Consumer Electronics manufacturers increasingly rely on Metal Injection Molding for small parts. MIM technology produces miniaturized components with precise geometries and excellent surface finish. Asia Pacific leads global adoption, capturing nearly 47% of the market share. The table below highlights factors driving MIM’s growth in this industry:

| Aspect | Detail |

|---|---|

| Share of MIM parts volume | 36% from Consumer Electronics |

| New ultra-thin product casings | 24% involve MIM |

| IoT smart component prototyping | 28% of firms use MIM |

| Output increase for <10g parts | 31% with multi-cavity tooling |

Rapid advances in powder metallurgy and automation have improved efficiency, supporting the demand for high-strength, cost-effective electronic components.

Key Takeaways

- Metal Injection Molding (MIM) produces small, complex parts with high precision and excellent surface finish, ideal for consumer electronics.

- MIM saves costs and time by reducing material waste, enabling high-volume production, and consolidating multiple parts into one.

- The process supports intricate designs and tight tolerances, allowing manufacturers to create innovative and reliable electronic components.

- MIM parts offer strong mechanical properties and durability, helping devices last longer and perform better.

- Although tooling costs are high, MIM is most cost-effective for large production runs and supports fast market delivery with proper planning.

MIM in Consumer Electronics: What and Why

How Metal Injection Molding Works

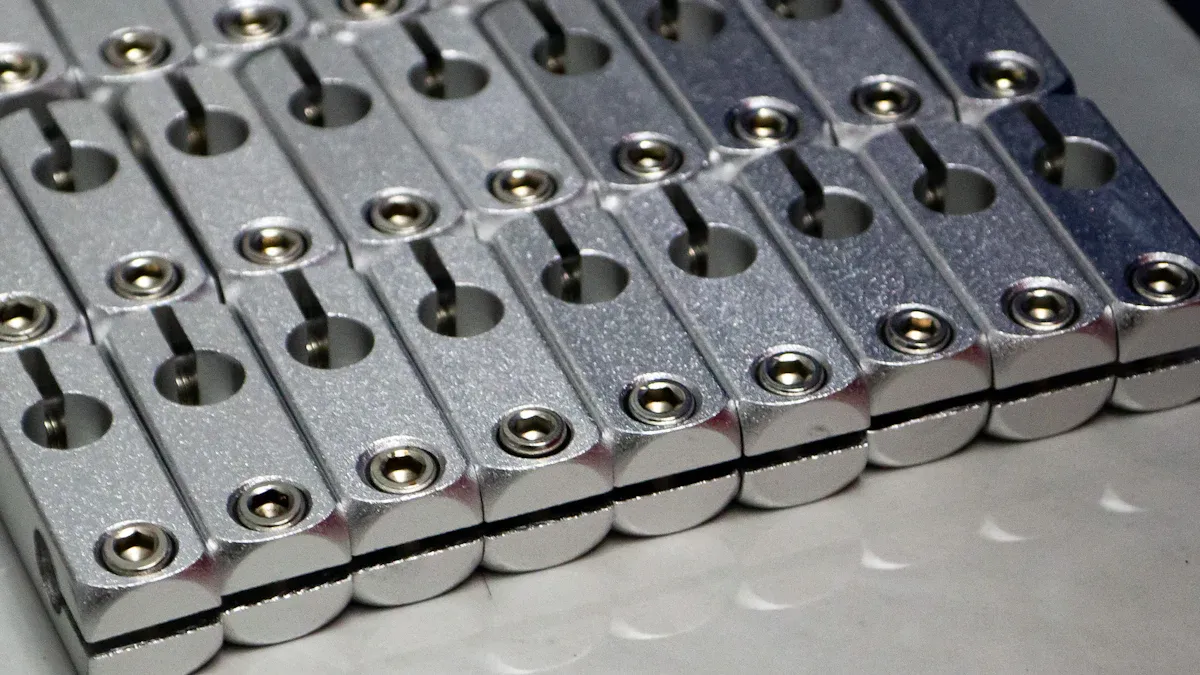

Metal Injection Molding (MIM) combines the versatility of plastic injection molding with the strength of metal. The process begins with the formulation of fine metal powders and a thermoplastic binder. Technicians blend these materials to create a homogeneous feedstock. The feedstock is then heated and injected into precision-engineered molds, forming “green parts” that are slightly larger than the final product to account for shrinkage during later stages.

After molding, the binder is removed through thermal, solvent, or catalytic debinding. This step produces fragile “brown parts” that retain the desired geometry and porosity. Sintering follows, where parts are heated in continuous furnaces just below the metal’s melting point. This fuses the metal particles, eliminates pores, and achieves densities between 95-98%. The sintered components exhibit uniform mechanical properties and smooth finishes. Optional post-processing, such as machining or polishing, further enhances the final product.

MIM stands apart from traditional metalworking techniques by using spherical powders for better flowability and enabling complex geometries that conventional powder metallurgy cannot achieve. The process supports mass production with high repeatability and minimal dimensional variance.

Key Steps in MIM:

- Powder formulation and feedstock preparation

- Injection molding into detailed molds

- Debinding to remove binder

- Sintering for strength and density

- Post-processing for final finish

Relevance to Small, Complex Electronic Parts

Consumer Electronics demand miniaturized components with intricate features and tight tolerances. MIM excels in producing small parts with excellent surface finish, high strength, and superior corrosion resistance. The process supports complex shapes, including contours, holes, small radii, logos, and text. Manufacturers can consolidate multiple functions into a single part, reducing assembly steps and improving reliability.

Compared to machining or investment casting, MIM offers thinner walls, better surface quality, and higher density. Automation and efficient feedstock usage minimize waste and enable cost-effective, high-volume production. MIM is ideal for parts smaller than a tennis ball, making it especially relevant for devices such as smartphones, wearables, and IoT components. The ability to mold complex shapes similar to plastic injection molding allows designers to innovate without compromising strength or precision.

MIM technology empowers Consumer Electronics companies to meet the growing demand for miniaturized, high-performance components while maintaining cost efficiency and rapid time-to-market.

Advantages of MIM for Consumer Electronics Components

Precision and Intricate Geometries

Metal Injection Molding delivers exceptional precision for small parts in consumer electronics. Manufacturers achieve tolerances as tight as ±0.003 inches, which is critical for miniaturized components. The process supports minimum feature sizes of approximately 0.1 mm and wall thicknesses as thin as 0.2 mm. These capabilities allow engineers to design intricate shapes, including undercuts, rounded corners, and uniform wall thicknesses, that are difficult or impossible with traditional methods.

The MIM process involves several steps that ensure high accuracy:

- Technicians compound fine metal powders with binders to create a moldable feedstock.

- Automated injection molding fills complex cavities, producing green parts slightly larger than the final size.

- Careful debinding removes binders without deforming the geometry.

- Sintering densifies the part, locking in the final shape and strength.

- Secondary operations, such as heat treating and coating, further refine dimensional control and appearance.

Quality control measures, including dimensional verification and mechanical property testing, guarantee consistent results across large batches. This repeatability is essential for the reliability and performance of consumer electronics devices.

MIM enables the creation of innovative and novel shapes, supporting the miniaturization trend in modern electronics.

| Parameter | Value |

|---|---|

| Minimum Feature Size | ~0.1 mm |

| Minimum Wall Thickness | 0.2–0.25 mm |

| Machine Precision | ±0.3% of size |

High-Volume Efficiency and Cost Savings

Consumer electronics companies benefit from the high-volume efficiency and cost savings that MIM offers. The technology becomes cost-effective for production volumes above 10,000 units and excels at annual volumes exceeding 200,000 parts. MIM allows manufacturers to produce complex small parts with stable costs, regardless of geometric complexity.

- MIM reduces material waste by up to 50%, achieving material utilization rates over 95%. Excess material can be recycled, supporting sustainable manufacturing.

- Tooling costs, while significant, are amortized over large production runs, decreasing the per-part cost.

- Compared to CNC machining, MIM can reduce production costs by 30-50% at scale. For example, producing 100,000 simple parts via MIM may cost $250,000, while CNC machining could cost $615,000.

- The process enables parts consolidation, combining multiple functions into a single component and reducing assembly time and labor costs.

Production cycle times for MIM are faster than CNC machining for large batches, though post-molding steps such as debinding and sintering extend the total cycle. The ability to produce thousands of identical parts with consistent quality supports rapid market demands in consumer electronics.

MIM offers design flexibility and minimal post-production finishing, further enhancing production efficiency and cost savings.

Superior Surface Finish and Cosmetic Appeal

Surface finish quality plays a vital role in consumer electronics, where appearance and tactile experience matter. MIM parts exhibit superior surface finish and tighter tolerances compared to traditional manufacturing methods. This results in reduced friction and enhanced wear resistance, which is critical for components like connectors, buttons, and hinges.

- MIM produces parts with uniform textures and excellent material homogeneity.

- Components can undergo various surface treatments, such as PVD coatings, painting, polishing, sandblasting, brushing, and heat treatment, to enhance aesthetics and functionality.

- The smooth finish ensures that moving parts operate quietly and reliably, improving user experience and product longevity.

Traditional manufacturing methods often leave rougher surfaces and broader tolerances, increasing friction and wear. MIM’s ability to deliver cosmetic appeal and durability makes it the preferred choice for high-end consumer electronics.

The combination of precision, efficiency, and superior surface finish positions MIM as a leading solution for small parts in consumer electronics.

Mechanical Strength and Durability

Metal Injection Molding (MIM) produces parts with impressive mechanical properties, making it a strong choice for small, high-performance components. MIM parts typically reach 95% to 98% of their theoretical density. This high density provides good mechanical strength and ductility, which are essential for reliable performance in demanding applications. The sintering process, a key step in MIM, can introduce some porosity. While this may slightly reduce fatigue resistance and impact toughness compared to forged parts, the mechanical strength of MIM components remains suitable for most consumer electronics applications.

| Property | MIM Parts | Forged Parts |

|---|---|---|

| Density | 95% to 99% of theoretical | Nearly 100% of theoretical |

| Porosity | Moderate, reduces fatigue and impact toughness | Minimal, enhances mechanical performance |

| Tensile Strength | Moderate | High |

| Hardness & Ductility | Moderate | Excellent |

| Fatigue Resistance | Moderate | Excellent |

MIM excels at producing small, intricate parts with complex geometries at high volumes and lower cost compared to machining. Achieving consistent density and minimizing voids is critical for optimal mechanical properties. Manufacturers use advanced process controls to ensure uniformity and reliability in every batch.

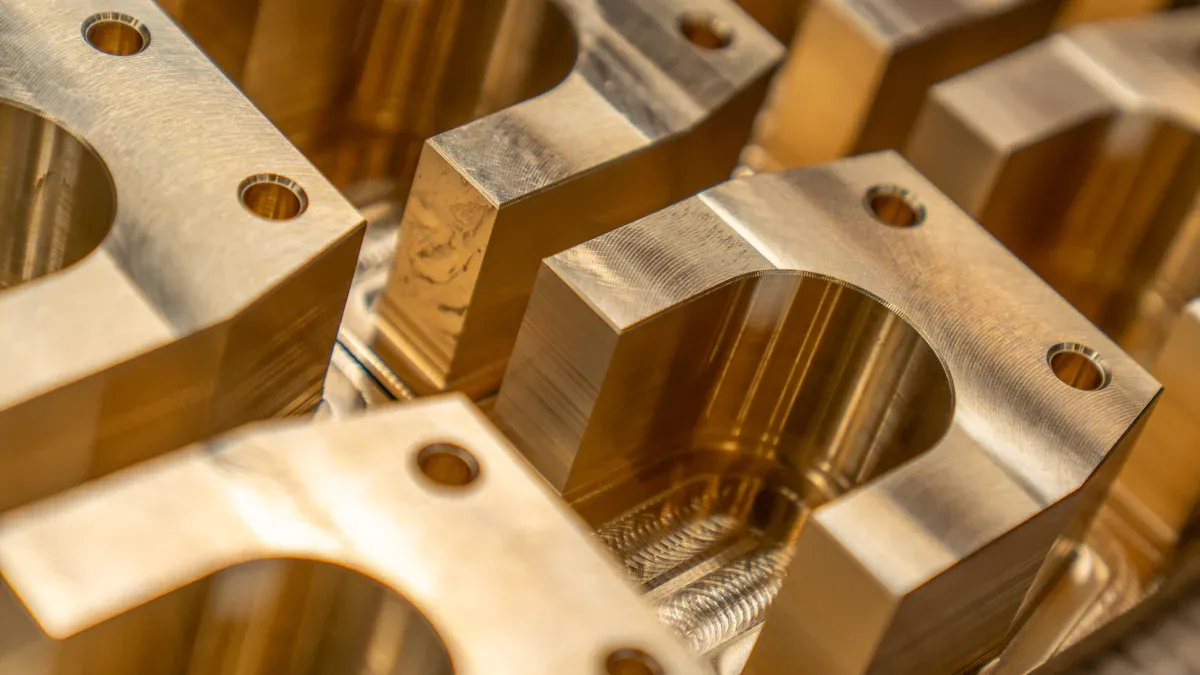

Durability in MIM components extends beyond the parts themselves. The quality and lifespan of the molds used in production play a significant role in the overall durability of consumer electronics devices. Steel molds offer high wear resistance and withstand large production volumes, ensuring consistent part quality and reducing defects. This consistency directly impacts the lifespan of electronic devices, as high-quality components lead to fewer failures and longer service life.

Several factors influence the durability of MIM components and molds:

- Thermal stress management through gradual heating and cooling cycles extends mold life by up to 25%, supporting consistent component quality.

- The use of mild mold release agents and proper application techniques can add approximately 100,000 cycles to mold life, reducing part defects.

- Protective coatings, such as PVD, increase mold resistance to wear and corrosion, resulting in fewer production interruptions.

- Improved handling and setup procedures reduce mold damage, increasing lifespan from 800,000 to over 1 million cycles.

- Climate-controlled storage preserves mold integrity and part quality, increasing mold lifespan by 20%.

Consistent production quality and robust mold maintenance practices ensure that MIM components contribute to the long-term durability and reliability of consumer electronics.

Design Flexibility and Parts Consolidation

MIM technology offers unmatched design flexibility, empowering engineers to create innovative products with complex shapes and features. The process supports the production of intricate geometries with high precision and tight tolerances. Designers can incorporate undercuts, thin walls, and detailed surface features that would be difficult or impossible to achieve with traditional metalworking methods.

MIM enables manufacturers to consolidate multiple components into a single, complex part. This parts consolidation reduces assembly steps and minimizes potential failure points, streamlining the manufacturing process and improving device reliability. By producing near-net-shape parts, MIM minimizes the need for extensive post-processing, which enhances manufacturing efficiency and reduces costs.

- MIM allows for the creation of novel shapes and configurations, giving designers the freedom to innovate.

- The process supports the integration of multiple functions into a single part, simplifying assembly and reducing the risk of misalignment or malfunction.

- Consistent quality across complex forms ensures seamless integration and optimal performance in consumer electronics devices.

- Manufacturers can push the boundaries of product innovation, resulting in differentiated and competitive products.

The design freedom and parts consolidation capabilities of MIM enable consumer electronics companies to deliver advanced, reliable, and aesthetically pleasing devices to the market.

Material Compatibility and Applications in Consumer Electronics

Common Materials Used in MIM for Electronics

Engineers select materials for metal injection molding based on the required properties of the final component. Stainless steel stands out as the most popular choice. It offers corrosion resistance, mechanical strength, and an attractive appearance. These qualities make it ideal for products exposed to moisture or requiring a premium look. Copper and its alloys provide excellent electrical and thermal conductivity, which is essential for connectors and heat sinks. Magnetic alloys serve in applications that need high magnetic permeability, such as inductors and transformers. Titanium alloys deliver a high strength-to-weight ratio and biocompatibility, making them suitable for lightweight and durable parts, especially in specialized electronics.

The table below summarizes the key materials and their applications:

| Material | Key Properties | Consumer Electronics Applications |

|---|---|---|

| Stainless Steel | Corrosion resistance, mechanical strength, aesthetic appeal | Watches, jewelry, accessories, structural parts |

| Copper & Alloys | Excellent electrical and thermal conductivity | Connectors, heat sinks, electronic contacts |

| Magnetic Alloys | High magnetic permeability, magnetization | Magnetic cores, inductors, transformers |

| Other Alloys | Specialized properties (e.g., titanium, tool steels) | Lightweight frames, wear-resistant parts, medical electronics |

Stainless steel and titanium alloys both resist corrosion and high temperatures. Titanium, however, requires careful processing due to its cost and powder flowability. Copper alloys remain essential for their conductivity, supporting efficient device performance.

Typical Small Parts Manufactured with MIM

Manufacturers use MIM to produce a wide range of small, complex parts for electronic devices. These parts often require tight tolerances and intricate features. Common examples include:

- Connectors for reliable electrical contact

- Structural parts for smart devices, such as internal frames and brackets

- Housings that protect sensitive components

- Precision gears and micro-mechanical parts

- Buttons and switches for mobile devices and wearables

MIM enables the creation of features like threads, undercuts, and thin walls directly in the molding process. This reduces the need for post-machining and speeds up assembly. The process also allows for part consolidation, combining several functions into a single component. As a result, manufacturers achieve faster production cycles, lower costs, and consistent quality. Devices become smaller, more powerful, and easier to assemble.

Tip: Choosing the right material and leveraging MIM’s design flexibility can significantly enhance device performance and reliability.

Limitations and Considerations for Consumer Electronics Companies

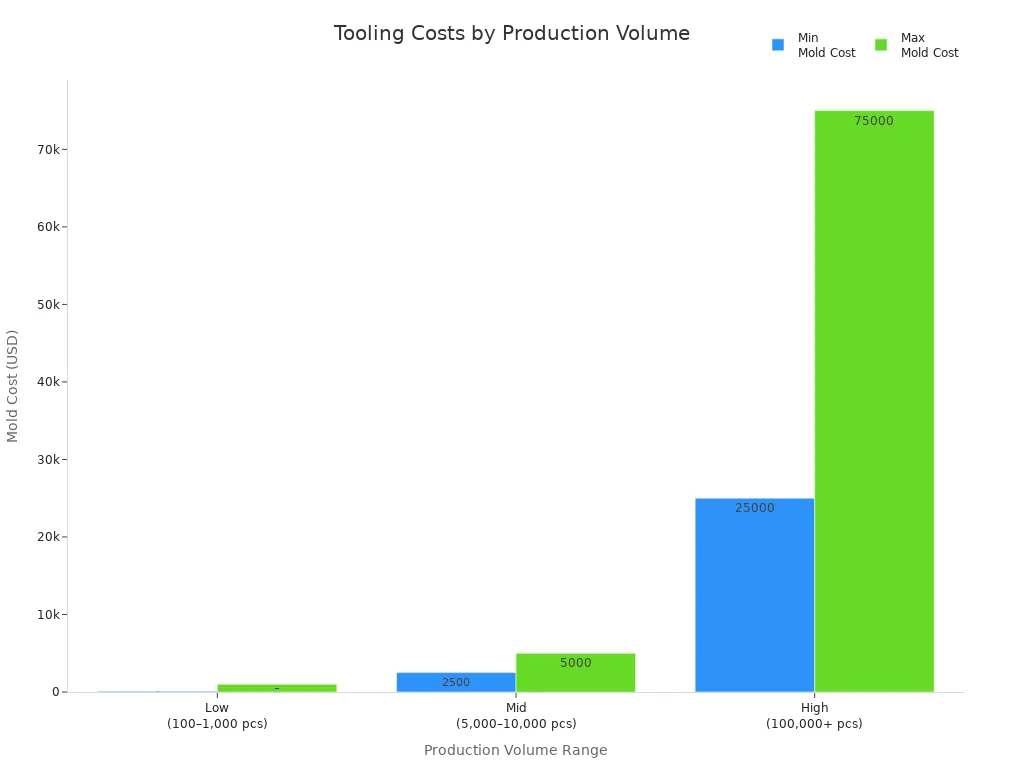

Tooling Costs and Lead Times

Metal Injection Molding requires significant investment in tooling, especially for high-volume production. Companies face upfront costs for mold creation, which can range from $25,000 to $75,000 for hardened steel molds. These costs are amortized over large production runs, making MIM most economical for mass manufacturing. For smaller batches, rapid tooling methods such as 3D-printed or aluminum molds offer lower initial costs but shorter tool life. Setup fees for mounting and calibrating molds add further expenses, particularly for short-run projects.

| Production Volume Range | Typical Mold Type | Approximate Mold Cost Range | Lead Time and Cost Implications |

|---|---|---|---|

| Low (100–1,000 pcs) | 3D-printed or Aluminum mold | $100–$1,000 | Lower upfront cost, higher per-part cost, suitable for prototyping |

| Mid (5,000–10,000 pcs) | Hardened-steel mold | $2,500–$5,000 | Moderate tooling cost, balanced per-part cost, suitable for medium runs |

| High (100,000+ pcs) | Hardened-steel mold | $25,000–$75,000 | High upfront tooling cost amortized over large volume, lowest per-part cost |

Traditional MIM lead times can extend several weeks, impacting time-to-market. Rapid molding and additive manufacturing provide alternatives with shorter lead times, sometimes under two weeks, enabling faster prototyping and design iterations. These methods offer flexibility and help companies respond quickly to market changes.

Note: High upfront tooling costs and longer lead times make MIM ideal for large-scale production, while rapid tooling suits prototyping and low-volume needs.

Size and Complexity Constraints

MIM offers remarkable design freedom, allowing engineers to create intricate features such as undercuts, threads, and micro details. The process supports tight tolerances and repeatability, which are essential for small electronic parts. However, prototype tooling faces challenges with material limitations and machining complexity. Micro features and tight tolerances may exceed the capabilities of prototype alloys, requiring extensive re-machining and tooling updates.

- MIM enables production of small, complex parts with minimal material waste.

- Prototype molds prioritize speed and flexibility but may lack production-level durability.

- Iterative design changes can slow early-stage feasibility assessments.

- Selecting appropriate manufacturing methods and materials early in the design process ensures cost-effectiveness and feasibility.

Tip: Early collaboration between design and manufacturing teams helps optimize part geometry and material selection for MIM feasibility.

Quality Control and Tolerances

Quality control in MIM relies on a series of rigorous measures to ensure tight tolerances and consistent part quality. Manufacturers test raw materials before production to verify strength and durability. Pre-production inspections of small batch runs help identify necessary mold adjustments. During production, dimensional inspections and visual checks detect surface defects and maintain appearance standards. Functional testing confirms that parts meet mechanical and electrical requirements.

- Material quality testing prevents poor-quality parts.

- Pre-production inspection validates mold design and material flow.

- Dimensional inspections ensure adherence to tolerances.

- Visual inspections catch surface defects early.

- Functional testing verifies performance.

- Post-production inspections confirm batch consistency.

Automation technologies, such as smart robots and data-driven controls, enhance quality control by reducing error rates and improving efficiency. Regular mold maintenance and supplier audits further support precision and reliability. MIM typically achieves dimensional tolerances around ±0.3% of nominal dimensions, with micro features down to 0.1 mm and thin walls as thin as 0.3 mm. Superior surface finishes often eliminate the need for additional finishing, making MIM suitable for high-precision electronic components.

Consistent quality control practices ensure that MIM parts meet the demanding standards of modern electronic devices.

Metal Injection Molding stands out as the preferred solution for small parts in Consumer Electronics. Manufacturers benefit from high-volume production, design flexibility, and consistent quality.

- MIM enables intricate geometries, tight tolerances, and efficient material use.

- The process supports rapid innovation, meeting the demand for miniaturized, high-precision components.

- Industry trends show increased adoption for connectors, hinges, and smartphone parts.

| Future Impact | Description |

|---|---|

| Advanced Materials | New alloys and composites expand application possibilities |

| Digitalization | Simulation and automation improve efficiency and quality |

| Sustainability | Eco-friendly practices drive greener manufacturing |

FAQ

What types of consumer electronics benefit most from MIM parts?

Smartphones, wearables, laptops, and IoT devices often use MIM parts. These products require small, complex components with high strength and excellent surface finish. MIM supports the miniaturization and durability needed in modern electronic devices.

How does MIM improve production efficiency for electronics manufacturers?

MIM enables high-volume production with consistent quality. Manufacturers reduce material waste and lower per-part costs. The process allows for parts consolidation, which streamlines assembly and shortens time-to-market.

Which materials are most common in MIM for electronics?

Stainless steel, copper alloys, and magnetic alloys see frequent use. These materials provide corrosion resistance, electrical conductivity, and mechanical strength. Engineers select materials based on the specific requirements of each electronic component.

Can MIM produce parts with branding or logos?

Yes. MIM technology allows for the direct molding of logos, text, and surface patterns onto parts. This capability enhances product branding and eliminates the need for secondary engraving or marking processes.

What quality control measures ensure MIM part reliability?

Manufacturers use material testing, dimensional inspections, and functional tests. Automated systems monitor production for consistency. Regular mold maintenance and supplier audits further support high-quality, reliable MIM components.