What are MIM Parts? These are metal components crafted using the Metal Injection Molding (MIM) process, a cutting-edge technology that merges metal strength with unparalleled design flexibility. Industries like automotive, aerospace, and consumer electronics rely on MIM parts for their intricate geometries. The automotive sector alone anticipates billions in growth due to MIM’s role in electric and autonomous vehicles.

Key Takeaways

- MIM parts are strong like metal and easy to shape. They are great for detailed parts used in cars and medical tools.

- The MIM process has steps like mixing, molding, removing binders, and heating. Each step is important to make good parts.

- MIM saves money when making many parts. It uses less material and keeps quality high, especially for small, detailed pieces.

How Are MIM Parts Made?

The Metal Injection Molding (MIM) process involves several precise steps to create high-quality metal components. Each stage contributes to the production of intricate and durable parts.

Mixing and Feedstock Preparation

The process begins with feedstock preparation. Fine metal powders are combined with binders, such as waxes and polymers, to form a homogenous mixture. This mixture, known as feedstock, is essential for shaping the parts. The table below highlights the materials used in this stage:

| Material Type | Description |

|---|---|

| Metal Powders | Fine metal powders are used in MIM feedstock. |

| Binders | Waxes and various polymers are included. |

Metal powders typically range from a few microns to several tens of microns in size. Common alloys include stainless steel, titanium, and nickel-based superalloys.

Injection Molding

The prepared feedstock is heated and injected into molds to form “green parts.” This step allows for the creation of complex geometries with high precision. Injection molding offers several advantages, including consistent quality, minimal material waste, and cost-effectiveness for mass production. You can achieve intricate designs that would be challenging with traditional methods.

Debinding Process

Debinding removes the binder material from the green parts. This step is critical to maintain the shape and integrity of the components. Thermal, solvent, or catalytic methods are used, depending on the material and design. Proper control during debinding prevents defects like cracking or warping, ensuring the parts are ready for the next stage.

Sintering and Final Densification

Sintering enhances the density and strength of the parts. The components are heated in a controlled atmosphere, allowing the metal powders to bond through thermal diffusion. This process eliminates any remaining organic materials and expels gases, resulting in near-full densification. The final parts exhibit excellent mechanical properties and are ready for secondary operations if needed.

The precision of each step ensures that MIM parts meet the highest standards of quality and performance, making them indispensable in industries like automotive and aerospace.

Advantages of MIM Parts

Design Flexibility and Complex Geometries

Metal Injection Molding (MIM) offers unmatched design flexibility, allowing you to create intricate geometries that traditional methods struggle to achieve. With MIM, you can produce components like:

- Medical devices such as joint replacements, stents, and surgical instruments.

- Aerospace parts including turbine blades and engine components.

- Automotive gears and transmission components.

- Small consumer electronics like connectors and housings.

- Complex shapes such as zigzag springs, hollow structures, and micro pipes.

This capability makes MIM ideal for industries requiring precision and innovation. Whether you need orthopedic implants or turbine engine components, MIM ensures your designs come to life with exceptional accuracy.

High Tolerance and Precision

MIM technology excels in delivering high tolerance and precision. You can achieve tolerances as tight as ±0.02 mm, ensuring every part meets exact specifications. This level of precision enhances the performance and reliability of components, especially in critical applications like medical devices and aerospace systems. Additionally, MIM’s ability to produce intricate designs with consistent quality sets it apart from traditional manufacturing methods.

Cost-Effectiveness for High-Volume Production

When it comes to high-volume production, MIM offers significant cost advantages. While initial mold costs may be higher, the overall production costs decrease as volume increases. Here’s a comparison:

| Method | Cost Advantage |

|---|---|

| MIM | Cost-effective for medium to high volumes |

| Machining | Higher costs for complex designs |

| Casting | Less economical for high volumes |

MIM also reduces material waste and speeds up production, making it a cost-effective solution for industries like automotive and consumer electronics.

Material Versatility

MIM supports a wide range of materials, giving you the flexibility to choose the best option for your application. Common materials include:

- Metals: Stainless steels (316L, 17-4PH), titanium alloys, tungsten heavy alloys, and copper alloys.

- Ceramics: Alumina, zirconia, and silicon nitride.

For example, stainless steel 316L is perfect for surgical instruments due to its corrosion resistance, while titanium alloys like Ti-6Al-4V are ideal for aerospace and medical implants. This versatility ensures that MIM parts meet the specific demands of various industries.

Limitations of MIM Parts

High Initial Investment Costs

Metal Injection Molding (MIM) requires a significant upfront investment, which can be a barrier for some projects. The costs primarily stem from tooling, process setup, and material selection. For instance, tooling expenses can range from $5,000 to over $100,000, depending on the complexity of the part. Process development and setup add another $10,000 to $50,000. While these costs may seem high, they become more economical for large production volumes, typically exceeding 10,000 parts. The table below provides a breakdown of typical MIM cost components:

| MIM Cost Component | Details |

|---|---|

| Tooling | $5,000 to $100,000+ depending on part complexity |

| Set Up | $10,000 to $50,000 for process development |

| Materials | 10-15% of part cost, higher for costly alloys |

| Labor | Lower contribution versus CNC machining |

| Secondary Processing | $2 to $20 per part depending on operations |

Despite the high initial costs, MIM becomes cost-effective for high-volume production, making it ideal for industries like automotive and consumer electronics.

Size and Weight Constraints

MIM is best suited for small, intricate components. Larger or heavier parts often face challenges due to the limitations of the injection molding process. The feedstock’s flow properties restrict the size and weight of parts that can be produced. For example, components exceeding 100 grams may require alternative manufacturing methods. This constraint makes MIM less suitable for applications involving large-scale metal parts, such as heavy machinery or structural components.

Technical Challenges in Process Control

The MIM process involves multiple stages, each requiring precise control to ensure quality. During debinding and sintering, maintaining the correct atmosphere is crucial to prevent metal loss and preserve alloy properties. Temperature management is equally important to avoid defects like cracking or blistering. The following challenges often arise during MIM manufacturing:

- Precise atmospheric control is essential during debinding and sintering to minimize additive metal loss.

- Sintering requires careful temperature management to prevent unwanted chemical reactions.

- Binder swelling and residual stress can lead to defects, necessitating careful solvent selection.

- The complexity of the process demands specialized expertise, increasing labor costs.

Each stage, from mixing to sintering, must be meticulously managed to produce high-quality parts. While these challenges require advanced technical knowledge, they also highlight the importance of working with experienced manufacturers like JH MIM to achieve optimal results.

Applications of MIM Parts Across Industries

Automotive Industry

MIM parts play a vital role in the automotive sector, offering precision and durability for critical components. You can find MIM parts in various systems, including:

- Engine Components: Valve lifters, pistons, camshafts, and connecting rods.

- Transmission Parts: Gears and synchronizer rings.

- Fuel System Components: Fuel injectors and fuel rails.

- Steering and Suspension Systems: Steering knuckles and suspension components.

- Body and Chassis Components: Brackets, clips, and structural elements.

These applications demonstrate how MIM technology supports the production of lightweight, high-performance parts, contributing to advancements in electric and autonomous vehicles.

Medical and Dental Applications

The medical field benefits significantly from MIM’s ability to produce biocompatible and precise components. Companies like MD Metalline specialize in crafting dental implants, orthodontic brackets, and surgical tools. MIM also enables the production of:

- Load-bearing orthopedic implants, such as spinal fusion devices and joint replacements.

- Dental instruments, including forceps and scalers.

- Surgical tools like scissors and clamps.

- Minimally invasive devices, such as endoscopic tools and catheter components.

These innovations ensure that MIM parts meet the stringent standards required for medical and dental applications.

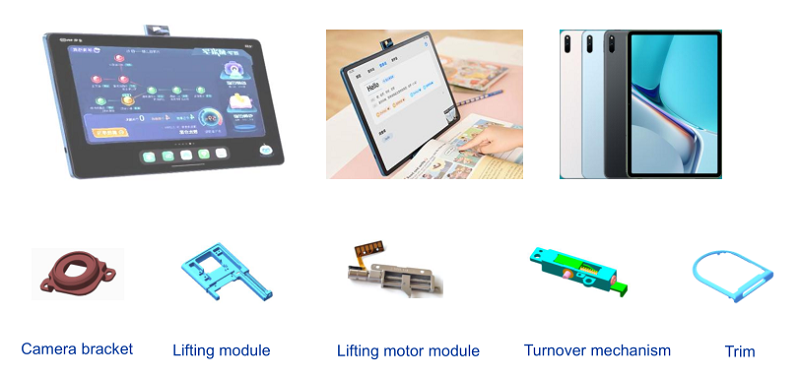

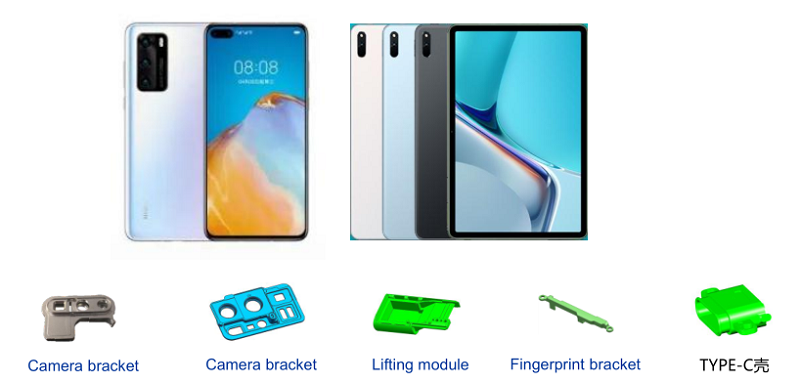

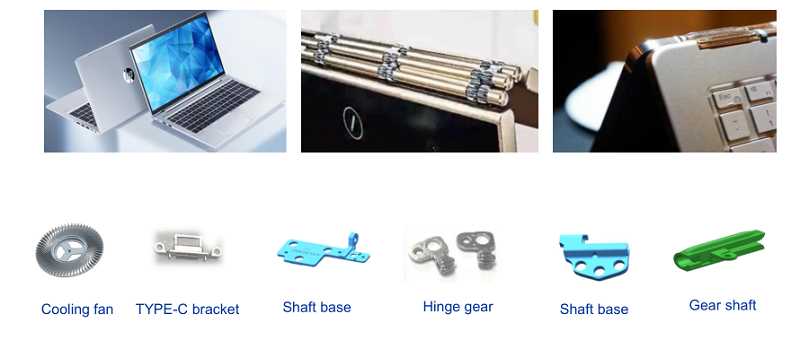

Consumer Electronics

MIM technology enhances consumer electronics by enabling the creation of intricate, high-quality components. You can benefit from:

- Precision and uniform texture for improved aesthetics.

- Consolidation of multiple parts into a single component, simplifying assembly.

- Reduced waste with material utilization rates exceeding 95%.

- Complex geometries for innovative designs.

These advantages make MIM an ideal choice for producing connectors, housings, and other small electronic parts.

Aerospace and Defense

In aerospace and defense, MIM parts contribute to performance and reliability. The technology is used to manufacture:

- Turbine engine components that withstand extreme conditions.

- Structural parts like brackets and fasteners, reducing weight while maintaining strength.

- High-precision satellite subsystems for harsh space environments.

Materials like titanium and high-performance superalloys ensure that MIM parts meet the rigorous demands of these industries.

MIM technology continues to revolutionize industries by delivering high-quality, cost-effective solutions for complex metal components.

MIM parts, created through the Metal Injection Molding process, combine metal strength with design flexibility. This method enables the production of intricate, high-precision components while offering cost advantages for medium to high production volumes. You benefit from material versatility, dimensional accuracy, and high production rates, making MIM ideal for industries like automotive and medical. However, MIM is best suited for small parts due to size constraints and requires significant initial investment. As industries demand lightweight, durable, and complex components, MIM technology continues to grow in importance, especially in automotive, medical, and defense sectors.

FAQ

What industries benefit the most from MIM parts?

Industries like automotive, medical, aerospace, and consumer electronics benefit significantly. MIM parts provide precision, durability, and cost-efficiency for complex, small-sized components.

Can MIM parts replace traditional manufacturing methods?

Yes, MIM parts often replace traditional methods for small, intricate designs. You gain better precision, material efficiency, and cost savings in high-volume production.

Why choose JH MIM for your MIM parts?

JH MIM offers unmatched expertise, advanced technology, and material versatility. You receive high-quality components tailored to your specific industry needs.

💡 Tip: Contact JH MIM for customized solutions that meet your exact specifications.