Sintered filter elements can handle extreme temperatures up to 900°C and still maintain exceptional mechanical strength and corrosion resistance. These amazing filtration devices start as stainless steel powder that gets compacted into shape and heated below its melting point. The process creates a rigid, permeable structure with interconnected pores that trap contaminants while letting fluids or gasses flow through.

These filters work better than conventional ones by providing a positive barrier to downstream processes. They typically last 5-10 years or longer. You can find them in grades from 0.1 to 100 microns, which makes them invaluable for industries that need precise filtration in harsh conditions. Sintered bronze filter elements and disks provide similar advantages with different material properties, making them perfect for specific uses. Companies like JH MIM have spent almost 20 years mastering metal injection molding and powder metallurgy to create precision-engineered products for customers worldwide.

This complete guide covers everything about stainless steel sintered filters, from basic principles to advanced applications in industrial sectors of all types.

What Are Stainless Steel Sintered Filters?

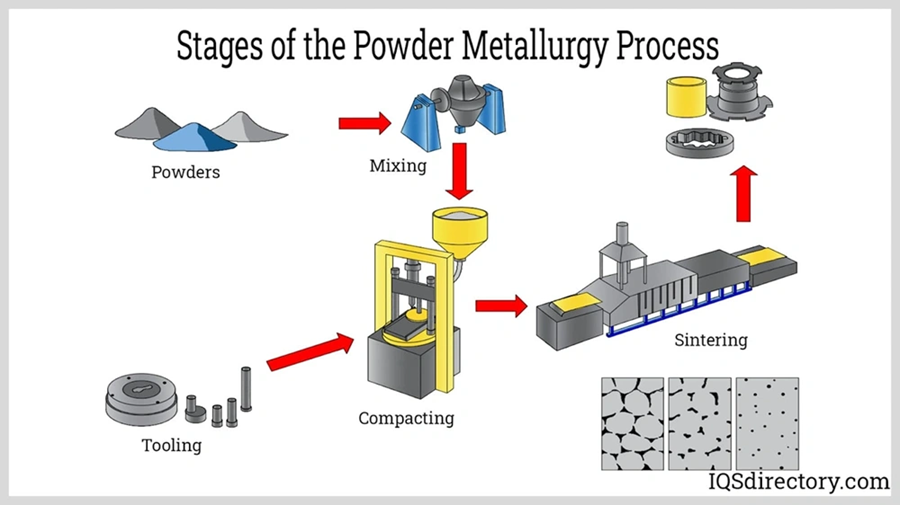

Stainless steel sintered filters are advanced depth filtration devices made through powder metallurgy techniques. Manufacturers create these filters by compacting stainless steel powder particles and heating them below their melting point. This process lets particles fuse at contact points without turning completely liquid [1].

Definition and Working Principle

Stainless steel sintered filters are porous structures that form when manufacturers press stainless steel powders together in a mold. The powders then get sintered into a strong porous body. The process creates filters with exact pore dimensions that work well even in tough industrial settings. Engineers control pore size and distribution carefully to match specific needs and deliver the best separation results.

These filters work through three main filtration methods:

- Large particle interception at the filter surface

- Mid-size particle impaction within the filter matrix

- Diffusion-controlled fine particle capture deep within the structure

The filters create a solid barrier for downstream processes and remove 99.9% or more of particles. Their connected pore network creates a winding path that catches particles through mechanical entrapment and adsorption. This structure allows great flow rates even when the filtered liquid contains varying amounts of solids.

Depth Filtration vs Surface Filtration

Depth filtration and surface filtration take different approaches to remove contaminants. Surface filtration keeps particles mostly on the filter’s surface, working like a sieve. This method works best with known particle sizes where low pressure drop matters.

Depth filtration happens when particles enter the filter media’s cross-section and get caught in its winding path. This method uses the entire filter media cross-section, which means it can remove more particles from the process fluid in a given area.

Stainless steel sintered filters mainly use depth filtration principles, but can also do surface filtration based on what’s needed. This flexibility makes them better than regular filters that only use one filtration method.

Comparison with Sintered Bronze Filter Elements

Sintered stainless steel and bronze filters share similar manufacturing processes but perform differently:

Material Strength: Stainless steel filters are stronger and more durable than bronze filters because of their irregular powder shape. They can handle pressure differences of more than 100 bar without changing shape.

Temperature Resistance: Stainless steel filters work at temperatures up to 450°C (842°F), while bronze filters only handle up to 200°C (392°F).

Corrosion Resistance: Stainless steel resists more types of corrosive fluids and chemicals than bronze, making it perfect for harsh environments. This resistance helps the filter last longer.

Filtration Precision: Stainless steel filters can achieve finer filtration with pore sizes from 0.5–100 microns. Bronze filters typically range from 1–100 microns. This precision makes stainless steel better for ultra-fine filtration needs.

JH MIM makes these high-performance sintered filter elements. With 20 years in metal injection molding and powder metallurgy, they deliver precision-engineered products to customers worldwide.

Manufacturing Process of Sintered Stainless Filters

Sintered stainless steel filters come to life through a sophisticated multi-stage manufacturing process. Fine metal powders transform into resilient, porous filtration media. Each stage plays a vital role in creating the filter’s structural integrity and filtration capabilities.

Powder Selection: SS304, SS316L, 904L

The journey begins with selecting high-purity stainless steel powders that have particle sizes between 5–100 µm. Manufacturers commonly use these grades:

- SS304: This grade contains 18-20% chromium and provides good general corrosion resistance at an economical price point

- SS316L: With 16-18% chromium content, this grade delivers superior resistance to chlorides and acids. It stands as the industry standard for challenging environments

- 904L: This specialty grade serves extreme corrosion resistance applications

Manufacturers carefully control the powder’s particle size distribution because it shapes the pore structure and determines filtration performance. Some companies blend different powder compositions to achieve specific mechanical properties or filtration characteristics.

Cold Compaction and Green Body Formation

The material undergoes compaction at pressures between 200 to 600 MPa after powder preparation. This stage uses several techniques:

- Die pressing creates specific shapes like disks or cylinders using a mold and a punch

- Cold isostatic pressing (CIP) delivers uniform pressure from all directions

This process creates a “green body” – a delicate, pre-sintered filter form that maintains its shape but lacks final strength and porosity. The compacting process largely determines the pore distribution and size, which sets the foundation for the filter’s eventual filtration capabilities.

Sintering in Controlled Atmosphere (1100–1300°C)

The green compact becomes a functional filter through sintering – the core process. Parts heat up in controlled atmosphere furnaces at temperatures between 1100–1300°C, staying well below stainless steel’s melting point. This crucial phase takes place in:

- Vacuum environments

- Hydrogen atmospheres

- Inert gas (such as argon) environments

Individual powder particles bond at their contact points during the sintering process. This creates a strong, interconnected network of pores. Temperature, time, and atmosphere control determine the filter’s final pore size, porosity, and mechanical strength.

Post-Processing: Electropolishing and Passivation

Filters undergo additional treatments to improve performance after sintering:

- Electropolishing: This step removes micro-burrs and smooths surfaces. It improves filtration precision and reduces contamination risks

- Passivation: The process uses nitric acid (20-30% concentration for 20-40 minutes, depending on grade)

Properly passivated stainless steel achieves 5-10 times greater corrosion resistance compared to untreated surfaces. A protective chromium oxide layer forms and shields against pitting and crevice corrosion, particularly in chloride environments.

Final steps might include sizing for precise dimensions, annealing to relieve internal stresses, and thorough cleaning of manufacturing residues. Companies like JH MIM, with nearly 20 years of powder metallurgy expertise, ensure consistent quality by rigorously controlling each production phase.

Key Technical Properties and Performance Metrics

The performance of sintered filter elements in tough industrial applications depends on their technical specifications. These key parameters determine how well they filter, how long they last, and where they work best.

Pore Size Range: 0.5–100 µm

Stainless steel sintered filters come with filtration ratings from 0.5 to 100 micrometers. The standard grades (0.1, 0.2, 0.5, 1, 2, 5, 10, 20, 40, and 100) make these filters versatile. Liquid filtration ratings range from 0.1 µm to 100 µm. Gas filtration can achieve 99.9% efficiency or better.

Porosity and Flow Rate Optimization

These filters typically have 25-45% porosity, though some special versions can reach 70%. Porosity affects both dirt-holding capacity and flow performance. Higher porosity means better flow rates but might reduce strength. To cite an instance, see how flow rates drop by about 30% when the mesh size goes from 100 to 50 microns. JH MIM can customize specifications based on what customers need, balancing filtration efficiency with pressure drop.

Temperature Resistance up to 900°C

Stainless steel sintered filters can handle heat up to 900°C. This is a big deal as it means that they work better than bronze filters, which only handle up to 150°C. Different alloys have different heat limits:

- 316L stainless steel: 482°C in oxidizing environments, 900°C in reducing conditions

- Inconel 600: 593°C oxidizing, 815°C reducing

- Hastelloy X: 788°C oxidizing, 927°C reducing

Chemical Compatibility: pH 1–14

316L grade stainless steel sintered filters work well with pH levels from 1-14. They resist corrosion from strong acids, alkaline solutions, and fluids containing chloride. Their resistance to corrosion helps them last 30% longer than other filter types.

Mechanical Strength: 3000+ psi Pressure Tolerance

These filters handle differential pressures over 3000 psi (210 bar). With compressive strength above 30 MPa, they manage high-pressure impacts and fluid fatigue well. They rarely deform and last 5-10 years, depending on use conditions and how often they’re cleaned.

Sintered stainless steel filter elements remain the top choice for applications that need precise filtration and extreme durability.

Applications Across Industrial Sectors

Stainless steel sintered filters stand out in extreme operating environments. Their unique mix of durability, precision filtration, and material resilience makes them essential in many industries.

Oil & Gas: Acid Gas and Hydraulic Filtration

These resilient filtration elements tackle some of the toughest jobs in oil and gas operations. You’ll find them filtering acid gasses, especially H₂S, in offshore rigs and subsea control modules. The results are impressive in FCC slurry oil filtration systems that run at about 350°C and 20 kg/cm². They achieve 99.5% filtration efficiency with catalyst solids concentration up to 12,000 ppm. Refineries use them to recover valuable catalysts and get filtrate quality below 1 ppm suspended solids.

Pharmaceutical: Sterile Gas and Solvent Filtration

Pharmaceutical companies count on sintered stainless steel filters for their most critical sterile applications. These filters remove particulate, microbial, and chemical contaminants from process streams. They shine in sterile filtration of liquids and gases, which helps maintain product sterility and safety. Bioreactors and fermentation processes benefit from their ability to maintain microbial control without compromising product integrity. Their durability through multiple sterilization cycles makes them perfect for pharmaceutical settings.

Semiconductor: ISO Class 0–1 Gas Purification

Semiconductor manufacturing requires exceptional purity levels. These filters deliver ISO Class 0–1 gas filtration for nitrogen, argon, and compressed dry air systems. They achieve an impressive 9-log reduction (99.9999999% removal) of particles down to the rated limit. The filters add less than 10 ppb of moisture under SEMI F27 test methods. Their monolithic structure prevents tearing or shedding particles, which keeps sensitive wafer processing safe.

Automotive: EGR and Exhaust Filtration

These filters play a crucial role in automotive applications by capturing soot and particulates in exhaust gas recirculation (EGR) systems. They handle exhaust filtration while resisting heat shock and clogging in diesel or CNG engines. Electric vehicles use them in battery cooling systems where they maintain optimal thermal management at temperatures above 300°C.

Hydraulics: Aviation and Pneumatic Systems

Aviation hydraulics showcase another vital use case. These filters process phosphate ester and MIL-H-5606 fluids at pressures above 3000 psi. Helicopter operators have seen a 90% drop in filter failures thanks to their superior performance. They’re crucial components in landing gear and flight control systems. The filters also excel at removing condensate, oil aerosols, and particulates from compressed air lines in pneumatic systems.

Cleaning, Maintenance, and Reusability

Proper maintenance of sintered filter elements will give them a longer service life and make them budget-friendly over time. Several cleaning cycles can keep these filters working at their best.

Ultrasonic Cleaning with Citric Acid

High-frequency sound waves (typically 40 kHz) create microscopic bubbles in ultrasonic cleaning solutions. These bubbles collapse near the filter surface and create powerful micro-jets that dislodge contaminants. Stainless steel elements respond best to a 10% citric acid solution. This solution removes deposits without damaging the porous structure.

Chemical Soaking: NaOH and HNO₃

Stubborn organic contaminants break down in a 3-5% sodium hydroxide (NaOH) solution at 40°C for 30-60 minutes. The solution dissolves oily residues effectively. A 5% nitric acid (HNO₃) bath for 8+ hours works well for inorganic compounds like scale or oxides. The filter needs thorough rinsing with deionized water until clear after either treatment.

Thermal Bake-Out for Carbon Removal

Carbon-rich environments leave deposits that need controlled heating to 450-600°C. This process burns away carbonized deposits through combustion. The temperature must rise slowly (≤5°C per minute) and cool gradually in an inert atmosphere.

Backflushing with Compressed Air

Clean compressed air flowing backward through the filter dislodges surface contaminants effectively. The best results come from using 1.2-1.5 times operating pressure in 3-5 second bursts, repeated 4-6 times. This method removes most surface particles without invasive cleaning.

Bubble-Point Testing (ASTM F316)

Bubble-point testing checks filter integrity after cleaning according to ASTM F316 standards. This test finds the minimum pressure needed to push bubbles through the largest pore in an isopropyl alcohol-wetted filter. The results show if the filter works properly and confirm that no structural damage occurred during cleaning.

Conclusion

Stainless steel sintered filters are at the forefront of filtration technology in many demanding industries. Their unique manufacturing process combines powder metallurgy techniques with precise thermal treatments to create filtration media with exceptional performance characteristics. These filters provide micron-level filtration precision and withstand extreme temperatures, pressures, and corrosive environments that quickly degrade conventional alternatives.

These filters’ versatility comes from their customizable pore sizes that range from 0.5 to 100 microns. They resist temperatures up to 900°C and handle pressures beyond 3000 psi. Such technical capabilities make them essential in oil and gas operations, pharmaceutical manufacturing, semiconductor fabrication, and automotive applications.

The filters can be reused through several cleaning methods: ultrasonic cleaning, chemical soaking, thermal treatment, and backflushing. This makes them highly cost-effective over time. Their regenerative capability and service life of 5-10 years make them both environmentally and economically smart filtration solutions.

JH MIM utilizes nearly two decades of powder metallurgy expertise to produce these sophisticated filtration elements. The company ensures consistent quality by controlling each manufacturing stage carefully. Their products deliver unique performance in the world’s most challenging industrial environments.

Stainless steel sintered filters remain the top choice when applications need both precision filtration and extreme durability. Their ongoing development and use in expanding industrial sectors show their fundamental importance in modern filtration technology. This is evidence of their exceptional capabilities and lasting value in critical processing operations.

Key Takeaways

Stainless steel sintered filters offer unmatched durability and precision for industrial filtration, combining advanced manufacturing with exceptional performance across demanding applications.

• Extreme durability: Withstand temperatures up to 900°C and pressures exceeding 3000 psi while maintaining 99.9% filtration efficiency

• Precision filtration range: Available in pore sizes from 0.5-100 microns, enabling customized solutions for specific industrial requirements

• Superior chemical resistance: Handle pH levels 1-14 and corrosive environments, significantly outperforming conventional filter alternatives

• Cost-effective longevity: Reusable through multiple cleaning methods with 5-10 year service life, reducing replacement costs

• Versatile industrial applications: Essential for oil & gas, pharmaceutical, semiconductor, automotive, and hydraulic systems requiring critical filtration

These filters represent the gold standard for applications demanding both precision filtration and extreme durability, making them indispensable for modern industrial operations where conventional filters fail.

FAQs

Q1. What are the main advantages of stainless steel sintered filters? Stainless steel sintered filters offer exceptional durability, withstanding temperatures up to 900°C and pressures over 3000 psi. They provide precision filtration with pore sizes from 0.5-100 microns, superior chemical resistance across pH 1-14, and long service life of 5-10 years with proper maintenance.

Q2. How do stainless steel sintered filters compare to other filter types? Compared to conventional filters, stainless steel sintered filters offer superior performance in extreme conditions. They provide better corrosion resistance, higher temperature tolerance, and longer lifespan than alternatives like sintered bronze filters. Their depth filtration capability also allows for higher dirt-holding capacity.

Q3. What industries commonly use stainless steel sintered filters? These filters are widely used in oil & gas for acid gas filtration, pharmaceuticals for sterile gas and solvent filtration, semiconductors for ultra-pure gas purification, automotive for exhaust filtration, and aerospace for hydraulic system protection. Their versatility makes them valuable across many demanding industrial applications.

Q4. How are stainless steel sintered filters manufactured? The manufacturing process involves selecting stainless steel powders (like SS304 or SS316L), cold compacting them into a “green body,” sintering at 1100-1300°C in a controlled atmosphere, and post-processing through electropolishing and passivation. This creates a strong, porous structure with precisely controlled filtration characteristics.

Q5. Can stainless steel sintered filters be cleaned and reused? Yes, these filters are highly reusable. Cleaning methods include ultrasonic cleaning with citric acid, chemical soaking in NaOH or HNO₃, thermal bake-out for carbon removal, and backflushing with compressed air. After cleaning, bubble-point testing can verify filter integrity. This reusability contributes to their cost-effectiveness over time.