Variable valve timing (VVT) represents advanced automotive engine technology that optimizes performance by controlling the opening and closing timing of intake and exhaust valves. Modern vehicles have substantially increased VVT system adoption to boost fuel economy while reducing exhaust emissions. This technology adapts valve operation based on driving conditions and stands as the lifeblood of contemporary automotive engineering.

What is variable valve timing, and how does it work? The system adjusts valve timing to improve engine combustion states, which helps achieve low fuel consumption, higher output, and reduced emissions. Three key components make up the variable valve timing system: a sprocket, housing, and rotor. These parts work together to enable precise control that makes VVT the quickest way to optimize engines.

Over the last several years, manufacturers have increasingly used sintered parts in VVT manufacturing because of their unique advantages. VVT solenoids and other components benefit from powder metallurgy techniques that allow flexibility in alloy design and the possibility of near-net-shape production. Diamet Corp. produces high-performance VVT components using sintered materials such as Fe-Mo-C and Fe-Cu-C that provide excellent fatigue strength after heat treatment. VVT technology not only improves performance but also represents a major step forward in making internal combustion engines more efficient and environmentally friendly.

Core Components and Functionality of VVT Systems

Variable valve timing mechanisms change the engine camshaft’s position relative to the crankshaft. This technology lets engines control when intake and exhaust valves open and close during combustion. The engine adapts to different operating conditions as a result.

What is variable valve timing in an engine?

Variable valve timing (VVT) gives engines the ability to advance or delay camshaft position. It modifies when valves open and close to match specific operational needs. Traditional fixed-timing engines keep the same valve timing in all conditions. VVT adjusts timing based on engine speed, load, and other factors continuously.

Cam-phasing represents the most common implementation. The camshaft rotates forward or backward relative to the crankshaft. Valve timing changes without affecting lift or duration. VVT creates the best timing for each operating condition through hydraulic actuation. Engines can now overcome the usual trade-off between low-end torque and high-end power.

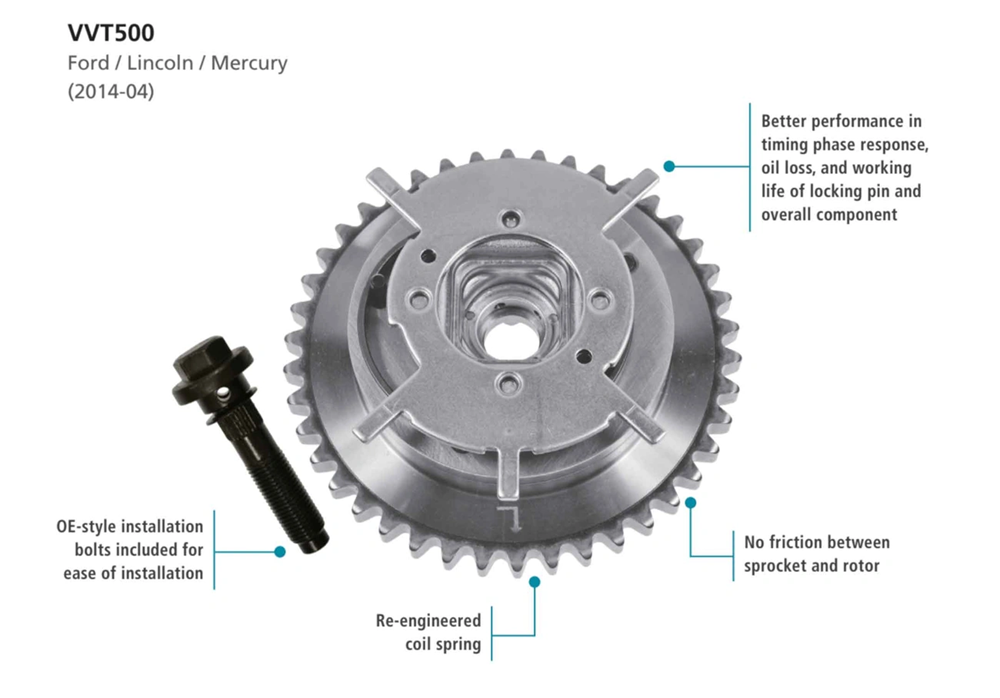

Key parts: rotor, housing, sprocket

A VVT system’s main components are the control solenoid and phaser mechanism (sprocket). The phaser cavity contains three key elements that work together:

- Rotor: Connects to the camshaft directly and rotates inside the housing

- Housing: Links to the engine timing sprocket and provides structural support

- Sprocket: Features integrated paddle designs that eliminate inserts and offer larger contact areas

These parts interact through precisely machined oil galleries. Pressurized oil fills either side of the rotor blades, which causes rotation relative to the housing. Today’s VVT sprockets feature design improvements. Tighter dimensional tolerances reduce component wear and oil loss.

Role of VVT in emissions and performance

VVT systems offer advantages beyond engine operation. They optimize valve overlap to reduce harmful emissions, especially NOx, through passive exhaust gas recirculation. Separate EGR valves become unnecessary.

The performance benefits are significant. Engines deliver better torque at different speeds. VVT advances valve timing at lower RPMs to improve fuel economy and create smoother idling. Higher speeds benefit from retarded exhaust timing. This increases volumetric efficiency because cylinders fill better. Smaller engines can now generate more horsepower and torque at lower RPMs thanks to this adaptability.

Material Selection and Sintering Techniques

The production of high-performance VVT components starts with choosing the right powder metallurgy materials that combine strength, durability, and ease of manufacturing. The choice of powder plays a crucial role in how well the final parts perform in tough engine conditions.

Fe-Mo-C vs Fe-Cu-C alloy compositions

Two main material compositions lead the way in VVT component manufacturing. Fe-Mo-C alloys deliver exceptional fatigue strength ratings of 340 MPa after heat treatment. This is a big deal as it means that they perform better than traditional materials. These alloys stay strong even at extreme temperatures of 1500°C, thanks to molybdenum’s high melting point (2620°C), which gives superior heat resistance. The addition of titanium, zirconium, and carbon in specialized molybdenum mixes boosts high-temperature hardness properties.

Fe-Cu-C materials with high copper content offer reliable performance with fatigue strength of 220 MPa. Copper’s lower melting point (1083°C) creates good liquid phase sintering that leads to uniform structures during manufacturing. Diamet Corporation employs these specific material compositions—Fe-Mo-C for ‘link A’ parts and Fe-Cu-C for ‘input cams’—in Nissan Motors’ VVT systems.

Face compressibility and density correlation

Research data shows a clear link between material density and face compression strength. FH655 shows the highest face compression values in raw sintered form among the tested materials. Face compression strength grows in proportion to both material hardness and density. Advanced mixing techniques can cut weight scatter by over 50% through better powder flow characteristics, which leads to better dimensional stability throughout manufacturing.

Near-net-shape benefits in powder metallurgy

Powder metallurgy achieves remarkable precision—reaching tolerances of ±0.04 mm and accuracy up to 0.02mm for critical VVT components. This precise manufacturing approach lets manufacturers form complex features like helical splines during the original compaction, which eliminates the need for costly secondary operations. Powder metallurgy’s material usage exceeds 95%, which means much less waste compared to traditional manufacturing methods.

The process turns carefully mixed powders into working parts through precise compaction (150-900 MPa) and controlled sintering. This near-net-shape capability helps VVT manufacturers create complex geometries that would get pricey with extensive machining.

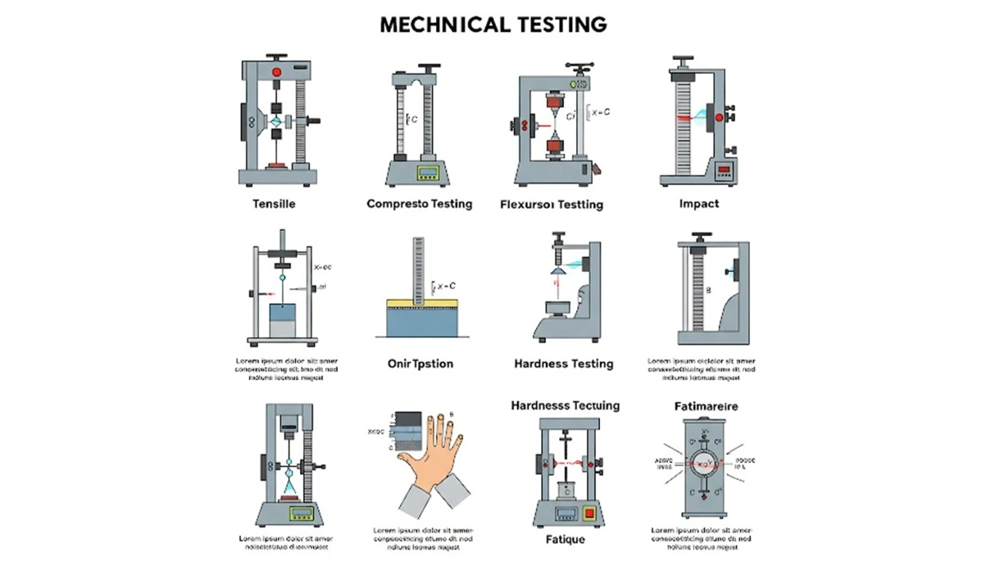

Mechanical Testing and Performance Evaluation

VVT components must pass testing protocols to ensure they work well under tough engine conditions. These tests give us vital information about how materials behave in real operating environments.

Face compression strength using the Yunker test

Yunker-type test systems help us assess face compression strength by measuring the load needed to compress the specimen’s face by 2 micrometers. Tests show that face compression strength goes up as density increases. FH655 shows the best face compression values among raw sintered materials. The FH12 materials that go through carburizing quench treatment show even better face compression strength than FH655.

Wear resistance via the block-on-ring test

Block-on-ring testing shows us how the rotor ring and housing interact with each other. This standard test method (ASTM G77) helps us learn about sliding wear behavior in different conditions. The results show:

- Raw materials (FH16 and FH655) show much larger wear volumes

- Gas nitrided FH16 shows about 5 times less wear than untreated FH16

- Lubrication cuts down wear rates by a factor of ~8×10⁶ compared to dry conditions

Mineral oil lubrication cuts friction by ~90 times while it cools contact surfaces and moves abrasive debris away.

Tooth strength and hardness measurements

Hardness tests on both the face and interior of components give us vital data about mechanical properties and wear resistance. These measurements are linked to how components perform in variable valve timing systems, and higher hardness usually means better durability in high-stress applications.

Heat Treatment and Surface Engineering for VVT Parts

Surface engineering technologies play a crucial role in VVT component performance under extreme conditions. Tests reveal three treatments that work best for VVT applications.

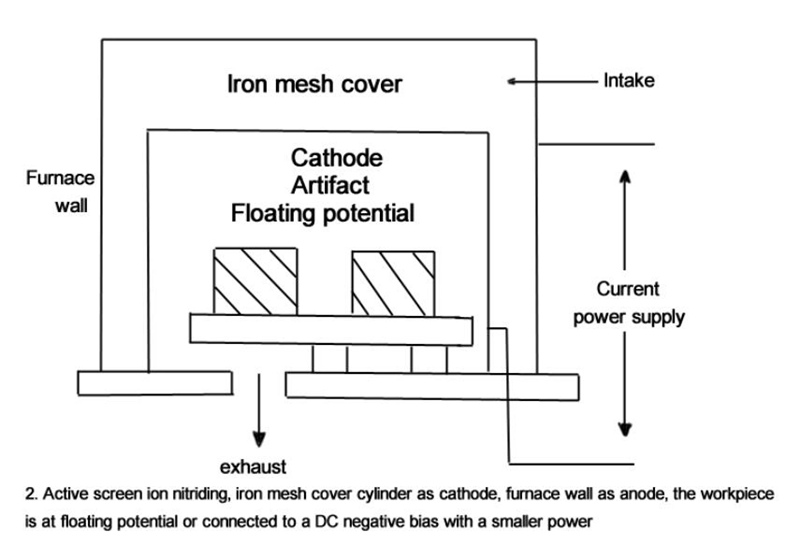

Gas nitriding for wear resistance

Gas nitriding takes place at 480-570°C in an ammoniac/nitrogen mixture. The process runs for 1-3 hours based on density and alloying. A white layer forms at 2-8 μm thickness with a nitride-enriched zone that goes about 2 mm deep into the component. Test results show gas nitriding as the best way to reduce wear volume in VVT components. FH16 materials treated this way show wear resistance five times better than untreated ones.

Carburizing quench for strength and cost balance

VVT components need both strength and budget-friendly solutions, and carburizing quench treatments fit perfectly. Parts get exposed to a carbon-rich atmosphere at 850-950°C. Carbon atoms then diffuse into the surface to form a hardened carbide layer. The carbon-enriched structure turns into martensite after quenching, with surface hardness reaching HRC 58-65. Many manufacturers choose FH12 materials with these treatments because they balance compression strength and cost well.

Manganese phosphating for friction reduction

Nissan’s VVT systems use manganese phosphate coatings on their “input cam” components. This treatment creates a thin, durable layer that boosts lubrication properties. The coating holds lubricants between moving parts effectively, which cuts down friction and stops early wear. Components that slide against each other benefit most from this treatment. The result helps maintain good fuel economy in variable valve timing systems.

Conclusion

Variable valve timing is a groundbreaking advancement in automotive engineering that offers multiple performance benefits. The combination of precision-crafted components—rotors, housings, and sprockets—creates adaptive engines that meet various operational needs. Modern vehicles now achieve better fuel economy, lower emissions, and improved performance through this technology.

Sintered manufacturing has reshaped VVT component production since the early 2000s. The advantages of powder metallurgy techniques are clear – they provide near-net-shape capabilities and material utilization above 95%. The dimensional precision of ±0.04 mm eliminates the need for expensive secondary operations. Complex features like helical splines can be created during the original compaction.

Material choice is vital to VVT system longevity. Fe-Mo-C alloys deliver superior fatigue strength at 340 MPa, while Fe-Cu-C materials provide reliable performance with useful liquid phase sintering properties. The right heat treatments—gas nitriding, carburizing quench, and manganese phosphating—make components more durable by improving wear resistance, strength, and reducing friction.

JH MIM’s 20 years of powder metallurgy expertise helps them deliver precision-engineered VVT components to global automotive manufacturers consistently. These developments help internal combustion engines stay viable and efficient despite tougher emissions standards. Over the last several years, the rise of sintered manufacturing techniques and material state-of-the-art will reshape the future of variable valve timing technology as automotive engineers look to optimize traditional powertrains.

Key Takeaways

Variable valve timing (VVT) technology represents a critical advancement in automotive engineering, optimizing engine performance through precise valve control while sintered manufacturing revolutionizes component production with superior materials and processes.

• VVT systems boost fuel economy and reduce emissions by dynamically adjusting valve timing based on driving conditions through rotor, housing, and sprocket components.

• Sintered manufacturing achieves 95%+ material utilization with near-net-shape precision (±0.04mm tolerance), eliminating costly secondary operations for complex VVT parts.

• Fe-Mo-C alloys deliver 340 MPa fatigue strength after heat treatment, significantly outperforming Fe-Cu-C materials (220 MPa) for demanding engine applications.

• Gas nitriding reduces wear volume by 5x compared to untreated materials, while carburizing quench provides optimal strength-to-cost balance for VVT components.

• Powder metallurgy enables complex geometries like helical splines during initial compaction, transforming VVT manufacturing since the 2000s with superior dimensional control.

The combination of advanced VVT technology and sintered manufacturing techniques ensures internal combustion engines remain efficient and environmentally compliant, meeting increasingly stringent automotive standards while maintaining performance excellence.

FAQs

Q1. What is variable valve timing and how does it improve engine performance? Variable valve timing (VVT) is a technology that adjusts the timing of valve opening and closing in an engine. It improves performance by optimizing fuel economy, increasing power output, and reducing emissions across different driving conditions.

Q2. What are the main components of a variable valve timing system? The main components of a VVT system are the rotor, housing, and sprocket. These parts work together to control the precise timing of valve operations, allowing the engine to adapt to various operating conditions.

Q3. How does sintered manufacturing benefit VVT component production? Sintered manufacturing offers near-net-shape production capabilities, high material utilization (over 95%), and the ability to create complex geometries like helical splines during initial compaction. This results in more precise and cost-effective VVT components.

Q4. What materials are commonly used in VVT component manufacturing? Two primary material compositions used in VVT component manufacturing are Fe-Mo-C and Fe-Cu-C alloys. Fe-Mo-C alloys offer superior fatigue strength of 340 MPa after heat treatment, while Fe-Cu-C materials provide reliable performance with beneficial liquid phase sintering properties.

Q5. What surface treatments are applied to VVT components to enhance performance? Common surface treatments for VVT components include gas nitriding for improved wear resistance, carburizing quench for enhanced strength, and manganese phosphating for friction reduction. These treatments significantly improve the durability and efficiency of VVT systems.