Casting according to the molding process classification, can be divided into gravity casting and pressure casting, die casting is molten metal under high-pressure high-speed filling and solidification under the pressure casting method, it is characterized by the metal liquid is under pressure filling cavity and crystallization solidification; Liquid metal fills the cavity at a high speed (10~100 m/s), and the filling time of liquid metal is very short (0.1~0.2 s).

Die casting advantages and disadvantages

Advantages of die-casting

- High production efficiency, suitable for mass production

- High dimensional precision casting, smooth surface

- High casting strength, 25%~30% higher than ordinary casting strength

- High metal utilization rate, small follow-up processing

Disadvantage of die casting

- The liquid metal filling speed is high, the flow state is unstable, and the casting is easy to produce pores

- The equipment cost is expensive, the die-casting machine, melting furnace, holding furnace, die-casting mold and other costs are very expensive

- High melting point alloy (copper, iron, etc.), die casting die life is short

The three main elements of die casting process are: die casting alloy; Die casting machine; Die-casting die

Die casting process is the organic combination of three elements and the use of the process so that various process parameters meet the needs of die casting production.

Die-cast alloy

Die-casting alloy should have the following characteristics:

Easy to die casting: fluidity, shrinkage, molding, etc. to meet the requirements of die casting as much as possible.

Mechanical properties: strength, extensibility, brittleness, etc. meet the design requirements of the product.

Machinability: easy to process and the quality of the machined surface can meet the requirements of product design.

Surface treatment: polishing, electroplating, painting, oxidation and other requirements can meet the requirements of product design.

Corrosion resistance: The product has a certain corrosion resistance in the final use environment.

| Main die casting alloy | casting temperature | Characteristics and performance |

| Aluminium alloy | 650~680℃ | 1. Low density, can produce parts requiring reduced quality

2. High strength, good plasticity 3. Good oxidative corrosion resistance |

| Zinc alloy | 420~440℃ | 1. Good die-casting characteristics: easy to die-cast products with complex shapes and high dimensional accuracy

2. High tensile strength and hardness, good impact toughness and elongation 3. Good processing performance: product surface, easy to do a variety of surface treatment 4. Efficient production |

| Magnesium alloy | 640~680℃ | 1. Low density, high specific strength

2. Good mobility 3. Good shock absorption and magnetic shielding performance |

| Terne metal | About 200℃ | 1. Low melting point, good liquidity, shrinking

2. Good plasticity 3. The casting surface is smooth, easy to do a variety of surface treatment |

| Copper alloy | 900~980℃ | Due to high melting point and low die life, the use should be reduced |

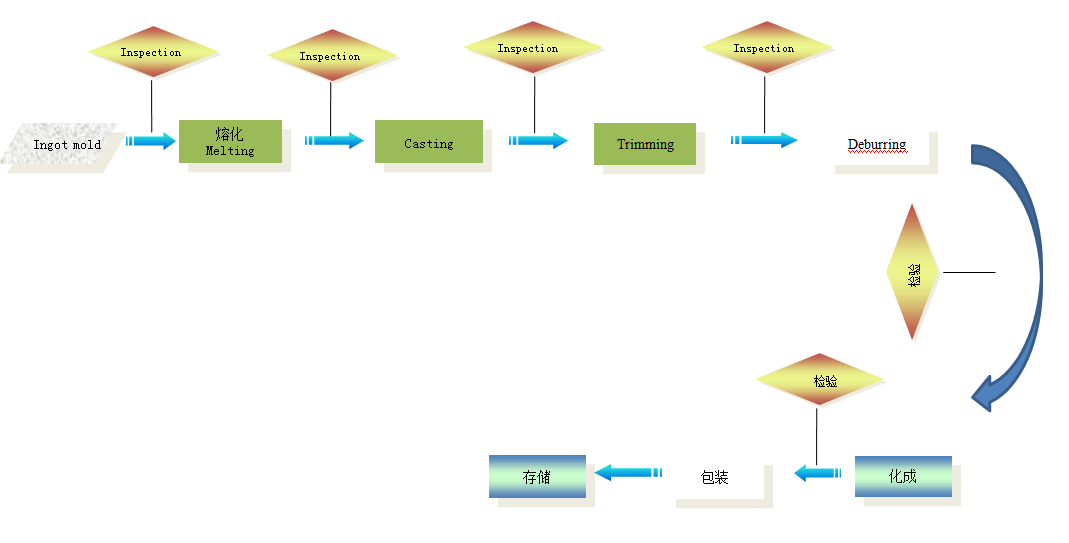

Die Casting process flow chart

| Process | Machine | Fixture | Control items | Measurement |

| Melting | Melting furnace | Material composition, consistency | Spectrometer,densimeter | |

| Diecasting | 300T Die casting machine | special mold | 1. Profile

2. Position, 3. Dimension tolerance |

1. Profile measure

2. CMM 3. Pin gauge |

| Trim | 20T oil pressure | Special Trim die | Appearance | Visual |

| Deburr | Deburring table | chamfer tool | Appearance | Visual |

When choosing die casting alloy, it is necessary to consider its application field, required performance, cost and other factors. Aluminum alloy die casting is suitable for areas requiring lightweight, high strength and corrosion resistance, such as automotive, aerospace, electronics and so on. Zinc alloy die-casting parts are suitable for fields requiring good fluidity, wear resistance and corrosion resistance, such as home appliances, electronics, automobiles, etc. Magnesium alloy die castings are suitable for areas requiring lightweight, high strength and high rigidity, such as aerospace and automotive.

Contact JH MIM to learn more about their aluminum die-casting capabilities.