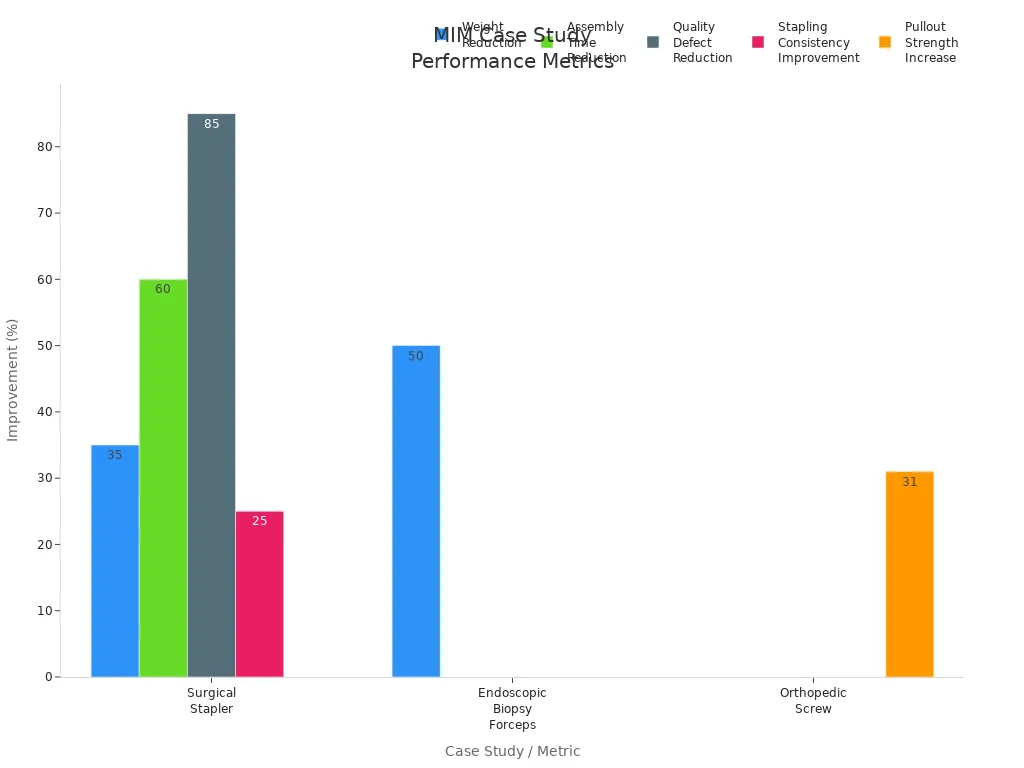

Aerospace and defense sectors often face strict requirements for weight reduction and precision. Metal Injection Molding has enabled manufacturers to address these challenges with measurable results. For example, in one case, engineers optimized a surgical stapler component by reducing the number of parts from twelve to three. This change led to a 35% decrease in weight, a 60% reduction in assembly time, and an 85% drop in quality defects. The stapler also achieved a 25% improvement in consistency. In another case, orthopedic screws produced through MIM demonstrated a 31% increase in pullout strength and maintained thread accuracy within ±0.02mm. These improvements ensured better mechanical reliability and long-term durability.

| Case Study / Metric | Measurable Outcome | Description / Impact |

|---|---|---|

| Surgical Stapler Component Optimization | Weight reduction: 35% | Reduced from 12 parts to 3, improving assembly |

| Assembly time reduction: 60% | Faster production, lower labor costs | |

| Quality defect reduction: 85% | Improved reliability | |

| Stapling consistency improvement: 25% | Enhanced performance | |

| Orthopedic Screw Performance Enhancement | Pullout strength increase: 31% (850N vs. 650N) | Better mechanical reliability |

| Thread accuracy: ±0.02mm | High precision for integration | |

| Fatigue resistance: >5 million cycles | Long-term durability | |

| Endoscopic Biopsy Forceps | Weight reduction: 50% | Lighter, improved handling |

| Integrated irrigation channel: 0.4mm | Enabled by MIM | |

| Surface finish: <1 μm Ra | Smooth operation |

These results highlight how MIM in Aerospace supports the creation of lightweight, high-precision components that meet demanding industry standards.

Improving System Performance

Metal Injection Molding has also contributed to significant improvements in overall system performance for aerospace and defense applications. The process enables near-net-shape manufacturing, which reduces the need for secondary machining and assembly. This leads to faster production cycles and improved reliability. Engineers benefit from design flexibility, allowing them to create complex, lightweight parts with integrated features. Parts produced by MIM achieve densities above 98%, providing excellent wear, corrosion, and heat resistance. These properties extend the lifespan of components in harsh environments.

| Aspect | Description |

|---|---|

| High Precision & Accuracy | Near-net-shape manufacturing, less secondary machining, improved reliability |

| Design Flexibility | Complex, lightweight parts with integrated features |

| Mechanical Properties | Densities above 98%, excellent wear, corrosion, and heat resistance |

| Cost & Time Efficiency | Lower costs, faster production, scalable manufacturing |

| Environmental Benefits | Use of recycled materials, less waste |

| Aerospace & Defense Examples | Remington firearms: improved accuracy and reliability; micro-engineered parts with tight tolerances |

Note: MIM in Aerospace not only enhances component quality but also supports sustainable manufacturing by reducing waste and enabling the use of recycled materials.

Challenges and Future Trends for MIM in Aerospace

Design and Material Considerations

Engineers in aerospace and defense face unique challenges when designing for Metal Injection Molding. They must balance complex geometries with manufacturability and performance. Key design considerations include:

- Avoiding overhangs in part geometry to simplify sintering and reduce costs.

- Maintaining uniform wall thickness to prevent defects such as warpage or sink marks.

- Adding draft angles to cores or undercuts for easier part ejection.

- Designing external threads with flats to simplify parting lines.

- Strategically placing parting lines, gates, and ejector pin marks for optimal manufacturability.

Material selection plays a critical role. Titanium alloys, aluminum, magnesium, and zinc each offer properties suited to aerospace and defense needs. Titanium provides high strength-to-weight ratio and corrosion resistance, while aluminum and magnesium deliver lightweight solutions. MIM in Aerospace enables the production of small to medium-sized, intricate parts with tight tolerances, often achieving densities of 94-97% and mechanical properties comparable to wrought or forged materials.

| Material | Key Properties | Typical Applications |

|---|---|---|

| Titanium Alloy | High strength-to-weight, corrosion resistance | Aircraft, spacecraft components |

| Aluminum | Lightweight, thermal conductivity | Aerospace structures |

| Magnesium | Lightest structural metal | Weight-critical aerospace parts |

| Zinc | Complex shapes, durability | Safety systems, connectors |

Qualification and Certification

Aerospace and defense industries require rigorous qualification and certification for MIM components. Manufacturers must ensure dimensional accuracy and consistency through precision tooling and automated measurement systems. Traceability is maintained with comprehensive material reporting and unique part IDs. Qualification testing simulates real-world conditions, including temperature, pressure, vibration, and chemical exposure. Destructive tests verify strength and durability.

Certifications such as ISO 9001:2015, AS9100D, ITAR, and Nadcap are essential. Nadcap covers special processes like metallic materials manufacturing, nondestructive testing, and measurement inspection. Quality assurance tools include coordinate measuring machines, optical comparators, and first article reports. Process controls such as PFMEA and PPAP help maintain stability and compliance. Certificates of conformance verify that parts meet customer specifications.

Note: Compliance with regulatory standards from agencies like the FAA and EASA ensures that MIM in Aerospace meets strict safety and quality requirements.

Advanced Materials and Sustainability

The future of MIM in Aerospace will focus on advanced materials and sustainable practices. Manufacturers now use generative design and topology optimization to minimize material usage and reduce weight. New material options, including high-strength titanium and stainless steel, support the production of lightweight, high-performance parts. Design optimization through CAD and simulation maintains strength while reducing mass.

Sustainability initiatives include the use of recycled materials, energy-efficient processing, and waste reduction. Automation and data analytics optimize process parameters, further reducing waste. Hybrid manufacturing techniques, such as combining MIM with 3D printing, enable the creation of complex geometries and improve surface finish. These innovations support the production of lighter, stronger components that meet both performance and environmental goals.

Tip: Sustainable MIM practices help aerospace and defense manufacturers reduce environmental impact while maintaining reliability and quality.

MIM in Aerospace continues to transform the industry by delivering lightweight, high-precision components. This technology provides unmatched design flexibility, superior material performance, and efficient production. Industry leaders see clear benefits:

- Enhanced reliability for mission-critical systems

- Greater freedom in component design

- Improved cost and time efficiency

Aerospace and defense manufacturers who adopt MIM in Aerospace position themselves at the forefront of innovation.

FAQ

What types of metals can MIM use in aerospace and defense?

Engineers select from stainless steel, titanium, nickel-based superalloys, and cobalt-chromium alloys. These materials deliver high strength, corrosion resistance, and durability. MIM supports a wide range of alloys to meet specific aerospace and defense requirements.

How does MIM improve component precision?

MIM achieves tight tolerances and complex geometries by using precision molds and controlled sintering. This process produces parts with dimensional accuracy within ±0.3–0.5%. Manufacturers rely on MIM for consistent, high-precision components.

Is MIM suitable for high-volume production?

Yes. MIM excels in high-volume manufacturing. The process uses automated injection molding and sintering, which ensures consistent quality and reduces per-unit costs. Aerospace and defense industries benefit from scalable production.

What certifications are important for MIM aerospace parts?

Key certifications include AS9100 for quality management, Nadcap for special processes, and ISO 9001:2015. These standards ensure that MIM components meet strict aerospace and defense requirements.

Can MIM parts withstand extreme environments?

MIM parts show excellent resistance to heat, corrosion, and mechanical stress. Engineers design these components for use in harsh aerospace and defense environments, ensuring long-term reliability and performance.