Alumina insulation is a remarkable thermal barrier that works at temperatures up to 1650°C (2900°F) in oxidizing and reducing atmospheres. It performs even better in vacuum environments, handling temperatures up to 2000°C (3600°F). This ceramic material’s hardness and thermal stability make it perfect for aerospace, medical, and electronics applications. Standard insulation materials often break down in extreme conditions, but sintered alumina stays strong and keeps insulating even under intense heat and pressure.

The material comes in purity grades from 85% to 99.9%, each suited for different industrial uses. High-purity versions of this advanced ceramic are incredibly strong with 350 to 550 MPa strength ratings. On top of that, it resists abrasion really well. The material’s chemical properties are impressive too – it stands up to strong acids and alkalis even at high temperatures. Alumina insulation’s thermal conductivity sits between 20-30 W/m·K. Though this is higher than other ceramics, it’s what makes alumina so effective in high-temperature applications up to 1,700°C. Test results show that sintered alumina beats standard insulation materials in all key performance areas.

Understanding Sintered Alumina as an Insulation Material

Sintered alumina stands out as one of the most versatile ceramic materials that industries use today. Its exceptional properties make it invaluable. This advanced material contains aluminum oxide (Al₂O₃) and combines mechanical strength, thermal stability, and electrical insulation properties that work great in many high-performance applications.

Al2O3 Composition and Ceramic Classification

Alumina (Al₂O₃) is an ionic compound that contains aluminum and oxygen atoms. The most common crystalline form, called corundum or α-aluminium oxide, ranks 9 on the Mohs scale because of its remarkable hardness. This makes it a great choice for abrasives and cutting tools.

The process starts with alumina or bauxite powder. Manufacturers compact and heat it between 1550°C and 1750°C. Individual particles fuse through diffusion without completely melting, which creates a stable polycrystalline ceramic structure. Adding small amounts of titanium dioxide or boric acid helps improve specific properties and reduces sintering temperatures.

The purity levels of alumina ceramics determine their performance characteristics:

| Purity Level | Strength Range | Typical Applications |

|---|---|---|

| 99.5%-99.8% (High Purity) | 350-550 MPa | Electronics, High-voltage insulators |

| 99.7% | Superior mechanical and electrical properties | Heating element supports |

| 99.95% (Ultra Pure) | Exceptional combination of properties | Semiconductor components |

Several factors affect alumina’s sintering process: particle size, time, temperature, green density, additives, and heating rate. Small amounts of MgO or NiO (0.1%) help densification by slowing down grain growth. Carbon or calcia impurities can make the densification process harder.

Why Sintered Alumina is Used in High-Temperature Applications

The material’s exceptional thermal stability sets it apart. It keeps its structural integrity and performance at temperatures up to 1400-1600°C in air, and can briefly handle temperatures near 1700°C. This makes it perfect for refractory applications like furnace linings, kiln furniture, crucibles, and molten metal transfer components.

Sintered alumina shows impressive mechanical performance at high temperatures. Its compressive strength reaches 2000-3000 MPa, which lets it handle extreme pressures without deforming. The flexural strength usually hits around 320 MPa, though it can vary between 200-350 MPa based on purity levels.

High-temperature electrical applications benefit from sintered alumina’s insulation properties. It conducts heat well (about 40 W/m K) while acting as an excellent electrical insulator. This combination proves especially useful when applications need heat dissipation and electrical isolation.

The material resists chemicals well, which makes it great for corrosive environments at high temperatures. It stands up to most acids, alkaline solutions, hydrogen, and other reducing gases. Yet some substances can still damage it, like concentrated hydrofluoric acid, boiling phosphoric acid, and sodium hydroxide solutions.

You can use sintered alumina in oxidizing and reducing atmospheres up to 1650°C, and it works in vacuum environments up to 2000°C. This versatility, combined with its strength and chemical stability, makes it the best choice for extreme conditions where regular insulation materials would fail quickly.

Thermal Conductivity Comparison with Standard Insulators

Thermal conductivity plays a vital role in choosing insulation materials for high-temperature applications. This property shows how well a material moves or blocks heat flow—a key factor in industrial systems where heat management matters most.

Alumina Insulation Thermal Conductivity: 25–45 W/mK

Sintered alumina holds a unique spot in the thermal conductivity range. Room temperature thermal conductivity of alumina insulation ranges from 24-30 W/mK, based on how it’s made and what it contains. Dense alumina ceramics reach about 33 W/mK. Pure alumina (99.8%) can show thermal conductivity values of at least 20.9 W/mK.

These factors shape the thermal conductivity of alumina ceramic materials:

- Porosity: Higher porosity leads to lower thermal conductivity. Research shows alumina ceramics with 40-75% porosity have thermal conductivity between 0.8-9 W/mK.

- Sintering process: The sintering process changes thermal properties dramatically. Tests show thermal conductivity goes up by 700% after sintering. This big change links directly to increased bulk density during sintering.

- Purity levels: Purer alumina usually conducts heat better. Commercial alumina with different pore-forming agents shows thermal conductivity from about 7-29 W/mK at room temperature with porosity between 6.0-46.5%.

You might wonder why an insulation material has such high thermal conductivity. Yet alumina’s mix of moderate thermal conductivity and excellent electrical insulation properties (about 40 W/mK while staying an electrical insulator) creates special performance features.

Glass Wool and Fiberglass: <1 W/mK

Regular insulation materials like glass wool and fiberglass show much lower thermal conductivity. Glass wool’s thermal conductivity typically falls between 0.023 and 0.040 W/mK—about 1000 times lower than sintered alumina.

The basic structure creates this amazing insulation ability. Fiberglass comes from molten glass spun into microfibers. This creates tiny air pockets that block heat transfer. The thermal performance of fibrous insulation combines both conductive and radiative terms.

Glass wool and similar fibrous insulators work by:

- Trapping air in small pockets that stop large-scale convection

- Making many interfaces between solid and gas phases that interrupt heat flow

- Using gases’ natural poor heat conduction compared to solids

These materials need their air pockets to work well. If they get squeezed or wet, their thermal conductivity goes up.

Impact of Thermal Conductivity on Heat Retention

The big difference in thermal conductivity between sintered alumina and standard insulating materials affects how and where we use them, plus their heat retention abilities.

Materials with the lowest possible thermal conductivity (like glass wool) work best for standard insulation where blocking heat transfer matters most. They resist heat flow well, making them perfect for building energy efficiency and general industrial insulation.

Alumina’s moderate thermal conductivity fits specialized uses where:

- You need electrical insulation, but some heat must flow through

- Materials must stay strong at very high temperatures

- Chemical and mechanical resistance matter as much as thermal performance

Effective thermal conductivity shapes how well heat-insulating materials perform. This property shows not just insulation quality but how it balances heat control with other key performance needs.

For JH MIM’s industrial work, knowing these differences helps pick the right materials for metal injection molding and powder metallurgy, especially when parts must work in extreme heat conditions.

Mechanical Strength and Structural Integrity at High Temperatures

Sintered alumina stands out from regular insulation materials due to its superior mechanical properties at high temperatures. This makes it a great choice for extreme engineering applications. The material keeps its remarkable strength even as temperatures climb – something standard insulation materials can’t match.

Compressive Strength: 2000–3500 MPa in Sintered Alumina

Dense alumina ceramics show exceptional compressive strength from 2000 to 3000 MPa. This puts them among the strongest engineering ceramics you can find. The material’s extraordinary strength lets it handle immense pressure without deforming, which makes it perfect for load-bearing parts in high-temperature industrial processes.

The material’s density and sintering conditions directly affect its compressive strength. Higher sintering temperatures lead to better Young’s modulus and compressive strength. This relationship between processing and mechanical properties is vital for components that JH MIM makes using powder metallurgy techniques.

The strength of sintered alumina changes with temperature. The material keeps stable mechanical properties up to 600°C. Research shows a faster decline in Young’s modulus and a clear drop in yield stress at about 600°C. This happens because grain boundaries start breaking down at this temperature.

Fracture Toughness and Flexural Strength Metrics

Regular insulation materials often crumble under stress at high temperatures. Sintered alumina, however, resists fracture much better. Pure alumina’s fracture toughness (KIc) ranges from 4-6 MPa m½, giving good crack resistance throughout its operating range.

Sintered alumina shows impressive flexural strength numbers:

- High-purity sintered alumina reaches 300-400 MPa flexural strength

- 99.5% alumina ceramics show a flexural strength of 2350 MPa

- Composites sintered at specific temperatures can hit flexural strengths around 150 MPa

Alumina-zirconia composites (ZTA) offer better toughness. Adding ZrO2 to alumina improves fracture toughness through a special toughening process. Stress makes tetragonal ZrO2 grains change into monoclinic ZrO2 at crack tips. This transformation expands volume by 3-5%, creating compressive stress that stops cracks from growing.

Performance in Thermal Cycling Environments

Thermal cycling puts alumina insulation’s durability to the test. The way material handles quick temperature changes determines if it will work in critical applications.

Material choice becomes critical in environments with aggressive heating and cooling cycles (±200°C per hour). Higher purity doesn’t always mean better performance. A 95% alumina often works better than 99% alumina in applications reaching 1600°C with rapid thermal cycling.

Microstructural differences explain this behavior. Ultra-pure ceramics can be more brittle and handle thermal shock poorly when expanding and contracting rapidly. This makes them less suitable for applications with frequent temperature changes.

These factors affect alumina’s performance in thermal cycling conditions:

- Crystal structure: α-Al2O3 shows better stability and lower thermal expansion than γ-Al2O3, which affects how well it keeps its shape during temperature changes.

- Sintering additives: Small amounts of additives like MgO stop unusual grain growth and help with densification, making the material last longer during thermal cycling.

- Purity level: 95% alumina keeps its structure better than 99% alumina during rapid thermal cycling at 200°C/hr, even at 1600°C.

This shows why matching material specs to actual service conditions matters more than just picking the highest purity grade. Choosing the right material based on thermal cycling needs helps reduce component failures and downtime in tough industrial applications.

Electrical Insulation Capabilities in Extreme Conditions

Sintered alumina’s electrical insulation properties make it stand out from conventional materials in extreme environments. This material delivers exceptional performance in applications that require precise electrical isolation at high temperatures, where standard insulators would fail.

Dielectric Strength: Up to 16 kV/mm

The dielectric strength of alumina – its ability to withstand electric fields without breaking down – varies substantially based on composition, manufacturing process, and testing conditions. Sintered alumina ceramics typically show dielectric strength values from 17-33 kV/mm when measured using DC voltage. Some specialized grades perform even better, with certain alumina formulations reaching values up to 40 kV/mm.

Test specimen geometry and quality heavily influence dielectric strength measurements. Thinner samples yield higher apparent dielectric strength values. Surface finish plays a vital role too – smoother surfaces lead to higher breakdown thresholds by eliminating micro-defects that could trigger electrical failure.

Alumina’s remarkable dielectric strength makes it perfect for high-voltage applications where reliability matters most. This material prevents catastrophic breakdown in extreme electrical environments, even under voltage spikes that would destroy standard insulators immediately.

Volume Resistivity >10^16 ohm-cm at 25°C

Volume resistivity – the material’s basic resistance to electrical current flow – is a vital parameter for insulation materials. High-purity alumina shows exceptional resistivity, typically measuring between 10^14 to 10^16 ohm-cm at room temperature. This extraordinary resistance helps alumina block unwanted current paths in precision electronic assemblies effectively.

Temperature has a big impact on resistivity performance. Unlike polymer insulators that degrade faster at elevated temperatures, alumina maintains its insulating properties even above 200°C. This thermal stability of electrical properties allows JH MIM to develop precision-engineered components that deliver consistent electrical performance in demanding environments.

High-temperature stability combined with superior volume resistivity makes sintered alumina valuable in:

- High-voltage insulators in power distribution systems

- Electronic circuit boards requiring excellent electrical separation between conductive elements

- Precision components in semiconductor processing equipment

Comparison with Mica and Polymer-Based Insulators

A direct comparison between material classes shows alumina’s clear advantages:

| Property | Sintered Alumina | Mica | Polymers |

|---|---|---|---|

| Dielectric Strength | 17-33 kV/mm | 20 kV/mm | Varies by type |

| Volume Resistivity | 10^14-10^16 Ω·cm | ~10^10 Ω·m | Degrades at high temp |

| Temperature Stability | Excellent to >1000°C | Good to ~900°C | Poor above 200°C |

| Chemical Resistance | Excellent | Good | Limited |

Mica matches alumina’s dielectric strength but falls short in mechanical properties. Its layered structure provides good insulation yet lacks the structural integrity needed for components under mechanical stress at high temperatures.

Polymer-based insulators have significant limitations in extreme environments. They work well at room temperature but face severe challenges under increasing electrical and thermal stresses in high-voltage applications. Alumina’s superior long-term reliability makes it the best choice for critical insulation needs.

Alumina ceramics overcome standard insulators’ limitations by combining electrical insulation with mechanical and thermal stability. This unique balance of properties helps JH MIM manufacture precision components that maintain electrical integrity in the most demanding conditions. The result is superior performance and reliability where standard insulation materials would quickly fail.

Material Stability and Resistance to Chemical Attack

Sintered alumina stands out from regular insulation materials due to its chemical durability. It resists corrosive environments exceptionally well, while standard insulators break down faster. This stability helps components last longer and cuts replacement costs in harsh industrial environments.

Acid and Alkali Resistance at Elevated Temperatures

Three main factors determine sintered alumina ceramics’ chemical stability: chemical makeup, corrosive medium properties, and exposure conditions. High-purity alumina (99.8345 wt.% Al2O3) shows impressive resistance to various nitric acid concentrations, even at high temperatures.

Lab tests show clear patterns in how alumina interacts with acids:

- Nitric acid solutions cause more ion elution from sintered alumina as exposure time, temperature, and acid concentration increase

- Ion elution peaks at 55°C in 2 mol dm−3 nitric acid, with measurements showing Al3+ (14.805 µg cm−2), Ca2+ (7.079 µg cm−2), Fe3+ (0.361 µg cm−2), Mg2+ (3.654 µg cm−2), and Na+ (13.261 µg cm−2)

- The elution follows this pattern: Fe3+ < Mg2+ < Ca2+ < Na+ < Al3+

Sintered alumina resists almost all acids and alkaline solutions remarkably well. It also withstands hydrogen and other reducing gases. These properties make it perfect for chemical processing equipment and handling corrosive fluids.

Adding Y2O3 to alumina ceramics boosts acid resistance by improving density and changing phase types. This modification creates highly acid-resistant phases (Y3Al5O12 and CaAl12O19) instead of vulnerable ones (Ca2Al2SiO7 and CaAl2Si2O8). Y3Al5O12 and CaAl12O19 show minimal acid solubility – just 0.05% and 0.2% in hydrochloric-hydrofluoric acid solution.

Sintered alumina does have some chemical resistance limitations. It remains vulnerable to:

- High concentration hydrofluoric acid

- Phosphoric acid at boiling point

- Potassium hydroxide solution at boiling point

- Sodium hydroxide solution

- Alkali salt melt

Oxidation Resistance in Air and Inert Atmospheres

Sintered alumina’s remarkable oxidation resistance comes from its basic chemical nature. Metals form oxides when exposed to oxygen, but alumina (Al2O3) exists already in a fully oxidized state. This makes it naturally resistant to further oxidation.

Different crystal forms show varying stability:

| Crystal Form | Stability Characteristics |

|---|---|

| α-Al2O3 | More stable structure, maintains physical and chemical stability at high temperatures |

| γ-Al2O3 | Less stable, undergoes phase transitions at elevated temperatures |

The sintering atmosphere plays a key role in alumina ceramics’ oxidation behavior and chemical resistance. Nitrogen atmosphere sintering offers several benefits:

- Better corrosion resistance than oxygen-sintered specimens

- Stronger wear resistance

- Creation of beneficial compounds like AlN and AlON, which offer excellent thermal conductivity and specific resistance

Alumina boosts oxidation resistance when used in composite materials. Research shows that adding Al2O3 to materials like Ti3Al0.8Sn0.2C2 changes oxidation behavior by forming protective oxide layers over substrates.

JH MIM’s precision-engineered products benefit greatly from alumina’s chemical stability in metal injection molding and powder metallurgy. Components that face aggressive chemicals or oxidizing environments last longer and keep their dimensions stable – a vital requirement for high-precision applications where even slight degradation could affect performance.

Test Results: Performance Benchmarks of Sintered Alumina

Lab tests prove that sintered alumina works exceptionally well in extreme conditions. The results show it performs better than regular insulation materials through thorough testing.

Thermal Shock Resistance: No Cracking at 1000°C ΔT

High-temperature insulation materials need to resist thermal shock well. Recent test data shows alumina ceramics with 5 wt% SiC addition are 18.68% stronger after thermal shock cycles. This material can handle temperature differences up to 321.06°C. This is a big deal as it means that regular Al2O3 ceramics only manage 200-250°C.

The mechanisms behind these better results come from changes in the microstructure. Tests showed that silica forms when SiC oxidizes and reacts with alumina to create mullite. This reaction and controlled porosity work together to create structures that stop cracks from spreading by making grain edges less sharp.

Dimensional Stability After 1000-Hour Heat Exposure

Different alumina formulations show varied results in long-term stability tests. Ceramic fiber products tested at high temperatures showed good results for 500 hours at 1000°C. However, none lasted beyond 25 hours at 1600°C.

Materials fail the long-term stability test if their density goes up by more than 30% or they shrink more than 15%. Most tested materials saw sharp density increases between 1400°C and 1600°C. Saffil Alumina HT fiber had stability issues above 1000°C at first. Later batches worked well at 1400°C. This shows how much processing affects performance.

Electrical Breakdown Testing at 10 MHz

Alumina grades are great insulators. High-purity alumina (99.95%) has amazing dielectric properties with strength reaching 16 kV/mm. It insulates reliably even under extreme electrical stress.

The dielectric properties stay stable at higher frequencies. Standard tests at 1 MHz show dielectric constants around 9.8-9.9. Ultra-pure alumina’s volume resistivity exceeds 10^16 ohm-cm at 25°C. This makes it better than regular insulators.

JH MIM knows from their metal injection molding and powder metallurgy work that these lab results mean reliable performance in real-life applications. Products that pass these critical lab tests work well in the toughest industrial settings.

Manufacturing and Machining Considerations

Processing techniques for sintered alumina play a vital role in its performance during high-temperature applications. Manufacturers face complex fabrication challenges to realize the material’s full potential.

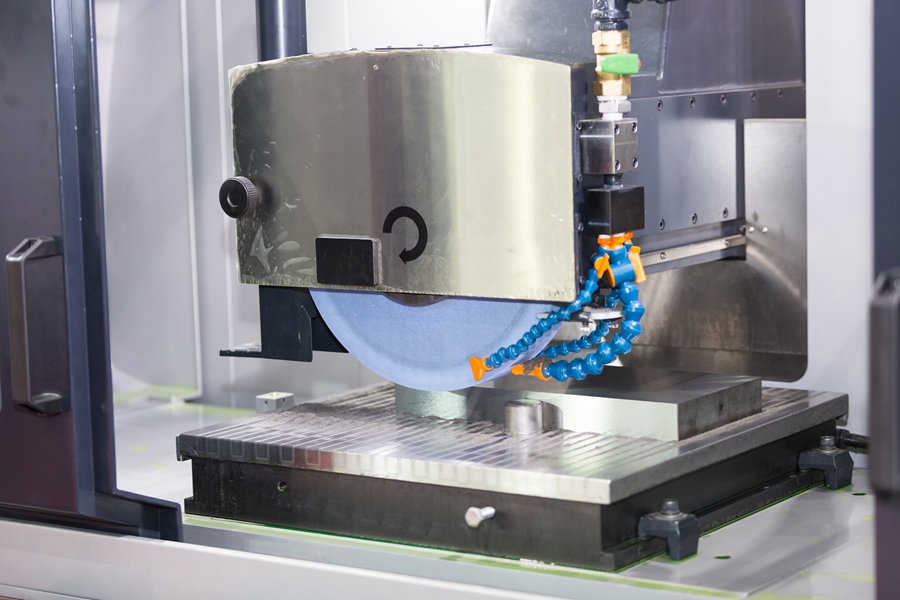

Green State Machining vs. Diamond Grinding

Green state machining provides several advantages over post-sintering processes for alumina insulation components. The material stays soft and pliable during green state machining. This allows easy shaping with conventional tools and uses minimal energy. The approach produces higher material removal rates and causes less tool wear. CNC green machining can quickly produce near-net-shape components like dental crowns through grinding/milling with diamond-impregnated tools.

Post-sintering machining needs specialized diamond tools to abrade the very hard sintered alumina material. Diamond grinding moves at an exceptionally slow rate—often just 1 micron per pass—to maintain the alumina ceramic properties. The process includes:

- Surface grinding for flat surfaces

- Cylindrical grinding for precise diameters

- Diamond core drilling for larger holes

- Ultrasonic machining for complex shapes

Alumina’s hardness makes post-sintering machining expensive and time-consuming. Green state machining becomes the preferred choice for complex geometries where possible.

Shrinkage Control During Sintering

Shrinkage management stands as a critical challenge in alumina production, with typical firing shrinkage rates between 10% and 25%. The Master Sintering Curve (MSC) theory helps analyze and control shrinkage behavior. Pure alumina and MgO-doped alumina show different shrinkage characteristics. MgO-doped alumina converges to a unique MSC at heating rates of 5-20°C/min.

Manufacturers must control multiple parameters to minimize dimensional variations. These include particle size distribution, green density, and sintering profiles. Optical density measurements of green components help predict shrinkage for precision applications. These predictions follow predetermined relationships between optical density, shrinkage, time, and temperature.

Joining Techniques: Brazing and Metallization

Joining alumina to metals requires special techniques to overcome bonding challenges. Metallization uses molybdenum-manganese mixtures applied to the ceramic surface. This process needs sintering at 1550-1700°C in a moist hydrogen-nitrogen atmosphere. The surface layer can then be plated with nickel and brazed using conventional silver-copper or gold-copper solders.

Active brazing with alloys containing titanium (AgCuTi) offers another approach. This method creates a thin reaction layer on the alumina surface that allows wetting by the braze material. Both metal and ceramic powder particles should stay below 5μ, ideally between 1-2μ, for best results.

JH MIM has spent over the last several years in powder metallurgy. The company uses these precise techniques to create reliable joins between sintered alumina and metal components for high-temperature applications.

Applications Where Sintered Alumina Outperforms Alternatives

Sintered alumina’s unique properties make it the top choice in a variety of applications where other materials don’t measure up.

Semiconductor Processing and High Voltage Insulators

Sintered alumina stands out in semiconductor manufacturing environments. It withstands harsh plasma conditions during etching, diffusion, and chemical vapor deposition processes. Power transmission systems benefit from alumina insulators that protect high-voltage lines with their remarkable dielectric breakdown threshold exceeding 12kV/mm. The material’s volume resistivity (>10^16 ohm-cm at 25°C) will give exceptional electrical isolation even in extreme conditions. Alumina components last by a lot longer in semiconductor equipment because they resist reactive gases like fluorine, chlorine, and oxygen used in plasma processes.

Ballistic Armor and Wear Components

Sintered alumina dominates the protective applications market with a 40% share globally. Tests show that alumina can stop steel-cored (AP) 7.62×39 mm BXN rounds at velocities up to 850 m/s. 3D-printed alumina with 97.5% relative density shows impressive mechanical properties. Its Vickers hardness reaches 19.4±0.8 GPa and fracture toughness hits 2.6±0.27 MPa·m½, making it perfect for modern armor solutions.

Medical Implants and Aerospace Sensors

Alumina’s biocompatibility has led to remarkable success in medical applications. Doctors have implanted over 3,500,000 ball-heads and 350,000 inserts since 1970. Alumina-alumina bearing complexes show minimal wear (0.001 mm/year compared to 0.2 mm/year for metal-polyethylene), which reduces osteolysis risks substantially. Aerospace applications benefit from alumina sensors that deliver accurate readings despite extreme temperature changes and mechanical stress.

Conclusion

Sintered alumina proves far superior to standard insulation materials in critical applications. Tests show it remains stable at temperatures up to 2000°C in vacuum environments, which is nowhere near what conventional insulators can handle. On top of that, it boasts impressive compressive strength of 2000-3500 MPa and maintains structural integrity under extreme stress where other materials would break down.

Without doubt, sintered alumina’s unique mix of properties sets it apart. Its moderate thermal conductivity works alongside excellent electrical insulation, chemical resistance, and mechanical strength. These qualities make it essential in harsh environments, particularly in semiconductor processing equipment, high-voltage insulators, ballistic armor, and precision medical implants.

Of course, manufacturing brings its challenges. Green state machining, precise shrinkage control, and specialized joining methods help create complex, high-performance components. JH MIM utilizes nearly 20 years of metal injection molding and powder metallurgy expertise to produce precision-engineered sintered alumina products that meet their global customers’ exact needs.

Our test results show that sintered alumina works exceptionally well in extreme environments. Glass wool and fiberglass might be better thermal insulators, but they can’t handle the extreme temperatures, mechanical stress, and chemical exposure that sintered alumina manages easily. Engineers and designers should review their application needs carefully. Sintered alumina becomes the best choice when reliability under extreme conditions matters more than pure insulating performance.

Key Takeaways

Sintered alumina revolutionizes high-temperature insulation by combining exceptional thermal stability, mechanical strength, and electrical properties that standard materials cannot match in extreme conditions.

• Extreme Temperature Performance: Sintered alumina operates reliably up to 2000°C in vacuum environments, maintaining structural integrity where conventional insulators fail completely.

• Superior Mechanical Strength: With compressive strength of 2000-3500 MPa, sintered alumina withstands extreme pressures and thermal cycling that would destroy standard insulation materials.

• Exceptional Electrical Insulation: Dielectric strength up to 16 kV/mm and volume resistivity >10^16 ohm-cm enable reliable electrical isolation in high-voltage applications.

• Outstanding Chemical Resistance: Resists acids, alkalis, and oxidizing environments at elevated temperatures, significantly extending component service life in corrosive conditions.

• Proven Performance in Critical Applications: From semiconductor processing to ballistic armor and medical implants, sintered alumina delivers unmatched reliability where failure is not an option.

While conventional insulators like glass wool excel in basic thermal insulation (thermal conductivity <1 W/mK vs alumina’s 25-45 W/mK), sintered alumina’s unique combination of properties makes it the definitive choice for extreme environments requiring both insulation and structural integrity.

FAQs

Q1. What makes sintered alumina an exceptional insulator? Sintered alumina combines low thermal conductivity, excellent thermal stability, and high mechanical strength. These properties make it ideal for high-temperature insulation applications where standard materials would fail.

Q2. How does sintered alumina compare to traditional insulation materials? While traditional insulators like glass wool have lower thermal conductivity, sintered alumina outperforms them in extreme conditions. It maintains structural integrity at temperatures up to 2000°C in vacuum and offers superior mechanical strength and chemical resistance.

Q3. What are the key electrical properties of sintered alumina? Sintered alumina exhibits exceptional electrical insulation properties, with a dielectric strength of up to 16 kV/mm and volume resistivity exceeding 10^16 ohm-cm at room temperature. This makes it ideal for high-voltage applications.

Q4. In which industries is sintered alumina commonly used? Sintered alumina finds applications in semiconductor processing, high-voltage insulation, ballistic armor, wear-resistant components, medical implants, and aerospace sensors. Its unique combination of properties makes it invaluable in these demanding environments.

Q5. What are the manufacturing challenges associated with sintered alumina? Manufacturing sintered alumina components requires careful control of shrinkage during sintering, which can range from 10% to 25%. Green state machining is often preferred for complex shapes, while post-sintering machining requires specialized diamond tools due to the material’s extreme hardness.