What is titanium powder?

The titanium alloy indicated by TC4 is an alloy in which titanium is the base element and other elements are added. Titanium alloy has been utilized extensively in the domains of aircraft, the chemical industry, the nuclear industry, sports equipment, and other industries because of its benefits of high-temperature resistance, high corrosion resistance, high strength, low density, and biocompatibility. It serves as a key structural component of modern engines and airplanes.

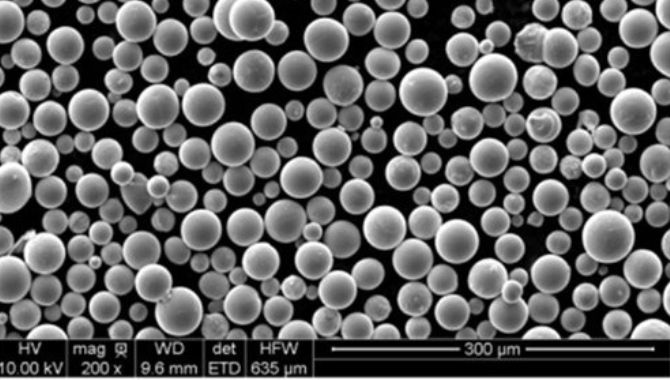

Titanium alloy powder is a substance created by melting qualified titanium alloy liquid metal and atomizing it into powder. This titanium powder can then be formed into rods, turbine disks, aircraft keel joints, rotating electrodes, vacuum decompression, or other structures. Titanium powder is available in a variety of grain sizes, including 0–15 microns, 45–105 microns, 53–150 microns, 75–250 microns, and more.

What are the titanium alloy powders?

Titanium alloys are also divided into the following three categories: α alloy,(α+β) alloy and β alloy. China is represented by TA, TC and TB respectively.

Titanium powder preparation

The traditional process for extracting titanium powder is known as the Kroll process. The technology requires up to 1040°C and involves a range of sub-processes, including alloying, hot isostatic pressing, etc. After this, more methods are needed to produce pre-alloyed titanium powder. In order to remove contaminants, the material must undergo the hydride-dihydride process, cold pressing, vacuum hot pressing, final vacuum annealing, plasma rotating electrode process, titanium gas atomization process, and plasma atomization. In order to produce the final product, a series of metal integration strategies must be implemented. Powder injection molding, or metal injection molding, is a low-cost and long-used method to manufacture large quantities of metal in small sizes. Then there is the direct powder rolling process, which is used to produce medium and thick plates. In order to quickly manufacture, strengthen, and repair metal parts, laser engineering net forming technology is used. In order to consolidate titanium powder to its large theoretical density, the parts must be subjected to hot isostatic pressing at high pressure and temperature. Finally, in order to achieve the final product, spark plasma sintering or current-assisted sintering is used to obtain titanium powder with better mechanical properties, good grain size, and no excess grain growth.

Titanium sintering

The most common method for sintering titanium alloy powder is solid-phase diffusion. The alloying elements in titanium alloys are discovered to appear as an instantaneous liquid phase or to create diffusion channels during sintering, boosting the densification process, also known as intensive sintering, when the mixed element method is employed to prepare titanium alloys.

Three fundamental criteria—the solubility criterion, segregation criterion, and diffusion criterion—are necessary for the improved sintering process to be realized. In general, the additive should have a modest solubility in the matrix and a big solubility in the matrix, or they should create an intermediate compound. This is primarily because:

The low solubility of additives in the matrix can lessen the need for additives to maintain intensive sintering. (1) The solubility of the additive in the matrix will lead to the precipitation of the additive at the interface of the powder particles, which is conducive to the diffusion of the matrix. Additionally, the vigorous sintering process of densification is the diffusion of the matrix to additive, which is helpful for the quick expansion of the sintering neck and the eradication of pores. The expansion of the sintered body will arise from the opposite diffusion, the Kirkendall effect, and an increase in porosity if the additive’s solubility in the matrix is high.

Additionally, during the sintering process, the additives may precipitate at the boundary between powder particles and may persist there. The additive is enriched as a result of the precipitation on the diffusion contact surface between the powder particles. As a result, a channel for quick matrix diffusion is offered. The liquidus and solid phase lines on the phase diagram of the matrix and the added elements continue to degrade, as seen by this type of precipitation characteristic response. The improved sintering impact of the additive depends on how it affects the matrix material’s diffusion rate when the solubility and precipitation standards are met. The improved sintering effect is better the faster the material’s diffusion rate is.

Titanium powder use in aerospace, military, industrial processes, automotive, agricultural, medical restoration, orthopaedic implants, dental and root canal instruments and documents, sporting goods, jewelry, cell phones, and other applications.

Titanium alloy powder has been widely used in the aerospace field because titanium powder has high strength, high heat resistance, and high specific strength. Titanium alloy can improve the aircraft’s bulletproof ability while reducing the overall weight of the aircraft, reducing the distance of the aircraft take-off/landing runway, and increasing the aircraft’s maneuverability, maneuverability, and mounting capacity.

With the increasing national strength of China, the ability to maintain maritime rights and interests is also increasing, the number of carrier-based aircraft is also increasing, and the demand for seawater corrosion-resistant titanium materials will increase year by year.

Studies have shown that titanium alloy is still the preferred material under high temperature and pressure, highly corrosive medium, and high chlorine environment. Since the corrosion resistance of titanium and titanium alloy is mainly used in the petrochemical field, the heat resistance is not high, so compared with the titanium used in the aerospace field, the types of titanium are relatively single, and the main use is industrial pure titanium and TA10. The price of these two kinds of titanium is relatively cheap, and its melting process, processing process, and welding process are relatively mature in China, so it can be widely used in the domestic petrochemical field.

Because of its excellent resistance to seawater corrosion and Marine atmosphere corrosion, and very few dissolved ions, non-toxic and pollution-free to the environment, titanium can well meet the application needs of Marine engineering, and Marine engineering is expected to become a new type of titanium civil market. In Marine engineering, titanium is mainly used in offshore oil and gas development, seaside buildings, coastal power stations, seawater desalination devices, ships, Marine fisheries, ocean energy conversion, and other aspects. The application of titanium in the field of Marine engineering can not only reduce the quality of related equipment but also reduce maintenance costs and extend the service life of related equipment. For example, when titanium is used in ships, its equipment life can be extended to 30 to 40 years, while ships such as aluminum alloy and mild steel need maintenance for 10 years. Not only that, titanium also has excellent low-temperature performance, can maintain a certain plasticity at -253 ° C, and the volume change in the low-temperature environment is small, very suitable for the Arctic icebreaker and other uses.

Because of its lightweight, low elastic modulus, non-toxicity, non-magnetism, and small biological reaction, titanium is recognized by the world as the most ideal metal material for human implants in the biomedical field. Titanium and titanium alloy processing materials are widely used in orthopedics, cardiovascular systems, neurosurgery, oral surgery, and human culture machines. In addition, titanium is also used in biopharmaceutical fields because of its non-toxicity and good bactericidal effect of surface TiO2. In terms of human implants, titanium is used to prepare the femoral head, implant teeth, hip joints, knee joints, prostheses, fastening screws, etc. It can also be seen that titanium is mainly used in orthopedics, and orthopedics implant biomaterials account for about 38% of the market share, which is the largest market for implant biomaterials. Orthopedic implant products mainly include spine products, trauma products, artificial joint products, and neurosurgery products.

CHOOSE JH MIM TITANIUM POWDER METALLURGY

Titanium powder metallurgy printing of 3D auto parts is one of the recent breakthroughs in metal manufacturing. It allows the production of different parts for cars, aerospace frames, and engines through 3D printing. Titanium powder also plays an important role in metal injection molding and powder metallurgy.

Titanium powder metallurgy (P/M) offers the possibility of manufacturing clean or nearly clean-shaped parts without the material losses and costs associated with complex parts machined forged billets. The powder can be element mixed or pre-alloyed and then cured by metal injection molding, hot isostatic pressing, powder direct rolling, or laser engineering forming.

Related :