What is aluminum die casting?

Aluminum die-casting products are mostly employed in electronics, autos, motors, home appliances, and some communication industries, among others. Some high-quality aluminum alloy products with high performance, precision, and toughness are also utilized in large airplanes, ships, and other industries with high demands. The primary application is still in some equipment parts.

Table of Contents

MIM vs Die casting, Choose Which?

Aluminum die casting process: The working process of a product die casting is explained

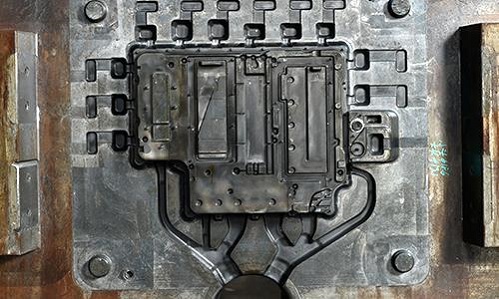

High-precision die mold for casting aluminum new energy automobile parts

1) Mold closing: the mold is closed and waiting for pouring.

2) Casting: The manipulator or operator pours material from the furnace into the barrel.

3) Injection: according to the set process parameters, injection.

4) Open the mold: open the mold, pull the core with the inclined guide column, and pull the core simultaneously.

5) Core-pulling: the mold is pulled out from the side under the action of the core-pulling device to facilitate ejection; If the core is pulled by the front (fixed) die, the core needs to be pulled before the mold is opened.

6) Top piece: under the action of the pushing mechanism, the casting is pushed out for easy removal.

7) Pick up: manually or automatically remove the casting from the mold; If there is a buckle needle, pay attention to the direction and Angle, can not beat and pull savagely, otherwise, it is easy to damage the thimble.

8) Spraying: clean the mold cavity, and spray the release agent evenly before and after the mold.

9) First reset mechanism: If there is a thimble under the core withdrawal, it is necessary to make a pull rod and other first reset mechanism to protect the mold.

10) Re-close the mold and repeat the above process.

Process steps for aluminum die casting:

- Annealing treatment: After heating aluminum alloy die casting to 300 ° C for a length of time, the process of cooling to room temperature with the furnace is known as annealing. During annealing, the solid solution will display differentiation and aggregation, which may eliminate internal stress from aluminum alloy die casting, keep the scale of aluminum alloy die casting steady, prevent deformation, and improve the plasticity of aluminum alloy die casting.

- solution treatment: the aluminum die casting is heated to the melting point of the crystal, then held at that temperature for a long time, and then cooled, allowing the strengthened component to dissolve while preserving the high temperature until it reaches room temperature. Solution treatment can increase the strength and flexibility of aluminum die casting as well as its corrosion resistance. The impact of solution treatment is often related to three factors: solution treatment temperature, heat preservation during solution treatment, and cooling pace.

- Aging treatment: the solution treatment of aluminum alloy die-casting parts heated to the prescribed temperature, continuing for some time after the oven, and placed in the air cooling method is known as aging. Natural aging is achieved when the aging enhancement is performed at ambient temperature. Artificial aging occurs when the aging augmentation is finished at a temperature higher than room temperature and held for some time. The aging treatment promotes the spontaneous process of supersaturated solid solution differentiation, which can reduce the alloy matrix’s lattice to a relatively stable condition.

Precautions for aluminum die-casting production:

Aluminum die-cast engine housing

1, the wall thickness, the thickness of the gap is too large to add impact;

2, de-molding, which is more difficult than injection molding demoulding, is the setting of the inclination of the drawing die and the releasing force should pay extra attention to, the inclination of the drawing die is 1-3 degrees, considering the smoothness of the drawing die, the inclination of the drawing die is smaller than that of the drawing die, the drawing die is also 1 degree, and the drawing die is 2-3 degrees;

3, mold, if there are multiple directions of the core, even if the two ends, do not put the core in the lower position, the core will crack;

4,Some aluminum alloy die-casting parts will have other provisions, such as oil injection, powder injection, etc., at this time, it is necessary to avoid the convenient setting of the gate overflow chute;

5, in the layout to prevent complicated mold cloth, can not use multiple core or spiral core pumping;

6, stop the outside processing, you need to leave the processing amount in the whole machine planning, not too much, otherwise the pores inside will be exposed, and not too little, otherwise the rough precision positioning a processing, the black skin has not fallen, the mold should be sparking. The retention should not be greater than 0.8mm, the surface processed into the surface can not see the porosity, because there is a hard layer of protection;

7, another is to pay attention to the selection of materials, with ADC12 A380, etc., to see the detailed provisions;

8, aluminum alloy die casting is not elastic, to do the buckle as long as the same as plastic;

9, usually do not do deep holes, only do spot holes when opening the mold, and then processing;

10, if it is a thin-wall machine is not too thin, use reinforced ribs, and increase bending.

Yes, this is a routine operation for most companies before making an inquiry.

We have metal 3D printing equipment and can provide sample 3D printing.

3D drawings allow engineers to better understand the structure of the product, and 2D documents can provide more information, including materials, tolerances, surface treatment, etc. More detailed information is conducive to more accurate quotations by engineers.

In the case of detailed inquiry drawings and information, it usually only takes 2-3 days for us to give you a detailed quotation, including the product price and mold price.

After confirming the order, we usually take 5-7 days to prepare the DFM report of the product. After confirmation, we spend 25 days to complete the mold and provide T1 samples to customers for testing in the following 10-15 days.

If there is a problem with the test, we will re-sample it for free based on the feedback and provide a suitable sample.

MIM products MOQ 2000 PCS

CNC products MOQ 2000 PCS

Alu die casting, MOQ 2000 PCS

PM product MOQ 5000 PCS

Typically, the lead time for processing and submitting samples is 30 days. However, according to the order quantity and special requirements of customers, we can extend or shorten the delivery cycle accordingly.

1-year product warranty

World-class testing equipment

30+QC Workers

Key sizes 100% checking before shipment

ISO9001+IATF16949

Usually, T/T is used as the payment method

Mold: 50% deposit, 50% payment after confirming the sample.

Bulk production: 30% deposit, 30% see bill of lading Copy, pay 70% balance.