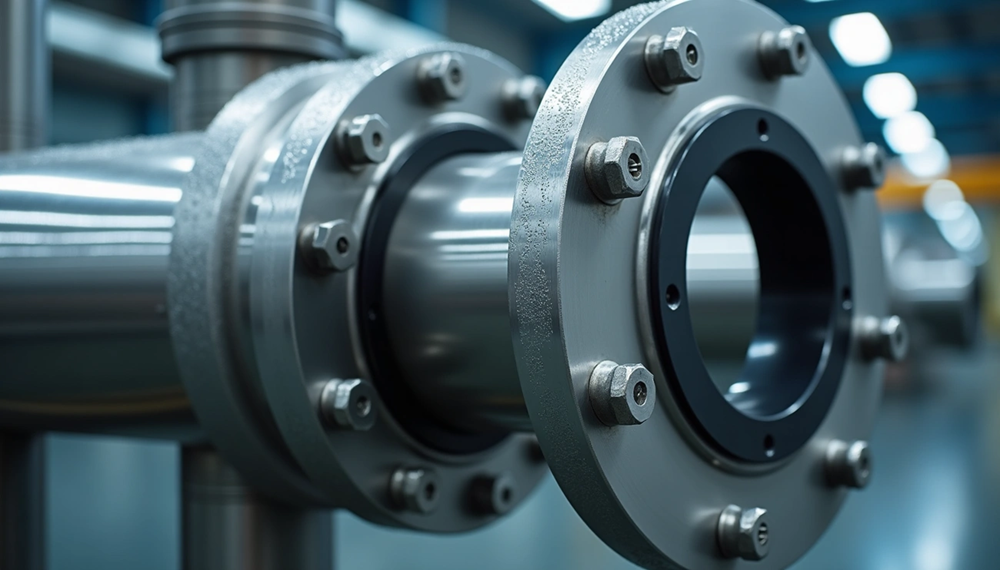

Water pump flanges play a vital role in many piping and pumping systems used by plumbing, automotive, and oil and gas industries. These connection points serve multiple engineering purposes and keep system integrity intact under tough conditions. The flanges create solid, resilient joints that resist damage from shock, vibration, or high pressure by distributing pressure evenly around connections.

What makes flanges special? They work as connecting elements that let you take apart pumps or piping sections without draining the whole system. Some pump flange types, like brass pump flange ball valves, come with purge/drain features that help fill or empty systems when needed. Engineers must design water pump flange connections with precision, especially when they face high-stress environments with frequent temperature changes. The oil and gas industry uses many flanges in vessels and piping systems because they handle these demanding conditions well. This guide covers water pump flange size options, manufacturing methods like powder metallurgy, design elements, and real-world applications that help engineering professionals work with hydraulic systems.

Understanding Water Pump Flanges in Plumbing Systems

Flanges are the foundations of many modern plumbing infrastructures. They serve as vital connection points between pipes, valves, pumps, and other equipment. The right selection and implementation of flanges determines system integrity and operational efficiency.

Flange definition in plumbing and pump systems

A flange in plumbing terminology describes a protruding lip, ridge, or rim that attaches two objects, especially shafts and pipes. These flat circular disks come with bolt holes to create secure, leak-proof connections between piping components. Welding remains the most preferred method to connect pipes, while flanges rank as the second choice. Unlike permanent welded joints, flanges let you easily assemble and disassemble various parts.

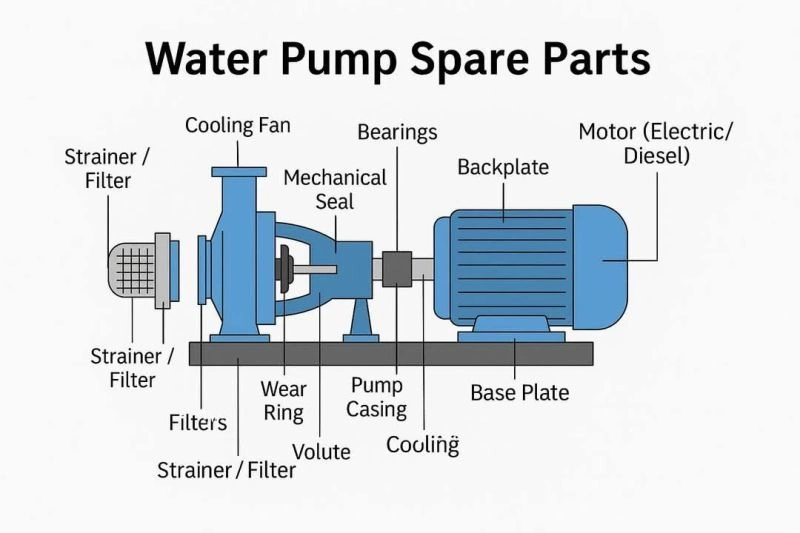

What are flanges used for in water pump assemblies?

Water systems rely on pump flanges for several vital functions. They create secure, leak-proof connections between pipes, valves, and pumps to ensure uninterrupted water flow and distribution. Pump flange valves also let you replace or service pumps without draining the entire system when closed.

Flanges provide multiple advantages:

- They distribute pressure evenly around connections to create resilient joints that resist shock and vibration

- They provide easy access for inspection, maintenance, and system modifications

- They handle piping requirements of all sizes through various configurations

These benefits make flanges especially valuable in high-pressure water distribution systems where reliability matters most.

Common water pump flange connection types

Different flange connection types suit specific applications based on pressure requirements, installation constraints, and maintenance needs:

Slip-on flanges slide over pipes and secure through welding. They work best for low-pressure applications with straightforward installation needs. Weld neck flanges use a tapered hub design to transfer pipe tension and handle high pressures effectively. This makes them perfect for demanding environments. Socket weld flanges connect through filet welds and excel with small-bore lines. They offer 50% higher fatigue strength compared to double-welded slip-on flanges.

Threaded flanges use internal threads that match male threads on pipes, which eliminates the need for welding. You’ll find them useful when you need frequent disassembly. Blind flanges act as blank disks that seal off pipe ends during maintenance or terminate pipeline sections.

Powder metallurgy has become a prominent manufacturing process for water pump flanges. This process helps control material properties and porosity precisely – factors that determine flange performance in demanding applications.

Key Benefits of Using Flanges in Water Pump Design

Engineers choose flanged connections in water pump systems because of their practical advantages. These connections provide specific benefits that make systems perform better and last longer during operation.

Improved maintenance access in closed-loop systems

Water pump’s flanged connections work best for maintenance tasks because technicians can take them apart without disrupting the whole system. This feature is a great way to get value in closed-loop systems that need regular checks. The right flange design lets workers remove and replace components quick to cut down system downtime during repairs.

The practical benefits include:

- Lower labor costs with easier servicing

- Better preventive maintenance through simple component checks

- Reduced lifecycle expenses compared to welded joints that need cutting and re-welding

The powder metallurgy manufacturing process makes these maintenance advantages even better. It controls material properties carefully to create consistent gasket surfaces and better seals that last through multiple assemblies.

Enhanced vibration resistance and pressure distribution

Flange connections in water pumps help isolate vibration from pumps and rotating parts, which reduces wear on pipes and connected equipment. The design and materials give them this ability to absorb vibration. Flanges made through powder metallurgy are even better because their controlled material porosity helps dampen mechanical vibrations.

Quality flanges spread pressure evenly around connection points to create strong joints. These joints resist damage from shock, vibration, and high pressure. The flange’s internal crystal structure can bend slightly under vibration without breaking – engineers call this property ductility.

Simplified installation in tight or complex layouts

Flanges are the quickest way to install pumps in tight spaces. Their design makes alignment easier, which becomes crucial in modernized projects or packed mechanical rooms. The right water pump flange sizes can handle movement in all directions caused by heat expansion, settling, or installation gaps.

Yes, it is possible to rotate flanged water pumps for the best fit. This reduces stress on connections that might cause leaks or failures. The combination of this flexibility and simple bolting makes flanges valuable especially when you have complex plumbing layouts where regular connection methods don’t work well.

Powder Metallurgy in Water Pump Flange Manufacturing

Powder metallurgy transforms the production of water pump flanges through a precise manufacturing process that differs from traditional methods.

Advantages of powder metallurgy over traditional casting

Powder metallurgy brings great benefits compared to casting, mainly through better material efficiency. Traditional casting needs excess material trimming, while powder metallurgy uses almost 100% of raw materials. The process achieves remarkable dimensional accuracy of ±0.01-0.02 mm with no need for secondary machining. Traditional casting needs multiple secondary operations. On top of that, powder metallurgy parts show lower scrap rates when working with valuable materials like copper and stainless steel.

Material properties: porosity control and strength

The most distinctive advantage comes from microstructure control. Powder metallurgy makes precise porosity control possible – a vital feature for applications that need specific flow characteristics or weight reduction. Parts show consistent mechanical properties and reach densities between 6.6-7.0g/cm³. The controlled microstructure creates components that are more wear-resistant with hardness ratings of 65-90 HRB.

Case study: sintered stainless steel flanges for hydronic pumps

Sintered stainless steel flanges show exceptional results in hydronic applications. These flanges use FC-0205, FC-0208, or FN-0205 iron-based powders mixed with stearate binders. The manufacturing process involves compaction at 400–800 MPa and sintering at around 1120°C. The final products can handle 20 bar continuous pressure ratings. They maintain tight tolerances even after many assembly cycles, which makes them perfect for systems that need frequent maintenance.

Design Considerations for Engineers

Engineers need to pay careful attention to flange design details to build successful water pump systems. Every design aspect plays a role in how well the system performs and how long it lasts in hydraulic applications.

Water pump flange size selection based on flow rate

Flow velocity is the key factor in choosing the right water pump flange size. Engineers should avoid high velocities that can lead to erosion, cavitation, or squirm. Flow velocities above 100 ft/sec need heavy-gage liners for protection. You should multiply actual flow velocity by 4 when you expect turbulence—this usually happens within ten pipe diameters downstream of elbows, valves, or other components that disrupt flow. Powder metallurgy flanges give you better dimensional precision for critical flow applications and maintain ±0.01-0.02 mm accuracy without extra machining.

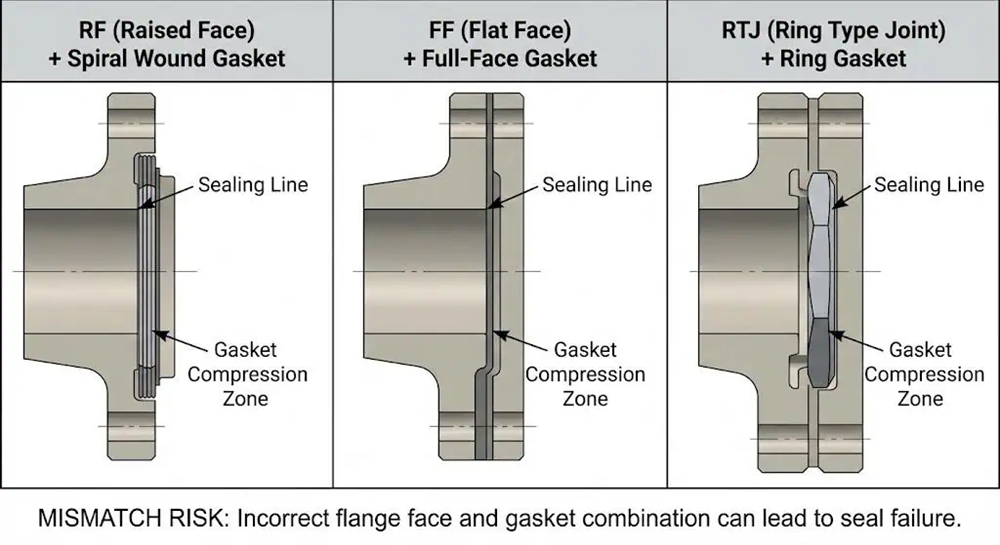

Gasket compatibility and sealing surface design

Surface characteristics affect how well gaskets perform. Surface roughness measurements—mainly Ra (average roughness) and Rz (ten-point height)—help you pick the right gasket. The gasket material must adapt to flange surface irregularities under compression for the best seal. So, the compressive load needs to stay high enough throughout the system’s life. Sintered flanges from powder metallurgy processes have more consistent surfaces, which makes gasket sealing more reliable.

Bolt pattern standards: ANSI vs DIN

ANSI and DIN are two different flange standardization systems:

- ANSI flanges use imperial measurements and are common in North American applications

- DIN flanges use metric measurements and are standard throughout European markets

You can’t mix these standards—a DN50 DIN flange (50mm) won’t line up with a 2-inch ANSI flange (50.8mm). This mismatch leads to bolt holes that don’t line up and possible seal failures. Flanges made through powder metallurgy keep tighter tolerances, which helps them work better with standardized bolt patterns.

Thermal expansion and corrosion resistance factors

Dimensional changes from thermal cycling create too much stress in piping systems. Your flanges must handle these changes through the right material choice. On top of that, corrosion is a big challenge—especially crevice corrosion at flange joints. This type of localized attack starts more easily than other kinds of corrosion. Powder metallurgy creates flanges with uniform microstructures that fight off intergranular corrosion better, which matters because this corrosion typically shows up at grain boundaries.

Conclusion

Water pump flanges play a vital role in many industrial applications. Engineers must really understand their design principles to achieve the best system performance. This piece explores how flanges create secure, removable connections that distribute pressure evenly and resist vibration and shock. A proper flange setup will boost system’s durability and make maintenance easier.

Powder metallurgy has changed flange manufacturing by delivering better material efficiency and dimensional precision. Sintered flanges prove most valuable in demanding hydraulic applications because they offer controlled porosity levels, uniform microstructures, and exceptional wear resistance. Engineers who choose powder metallurgy flanges get tighter tolerances, more consistent surfaces, and better corrosion resistance than traditional cast components.

Your water pump flange design success depends on several key factors. The right size selection based on flow requirements stops erosion and cavitation problems. You need compatible gaskets to ensure reliable sealing under operating conditions. Standard bolt patterns—whether ANSI or DIN—prevent misalignment issues. The material choice must work well with both thermal expansion and corrosion resistance to keep the system running smoothly over time.

Combining powder metallurgy with water pump flange design gives engineers a groundbreaking way to optimize hydraulic systems. This manufacturing method creates components with precise properties that handle tough conditions without losing their shape. Water management systems now just need more efficiency and reliability. That’s why properly designed flanges made through powder metallurgy will definitely remain vital in modern engineering solutions.

Key Takeaways

Water pump flanges are critical connection components that require careful engineering consideration for optimal hydraulic system performance. Here are the essential insights every engineer should know:

• Flanges enable maintenance without system drainage – Unlike welded connections, flanged joints allow pump removal and servicing while keeping the rest of the system operational, reducing downtime and labor costs.

• Powder metallurgy delivers superior flange performance – This manufacturing process achieves ±0.01-0.02 mm dimensional accuracy, controlled porosity, and uniform microstructures that outperform traditional casting methods.

• Flow velocity determines proper flange sizing – Engineers must keep velocities below 100 ft/sec to prevent erosion and cavitation, multiplying by 4 when turbulence is expected near flow-disrupting components.

• ANSI and DIN standards are not interchangeable – A DN50 DIN flange (50mm) won’t align with a 2-inch ANSI flange (50.8mm), causing bolt hole mismatches and potential seal failures.

• Surface finish directly impacts gasket sealing – Proper surface roughness (Ra and Rz measurements) ensures gasket materials can conform under compression, with sintered flanges offering improved consistency.

These design principles form the foundation for reliable water pump systems that withstand pressure, vibration, and thermal cycling while maintaining long-term operational integrity.

FAQs

Q1. What are the main advantages of using flanges in water pump systems? Flanges offer several key benefits, including improved maintenance access, enhanced vibration resistance, even pressure distribution, and simplified installation in complex layouts. They allow for easy disassembly without draining the entire system, distribute pressure evenly to create resilient joints, and provide flexibility during installation in tight spaces.

Q2. How does powder metallurgy improve water pump flange manufacturing? Powder metallurgy offers significant advantages over traditional casting methods for water pump flange production. It achieves higher material efficiency, superior dimensional accuracy (±0.01-0.02 mm) without secondary machining, and enables precise control of porosity levels. This results in flanges with consistent mechanical properties, improved wear resistance, and enhanced performance in demanding hydraulic applications.

Q3. What factors should engineers consider when selecting water pump flange sizes? Engineers must primarily consider flow velocity when selecting water pump flange sizes. It’s crucial to avoid excessive velocities that can cause erosion, cavitation, or squirm. Generally, flow velocities should not exceed 100 ft/sec, and engineers should multiply the actual flow velocity by 4 when turbulence is expected, typically within ten pipe diameters downstream of flow-disrupting components.

Q4. Why is gasket compatibility important in water pump flange design? Gasket compatibility is critical for ensuring reliable sealing in water pump flange connections. The gasket material must be able to conform to flange surface irregularities under compression. Surface characteristics, particularly roughness measurements like Ra (average roughness) and Rz (ten-point height), play a significant role in determining appropriate gasket selection and maintaining proper sealing throughout the system’s lifetime.

Q5. What are the differences between ANSI and DIN flange standards? ANSI and DIN are two distinct flange standardization systems that are not interchangeable. ANSI flanges use imperial measurements and are commonly used in North American applications, while DIN flanges utilize metric measurements and are prevalent in European markets. For example, a DN50 DIN flange (50mm) will not align with a 2-inch ANSI flange (50.8mm), which can lead to bolt hole mismatches and potential seal failures if not properly accounted for in the design.