Tungsten machining comes with its own set of challenges because of its unique physical properties. This element has the highest boiling point among all chemical elements and reaches a melting point of 6,192 degrees Fahrenheit (3422°C) – second only to carbon. These properties make specialized manufacturing essential . The metal’s density is 19.3 times that of water, similar to gold or uranium, which makes it heavy and hard to work with .

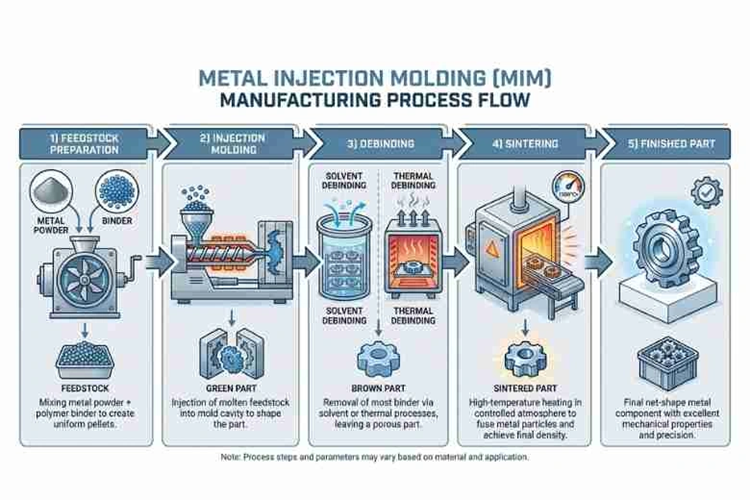

Manufacturers can create tungsten components through two main methods: Powder Metallurgy (PM) and CNC machining. Both approaches help achieve precision in tungsten machining, but they vary in costs and suitable applications. CNC machining tungsten yields great results, yet the metal’s brittleness and hardness often cause cracking. This leads to high scrap rates – sometimes reaching 30% before process improvements . The tungsten carbide machining process needs very strong tooling because the material is incredibly hard . Companies looking for tungsten machining services should know how each method affects their costs to balance quality and budget. Modern powder metallurgy methods like Metal Injection Molding (MIM) work well for small, complex tungsten alloy parts that need fine detail. Traditional PM is better suited for simpler, larger components when production costs need to stay low .

Understanding Tungsten Machining Methods

Manufacturing tungsten components needs special approaches because of the metal’s unique traits. The right machining method can make a big difference in both cost and quality. Let’s get into the main techniques used to work with this challenging material.

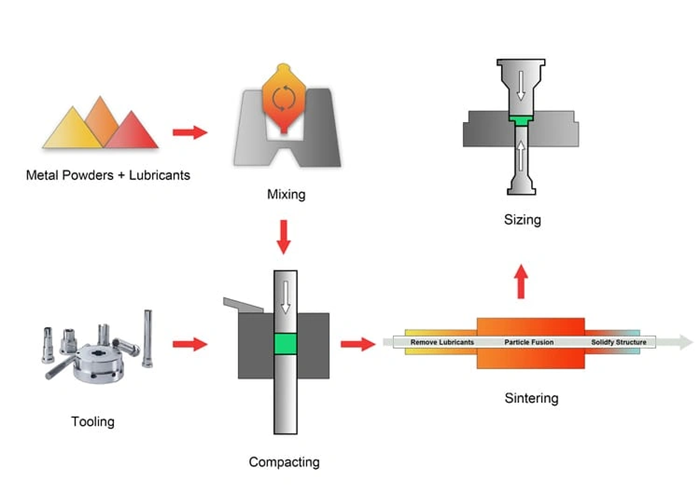

Powder Metallurgy (PM) Process Overview

Powder Metallurgy is the go-to method to make tungsten components. This makes sense because tungsten’s melting point of 6,192°F (3,422°C) makes normal casting impossible. The PM process has several key steps:

- Powder Preparation: The process starts with fine tungsten powder. Manufacturers often mix it with other metals like nickel, iron, or copper to create an even mixture.

- Compaction: The mixed powder gets squeezed under high pressure into a “green” compact shape. Pressures can reach up to 30,000 pounds per square inch. Common approaches include uniaxial pressing (pressure from one direction) or isostatic pressing for better green density.

- Sintering: The compact heats up to temperatures between 1800-2700°C in a hydrogen atmosphere that helps reduce oxides. During this step, tungsten particles bond together through solid-state diffusion. This makes the part stronger and denser without actually melting.

- Post-Processing: The final step involves heat treatment (annealing). This removes trapped hydrogen gas and helps relieve stresses from sintering.

PM is great at using materials efficiently. Most parts use over 97% of the raw material. The process also lets manufacturers control the final product’s makeup and structure to match specific needs.

PM does have its limits with complex parts. The compaction step makes it hard to create pieces with intricate shapes, undercuts, or very thin walls. Getting to full theoretical density is also tricky, and most PM tungsten parts have some remaining porosity.

CNC Machining Process for Tungsten

CNC machining is another way to make tungsten components. This works better for complex shapes or when PM isn’t practical. Computer-controlled machines remove material from tungsten blocks in different ways:

The process includes turning, where the tungsten piece spins against a cutting tool, and milling, which uses a spinning cutter to remove material. Drilling needs carbide-tipped or solid carbide drills, with extra clearance angles and automatic feeds to stop binding and seizing.

Tungsten’s extreme hardness and brittleness create some machining challenges. The material’s density needs high torque at lower RPMs. Parts must be machined at high temperatures—above the transition point—to avoid cracking or splitting.

Tool choice is key in tungsten CNC machining. Experts like precision-ground carbide tools with positive rake angles. Cutting speeds should stay low, usually 100-150 feet per minute, with light feed rates and shallow cuts to protect the tools.

Cooling methods change based on the job. Some prefer air cooling over flood coolant, while others use high-pressure cutting fluid at 12-20% concentration. Straight oil works well in some cases because the low cutting speeds keep fire risk down while helping with extreme pressures.

Tungsten Carbide Machining Process Differences

Tungsten carbide—a mix of tungsten and carbon—is trickier to machine than pure tungsten. It’s really tough, with a Mohs hardness of 8.5-9, and is about 2-3 times as rigid and dense as steel.

Regular machining methods don’t work well with tungsten carbide. Special techniques are needed:

Wire EDM (Electrical Discharge Machining) works best for clean, precise cuts that don’t stress the carbide too much. Wire Cutting is great for drilling or making irregular edges, especially when you need to pierce and shape without causing cracks.

Grinding helps achieve smooth surface finishes and keep dimensions accurate on flat or round surfaces. Casting Mold Processing works well for complex carbide shapes, which cuts down on multiple machining steps.

Controlling vibration and cutting force is vital when working with tungsten carbide because it’s so dense, rigid, and brittle. Poor control can lead to tiny cracks and breaking, which slows down the whole process.

The choice between PM and CNC machining for tungsten parts comes down to things like production volume, shape complexity, size requirements, and costs.

Material Behavior in PM vs CNC Machining

Tungsten’s natural properties create unique challenges in both Powder Metallurgy (PM) and CNC machining processes. The right manufacturing method and production settings depend on understanding how this material behaves.

Brittleness and Fracture Risk in Pure Tungsten

Pure tungsten becomes very brittle at room temperature. This makes it likely to crack or chip during regular machining. The material’s ductile-to-brittle transition temperature (DBTT) usually stays above 200°C. You need to keep temperatures well above this point to avoid cracking or lamination while machining.

Tungsten fails most often through intergranular fracture. Research shows that up to 95.9% of fracture surfaces in regular pure tungsten samples break between grains. This happens because:

- Grain boundaries have poor cohesion, made worse by impurities like carbon, oxygen, potassium, and phosphorus

- Larger grains can collect impurities at boundaries, which increases the risk of brittleness

- The material’s high notch sensitivity makes it break easily under stress during machining

Yes, it is true that experienced powder metallurgy manufacturers like JH MIM know they must remove all possible stress points before making tungsten components.

Thermal Conductivity and Heat Management

Tungsten’s thermal behavior creates special machining challenges. Heat spreads quickly due to its excellent thermal conductivity. The heat from cutting can still damage tools badly. Tungsten carbide expands with heat at one-third to one-half the rate of tool steel. This difference causes problems during machining.

Managing heat becomes vital since tungsten alloys need:

- Strong, sharp tools that can handle very high temperatures

- Top-quality cutting fluids and lubricants to reduce wear

- Careful control of cutting settings to create less heat

Tungsten carbide moves heat much faster than tool steel, with thermal conductivity at 42 W/mK. The heat spreads more slowly as binder content goes up. This affects how heat moves through the piece during machining.

Elastic Modulus and Tool Deflection Considerations

Tungsten’s unusual elastic properties affect machining accuracy and tool choice. Tungsten carbide has a Young’s modulus of 90 x 10^6 psi. This makes it much stiffer than other metals and creates stronger cutting forces during machining.

This high stiffness leads to two big problems in CNC machining:

Tools wear out or break quickly, often within seconds. Carbide tools are about three times stiffer than high-speed steel but still break easily when machining tungsten. The material’s stiffness and brittleness mean that even small tool movements can cause chips or cracks.

Controlling vibration becomes crucial. Machining experts say that “even a little vibration will chip tools rapidly” [11]. The material’s weight and hardness make vibration problems worse. You need:

- Very rigid CNC machines with lots of torque

- Tools that barely bend, usually the widest possible with fewer flutes

- Very slow cutting speeds and steady feed rates to prevent cracking

Tungsten’s special elastic, thermal, and fracture properties need specific approaches in both PM and CNC machining. PM processes can control material behavior through careful powder preparation and sintering settings. CNC operations must adapt to tungsten’s natural properties by changing tools, cutting methods, and machine selection.

Cost Breakdown: PM vs CNC for Tungsten Parts

The economics of tungsten machining differ greatly between Powder Metallurgy (PM) and CNC approaches. Each method comes with its own cost structure and efficiency profile. Manufacturers can make better decisions based on production volume, part complexity, and budget constraints by understanding these differences.

Tooling and Setup Costs in PM

The original tooling investments make up much of the PM costs for tungsten components. PM tooling usually costs between USD 5,000 and USD 15,000 for most parts. Large, complex components with multiple levels can cost up to USD 30,000. PM tooling costs less than metal injection molding (MIM), die casting, forging, or lamination processes.

Production volume changes PM economics dramatically:

- Below 500 units: Poor cost efficiency, not recommended

- 500-5,000 units: Fair efficiency with break-even around 3,000 units

- 5,000-50,000 units: Good efficiency with break-even near 2,000 units

- Above 50,000 units: Excellent cost efficiency with break-even at approximately 1,000 units

Simple PM parts need 6 weeks for tool design, building, and first article production. Complex components take up to 12 weeks. JH MIM’s 20 years of industry experience show that well-designed tooling brings great long-term benefits despite higher upfront costs.

Machine Time and Labor in CNC Machining

CNC machining tungsten brings unique time and labor challenges. CNC is a serial process that needs many passes and setup time for each part. Output is measured in parts per hour instead of the simultaneous production possible with PM. Tungsten’s extreme hardness requires slower cutting speeds of 100-150 feet per minute, along with light feed rates to prevent tool chipping.

Working with pure tungsten needs special expertise and equipment. The material’s extreme hardness and brittleness mean technicians must know how to pick the right tooling, speeds, and cooling strategies. CNC machining tungsten takes lots of machine time because the process must happen at high temperatures—above the material’s transition temperature—to prevent cracking.

Material Waste and Yield Efficiency

Material utilization rates show a clear difference between these processes. CNC machining turns 50–80% of the original billet into chips, which means poor material efficiency. PM shapes components directly from powder with almost no scrap and achieves over 95% material utilization.

PM gives big cost advantages for expensive materials like tungsten. More than 97% of the starting raw material goes into the finished part. This high yield matters even more since pure tungsten costs between USD 350 and USD 850 per kilogram. Tungsten heavy alloys cost from USD 450 to USD 1,000 per kilogram.

Post-Processing and Finishing Costs

Both methods need different levels of post-processing. PM creates near-net shapes, but many tungsten components still need extra work to meet final specifications. Steps like machining, sizing, or surface finishing add to manufacturing costs.

Heat treatment is a major post-processing expense that costs USD 500 to USD 2,000 based on material and batch size. Hot Isostatic Pressing (HIP) costs about the same but often removes the need for separate heat treatment.

Parts likely need machining of mating interfaces, surfaces, or threads, regardless of how they were first made. Costs change based on material and part complexity. Surface finishing can add hundreds or thousands of dollars, especially for complex tungsten components with internal features.

PM works best for high-volume production of moderately complex tungsten parts, even with higher original tooling costs. The choice between methods depends on production volume, component complexity, and performance needs.

Precision and Tolerance Capabilities

The choice between PM and CNC processes for tungsten parts largely depends on precision requirements. These manufacturing approaches each bring their own capabilities to dimensional control, material density, and surface characteristics.

Dimensional Accuracy in CNC Machining

CNC machining of tungsten components delivers exceptional dimensional precision, especially with complex geometries. This process can achieve tolerances of ±0.0005″ or better when done right. Advanced CNC equipment with coordinated measuring machines (CMM) shows remarkable precision. Standard deviations stay below 0.0035 mm, and relative errors fall within a 0.005–0.015% range. The direct material removal process eliminates dimensional changes from thermal processing, which leads to this accuracy.

The material’s brittleness creates unique challenges to maintain tight tolerances on tungsten. Controlled machining parameters prevent micro-fractures that could compromise dimensional integrity. Current tolerance capabilities for tungsten CNC machining range from 0.05mm for standard applications to 0.02mm for ultra-precision needs. Machinists have found that equipment needs to be nowhere near these tolerances to achieve such precise results.

Density and Porosity Control in PM

PM gives different precision advantages, especially in material density and porosity control. Standard PM processes achieve about 96% of theoretical density through final sintering. Different tungsten powder types yield specific density results:

- Pure tungsten: ≥18 g/cm³

- Doped tungsten: ≥18.5 g/cm³

- Tungsten-nickel-iron: ≥18 g/cm³

- Tungsten heavy alloys: ≥17.5 g/cm³

Conventional PM processes still face challenges with porosity control. Research shows porous tungsten can achieve adjustable porosity from 20% to 40%. Specific fabrication methods produce controlled porosity between 21.98% and 38.16%. Uniform porosity distribution remains hard to achieve consistently, even after years of refinement. This is a vital factor for applications like electron emitters.

Surface Finish Comparison: PM vs CNC

Surface quality marks another key difference between these methods. CNC machining creates tungsten parts with surface roughness values measured on the Ra (average roughness) scale. Standard surface finishes of 3.2 μm Ra are typical for general machining. Finer finishes of 1.6, 0.8, or even 0.4 μm Ra need additional finishing passes. These extra steps increase costs due to more machine time and stricter quality control.

PM tungsten components usually have rougher as-sintered surfaces that need post-processing. Powder particles create irregularities during compaction and sintering. This means parts need secondary operations like grinding, polishing, or machining to match CNC surface quality. Metal Injection Molding (MIM) stands out as a specialized PM technique. Companies like JH MIM have refined this process over the last several years. Their tungsten alloy parts come out with better surface finishes right after sintering, which reduces the need for extra finishing work.

Application Suitability Based on Manufacturing Method

The best manufacturing approach for tungsten components depends on specific application needs. Engineers need to assess part geometry, production volume, and performance requirements beyond just the cost factors to make smart decisions.

When to Use PM for Tungsten Components

Powder Metallurgy stands out as the best method for tungsten parts under certain conditions. PM works best for components with simple geometries that don’t have complex internal features, undercuts, or thin walls. The process works great at producing simple forms like blocks, rods, or rings, where you don’t need intricate designs.

PM shows better economics for larger tungsten components. The tooling can handle bigger parts without costs rising as much as other methods. This makes PM a great fit for substantial applications such as:

- Radiation shielding components

- Counterweights for aerospace applications

- Automotive components like connecting rods

- Electronic parts requiring favorable electromagnetic properties

PM is most cost-effective at medium production volumes, usually between 500-50,000 units per year. These numbers let the lower tooling costs make up for the limits in geometric complexity.

When CNC Machining is the Better Fit

CNC machining becomes the top choice whenever geometric precision matters more than volume. That’s why CNC machining is a great way to get results for prototyping and low-volume custom parts where you need flexibility and tight tolerances.

This process delivers great results for:

- Parts needing dimensional accuracy within ±0.0005″ or better

- Components with complex external geometries via multi-axis motion

- Applications that need quick turnaround without big tooling investments

- Projects requiring minimal porosity or maximum density

CNC machining lets you modify designs easily between production runs, which makes it perfect for iterative development work or specialized one-off components.

Hybrid Approaches: PM Preform + CNC Finish

These insights about both methods have led manufacturers to use hybrid approaches that leverage each technique’s strengths. They typically create a near-net-shape PM preform and finish-machine it to meet exact specifications.

Vista Metals shows this hybrid strategy in action through their tungsten carbide preform production. Their process combines strict raw material control, precise blending, and near-net-shape forming with diamond-tipped CNC machining to hit exact dimensions and tolerances.

This combined approach offers several benefits:

- Less material waste than pure CNC machining

- Lower tooling costs than pure PM for complex geometries

- The economy of PM with better surface precision

- Faster production than using either method alone

The hybrid method has ended up as the best solution for many precision tungsten applications. It bridges the gap between mass production efficiency and custom part quality.

Scalability and Production Volume Considerations

Production volume plays a decisive role in selecting the right manufacturing method for tungsten parts. The economics of scale reshape the cost calculations in manufacturing techniques of all types.

Batch Size Economics in PM

Powder Metallurgy’s cost efficiency depends heavily on batch optimization. Standard shapes like bars and plates work best economically in 500kg multiples. Custom profiles need 200kg batches to make financial sense. These batch sizes help cut setup costs from about 350 per production run. PM shows its value at the time production volumes reach medium to high levels, as tooling costs get spread across larger quantities. Companies like JH MIM, a 20-year old player in the Metal injection molding and Powder metallurgy industry, typically suggest PM for projects needing more than 3,000 units.

CNC Machining for Prototyping and Low Volume

CNC machining shines in low-volume tungsten production. This method provides flexibility without heavy tooling investments, which makes it perfect for developing prototypes or specialized components. Many precision tungsten machining services can handle anything from single prototypes to small batch orders. This flexibility lets teams quickly iterate designs without worrying about PM’s minimum volume requirements.

Lead Time and Turnaround Differences

Each method comes with distinct turnaround times. PM production cycles take several weeks to months. CNC tungsten machining services usually complete orders within 20-30 days. These timing differences are vital for project planning. Shipping adds more time – express delivery takes 7-10 days, air freight needs 3-5 days, and sea freight requires 40-50 days.

Conclusion

The choice between Powder Metallurgy and CNC machining for tungsten components depends on several key factors. Our analysis shows how production volume, part complexity, dimensional requirements, and budget affect manufacturing decisions.

PM processes shine best for medium-to-high volume production runs. These typically go beyond 3,000 units, where material utilization rates above 97% lead to huge cost savings. On top of that, it gives better control over material composition and microstructure. This allows manufacturers to customize specific properties for demanding applications.

CNC machining, on the other hand, works great for prototyping and low-volume production. The process hits exceptional precision with tolerances of ±0.0005″ or better. You won’t need the high tooling investments that PM requires. CNC is also a great way to get complex geometries where PM has limitations.

In spite of that, hybrid approaches that combine PM preforms with CNC finishing might be the most balanced solution for many applications. This method cuts down material waste while you retain control over precise tolerances and surface finishes. Though it takes more work to set up, hybrid manufacturing makes the best of both processes.

Thermal properties, brittleness, and fracture risk are the biggest problems with any manufacturing method. Of course, tungsten’s extraordinary hardness and density just need specialized expertise and equipment. These factors make production costs higher than conventional metals.

Companies with deep experience in powder metallurgy techniques have developed optimized processes. JH MIM’s 20 years in the industry shows how they’ve minimized these challenges. They deliver precision-engineered components to customers worldwide. Their knowledge is especially valuable when balancing cost, quality, and production efficiency.

A full picture of specific application requirements should guide your production method choice. Tungsten’s challenging properties haven’t stopped it from being essential in many high-performance applications. Its unmatched mix of density, high-temperature resistance, and thermal conductivity makes it irreplaceable. Both PM and CNC techniques keep improving, without doubt expanding this remarkable material’s practical uses across industries.

Key Takeaways

Understanding the cost dynamics between Powder Metallurgy (PM) and CNC machining for tungsten components reveals critical insights for manufacturers seeking optimal production strategies.

• PM dominates high-volume production: Powder Metallurgy becomes cost-effective above 3,000 units, achieving 97% material utilization versus CNC’s 20-50% efficiency due to waste.

• CNC excels for precision and prototyping: CNC machining delivers tolerances of ±0.0005″ and rapid turnaround without tooling investment, ideal for low-volume custom parts.

• Hybrid approaches maximize both methods: Combining PM preforms with CNC finishing reduces material waste while maintaining precision, offering the best of both worlds.

• Production volume determines economics: PM requires 500-50,000 units for efficiency, while CNC proves superior for prototypes and specialized one-off components.

• Tungsten’s properties demand specialized expertise: The material’s brittleness, extreme hardness, and high melting point (6,192°F) require advanced techniques regardless of manufacturing method.

The choice between PM and CNC ultimately hinges on balancing production volume, geometric complexity, precision requirements, and budget constraints. Companies with extensive powder metallurgy experience can guide manufacturers toward the most cost-effective solution for their specific tungsten component needs.

FAQs

Q1. What are the main differences between powder metallurgy (PM) and CNC machining for tungsten parts? Powder metallurgy excels at medium to high volume production (over 3,000 units) with high material utilization (over 97%), while CNC machining offers superior precision (tolerances of ±0.0005″) and flexibility for prototypes and low-volume custom parts without tooling investments.

Q2. How does the cost structure differ between PM and CNC for tungsten components? PM has higher initial tooling costs but becomes more economical at larger volumes, while CNC has lower upfront costs but higher per-part expenses due to material waste and machining time. PM is typically cost-effective for 500-50,000 units annually, whereas CNC is better for prototyping and small batches.

Q3. What are the key challenges in machining tungsten? Tungsten’s extreme hardness, brittleness, and high melting point (6,192°F) pose significant challenges. These properties require specialized tooling, controlled machining parameters, and often high-temperature processing to prevent cracking and achieve desired tolerances.

Q4. Is there a hybrid approach that combines the benefits of PM and CNC for tungsten parts? Yes, a hybrid approach involves creating a near-net-shape PM preform that is subsequently finish-machined using CNC. This method reduces material waste compared to pure CNC machining while maintaining precision and allowing for complex geometries that may be difficult with PM alone.

Q5. How do production volume and part complexity influence the choice between PM and CNC for tungsten components? For simpler geometries and higher volumes (typically over 3,000 units), PM is often more cost-effective. CNC is preferred for complex parts, prototypes, or low-volume production where precision and design flexibility are crucial. The optimal choice depends on balancing production volume, geometric complexity, precision requirements, and budget constraints.