In 2023, the consumer product segment, which includes devices like smartphones, accounted for approximately 30.8% of revenue in the Metal Injection Molding market.

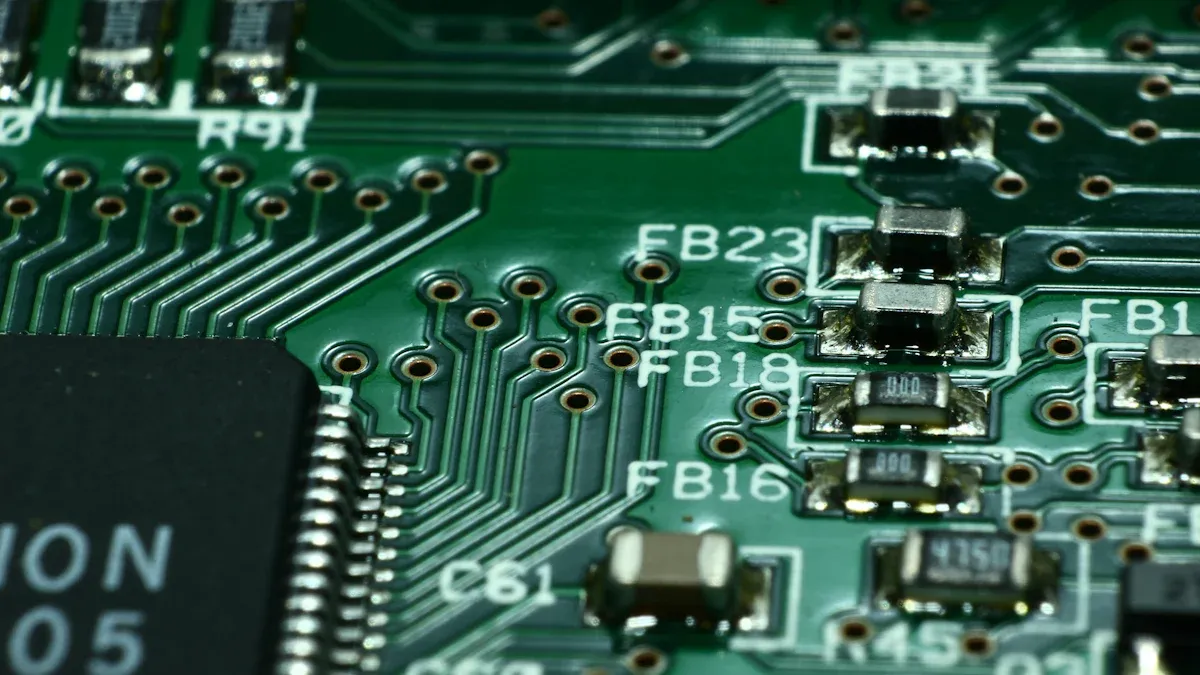

Manufacturers in consumer electronics increasingly choose MIM to meet the demand for lightweight, durable, and miniaturized components. Industry experts recognize that MIM enables the creation of complex geometries, thin-walled parts, and micro-sized elements that traditional techniques struggle to achieve. This technology delivers high-precision results, reduces material waste, and supports efficient, high-volume production.

Key Takeaways

- MIM produces small, complex electronic parts with high precision and tight tolerances, ensuring reliable fit and function.

- The process supports many metal types, allowing engineers to choose materials that improve strength, conductivity, and durability.

- MIM reduces material waste and lowers production costs, making it ideal for high-volume manufacturing of consumer electronics.

- Parts made by MIM have strong mechanical properties and excellent surface finishes, often needing little or no extra processing.

- Compared to CNC machining, die casting, and stamping, MIM offers superior value for small, detailed, and high-precision components.

MIM Precision and Complexity

Tight Tolerances for Electronics

Consumer electronics demand components with extremely tight tolerances to ensure proper fit, function, and reliability. Metal injection molding delivers the precision required for these applications. Manufacturers can achieve tolerances within ±0.3% of the nominal dimension, such as ±0.03 mm on a 10 mm stainless steel part. For intricate parts like Bluetooth headset accessories, tolerances as tight as ±0.002 inches (about ±0.05 mm) are possible. Smartphone components, including SIM card slots, often require tolerances around ±0.02 mm to guarantee a precise fit and long-term durability.

- MIM achieves high precision, especially for small and detailed parts.

- The process supports excellent repeatability and batch-to-batch consistency.

- Advanced process control and expertise help maintain these tight tolerances, even when accounting for shrinkage during sintering.

- Compared to investment casting, MIM offers better tolerance and productivity, making it ideal for high-volume, precision electronics manufacturing.

Note: Final dimensions may require additional shape correction methods, such as machining or polishing, to meet exact specifications.

Complex Geometries and Miniature Parts

Modern consumer electronics often feature components with complex shapes and miniature sizes. Metal injection molding excels in producing these challenging parts. The process enables the creation of highly detailed features without the need for expensive secondary processing. Manufacturers can reliably produce parts with minimum wall thicknesses of about 0.010 inches (0.25 mm), and in some micro applications, as thin as 0.008 inches (0.2 mm). Feature sizes as small as 0.1 mm are achievable, supporting the trend toward miniaturization in electronics.

| Parameter | Value |

|---|---|

| Minimum Feature Size | 0.1 mm |

| Minimum Wall Thickness | 0.3 mm |

| Machine Precision | ±0.3% (±0.1 mm) |

Common examples of consumer electronics components manufactured using this process include:

- SIM slot parts

- Drone brackets

- Earphone frames

- Connectors and structural parts for smart devices

- Housings for compact electronic assemblies

These examples highlight the ability of MIM to deliver intricate, compact, and high-performance parts that meet the evolving needs of the electronics industry.

MIM Material Versatility

Diverse Metal Options for Electronics

Manufacturers in the consumer electronics industry require a wide selection of metals to meet diverse application needs. Metal injection molding supports this demand by processing fine metal powders such as stainless steel, tungsten alloys, high-strength steel alloys, and copper. These materials enable the production of intricate and precise parts, including connectors, housings, buttons, switches, and fasteners.

- Stainless steel provides corrosion resistance and mechanical strength.

- Tungsten alloys offer high density and wear resistance.

- Copper delivers excellent electrical and thermal conductivity.

- High-strength steel alloys ensure durability for structural components.

This versatility allows engineers to select the optimal metal for each component, ensuring both performance and reliability. MIM stands out as an ideal solution for high-volume production, where consistency and material choice are critical.

Tip: Selecting the right metal alloy for each application can enhance the performance and lifespan of electronic devices.

Tailored Properties for Performance

The choice of metal powder in MIM directly impacts the performance of electronic components. Different powders influence properties such as electrical and thermal conductivity, corrosion resistance, and mechanical strength. For example, copper alloys improve electrical contacts and heat dissipation, while stainless steels increase durability and resistance to environmental factors.

| Metal Powder Type | Key Properties | Impact on Electronic Components Performance |

|---|---|---|

| Copper Alloys | Excellent electrical and thermal conductivity | Enhances electrical contacts and heat dissipation efficiency |

| Stainless Steels | Corrosion resistance, high strength | Improves the durability and mechanical strength of parts |

| Titanium Alloys | High strength-to-weight ratio | Enables lightweight, strong components |

| Superalloys | High-temperature strength, corrosion resistance | Suitable for high-stress, high-temp electronic environments |

| Tungsten Heavy Alloys | High density, mechanical strength | Provides shielding and wear resistance in specialized parts |

Engineers can tailor the feedstock composition to achieve specific mechanical, thermal, or corrosion-resistant properties. The MIM process also supports the development of new alloy systems, enabling the creation of non-standard materials for unique requirements. This flexibility ensures that each electronic component meets precise specifications for its intended function.

MIM Cost-Effectiveness in High-Volume Production

Material Efficiency and Reduced Waste

Material efficiency plays a crucial role in the manufacturing of consumer electronics. Metal Injection Molding stands out for its ability to maximize material utilization and minimize waste. Traditional machining methods often waste between 30% and 40% of raw material as chips and scrap. In contrast, MIM generates less than 5% material waste, making it a highly efficient process for high-volume production. This efficiency becomes even more significant when producing small, complex metal components at volumes exceeding 20,000 units annually.

Manufacturers benefit from several waste-reducing features of the process:

- MIM manufacturers can reduce material waste by approximately 50% compared to traditional methods.

- Some producers achieve up to 95% material utilization in each product.

- Excess material from the process can be recycled, enabling the potential for zero waste.

- The process supports high-volume production of small, complex parts, such as those used in consumer electronics.

- Combining multiple parts into one during molding further reduces material waste.

These advantages not only lower raw material costs but also support sustainability initiatives by reducing the environmental impact of manufacturing. Companies that adopt MIM for electronics components can achieve both economic and ecological benefits.

Lower Costs for Mass Manufacturing

Cost savings remain a primary driver for manufacturers choosing MIM for consumer electronics components. The process delivers significant reductions in per-unit costs, especially at high production volumes. Although the initial investment in molds and equipment is substantial, the cost per part drops sharply as production scales up.

The following table compares the cost per unit and initial investment for MIM and CNC machining when producing 100,000 units:

| Production Method | Cost Per Unit | Initial Investment |

|---|---|---|

| Metal Injection Molding (MIM) | $2.50 | $100,000 (for 4 molds) |

| CNC Machining | $6.15 | $615,000 (equipment & labor) |

This comparison shows that MIM can reduce total production costs by 30-50% per unit compared to CNC machining. The process maintains consistent setup times regardless of part complexity and achieves tighter precision tolerances, which further enhances its value for mass manufacturing. While die casting offers lower tooling costs and faster cycles, MIM provides better precision and lower labor costs, resulting in superior overall value for high-volume production.

Scalability also impacts overall production costs. As production volume increases, the initial setup costs become less significant on a per-unit basis. MIM enables cost-effective mass production of complex, high-precision parts, making it ideal for large-scale consumer electronics manufacturing. The process’s speed and automation reduce manual labor and downtime, allowing manufacturers to meet large-scale demand efficiently while maintaining consistent quality. This scalability directly lowers overall production costs and supports the rapid growth of the consumer electronics market.

Tip: Companies that invest in MIM for high-volume production gain a competitive edge through lower costs, higher efficiency, and the ability to deliver innovative products to market faster.

MIM Mechanical Properties and Durability

High Strength and Density

Consumer electronics require components that withstand daily use and mechanical stress. Metal injection molded parts deliver impressive mechanical strength, making them suitable for demanding applications. For example, MIM 316L stainless steel components typically reach a tensile strength of around 539 MPa and show high ductility with elongation to fracture at approximately 92%. MIM 420 stainless steel parts offer even higher tensile strength, exceeding 635 MPa, with a yield strength of at least 440 MPa and elongation above 20%. These values ensure that electronic device parts resist deformation and maintain structural integrity.

| Property | Value |

|---|---|

| Tensile Strength (MIM 316L SS) | ~539 MPa |

| Elongation to Fracture (316L SS) | 92% |

| Tensile Strength (MIM 420 SS) | ≥635 MPa |

| Yield Strength (MIM 420 SS) | ≥440 MPa |

| Elongation (MIM 420 SS) | ≥20% |

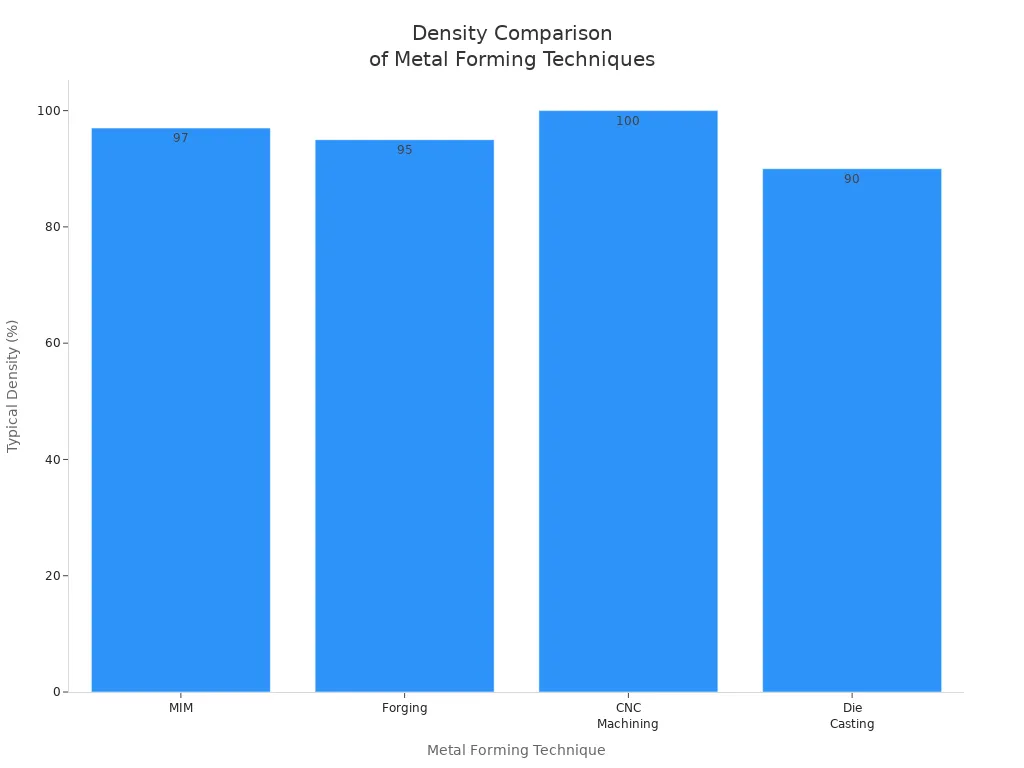

Density also plays a crucial role in the performance of electronic components. Metal injection molded parts achieve densities between 95% and 99% of theoretical full density. This high density results from the use of fine metal powders and precise sintering processes. While forged and CNC machined parts reach nearly 100% density, MIM parts outperform die cast components, which often have lower density due to porosity.

| Metal Forming Technique | Typical Density Range | Notes |

|---|---|---|

| Metal Injection Molding | 95%–99% of theoretical | High density, minimal residual porosity |

| Forging | Nearly 100% | Maximum density, minimal porosity |

| CNC Machining | 100% | Fully dense, cut from solid material |

| Die Casting | Lower than MIM, variable | Porosity present, lower density |

Consistent Quality and Reliability

Manufacturers in the consumer electronics industry demand consistent quality and reliability from every component. Metal injection molding supports these requirements through advanced quality control measures at every stage of production.

- Material inspection and verification ensure that only high-quality feedstock enters the process. Spectrometers and hardness testers confirm that raw materials meet strict mechanical and chemical standards.

- Precision measurement tools, such as coordinate measuring machines (CMMs), calipers, and micrometers, verify that each part meets tight dimensional tolerances.

- In-process monitoring uses automated sensors and machine vision systems to detect deviations in real time, allowing immediate corrections.

- Tool wear monitoring tracks the condition of molds and cutting tools, preventing defects and maintaining surface quality.

Manufacturers also apply surface treatments like PVD coating, sandblasting, and polishing to enhance durability and appearance. Strict control of batch-to-batch consistency guarantees that every production run delivers uniform mechanical and dimensional properties. These practices ensure that metal injection molded components meet the high standards required for modern consumer electronics.

MIM Design Flexibility and Surface Finish

Innovative and Miniaturized Designs

Manufacturers in the consumer electronics industry often seek new ways to create smaller, more intricate products. Metal injection molding enables the production of complex, precision metal parts that match the mechanical properties of wrought steel. This process supports the creation of custom components with micro-scale geometries, which traditional machining cannot achieve.

- The technology allows for the design of very small parts with intricate features, supporting the trend toward miniaturization in devices such as TWS earphones, hearing aids, and bone conduction earphones.

- Companies can produce small custom parts efficiently, maximizing the number of parts per furnace run and reducing raw material costs.

- Molds used in this process offer quick scalability, making it easy to adjust production volumes as market demands change.

- The process also enables innovative solutions, such as combining Pogo Pin spring connectors with metal parts to create stable electrical connections on irregular curved surfaces. This approach helps engineers design compact devices without sacrificing performance.

These capabilities give designers the freedom to push boundaries and develop next-generation consumer electronics.

Superior Surface Finish and Aesthetics

The appearance and feel of electronic components play a significant role in consumer satisfaction. Metal injection molding produces parts with a fine surface finish, typically around 0.8μm Ra after sintering. Manufacturers can further enhance the finish using techniques such as electropolishing, bead blasting, and chemical etching.

- Electropolishing smooths surfaces, removes imperfections, and improves corrosion resistance, making it ideal for visible device parts.

- Bead blasting creates a uniform, satin-like texture, removes tool marks, and enhances coating adhesion.

- Chemical etching refines micro-features without damaging delicate details, which is especially useful for complex shapes.

- Additional coatings, such as PVD or nickel plating, can improve both durability and decorative appeal.

| Feature | Metal Injection Molding (MIM) | Die Casting |

|---|---|---|

| Surface Finish | Very fine | Good, but often requires additional finishing |

| Best For | Small, complex parts | Larger, less complex parts |

| Post-Processing | Minimal | Often required |

These finishing options ensure that parts not only meet functional requirements but also deliver the high-quality look and feel expected in modern consumer electronics.

MIM Compared to Other Manufacturing Methods

MIM vs. CNC Machining

Manufacturers often compare MIM and CNC machining when selecting a process for consumer electronics components. CNC machining offers exceptional accuracy and flexibility, making it suitable for prototypes and low to medium production volumes. However, MIM stands out for high-volume production of small, complex parts. The following table highlights key differences:

| Aspect | Injection Molding (MIM) | CNC Machining |

|---|---|---|

| Upfront Investment | High due to mold creation costs | Lower, faster tooling lead times |

| Production Speed | Very fast, ideal for mass production | Slower per-part cycle time |

| Cost per Part | Low at high volumes | Higher per-part cost |

| Design Flexibility | Difficult to change after mold creation | Easy to modify designs |

| Suitability | Best for large volume, cost-effective production | Best for low to medium volume, custom parts |

MIM achieves tight tolerances and supports intricate geometries that challenge CNC machining, especially for internal features. While CNC machining allows rapid design changes, it becomes less economical for complex, high-volume parts.

MIM vs. Die Casting

Die casting and MIM both serve the electronics industry, but each excels in different areas. MIM produces small, complex parts with high density and strength, using a wide range of metals, including ferrous alloys. Die casting works best for larger, simpler parts and primarily uses non-ferrous metals like aluminum and zinc.

- MIM enables intricate details, thin walls, and superior surface finish.

- Die casting offers faster cycles and lower costs for very high-volume runs.

- MIM supports high mechanical strength and tight tolerances, while die casting may require secondary finishing.

| Parameter | MIM | Die Casting |

|---|---|---|

| Suitable Part Size | Small, under 100 mm, <200g | Larger, wider size range |

| Complexity & Geometry | High, thin walls (~0.1mm) | Medium, limited thin wall ability |

| Material Options | Wide, including ferrous metals | Mainly non-ferrous metals |

| Surface Finish | High quality, tight tolerances | Medium, may need trimming |

MIM is ideal for small, high-precision electronics parts, while die casting suits larger, less complex components.

MIM vs. Stamping

Stamping remains a popular choice for producing large quantities of simple metal parts. It offers very low unit costs and rapid production speeds, especially for straightforward shapes like shields and cases. However, MIM provides better value for small, intricate components at medium to high volumes.

- Stamping excels in very high-volume runs of larger, simpler parts.

- MIM is preferred for connectors, hinges, and camera parts that require complexity and precision.

- Both methods involve significant tooling costs, but stamping dies last longer for extremely large runs.

Tip: Manufacturers should choose stamping for basic, high-volume parts and MIM for detailed, high-precision components in consumer electronics.

MIM stands out as the preferred manufacturing method for consumer electronics components. Manufacturers benefit from the ability to produce complex shapes, thin walls, and miniaturized parts that support innovative device designs.

- The process delivers high strength, excellent surface finishes, and tight dimensional tolerances, often eliminating the need for secondary finishing.

- MIM supports a wide range of materials, enabling durable and reliable products.

- Automation and smart manufacturing further improve quality and efficiency, meeting the demands of today’s electronics market.

FAQ

What types of metals can MIM process for electronics components?

MIM supports a wide range of metals, including stainless steel, titanium, copper, and specialty alloys. This versatility allows engineers to select materials that meet specific performance and durability requirements for consumer electronics.

How does MIM ensure precision in small electronic parts?

Manufacturers use advanced tooling and process controls to achieve tight tolerances. Automated inspection systems verify each part’s dimensions, ensuring consistent quality for miniature and complex components.

Is MIM suitable for high-volume production?

Yes. MIM excels in high-volume manufacturing. The process enables rapid production of thousands to millions of parts with consistent quality, making it ideal for consumer electronics.

Can MIM parts receive surface treatments or coatings?

Engineers can apply various surface treatments, such as PVD coating, electropolishing, or bead blasting. These treatments enhance appearance, corrosion resistance, and durability for electronic device components.

What are the main advantages of MIM over traditional machining?

MIM offers superior material efficiency, supports complex geometries, and reduces per-unit costs at scale. Manufacturers benefit from faster production, less waste, and the ability to create intricate designs not possible with traditional machining.

Pingback: Metallurgy Processes You Should Never Ignore Today