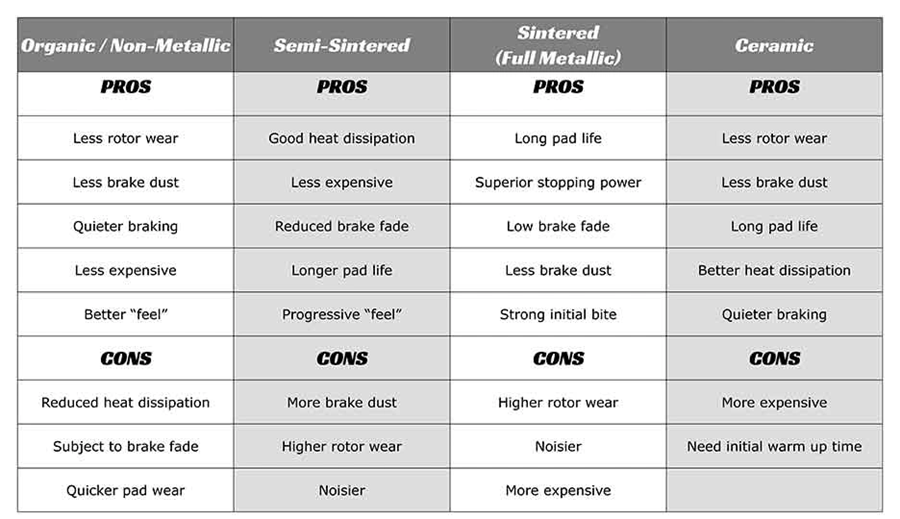

Sintered brake pads rule the motorcycle market today. These metallic pads deliver better stopping power and last longer than organic ones. Most motorcycles come equipped with these pads from the factory. Metal particles pressed together create a resilient braking surface that works reliably in riding conditions of all types. These pads work great in tough environments and stay effective in dirt, damp conditions, and high temperatures.

The differences between sintered and organic brake pads are quite noticeable. Sintered pads stop better and last longer, but they can wear down standard rotors by a lot. They really shine on steep terrain, which makes them perfect for everyone – from daily commuters to serious racers. The trade-off comes down to cost. Sintered brake pads cost more than organic ones, and a complete set of front and rear pads with rotors might set you back about $500. Many riders think the higher original cost is worth it because these pads last longer and handle tough conditions better, making them the smarter choice for long-term braking needs.

How Brake Pads Work in Disk Systems

Disk brake systems work through a precise mechanical process that turns a vehicle’s motion into controlled stopping power. The process begins when you press the brake pedal. Hydraulic pressure activates the caliper and squeezes the brake pads against the spinning rotor. These basic mechanics are the foundations of why sintered brake pads work differently than organic alternatives.

Friction Generation Between Pad and Rotor

The contact between brake pad and rotor produces friction that turns kinetic energy into heat. Two types of friction play a role here: abrasive and adherent. Abrasive friction happens when brake pads rub directly against the rotor. This creates heat and slowly wears down both parts. The adherent friction occurs when a thin layer of brake pad material sticks to the rotor during the break-in process. This creates a molecular bond that continuously breaks and reforms while breaking. This balanced interaction is a vital part of optimal braking performance, especially when you have sintered brake pads that need metallic particles to create effective friction in different conditions.

Heat Dissipation Through Caliper and Rotor

Heat management plays a significant role in brake performance. The system must quickly disperse the heat created when kinetic energy converts to thermal energy. This prevents brake fade—a dangerous drop in stopping power. Most rotors have ventilation features like internal vanes that improve airflow and help dissipate heat during long braking sessions. Sintered brake pads handle heat better because their metallic composition conducts heat more effectively than organic compounds. This allows them to maintain steady performance even during hard braking.

Role of Backing Plate in Structural Support

The backing plate’s role is vital to brake pad functionality. This metal plate attaches to the friction material and serves several key purposes. It keeps the brake pad from warping under extreme heat and pressure. The plate helps spread heat evenly across the pad’s surface and reduces noise and vibration during braking. This support becomes even more important for sintered brake pads because they can reach higher operating temperatures. The backing plate acts as a stable platform that lets the sintered material perform consistently in all types of riding conditions.

Material Science Behind Sintered vs Organic Pads

Brake pads’ material composition plays a crucial role in how they perform in riding conditions of all types. Let’s explore how sintered and organic brake pads are manufactured and why they behave differently in various scenarios.

Sintered Brake Pads: Metallic Particle Fusion Process

Manufacturers create sintered brake pads by fusing metallic particles under extreme pressure and heat. The sintering process heats materials to 800°C or higher to create a metal matrix that becomes the pad’s core structure. The base materials include powdered metals like copper, iron, bronze, and their alloys. These metal powders range from 30μm to 355μm in size and mix with friction additives such as graphite and carbon that act as solid lubricants.

The metal particles melt and fuse during this high-temperature process. This creates a dense, highly wear-resistant friction material. The final product can deform without breaking at high temperatures. Released particles fill the pores in the friction surface and help maintain structural integrity during heavy braking.

Organic Brake Pads: Resin-Bound Kevlar and Rubber

Organic brake pads take a different approach. They use non-metallic materials held together by synthetic resin. The composition includes Kevlar, carbon, rubber, glass/fiberglass, and silica. A single brake pad combines up to 25 different organic materials in its synthetic resin matrix. Steel fibers make up only 4-7% of the volume, which leaves room to add other performance-enhancing materials.

The manufacturing process is different from sintering. It uses heat-cured paste combined with high-friction organic fibers. The paste mixes with cellulose, aramid, and PAN fibers to create a compound that works well in dry weather. These pads don’t need any metal fusion phase during production.

Thermal Conductivity and Wear Resistance Comparison

The thermal properties between these pad types show significant differences. Organic brake pads start losing their effectiveness at temperatures above 300°C. Sintered pads can handle temperatures up to 1000°C. This is a big deal as it means that sintered options provide reliable stopping power during extended braking.

Sintered pads’ thermal conductivity measures between 30-35 W/m·K, which is 40-70 times higher than organic pads at 0.39-0.79 W/m·K. Research shows that sintered pads have better wear resistance. Their wear coefficients range from -4.95×10⁻⁵mm³/J to -2.08×10⁻⁵mm³/J based on riding conditions.

Performance Metrics: Sintered Brake Pads vs Organic Pads

Brake performance tests show clear differences between sintered and organic pads under riding conditions of all types. Lab results reveal how these materials work under extreme conditions.

Stopping Power in Wet and Dry Conditions

Organic brake pads give excellent original bite in dry conditions. They provide smooth, progressive braking and better control at lower speeds. Notwithstanding that, their performance drops significantly in wet environments. Braking coefficient comparisons indicate organic pads lose most of their stopping power in moisture. So, sintered pads keep a similar grip in both wet and dry conditions. Some tests show they experience only a 30% reduction in friction from dry to wet conditions compared to an 81% drop for other materials.

Heat Fade Resistance in Prolonged Braking

Temperature tolerance stands out as a key factor—organic pads start losing grip around 300°C. Their resins melt together in a process called glazing. Sintered pads, on the other hand, can handle temperatures up to 1000°C. This makes them perfect for long braking scenarios. Riders going downhill or riding aggressively get consistent stopping power even as heat builds up. Tests show sintered pads lose only 3% power at 600°F while organic compounds drop by 15%.

Rotor Wear and Pad Longevity

Sintered pads last longer with research showing wear coefficients between -4.95×10⁻⁵mm³/J and -2.08×10⁻⁵mm³/J based on riding conditions. These metallic compounds outlast organic alternatives by 50-80% under heavy use. This durability comes with a trade-off—sintered pads increase rotor wear by 30-50% because of their abrasive properties.

Noise Levels and Bedding-In Time

Organic pads run quieter and produce only 50-58 dB during braking. Sintered options generate 65-75 dB. The bedding process is different between these types. Organic pads need careful temperature cycling to release gasses and create an even transfer layer. Sintered pads just need good contact with the rotor surface to deliver their best performance.

Choosing the Right Pad for Your Riding Style

Your riding style should match your brake pad characteristics. Different friction materials work better for various riding styles based on their performance qualities.

Sintered vs Organic Motorcycle Brake Pads for Commuters

Daily commuters face changing weather and need frequent stops. Organic pads give you a smoother initial grip and gentler stops, making them perfect for city riding. Sintered pads are still a top choice among commuters who want longer-lasting brakes and don’t mind the noise. These pads work well in wet conditions and will give a reliable stop, whatever the weather throws at you.

Downhill and Touring Use Cases for Sintered Pads

Touring bikes of all sizes work great with sintered pads. These pads handle intense heat from long mountain descents without losing their grip. Many touring riders say they get better braking with sintered options that keep working consistently even after heavy use.

Mix-and-Match Strategy: Organic Front, Sintered Rear

You don’t have to use similar compounds on all your brakes. Many riders put organic pads up front and sintered ones in the back to get the best performance. This setup gives you better control up front and lasting power in the back. Just remember – never mix different materials in the same caliper.

Rotor Compatibility and Floating Rotor Considerations

Sintered pads and floating rotors are a perfect match for performance riding. These two-piece rotors connect a steel friction ring to an aluminum carrier with rivets. This lets the rotor expand without warping when it gets really hot. Racing teams created this design first, and it manages heat perfectly with sintered pads. The brakes keep working even when temperatures go past 250°F during aggressive rides.

Conclusion

Sintered brake pads perform better than organic ones in most riding conditions. Their metallic composition delivers exceptional stopping power, particularly when organic pads struggle. Riders who face wet conditions or need reliable braking on long descents will find sintered options work better.

The best feature of sintered pads is their heat management. These metallic compounds stay effective at temperatures up to 1000°C. Organic pads start to fail around 300°C. This heat resistance means reliable performance during long or aggressive braking without any fade.

Sintered pads cost more upfront but give better value over time. They last 50-80% longer than organic ones in tough riding conditions. This toughness comes from advanced powder metallurgy that fuses metal particles under extreme heat and pressure to create highly resistant materials. Companies that focus on powder metallurgy and have years of metal injection molding experience keep improving these materials for better braking.

The choice between sintered and organic brake pads comes down to your riding needs. City commuters who want smooth, quiet operation might like organic pads better. Touring riders and those who ride in changing weather will appreciate sintered pads’ consistent performance. Understanding the science behind these components helps riders choose what works best for their needs instead of just using stock parts.

Key Takeaways

Understanding the fundamental differences between sintered and organic brake pads helps riders make informed decisions based on their specific riding needs and conditions.

• Sintered brake pads withstand temperatures up to 1000°C versus organic pads’ 300°C limit, preventing brake fade during aggressive riding • Metallic sintered pads last 50-80% longer than organic alternatives but increase rotor wear by 30-50% due to their abrasive nature • Sintered pads maintain consistent stopping power in wet conditions while organic pads lose up to 81% effectiveness when moisture is present • Organic pads offer quieter operation (50-58 dB) and smoother initial bite, making them ideal for urban commuting scenarios • Strategic mixing works between axles—organic front pads for modulation, sintered rear pads for durability—but never within the same caliper

While sintered pads cost more initially, their superior heat resistance, weather performance, and extended lifespan make them the preferred choice for touring, downhill riding, and variable weather conditions. Organic pads remain excellent for riders prioritizing quiet operation and smooth city braking over maximum performance.

FAQs

Q1. What are the main differences between sintered and organic brake pads? Sintered brake pads are made of metallic particles fused together, offering superior heat resistance and consistent performance in wet conditions. Organic pads, made of non-metallic materials bound with resin, provide a smoother initial bite and quieter operation, but wear faster and perform poorly in wet conditions.

Q2. How do sintered brake pads perform in extreme conditions? Sintered brake pads excel in extreme conditions, maintaining effectiveness at temperatures up to 1000°C. They offer consistent stopping power during prolonged braking sessions, making them ideal for downhill riding and touring. They also perform well in wet environments, maintaining grip where organic pads may lose up to 81% of their effectiveness.

Q3. Are sintered brake pads more durable than organic ones? Yes, sintered brake pads typically last 50-80% longer than organic alternatives, especially under aggressive riding conditions. However, this durability comes at the cost of increased rotor wear, with sintered pads potentially accelerating rotor wear by 30-50% due to their abrasive nature.

Q4. Which type of brake pad is better for daily commuting? For daily commuting, the choice depends on priorities. Organic pads offer smoother, quieter operation ideal for controlled city braking. However, sintered pads are popular among commuters who prioritize longevity and consistent performance in variable weather conditions, ensuring reliable stopping power regardless of the environment.

Q5. Can you mix different types of brake pads on a bicycle? Yes, some riders use a mix-and-match strategy, installing organic pads on front brakes and sintered pads on rear brakes. This approach balances the need for modulation in the front with durability in the rear. However, it’s crucial never to mix different materials within the same caliper.