Powder metallurgy’s rise in gear manufacturing has transformed production efficiency in industries of all sizes. This innovative process beats traditional manufacturing methods with 97% of input materials reaching the final product, while conventional machining only manages 60-70%. Companies that use powder metallurgy can create complex geometries and integrated features in one step instead of multiple operations. The process creates components with such precise dimensional tolerances that extra machining becomes unnecessary.

The benefits of powder metallurgy go well beyond just saving materials. Manufacturers can achieve precise tolerances and intricate shapes while producing less waste. The process also lets them create lightweight, porous, self-lubricating, and high-strength components that work perfectly for gears, bushings, and bearings needing constant lubrication during operation. With more than 97% of raw materials ending up in the finished part, waste is minimal. Companies save money without sacrificing quality or performance. This piece shows how powder metallurgy cuts costs and breaks down the key steps that make it so effective for gear production.

How Powder Metallurgy Reduces Gear Manufacturing Costs

Powder metallurgy excels as a budget-friendly manufacturing approach for gear production. The process offers clear financial benefits over traditional methods through several factors that cut production costs.

97% Material Utilization vs 60% in Machining

Powder metallurgy’s biggest advantage lies in its remarkable material efficiency. The process makes use of 97% of raw materials while traditional machining methods only manage 60-70%. This near-net-shape manufacturing cuts waste and reduces production costs. Traditional machining wastes raw materials through cutting and shaping. The waste can reach up to 50% of the material. These numbers matter even more when you work with expensive metals or alloys.

Reduced Machining Steps and Labor Costs

Powder metallurgy makes the manufacturing process simpler by cutting down processing steps. Complex gear shapes that need multiple machining operations take shape in one step. Most powder metal gears need no extra machining. Companies like JH MIM have learned this over their 20 years in powder metallurgy. The result? Shorter production cycles and higher output.

Lower Energy Consumption in Sintering vs Forging

Energy efficiency in powder metallurgy creates more cost savings. The sintering process runs at temperatures below the metal’s melting point. This means it needs less energy than casting or forging. The numbers tell the story – sintering needs about 1.8 kWh per kilogram. Forging needs almost double that at 3 kWh per kilogram. Large-scale production makes these savings add up fast.

Minimal Scrap Generation and Recyclability

Powder metallurgy creates minimal waste – less than 3%. This small amount of scrap can go back into components or raw material. Raw materials for 75% of powder metallurgy parts come from recycled scrap steel. This creates a sustainable loop that helps both the environment and the bottom line. Metal recycling saves natural resources, too. Each ton of recycled steel saves 2,500 pounds of iron ore and 1,400 pounds of coal.

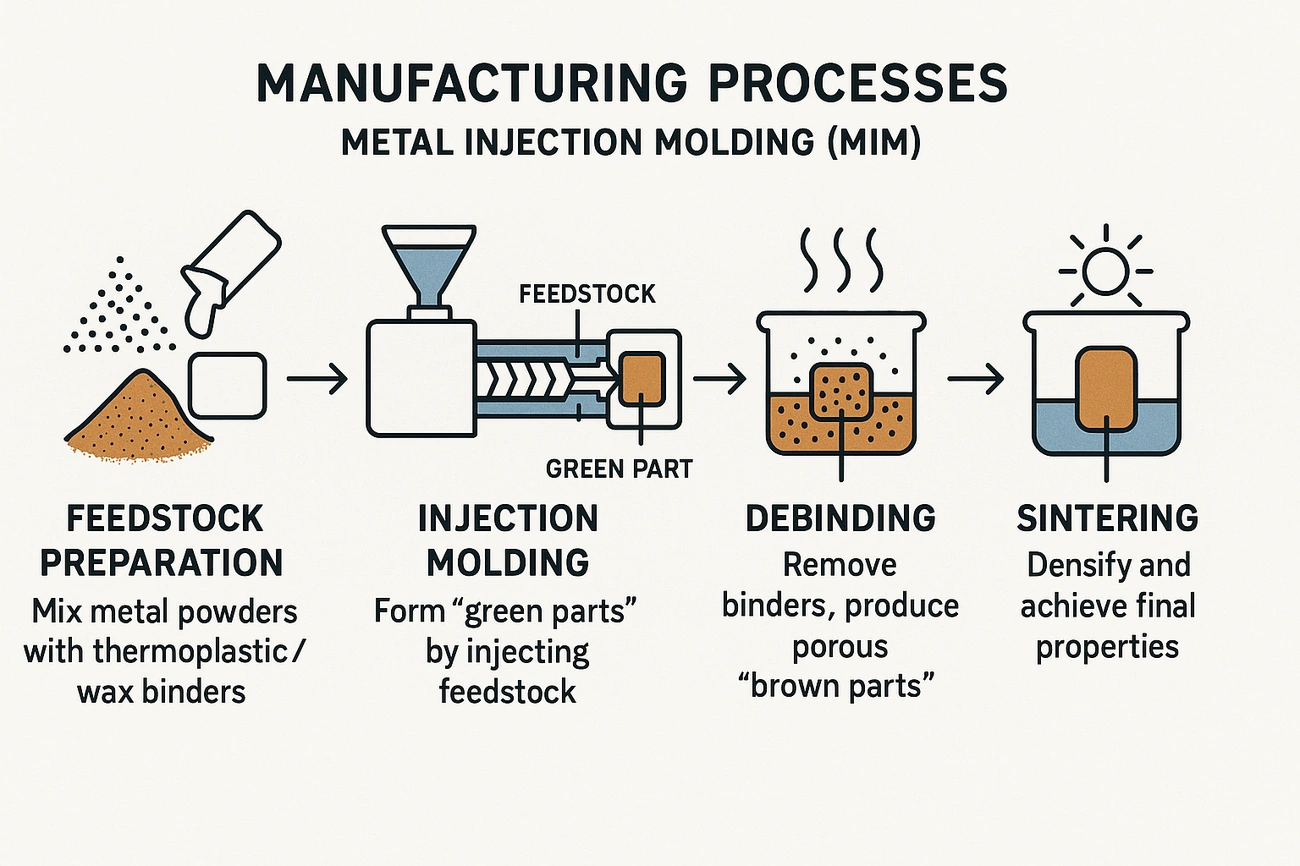

Key Process Steps That Enable Cost Savings

The manufacturing steps in powder metallurgy are the foundations of its cost advantages. The production process uses specific technical parameters that save money compared to traditional methods.

High-Pressure Compaction for Near-Net Shapes

High-pressure compaction starts the powder metallurgy process. Metal powders compress at 400-800 MPa to create “green” compacts. This vital step produces parts that closely match their final dimensions and need minimal machining. Iron-based materials in green components reach a 6.6-7.2 g/cm³ density, which makes them strong enough to handle. Standard mechanical presses can make 1,800-2,500 parts per hour, which helps avoid production delays that can get pricey.

Sintering at 2050–2150°F for Metallurgical Bonding

Sintering changes compacted powder into solid metal through heating at temperatures of 2050-2150°F (1120-1150°C). These temperatures stay below the metal’s melting point, which uses less energy than standard methods. Metal particles create strong bonds without fully melting, which results in a uniform microstructure. The high-temperature zone needs 15-60 minutes, and materials move through the furnace at 5-15 cm/minute.

Delubing and Oxide Reduction for Clean Microstructure

Components need significant preparation before full sintering. The temperature rises to 500-900°C to remove lubricants (0.5-0.8% zinc stearate or EBS) added during compaction. The controlled furnace atmosphere (typically 90% N₂, 10% H₂) then removes surface oxides between metal particles. These steps create better bonds and prevent defects, which improves the part’s quality without extra processing.

Post-Sintering Coining and Sizing for Dimensional Accuracy

Parts often need sizing or coining after sintering to achieve precise dimensions. This improves accuracy from IT8-IT9 to IT6-IT7 ranges, and small parts can reach tolerances of ±0.01-0.02mm. Surface density increases by 0.5-1.0 g/cm³ during post-sintering operations, which makes parts more resistant to wear without needing separate components or processes.

Real Industry Data: Comparing PM and Traditional Gear Production

Powder metallurgy delivers substantial cost savings and better performance in manufacturing sectors, as shown by concrete performance metrics.

40% Cost Reduction in Automotive Gear Sets

Automotive manufacturers have seen major financial benefits by switching to powder metallurgy gears. Production costs drop by about 40% when compared to traditional manufacturing methods. The economics work at different production volumes. Small components become profitable at around 100,000 pieces per year. Larger, complex components need just 30,000 pieces yearly to be economical. Automotive suppliers typically need new technologies to show at least 10-15% cost savings before they adopt them.

16.5% Higher Tensile Strength with Optimized Sintering

Higher sintering temperatures from 1120°C to 1290°C boost ultimate tensile strength by 16.5%. Tests show that well-manufactured powder metallurgy gears match the contact fatigue properties of traditional wrought steel gears. Surface-densified PM gears have an endurance limit of 1764 MPa compared to 1839 MPa for hobbed gears—just a 5% difference.

25% Yield Strength Gain with Controlled Atmosphere

The right sintering atmosphere leads to remarkable strength improvements. Research shows that yield strength increases by 25% through proper atmosphere management. Using nitrogen with natural gas addition to reach 0.1% CO levels creates beneficial carbon gradients and improves fatigue performance by 23%. The right atmosphere composition also cuts gas costs by about 35%.

Case Study: JH MIM’s Gear Production for Power Tools

JH MIM brings nearly 20 years of expertise in metal injection molding and powder metallurgy, serving global customers with precision-engineered products. Their powder metallurgy gears for power tools show excellent repeatability and dimensional consistency. These gears maintain tolerances as precise as ±0.01-0.02mm. The company’s optimized metal powder mixes provide the perfect balance between performance and cost.

Advantages and Limitations of Powder Metallurgy in Gear Production

Powder metallurgy provides unique operational benefits that have made it a popular choice in gear manufacturing.

Advantages of the Powder Metallurgy Process in Mass Production

Mass production gains significant benefits from powder metallurgy techniques. Production speeds can reach 500-1000 parts/hour, while traditional methods only manage 20-50 parts/hour. The process takes 40-50% less production time and needs just 5-7 manufacturing steps compared to conventional processes that require 12-15 steps. The economics make sense at volumes that exceed 10,000 parts because tooling costs can be properly spread out.

Advantages of Powder Metallurgy Over Casting for Complex Gears

Complex gear geometries are where powder metallurgy really shines compared to casting. The technique creates intricate designs with almost 100% material utilization. These gears run 2-5 dB quieter and have 2-3× better damping capacity than their conventional counterparts. JH MIM’s 20 years of experience in metal injection molding and powder metallurgy have helped deliver precision-engineered products to customers worldwide.

Limitations: Size Constraints and Press Capacity

Powder metallurgy’s benefits come with some limitations. Most parts can’t exceed 110mm in diameter due to press capacity constraints. Larger parts up to 300mm need specialized equipment. The technique can’t directly create undercuts, cross holes, threads, or reverse tapers.

When to Choose PM vs Forging or Machining

Powder metallurgy works best with high-volume production that needs tight tolerances. Forging still leads in maximum strength applications with 8% higher tensile strength and 27% better fatigue resistance than sintered alternatives. Low-volume projects with frequent design changes benefit more from machining.

Conclusion

Powder metallurgy revolutionizes gear manufacturing with its cost-saving advantages and multiple efficiency gains. The process boasts a 97% material utilization rate that cuts waste compared to traditional machining methods. It also helps manufacturers with fewer processing steps, less labor, and lower energy use. These benefits lead to a 40% cost reduction in automotive gear production.

Technical aspects of powder metallurgy make economic sense, too. High-pressure compaction creates near-net shapes, while sintering temperatures stay below melting points to save energy. This means companies can achieve exceptional dimensional accuracy with minimal secondary operations. These advantages really shine when production volumes hit 10,000 parts.

The performance improvements from powder metallurgy are impressive. Tests show that well-manufactured powder metallurgy gears are stronger, with tensile strength up 16.5% at optimal sintering temperatures. Controlled atmosphere sintering boosts yield strength by 25%, making these parts perfect for tough applications.

Size limits do exist for powder metallurgy parts, but the process works great for complex shapes and high-volume production. Companies like JH MIM, with their 20 years of experience, show how these precision-engineered components meet strict tolerances while cutting production costs.

Manufacturers should weigh their needs carefully when choosing between powder metallurgy, forging, or machining. Material efficiency, fewer processing steps, and better performance make powder metallurgy an attractive choice in many industries. These economic benefits become more obvious as production volumes grow, making powder metallurgy the go-to method for manufacturers who want quality without high costs.

Key Takeaways

Powder metallurgy revolutionizes gear manufacturing by delivering exceptional material efficiency and cost savings that traditional methods simply cannot match.

• 97% material utilization vs 60% in machining eliminates waste and reduces raw material costs significantly • 40% cost reduction achieved in automotive gear production through fewer processing steps and reduced labor • Single-step manufacturing creates complex geometries that would require multiple machining operations • Energy efficiency gains from sintering at lower temperatures compared to forging processes • Enhanced performance with 16.5% higher tensile strength and 25% yield strength improvements through optimized processing

The process becomes economically viable at 10,000+ parts annually, making it ideal for high-volume production where tooling costs can be properly amortized. Companies like JH MIM demonstrate how nearly two decades of powder metallurgy expertise translates into precision components with tolerances as tight as ±0.01-0.02mm, proving that cost savings don’t require performance compromises.

FAQs

Q1. What are the main advantages of using powder metallurgy for gear production? Powder metallurgy offers several advantages for gear production, including 97% material utilization, reduced machining steps, lower energy consumption, and minimal scrap generation. These factors contribute to a significant cost reduction, often up to 40% compared to traditional manufacturing methods.

Q2. How does powder metallurgy achieve tight tolerances in gear manufacturing? Powder metallurgy achieves tight tolerances through high-pressure compaction for near-net shapes, precise sintering processes, and post-sintering operations like coining and sizing. This allows for dimensional accuracies as tight as ±0.01-0.02mm for small parts, rivaling traditional machining methods.

Q3. Is powder metallurgy suitable for mass production of gears? Yes, powder metallurgy is highly suitable for mass production of gears. It becomes economically viable at volumes exceeding 10,000 parts annually, with production rates reaching 500-1000 parts per hour. This makes it particularly cost-effective for high-volume automotive and industrial applications.

Q4. What are the limitations of powder metallurgy in gear production? While powder metallurgy offers many advantages, it does have some limitations. Parts are typically limited to diameters up to 110mm due to press capacity constraints. Additionally, the process cannot directly form undercuts, cross holes, threads, or reverse tapers without secondary operations.

Q5. How does the strength of powder metallurgy gears compare to traditionally manufactured gears? Properly manufactured powder metallurgy gears can exhibit comparable or even superior strength characteristics to traditional gears. With optimized sintering processes, powder metallurgy gears can achieve 16.5% higher tensile strength and 25% higher yield strength compared to conventional methods. In terms of contact fatigue properties, they perform similarly to wrought steel gears.