Sintered bronze bushings deliver outstanding results in rotating applications because of their built-in lubrication and impressive load-bearing abilities. These specialized parts combine a porous bronze matrix with lubricant to create a maintenance-free solution that works better than standard bearings across many industrial uses.

Standard bearings can’t match what sintered bronze bearings offer – continuous lubrication through their network of oil-filled pores. The self-lubricating feature kicks in as friction heat builds up, which makes them perfect for high-frequency and high-speed uses. The sintering process transforms metal powders like bronze or copper into a tough structure. These bushings handle heavy loads while keeping peak performance. They come in many sizes and remain budget-friendly, making them a smart pick for engineers who need reliable bearing solutions.

Let’s get into why sintered bronze bushings consistently beat standard bearings through a complete engineering breakdown. We’ll explore everything from their unique porous structure to their self-lubricating systems. The manufacturing methods, performance benefits, and real-life applications make these components crucial in modern engineering.

What Makes Sintered Bronze Bushings Unique

Sintered bronze bushings get their exceptional performance from unique physical properties and manufacturing methods. These specialized components offer an elegant engineering solution that combines structural integrity with built-in lubrication.

Porous Structure and Oil Retention Mechanism

Sintered bronze bushings contain a network of interconnected pores at the microscopic level. These pores take up about 20-25% of their total volume. The porous matrix works like a tiny reservoir system throughout the component. The interconnected cavities create an even distribution of lubricant throughout the bearing structure once filled with lubricating oil. The porosity lets the bearing store between 10% to 40% of its volume in lubricating oil. This porous structure acts as a permanent lubricant repository and eliminates the need for external lubrication systems in many applications.

Self-Lubrication Explained: Heat-Activated Oil Release

Sintered bronze bushings use a remarkable “breathing” principle based on thermal expansion for self-lubrication. Friction between the shaft and bushing creates heat during operation, which makes both components expand slightly. The oil inside the pores expands as temperatures rise and moves outward toward the bearing surface. A thin lubricating film forms and reduces friction and wear. The oil pulls back into the pores through capillary action once rotation stops and the bearing cools. This continuous oil circulation will give a maintenance-free operation throughout the component’s life.

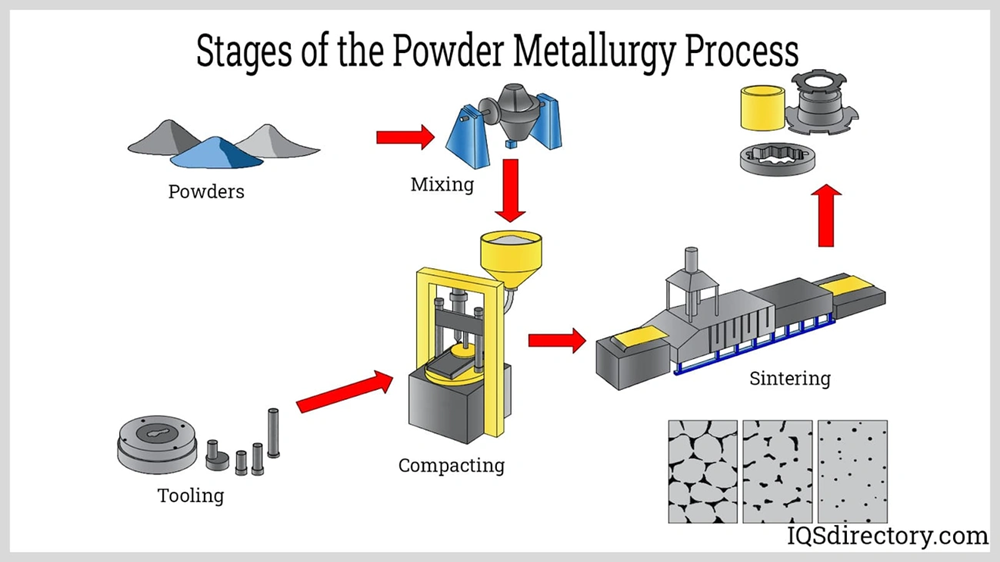

What is Sintered Bronze? Powder Metallurgy Basics

Sintered bronze comes from powder metallurgy – a specialized manufacturing process that JH MIM has mastered over nearly 20 years. The process starts with fine metal powders, usually copper-tin alloys for bronze bearings. These powders compress at pressures between 200-600 MPa to create the basic shape. The compacted part heats (sinters) at temperatures from 750°C to 900°C – below the material’s melting point. This controlled heating bonds metal particles through solid-state diffusion while keeping the porous structure intact. The final step uses vacuum impregnation with lubricating oil to fill the interconnected pores, creating a self-lubricating component.

Manufacturing Process of Sintered Bronze Bearings

The manufacturing of sintered bronze bushings uses a specialized process that creates their distinctive porous structure. The production method needs precise control at each step to deliver optimal performance.

Powder Compaction and Sintering at Sub-Melting Temperatures

Fine bronze powder, typically a copper-tin alloy, starts the production process. The powder undergoes high-pressure compaction between 200-600 MPa in engineered dies. This creates a “green compact” that’s strong enough to handle but needs more processing. The compacted shapes then move into specialized furnaces where temperatures range from 750°C to 900°C—significantly below bronze’s melting point. Solid-state diffusion happens at these temperatures and bonds individual particles together without complete melting. The result is a rigid structure with controlled porosity of 15-20% that forms the bearing’s self-lubricating properties.

Vacuum Oil Impregnation for Self-Lubrication

The porous bronze structure goes through vacuum oil impregnation after sintering. A vacuum chamber removes all air from the internal pores until it reaches levels of about 29″ Hg. Lubricating oil (typically SAE 30) enters the chamber next. Atmospheric pressure pushes the oil deep into every interconnected pore once the vacuum releases. Some manufacturers use hot oil impregnation at 80-120°C to improve oil penetration over an hour.

Dimensional Finishing and Quality Control Standards

Sintered bronze bushings must pass rigorous quality control before release. Inner and outer diameter inspections happen with tolerances as tight as ±0.01mm. Manufacturers run tests that include density measurements, porosity checks, and radial crushing load tests during production. Most facilities maintain ISO 9001:2000 certification to ensure quality consistently. Companies like JH MIM, with their unique experience of nearly 20 years in powder metallurgy, deliver sintered bronze bushings that meet engineering specifications precisely.

Performance Advantages Over Standard Bearings

Sintered bronze bushings offer significant performance benefits that make them better than standard bearings in many applications. JH MIM’s 20 years of powder metallurgy expertise show this clearly.

Friction Reduction in High-Speed Applications

Sintered bronze bushings work great at high rotational velocities. They can operate at speeds up to 69,000 r/min under light loads. Their self-lubrication mechanism creates a hydrodynamic condition with very low friction coefficients from 0.04-0.07. This saves energy in high-speed operations. All the same, users must choose the right oil to get the best performance at different speeds.

Wear Resistance in Oscillating and Rotating Loads

The lifespan of these bushings is 3-5 times longer than ordinary bearings. Consistent lubrication prevents metal-to-metal contact even when loads change. Iron-copper sintered bushings can support loads up to 30 N/mm² in electric power steering systems. Sintered bronze proves even more robust and handles static loads up to 50 N/mm².

Maintenance-Free Operation in Sealed Environments

Standard bearings need regular lubrication, but sintered bronze bushings work maintenance-free for 3,000-10,000 hours based on conditions. Automotive alternators equipped with these bushings last over 150,000 miles without service. Food processing conveyors run about five years without needing lubrication stops when using these bearings.

Noise Dampening in Household and Industrial Use

The porous structure absorbs vibrations naturally and reduces noise by 3-6 dB compared to ball bearings. This dampening effect makes household appliances like washing machines quieter. People can run them overnight without disturbance.

Application-Specific Benefits in Real-World Use

Sintered bronze bushings prove their worth in industries of all types where reliable performance under tough conditions is vital.

Bronze Bearing Use in Automotive Electric Motors

Sintered bronze bushings make automotive alternators and starters last by a lot longer. They work reliably for over 150,000 miles without needing maintenance. These parts also work well in electric window motors and wiper mechanisms. Special “gusher” bearings used in suspension joints let grease flow freely and make socket life last up to 10 times longer than milled metal versions.

Sintered Bearing Performance in Power Tools

Power tools depend on sintered bronze bearings to stay precise at extreme speeds—some working at 20,000 RPM. These bearings lubricate themselves, which helps them perform consistently in drills and grinders where compact design and heat stability matter most. Their ability to reduce vibration also helps keep operational noise down.

Industrial Machinery: Load and Speed Compatibility

Sintered bushings handle heavy loads in industrial conveyor systems and pumps that work in dirty environments. Iron-copper sintered versions show remarkable strength and can support compressive loads up to 50,000 psi. These components work well in textile machinery, packaging equipment, and farm implements, where maintenance is hard to do.

Limitations in High-Temperature or Contaminated Environments

Sintered bronze bushings have their limits in extreme conditions. Oil breaks down faster above 80-90°C, which can lead to dry running. Dirty environments can clog the pores and stop oil from releasing. Bearings with solid lubricants work better in these tough situations.

Conclusion

Sintered bronze bushings excel as superior engineering components compared to standard bearings in many industrial uses. These components feature a unique porous structure filled with lubricating oil. The oil provides continuous self-lubrication when activated by operational heat. This feature eliminates maintenance needs and extends service life substantially.

The powder metallurgy process creates these exceptional components through careful steps. Manufacturers compact and sinter materials below melting temperatures, then perform vacuum oil impregnation. This specialized method produces bearings with remarkable advantages. The bushings reduce friction in high-speed applications and resist wear under variable loads. They operate maintenance-free for thousands of hours and dampen noise effectively.

Electric motors, power tools, and industrial machinery benefit from these specialized bushings. Engineers value their reliable operation at speeds up to 69,000 r/min while keeping friction coefficients between 0.04-0.07. These bushings work well in most conditions but have limitations. Extreme heat or contaminated environments can cause oil degradation or clog the pores.

JH MIM’s 20 years of powder metallurgy expertise show in every precision-engineered component they produce. Their experience will give consistent quality in sintered bronze bushings that outperform standard options. As engineering needs evolve, these self-lubricating components remain vital solutions when reliability, longevity, and maintenance-free operation matter most.

Key Takeaways

Sintered bronze bushings represent a breakthrough in bearing technology, offering engineers maintenance-free solutions that consistently outperform standard bearings through innovative self-lubrication and superior durability.

• Self-lubricating design eliminates maintenance: Porous structure stores 10-40% oil volume, releasing lubrication automatically when heated by friction for 3,000-10,000 maintenance-free hours.

• Superior performance metrics: Achieve friction coefficients of 0.04-0.07, operate at speeds up to 69,000 RPM, and last 3-5 times longer than standard bearings.

• Powder metallurgy creates optimal structure: Sintering at 750-900°C below melting point creates 15-20% controlled porosity, then vacuum oil impregnation ensures complete lubrication.

• Proven across demanding applications: Excel in automotive electric motors (150,000+ miles), power tools (20,000 RPM), and industrial machinery with loads up to 50 N/mm².

• Cost-effective with limitations: Provide noise reduction of 3-6 dB and vibration dampening, but performance degrades above 80-90°C or in heavily contaminated environments.

For engineers seeking reliable, long-lasting bearing solutions, sintered bronze bushings offer an ideal combination of self-maintenance, durability, and performance that standard bearings simply cannot match in most industrial applications.

FAQs

Q1. What are the main advantages of sintered bronze bushings over standard bearings? Sintered bronze bushings offer self-lubrication, longer service life, reduced maintenance, and better performance in high-speed applications. They can operate maintenance-free for thousands of hours, have lower friction coefficients, and provide excellent wear resistance under varying loads.

Q2. How do sintered bronze bushings achieve self-lubrication? These bushings have a porous structure that’s impregnated with oil during manufacturing. As the bearing heats up during operation, the oil expands and creates a thin lubricating film on the surface. When the bearing cools, the oil retracts back into the pores, ready for the next cycle.

Q3. In which industries are sintered bronze bushings commonly used? Sintered bronze bushings are widely used in automotive applications (like electric motors and alternators), power tools, industrial machinery, and household appliances. They’re particularly valuable in scenarios requiring high-speed operation, heavy loads, or where regular maintenance is difficult.

Q4. What are the limitations of sintered bronze bushings? While highly effective in many applications, sintered bronze bushings may face challenges in extreme conditions. They can experience performance degradation at temperatures above 80-90°C due to oil breakdown. Additionally, heavily contaminated environments may clog the pores, interfering with the self-lubrication mechanism.

Q5. How are sintered bronze bushings manufactured? The manufacturing process involves compacting fine bronze powder under high pressure, then heating (sintering) the compacted shape at temperatures below the melting point of bronze. This creates a porous structure, which is then impregnated with oil using a vacuum process. The final steps include dimensional finishing and rigorous quality control.