MIM COST

The cost of MIM PARTS, consists of the following costs

- material cost

- the cost of molds, which are divided into metal injection molds and sizing molds.

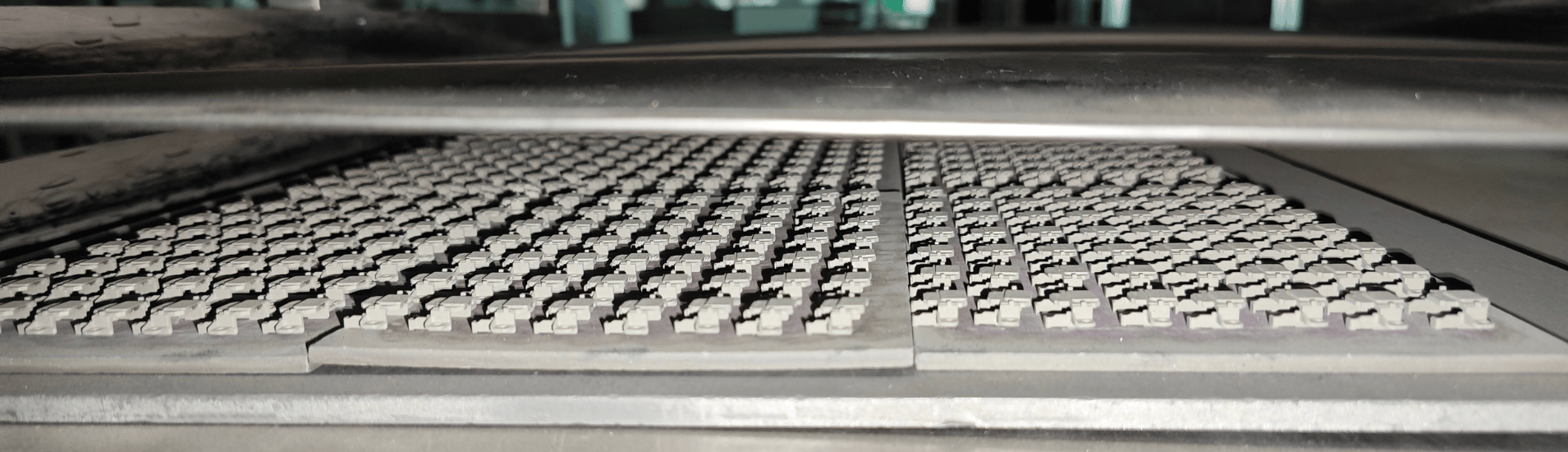

- product manufacturing cost, such as injection, degreasing, sintering, shaping, etc.

- product secondary processing costs, CNC, surface finishes, inspection, and warranty costs

- labor cost, overhead cost, profit margin, the tax cost

JH MIM, from the following aspects to reduce the cost of MIM products, to provide customers with cost-effective products.

First of all, we make the material of the product ourselves, we have 8 patents related to the material.

Secondly, the mold is made by ourselves to reduce the mold cost. 10+ years of experience in MIM mold design, reducing the deformation of the product, and reducing the post-shaping process, thus reducing costs.

Again, there is a lot of equipment for post-processing, no need to process through third-party

Finally, reasonable profit helps customers, get a win-win.

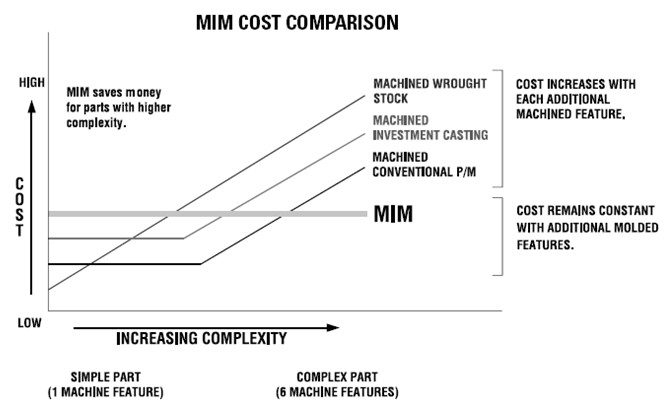

MIM Cost Compared To Other Processes

Send Your Inquiry Today